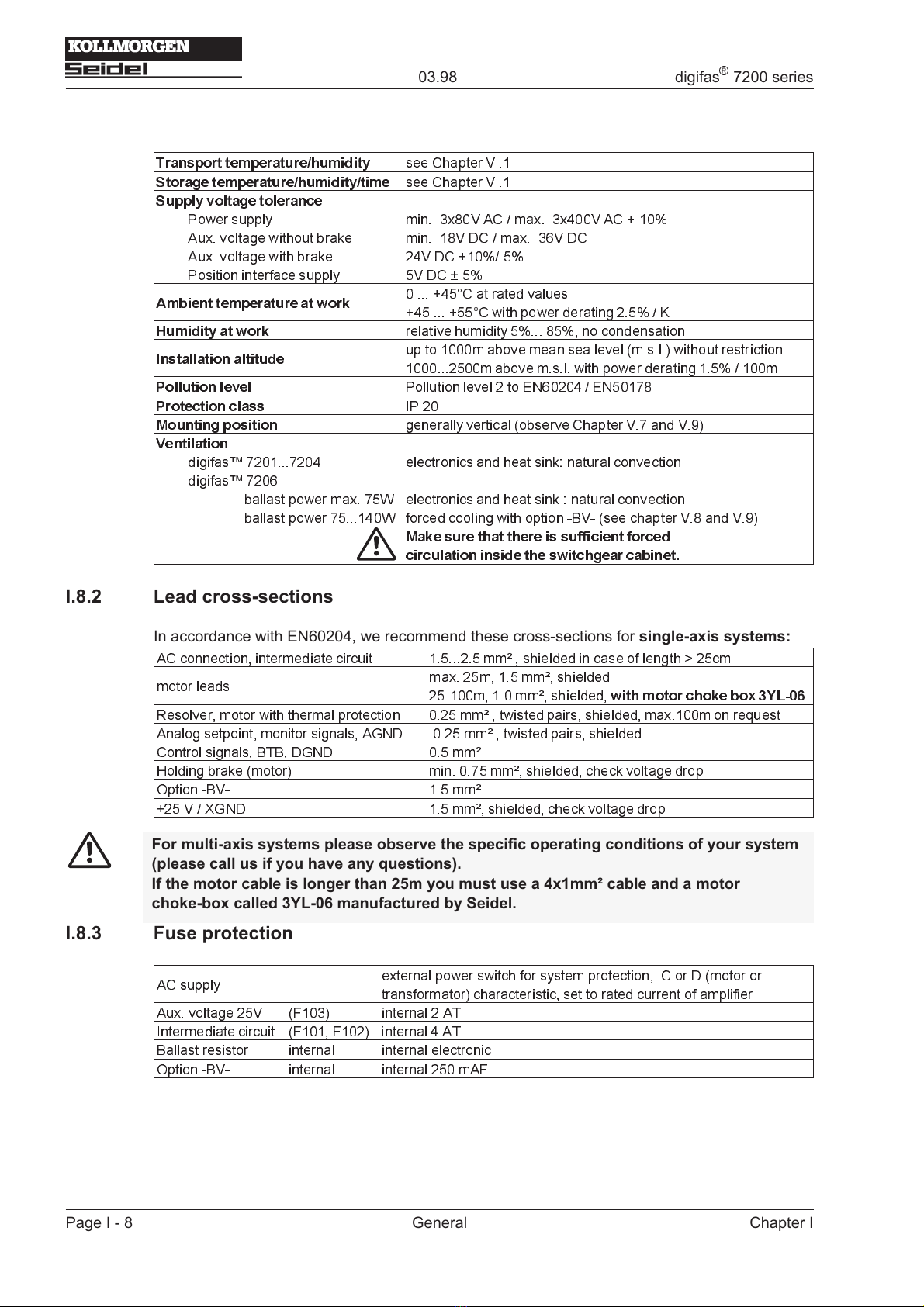

I.8.1 Permissible ambient conditions, ventilation, mounting position

Transport temperature/humidity

see Chapter VI.1

Storage temperature/humidity/time

see Chapter VI.1

Supply voltage tolerance

Power supply

Aux. voltage without brake

Aux. voltage with brake

Position interface supply

min. 3x80V AC / max. 3x400V AC + 10%

min. 18V DC / max. 36V DC

24V DC +10%/-5%

5V DC ± 5%

Ambient temperature at work

0 ... +45°C at rated values

+45 ... +55°C with power derating 2.5% / K

Humidity at work

relative humidity 5%... 85%, no condensation

Installation altitude

up to 1000m above mean sea level (m.s.l.) without restriction

1000...2500m above m.s.l. with power derating 1.5% / 100m

Pollution level

Pollution level 2 to EN60204 / EN50178

Protection class

IP 20

Mounting position

generally vertical (observe Chapter V.7 and V.9)

Ventilation

digifas 7201...7204 electronics and heat sink: natural convection

digifas 7206

ballast power max. 75W

ballast power 75...140W

electronics and heat sink : natural convection

forced cooling with option -BV- (see chapter V.8 and V.9)

Make sure that there is sufficient forced

circulation inside the switchgear cabinet.

I.8.2 Lead cross-sections

In accordance with EN60204, we recommend these cross-sections for single-axis systems:

AC connection, intermediate circuit 1.5...2.5 mm² , shielded in case of length > 25cm

motor leads max. 25m, 1.5 mm², shielded

25-100m, 1.0 mm², shielded,

with motor choke box 3YL-06

Resolver, motor with thermal protection 0.25 mm² , twisted pairs, shielded, max.100m on request

Analog setpoint, monitor signals, AGND 0.25 mm² , twisted pairs, shielded

Control signals, BTB, DGND 0.5 mm²

Holding brake (motor) min. 0.75 mm², shielded, check voltage drop

Option -BV- 1.5 mm²

+25 V / XGND 1.5 mm², shielded, check voltage drop

I.8.3 Fuse protection

AC supply external power switch for system protection, C or D (motor or

transformator) characteristic, set to rated current of amplifier

Aux. voltage 25V (F103) internal 2 AT

Intermediate circuit (F101, F102) internal 4 AT

Ballast resistor internal internal electronic

Option -BV- internal internal 250 mAF

Page I - 8 General Chapter I

03.98 digifas

®

7200 series

For multi-axis systems please observe the specific operating conditions of your system

(please call us if you have any questions).

If the motor cable is longer than 25m you must use a 4x1mm² cable and a motor

choke-box called 3YL-06 manufactured by Seidel.