KREMLIN Page 1 Manual : 573.171.112

SUMMARY

1. EC DECLARATION OF CONFORMITY ...................................................................................................... 2

2. GENERAL SAFETY INSTRUCTIONS......................................................................................................... 2

INSTALLATION REQUIREMENTS ............................................................................................ 2

EQUIPMENT REQUIREMENTS ................................................................................................ 3

MAINTENANCE REQUIREMENTS............................................................................................ 3

ENVIRONNMENT....................................................................................................................... 4

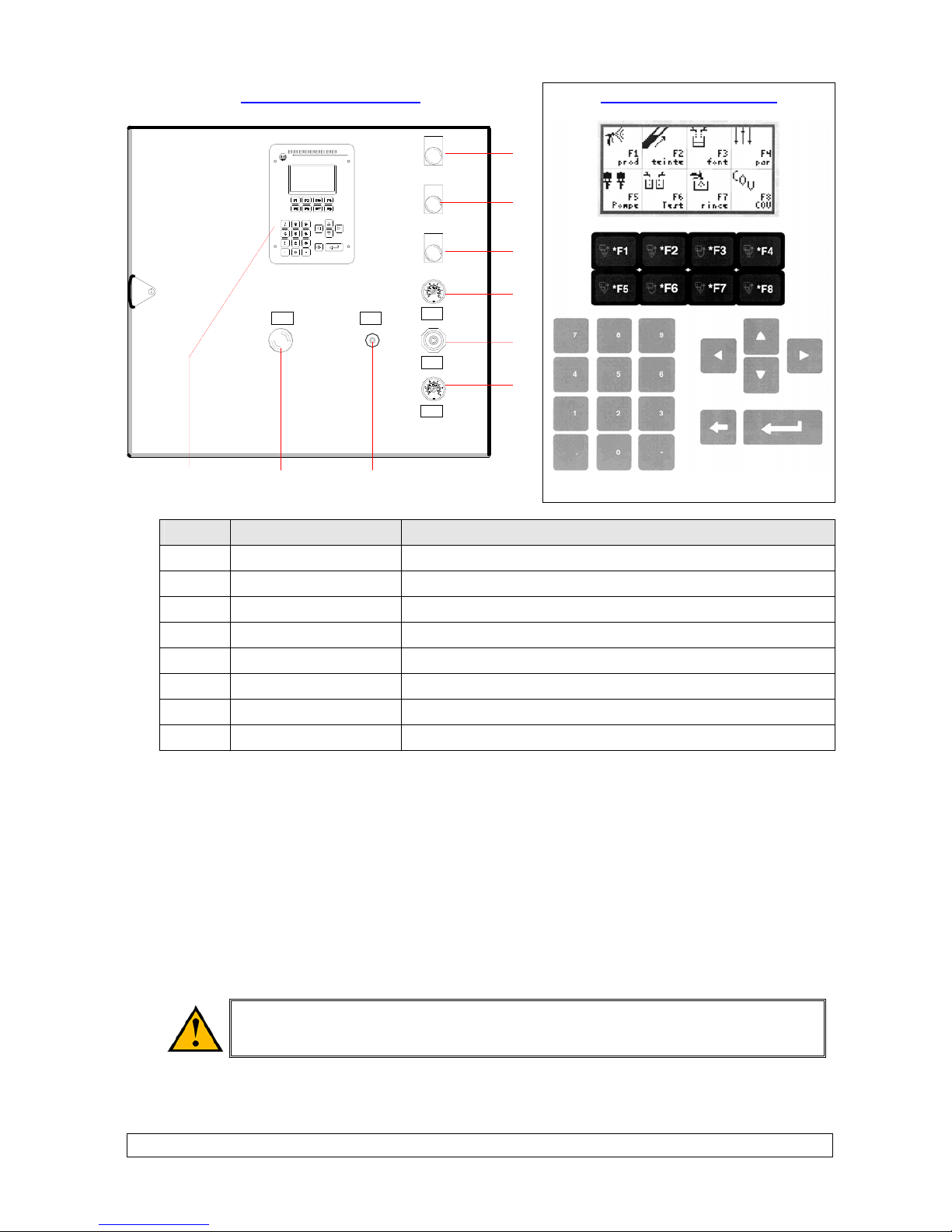

3. DESCRIPTION ............................................................................................................................................. 4

4. OPERATING PRINCIPLE ............................................................................................................................ 7

5. TECHNICAL FEATURES ............................................................................................................................ 8

6. INSTALLATION ........................................................................................................................................... 8

7. OPERATING .............................................................................................................................................. 10

DRIVING FROM THE MACHINE ............................................................................................. 10

SWITCHING ON THE MACHINE ............................................................................................. 10

8. FIRST SWITCHING ON ............................................................................................................................. 11

9. FIRST PLACING INTO OPERATION ........................................................................................................ 13

FLUSHING OF THE PUMPS AND OF THE MACHINE INTO SOLVENT ............................... 13

START-UP OF THE MACHINE ................................................................................................ 14

10. APPLICATION PROGRAMMING .............................................................................................................. 15

AUTHORIZATION..................................................................................................................... 16

LIST OF THE PARAMETERS .................................................................................................. 17

EXPLANATION OF THE PARAMETERS................................................................................. 18

GUN PRIMING.......................................................................................................................... 20

BASE FLUSHING ..................................................................................................................... 20

11. INDICATIONS GIVEN BY THE LED .......................................................................................................... 21

12. BATCH ....................................................................................................................................................... 21

13. TEST .......................................................................................................................................................... 21

14. WEEK-END FLUSHING OR PRODUCTION FLUSHING.......................................................................... 22

15. OTHER MENUS ......................................................................................................................................... 23

AUTOMATIC MENU ................................................................................................................. 23

AUTO-WASH MENU ................................................................................................................ 25

16. MAINTENANCE......................................................................................................................................... 27

17. TROUBLESHOOTING............................................................................................................................... 28

DIAGNOSTICS ......................................................................................................................... 29

18. DISASSEMBLY -REASSEMBLY ............................................................................................................. 33

MIXER....................................................................................................................................... 33

PILOTED VALVES (FLUID VALVES AND TEST VALVES)..................................................... 33

19. PREVENTIVE MAINTENANCE PLAN ...................................................................................................... 35

ADDITIONAL DOCUMENTS :

Annexes Pneumatic and electric diagrams

Mixing ratio chart

Doc. 573.171.120

Spare parts Cyclomix or Cyclomix PH Doc. 573.344.050 or Doc. 573.358.050

Color changer Doc. 573.188.050

Flow switch Doc. 573.320.050

AIRMIX filter Doc. 573.253.050