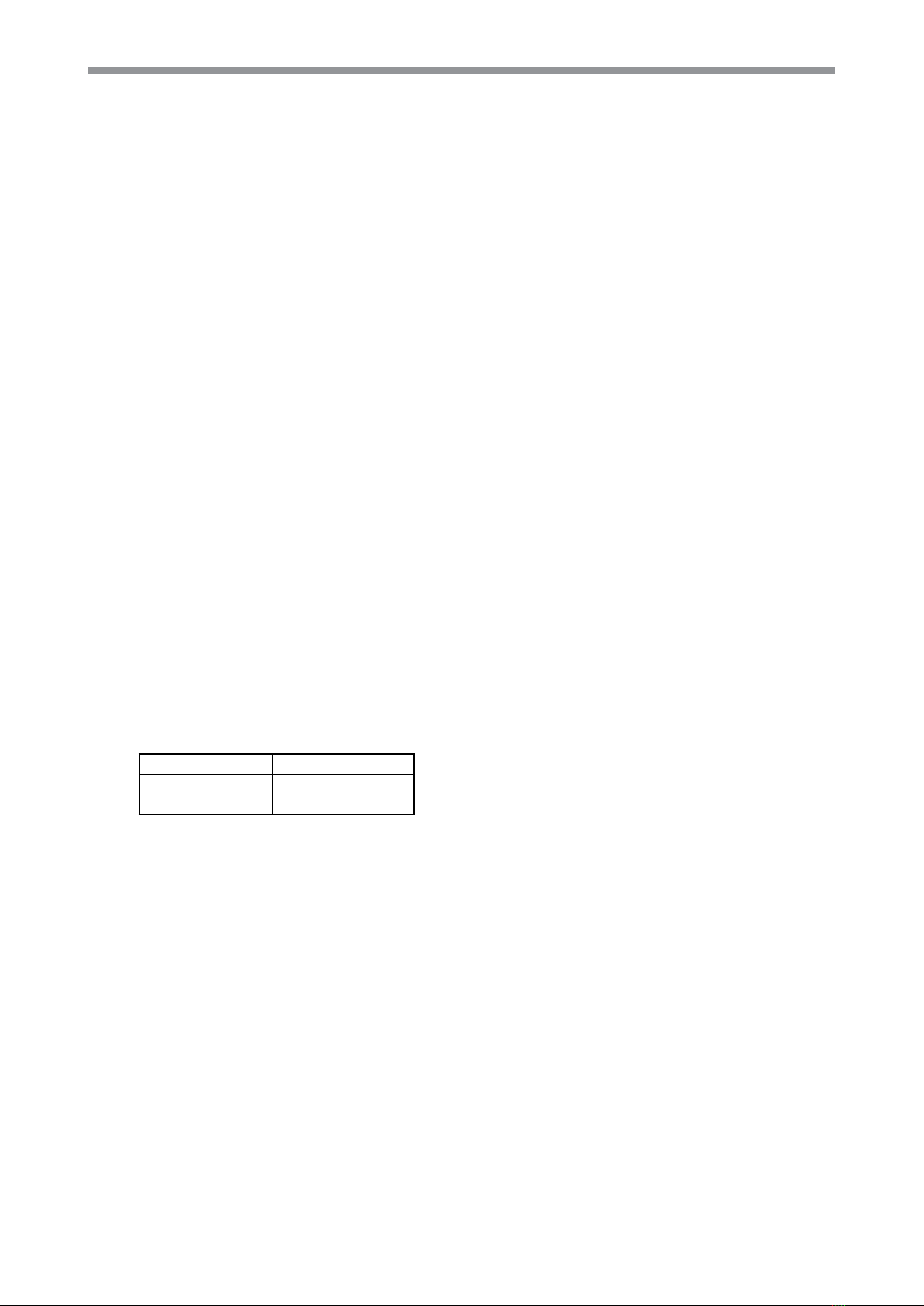

Contents

4-3-4-3-9 List of output data��������������������������������� 35

4-3-4-3-10 Details of output data�������������������������� 36

4-3-4-3-11 List of output signals ��������������������������� 41

4-3-4-3-12 Details of output signals ��������������������� 41

4-3-5 Timing chart ������������������������������������������������ 43

4-3-5-1 Timing charts for EW2C-H-NP, EW2C-H-

PN, and EW2C-H-CC ������������������������������ 43

4-3-5-2 Timing charts for EW2C-H-CCD�������������� 45

4-4 Actuator number setting�������������������������������������������� 58

4-5 Point data specications������������������������������������������� 58

4-6 How to use the size detecting function

4-6-1 When using an actual workpiece for size

detecting range setting�������������������������������� 60

4-6-2 When using direct input for size detecting

function setting �������������������������������������������� 60

4-7 Communication

4-7-1 Communication parameter specications���� 61

4-7-2 Communication cable���������������������������������� 61

4-7-3 Addresses���������������������������������������������������� 61

4-7-4 Communication commands������������������������� 61

4-7-5 List of communication commands ��������������� 62

4-7-6 Details of communication commands���������� 63

4-8 Parameters

4-8-1 Parameter setting method��������������������������� 69

4-8-2 Explanation of parameters �������������������������� 70

4-9 List of errors ������������������������������������������������������������� 72

4-10 Easy mode���������������������������������������������������������������74

4-10-1 I/O connector signal table for easy mode���74

4-10-2 Details of input signals for easy mode �������74

4-10-3 Details of output signals for easy mode ���� 75

4-10-4 Parameters������������������������������������������������ 76

4-10-5 Time charts ����������������������������������������������� 77

Chapter 5 Troubleshooting

5-1 If a problem occurs ��������������������������������������������������� 80

5-2 Countermeasures for alarms������������������������������������ 80

5-3 Alarm specications ������������������������������������������������� 80

5-3-1 List of alarms ���������������������������������������������� 81

Chapter 6 Specications

6-1 Basic specications of main unit ������������������������������ 82

6-2 Basic specications of the controller ������������������������ 83

Chapter 7 Outline Drawings

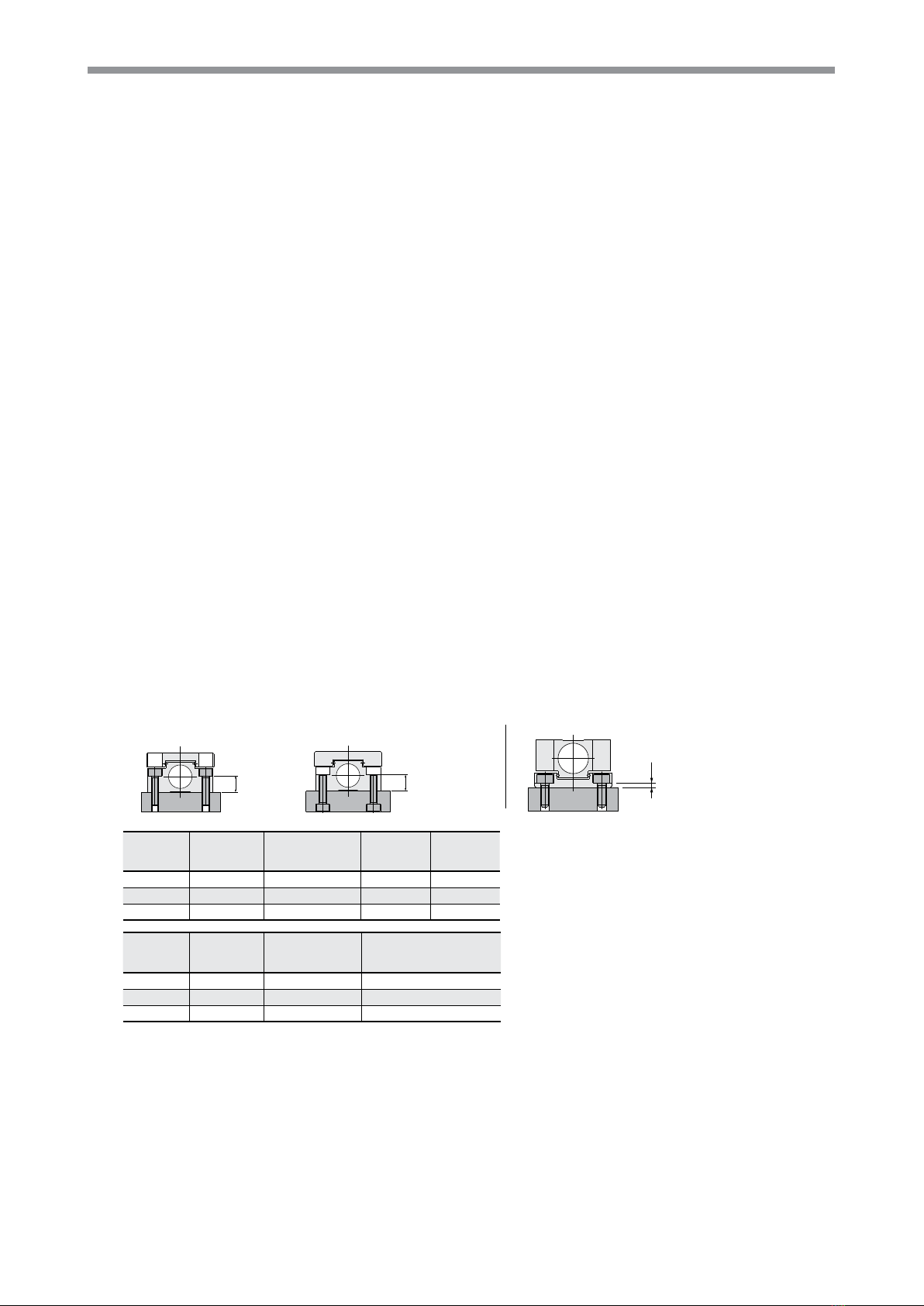

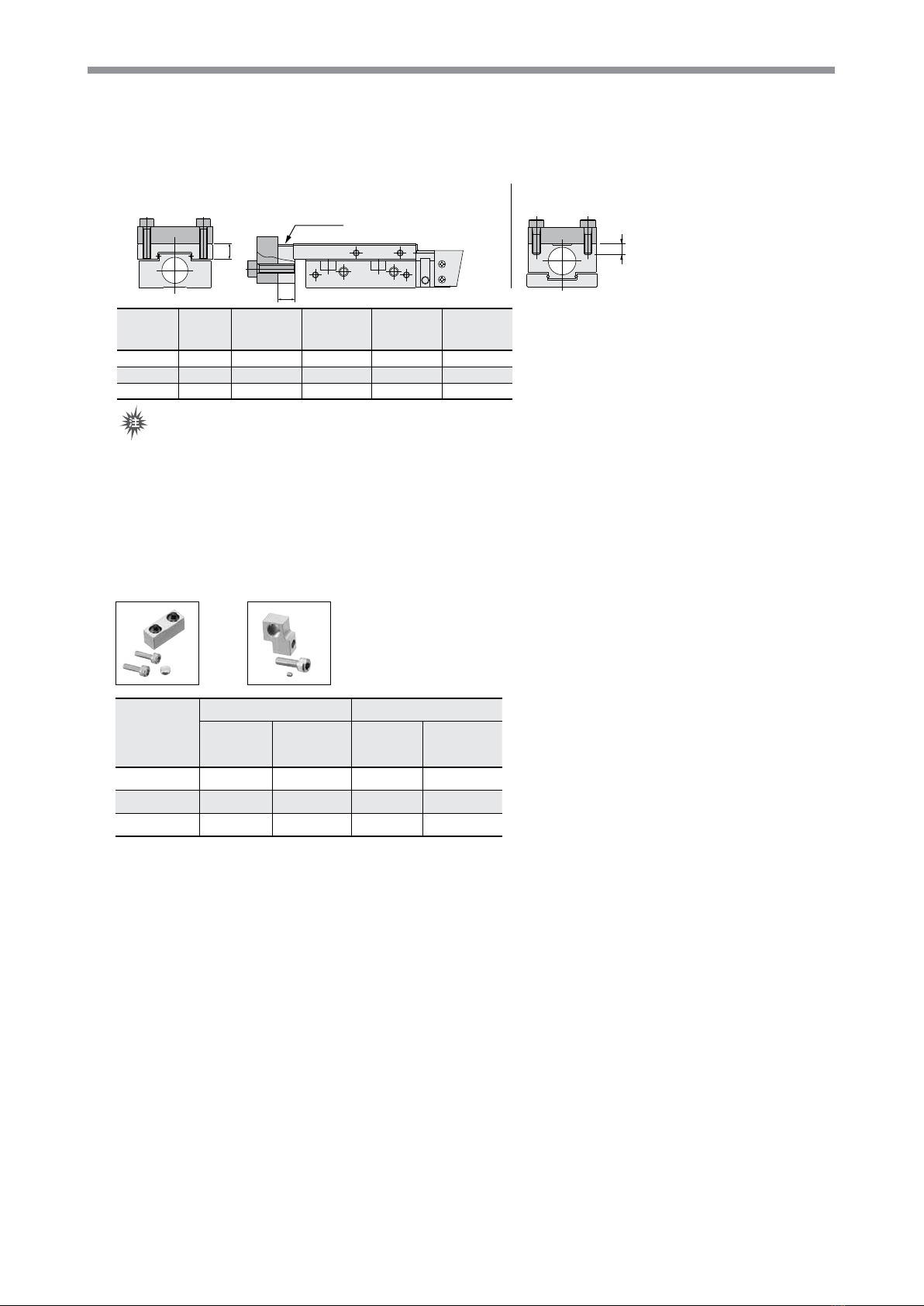

7-1 Main unit outline drawings ���������������������������������������� 88

7-2 Controller outline drawings ��������������������������������������104

7-3 Outline drawings for additional parts (Unit: mm)������105

Chapter 8 Technical Data

8-1 Accuracy������������������������������������������������������������������108

8-2 Allowable moment ���������������������������������������������������108

8-3 Displacement angle of the table in relation to bending

moment �������������������������������������������������������������������109

8-4 Thrust ����������������������������������������������������������������������110

- 1 -

Chapter 1 Safety Precautions

1-1 Safety�������������������������������������������������������������������������� 2

1-2 Precautions ����������������������������������������������������������������� 2

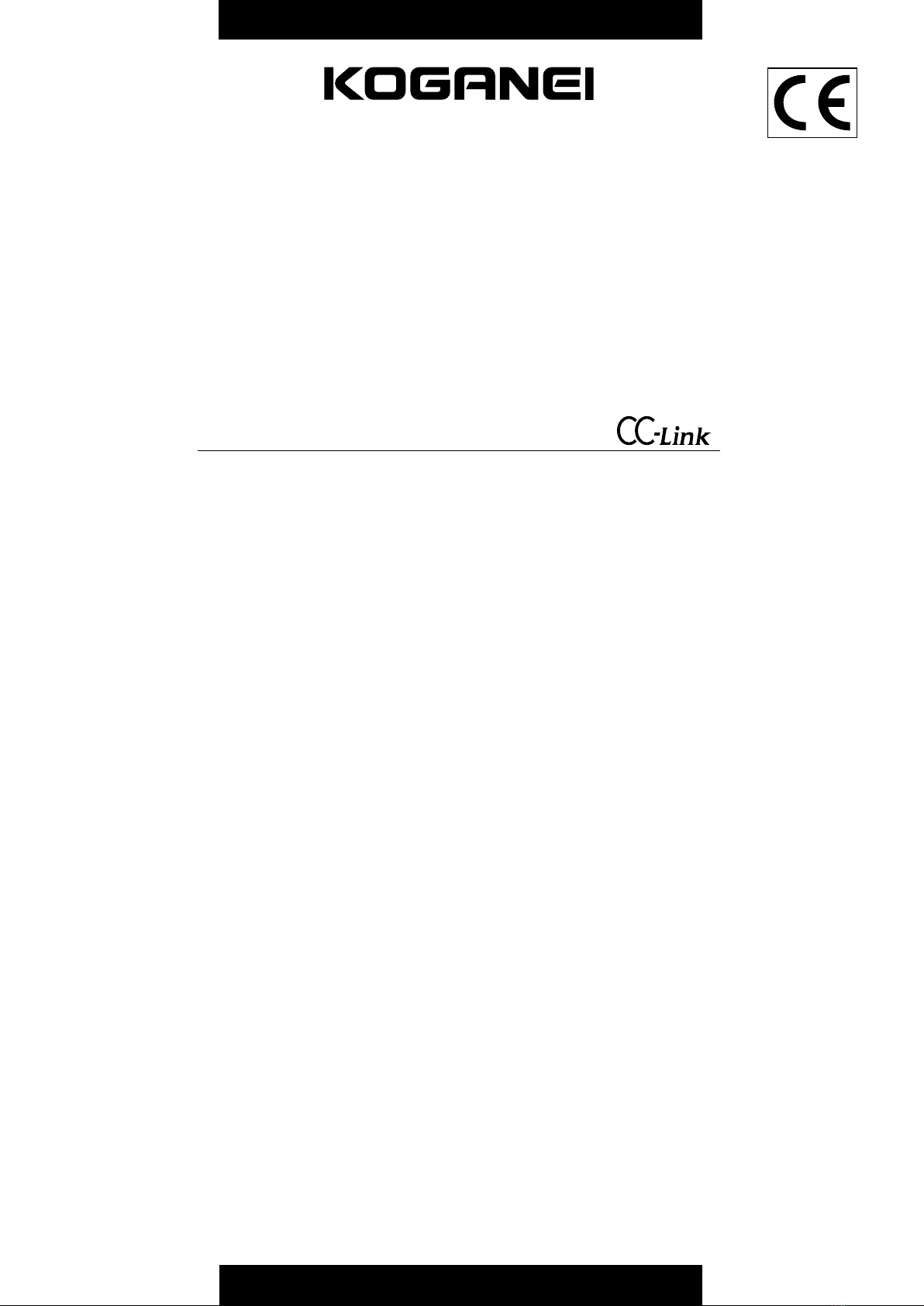

Chapter 2 System Conguration

2-1 Entire system conguration ���������������������������������������� 3

2-2 Options and accessories�������������������������������������������� 4

2-3 Setting up for operation ���������������������������������������������� 5

Chapter 3 Main Unit

3-1 Handling the main unit

3-1-1 Precautions���������������������������������������������������� 6

3-2 Mounting

3-2-1 Mounting the product ������������������������������������ 7

3-2-2 Mounting a workpiece����������������������������������� 8

3-2-3 Mounting the stroke adjuster������������������������� 8

Chapter 4 Controller

4-1 Appearance and functions

4-1-1 Point input type (NPN model and PNP model)

���������������������������������������������������������������������10

4-1-2 CC-Link type (remote I/O model and remote

device model) �����������������������������������������������10

4-2 Installation and connection to external devices

4-2-1 Controller installation �����������������������������������11

4-2-2 Connecting the power supply�����������������������11

4-2-3 Grounding work��������������������������������������������11

4-2-4 Wiring precautions �������������������������������������� 12

4-2-5 Connecting to the actuator�������������������������� 12

4-2-6 Connecting the I/O connector ��������������������� 12

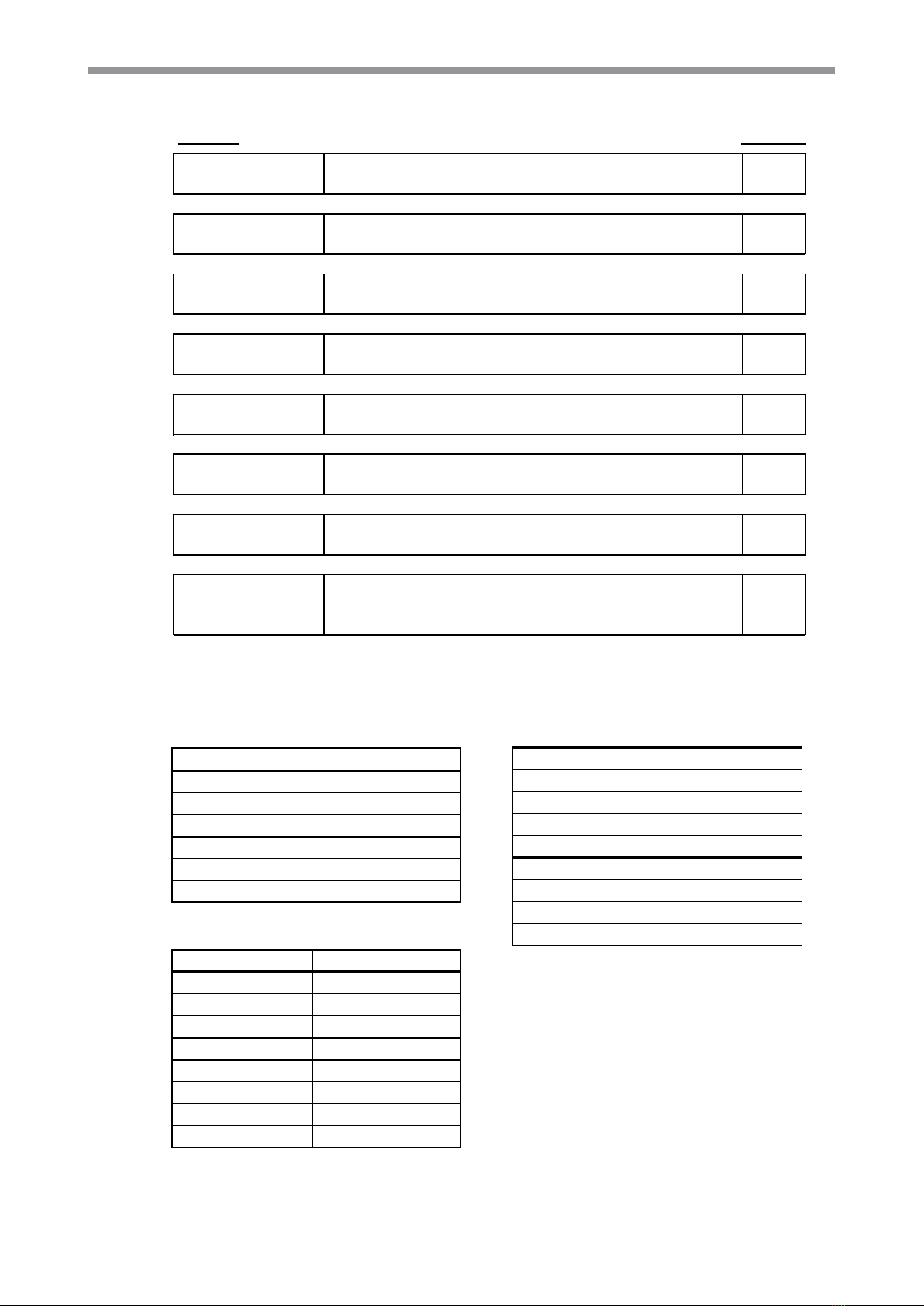

4-3 Interface (I/O and CC-Link)

4-3-1 Connector signal tables������������������������������� 12

4-3-1-1 I/O connector signal table ������������������������ 12

4-3-1-2 CC-Link connector signal table ���������������� 12

4-3-2 Details of input signals�������������������������������� 13

4-3-3 Details of output signals������������������������������ 14

4-3-4 Input/output circuits������������������������������������� 14

4-3-4-1 I/O input/output information (point input

type controller)����������������������������������������� 14

4-3-4-2 CC-Link input/output information (CC-Link

remote I/O type controller)����������������������� 17

4-3-4-3 CC-Link input/output information (CC-Link

remote device type controller)������������������ 18

4-3-4-3-1 Lists of input/output signals and input/

output data�������������������������������������������� 21

4-3-4-3-2 One-station mode (Remote device: One

station occupied) ���������������������������������� 22

4-3-4-3-3 Two-station mode (Remote device: Two

stations occupied)��������������������������������� 23

4-3-4-3-4 Four-station mode (Remote device: Four

stations occupied)��������������������������������� 25

4-3-4-3-5 List of input data ����������������������������������� 27

4-3-4-3-6 Details of input data������������������������������ 27

4-3-4-3-7 List of input signals������������������������������� 30

4-3-4-3-8 Details of input signals�������������������������� 31