3

General Information

Table of Contents

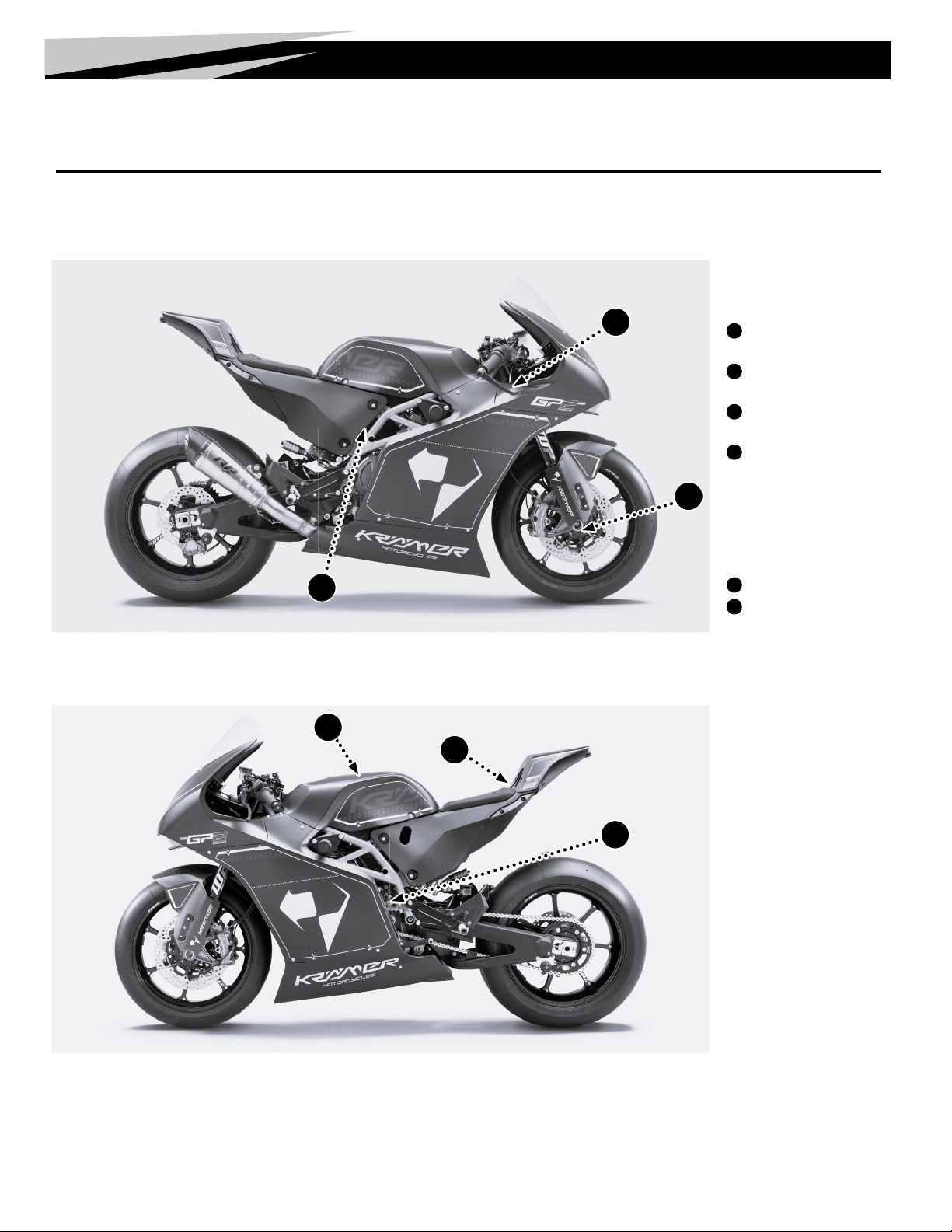

USAGE AND SETUP

Identication / Serial Numbers ...........4

Reference Views of Vehicle..............4

Serial Numbers .....................4

Operating Components ...............4

Control Components ...................5

Start Up Procedure ....................5

Shut Down Procedure ..................5

Vehicle Break-in Procedure..............6

Pre-Ride Inspection....................6

Post-Race Service .....................6

Post-Crash Inspection ................6

Transporting / Loading .................7

Raising the Motorcycle on Lift Stands .....7

Storage .............................8

MAINTENANCE / SERVICE

Service Schedule......................9

Krämer Motorcycles Onlineshop ..........9

Checking the Engine Oil Level ...........9

Changing the Engine Oil & Filter,

and Cleaning the Oil Screens ..........9

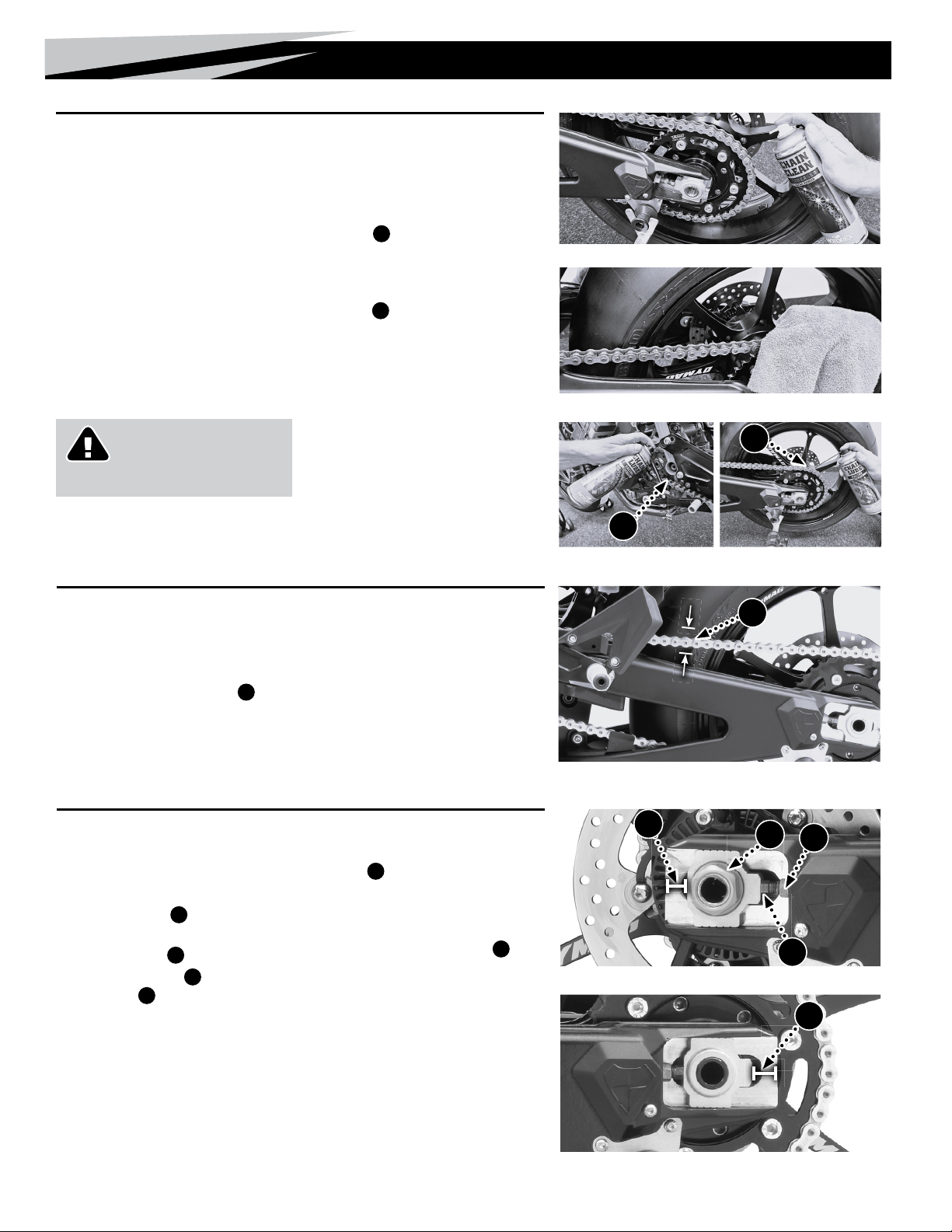

Chain Cleaning / Lubrication............10

Checking the Chain Tension ............10

Adjusting the Chain Tension / Rear Axle

Alignment ........................10

Fuel Filler Cap ....................... 11

Air Filter Servicing....................11

ENGINE

Repairs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Recommended Engine Maintenance......12

Engine Modes .......................12

Traction Control ......................12

Wheelie Control ......................12

Pit Limiter ..........................12

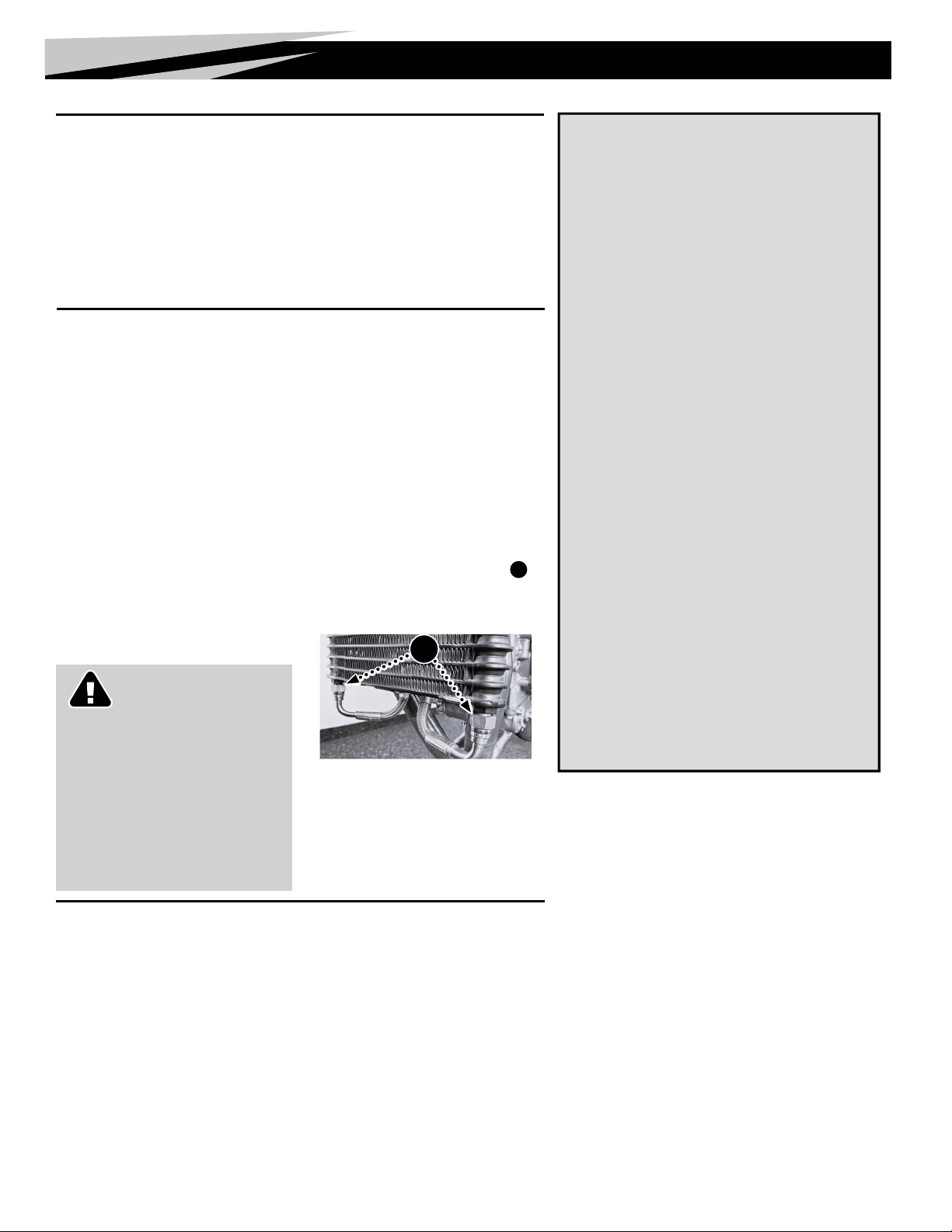

COOLING SYSTEM

Checking the Coolant Level.............13

Draining the Coolant ..................13

Filling/Bleeding the Cooling System ......13

CHASSIS

Handlebar Adjustment.................14

Steering Damper Setup ................14

Seat/Tank Height Adjustment ...........14

Bodywork Removal ...................15

Bodywork Installation .................15

Fuel Tank Draining Procedure ...........16

Fuel Tank Removal/Installation..........16

Clutch Lever Free Play and Reach

Distance ......................... 17

Front Brake Lever Response and Travel

Distance ......................... 17

Rearset Setup .......................18

Adjusting the Foot Pegs................18

Rear Brake Lever Adjustment ...........18

Shift Lever Height Adjustment...........18

BRAKE SYSTEM

Brake Inspection .....................19

Brake Bleeding ......................19

Changing the Brake Pads ..............20

SUSPENSION

Suspension Inspection.................21

Checking the Steering Head Bearing Play..21

Adjusting the Steering Head Bearing Play..21

Changing the Fork Offset...............22

Fork Suspension Settings ..............23

Adjusting Spring Preload...............23

Adjusting Compression Damping.........23

Adjusting Rebound Damping ............23

Fork Specications ...................23

Rear Shock Suspension Settings.........24

Adjusting the Spring Preload ...........24

Adjusting Compression Damping.........24

Adjusting Rebound Damping ............24

Shock Absorber Specications ..........24

WHEELS

Front Wheel Removal .................25

Front Wheel Installation ...............25

Rear Wheel Removal ..................26

Rear Wheel Installation ................26

ELECTRICAL

Tail light Operation....................27

Charging the Tail light .................27

Fuses ..............................27

Battery.............................28

Wiring Diagram ......................28

TECHNICAL DATA

GP2 890-RR Specications.............30

Fluid Capacities ......................30

Engine Specications .................30

Electrical System.....................30

TORQUE SPECIFICATIONS

Engine Torque Chart ..................31

Chassis Torque Chart..................32

Safety Wire .........................32

DASHBOARD

AIM MXS 1.3 Race GPS with Data Logger . 33

Dash Logger Indicators Overview ........33

Dash Logger Menu Conguration Settings . 34

Set Date and Time..................34

Set Backlight......................34

Set Video Input ....................34

Lap Time Setup....................35

Counters Management ..............35

GPS & Tracks .....................35

Wi-Fi Management .................36

System Info .......................36

GPS Search.......................36

Sampled Data Recall................37