Contents Page

Contents ....................................................3

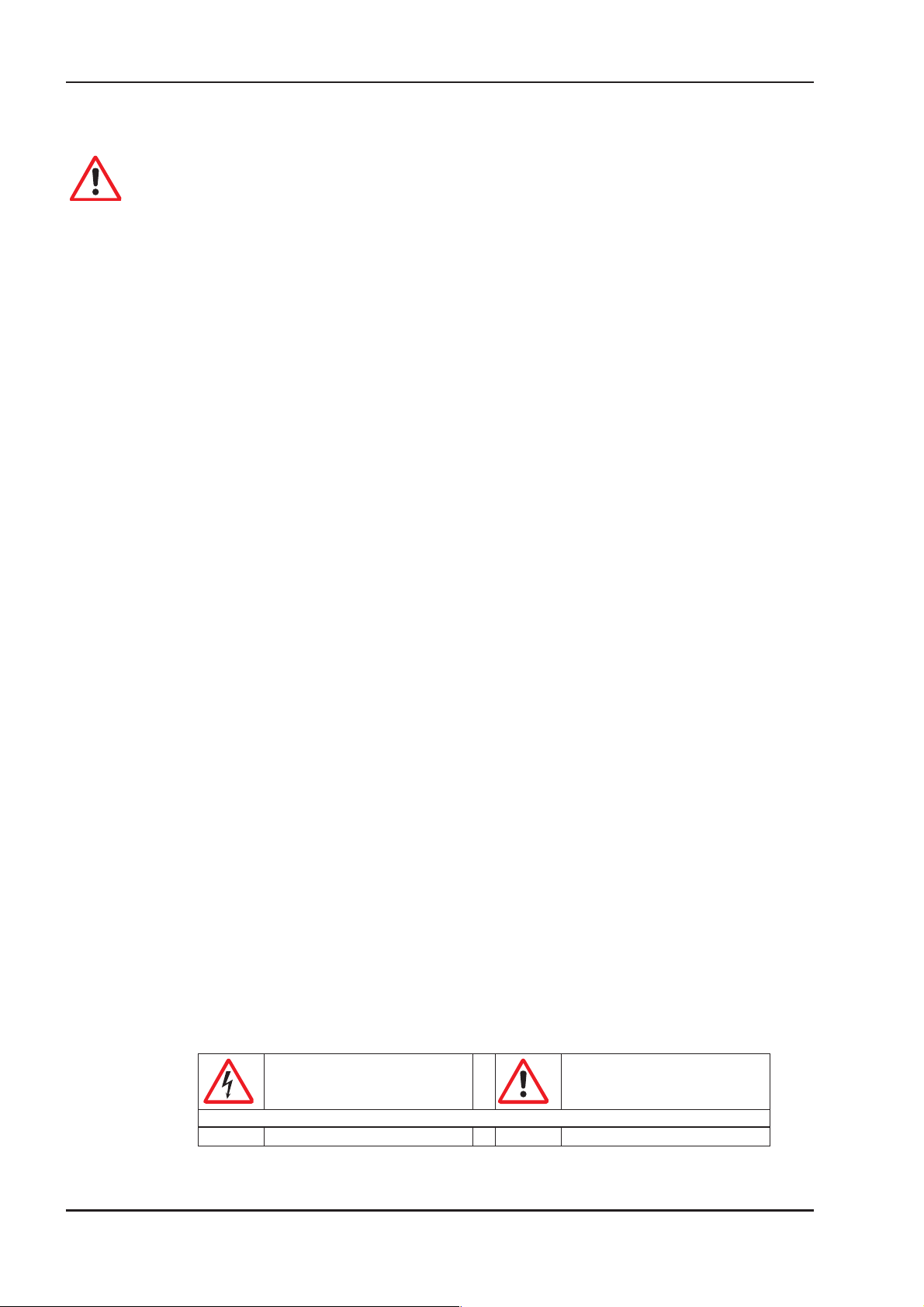

Safety Notes..................................................4

Important Notes ...............................................5

Manufacturer Declaration ........................................6

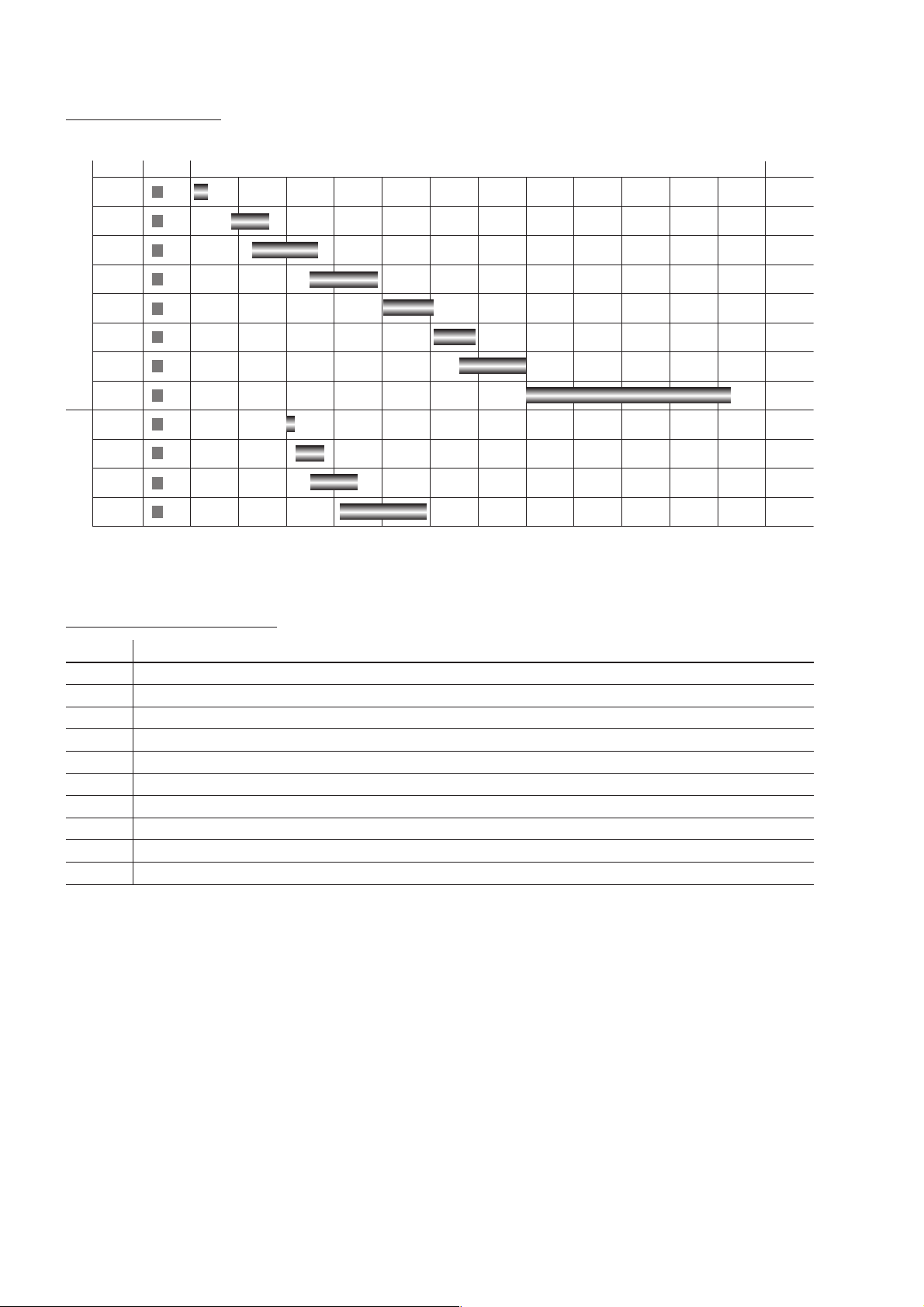

Contents

Servomotors DBL/DBK 3

Seidel 07/2002 Contents

I General

I.1 About this manual ...................................................................................7

I.2 Prescribed usage ...................................................................................7

I.3 Design of the motors.................................................................................8

I.4 General technical data ...............................................................................8

I.5 Standard features ...................................................................................9

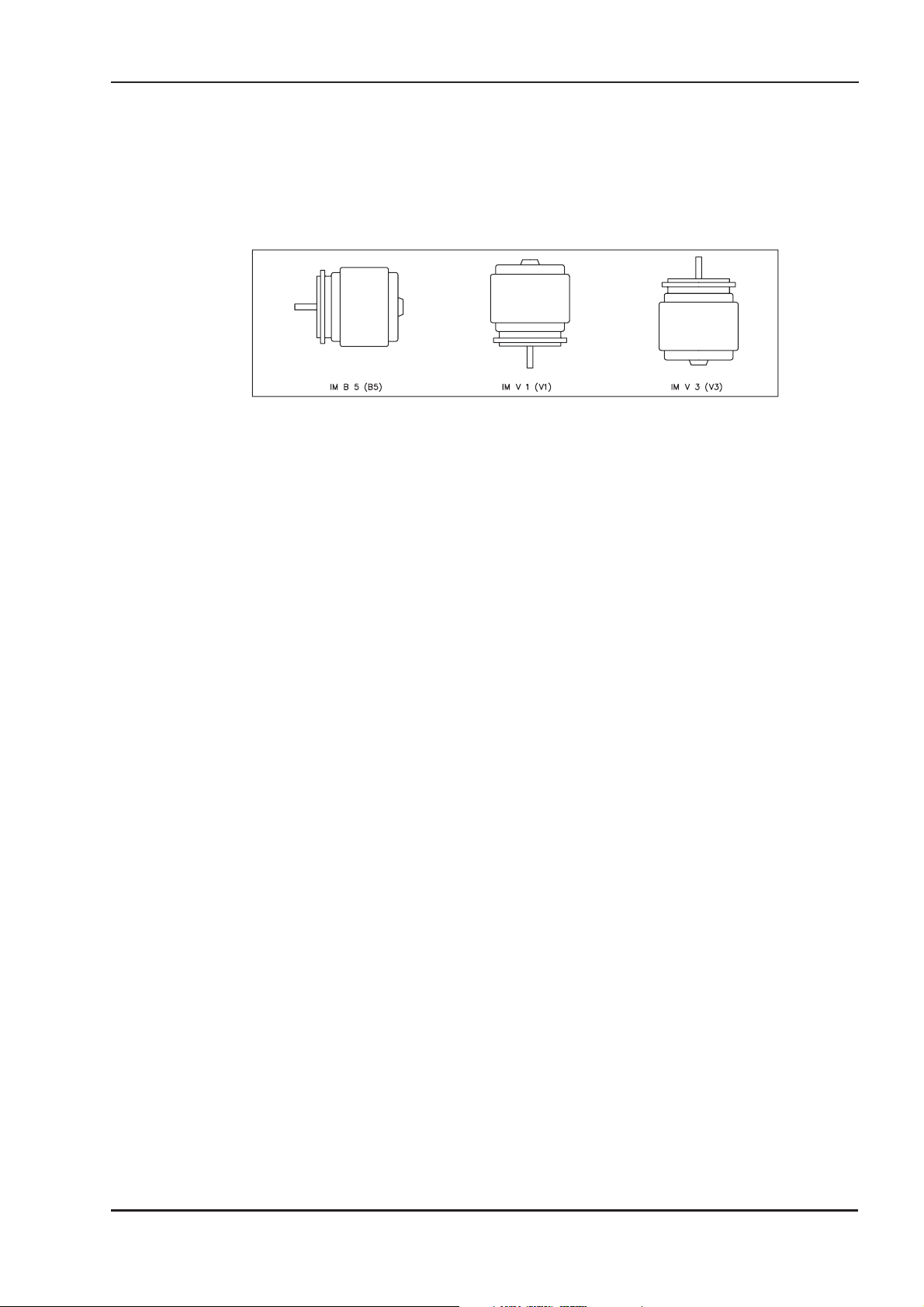

I.5.1 Style........................................................................................9

I.5.2 Shaft end, A-side ..............................................................................9

I.5.3 Flange ......................................................................................9

I.5.4 Protection class ...............................................................................9

I.5.5 Protective device ..............................................................................9

I.5.6 Insulation material class .......................................................................10

I.5.7 Vibration class ...............................................................................10

I.5.8 Connection method ...........................................................................10

I.5.9 Feedback unit ...............................................................................10

I.5.10 Holding brake ...............................................................................10

I.6 Options ..........................................................................................11

I.7 Selection criteria ...................................................................................11

I.7.1 Model number description ......................................................................12

I.7.2 Nameplate ..................................................................................12

II Installation / Setup

II.1 Important notes ....................................................................................13

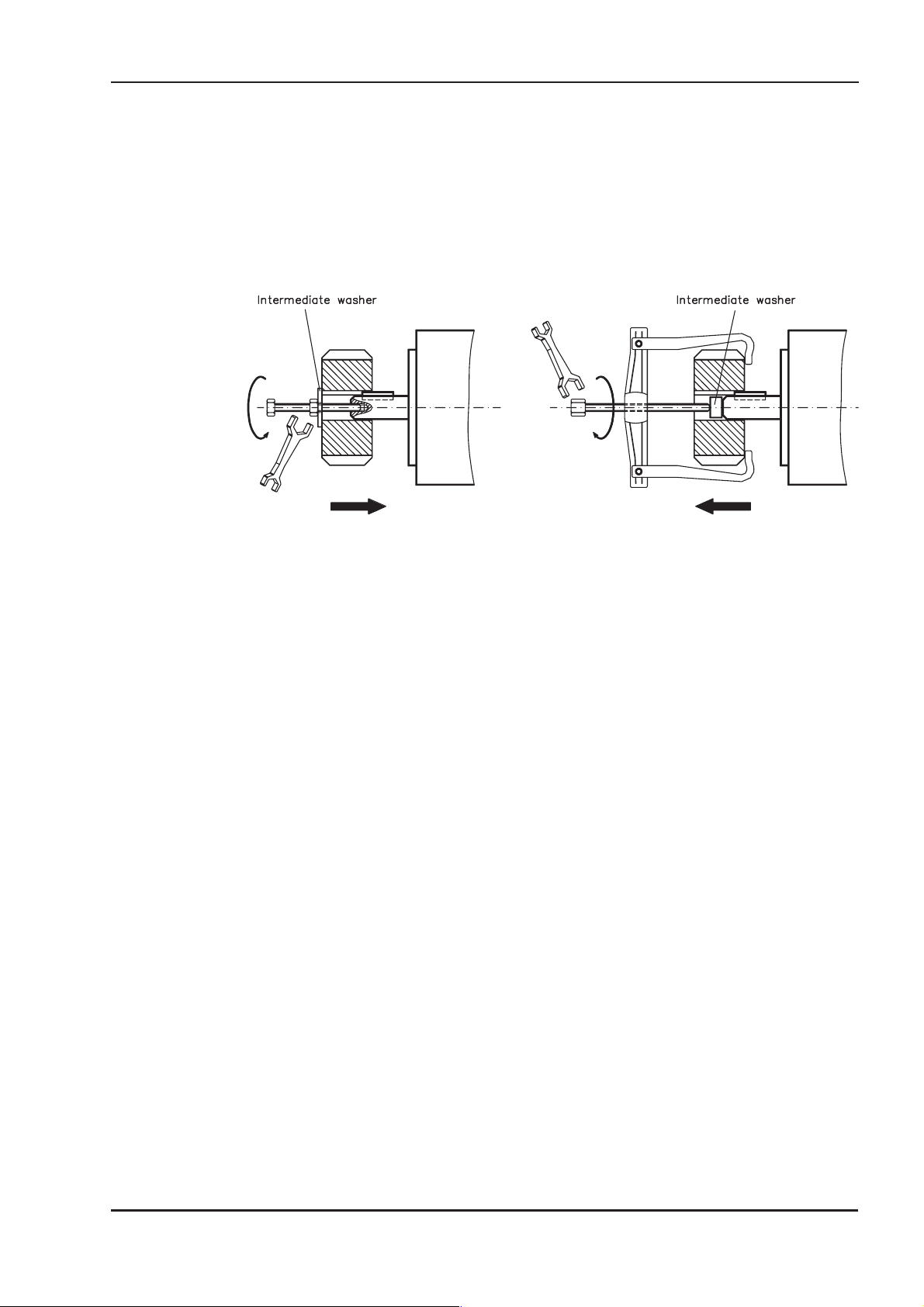

II.2 Assembly / Wiring ..................................................................................14

II.2.1 Connection of the motors ......................................................................16

II.2.1.1 Wiring diagram for resolver motors ...........................................................17

II.2.1.2 Wiring diagram for encoder motors ...........................................................18

II.3 Setup............................................................................................19

III Technical data

III.1 Definitions ........................................................................................21

III.2 DBL1 ............................................................................................22

III.3 DBL2 ............................................................................................26

III.4 DBL3 ............................................................................................30

III.5 DBL4 ............................................................................................34

III.6 DBL5 ............................................................................................38

III.7 DBL6 ............................................................................................42

III.8 DBL7 ............................................................................................46

III.9 DBL8 ............................................................................................50

III.10 DBK4............................................................................................54

III.11 DBK5............................................................................................58

III.12 DBK6............................................................................................63

III.13 DBK7............................................................................................70

IV Appendix

IV.1 Delivery package, transport, storage, maintenance, disposal ................................................73

IV.2 Removing faults ...................................................................................74

IV.3 Index ............................................................................................75