8

EN

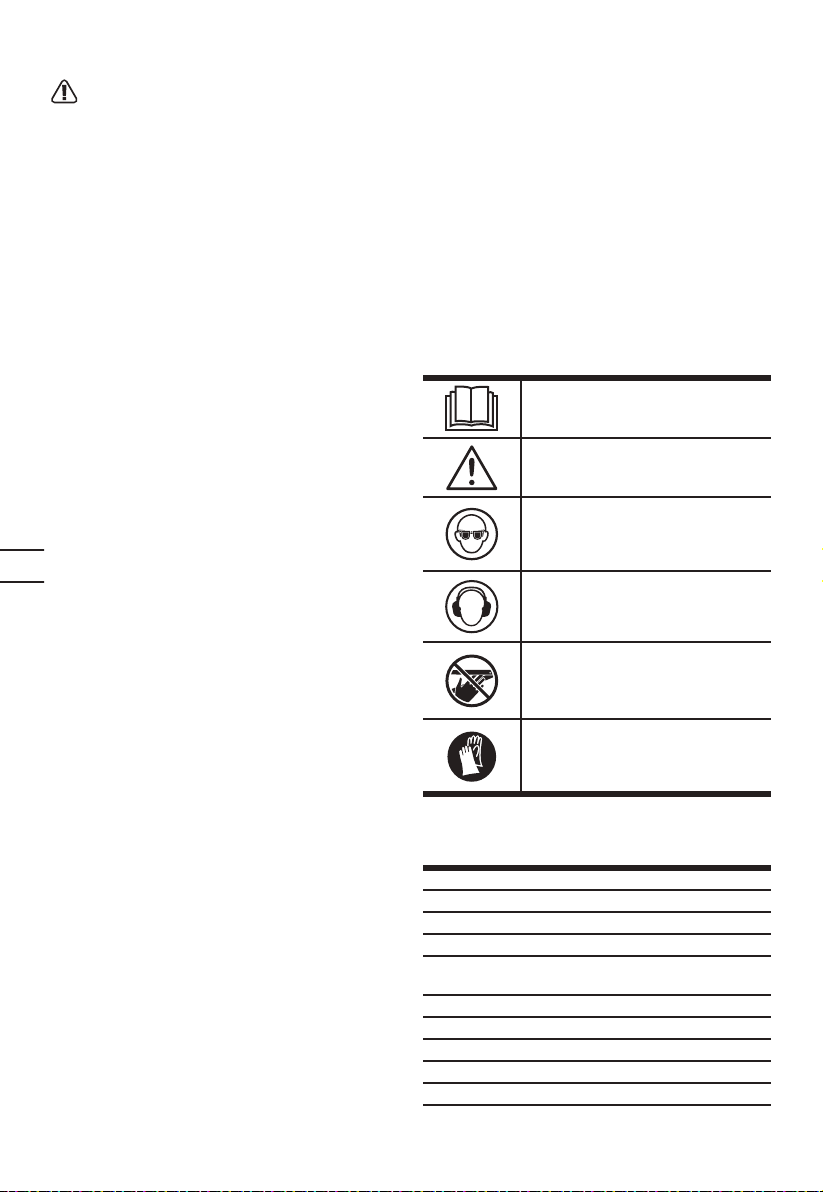

TECHNICAL DATA

Clamping range 0-940mm

Max. clamping force 1 metric ton (1000kg)

Clamp method Foot step

Max. Load 272kg

Footprint (standing) 1000x985x885mm

Footprint (folded) 775x350x335mm

Clamp travel – foot pedal 24mm per step

Weight 19kg

Construction Solid steel

OPERATING

INSTRUCTIONS

NOTE: Before using the tool, read the

instruction book carefully.

INTENDED USE

The workbench is a versatile workstation for holding,

clamping, supporting.

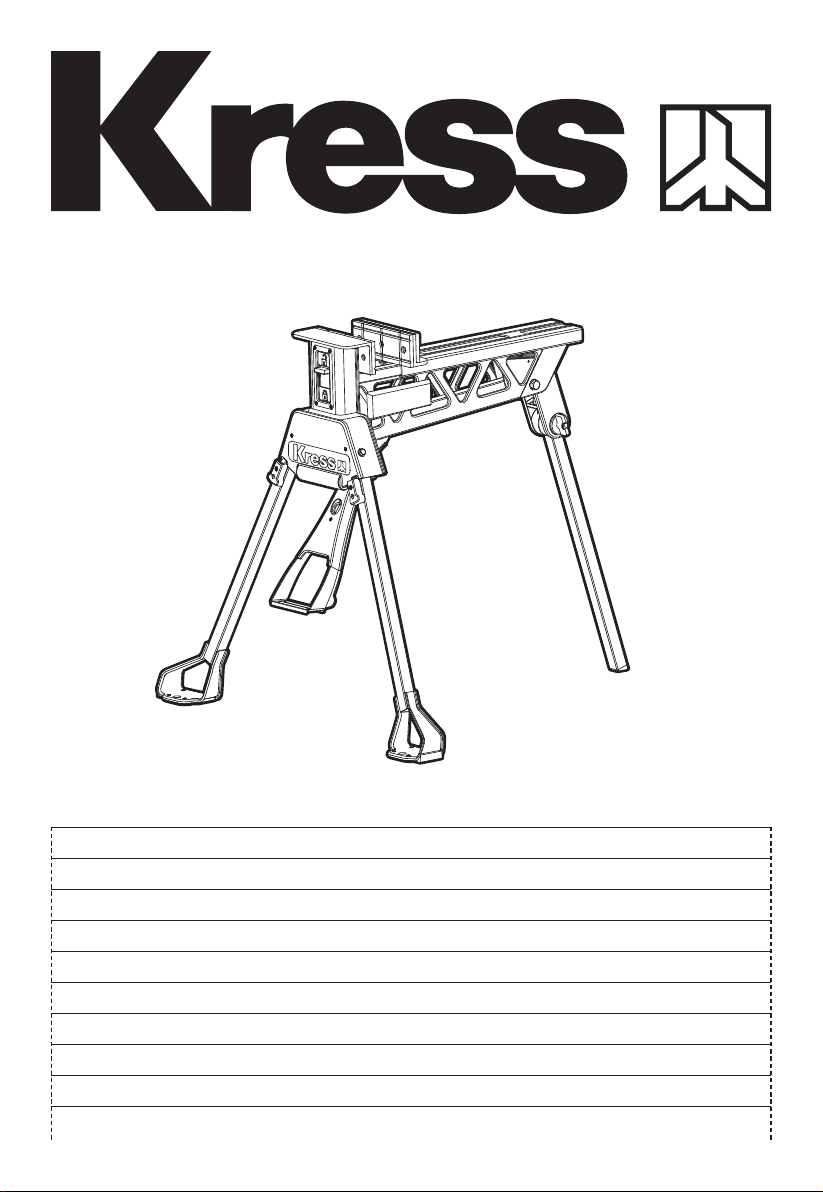

1. SET-UP INSTRUCTIONS

1. Put the workbench upside down on the ground,

loosen the Rear Leg Locking Knob (5) and slide the

rear leg from its storage position. Pivot the leg to

position and slide it all the way upward then lift and

slide it fully into its housing at the rear. Tighten the

knob. (See Fig. A-C)

2. Raise the Foot Pedal (9) until it “clicks” into position.

(See Fig. D-E)

3. Rotate the Front Legs (10) all the way forward until

they “click” into position. The Front Leg Locking Latch

(15) will be open automatically. (See Fig. E)

4. Turn the workbench upright and recheck that all

legs are locked rmly in position.

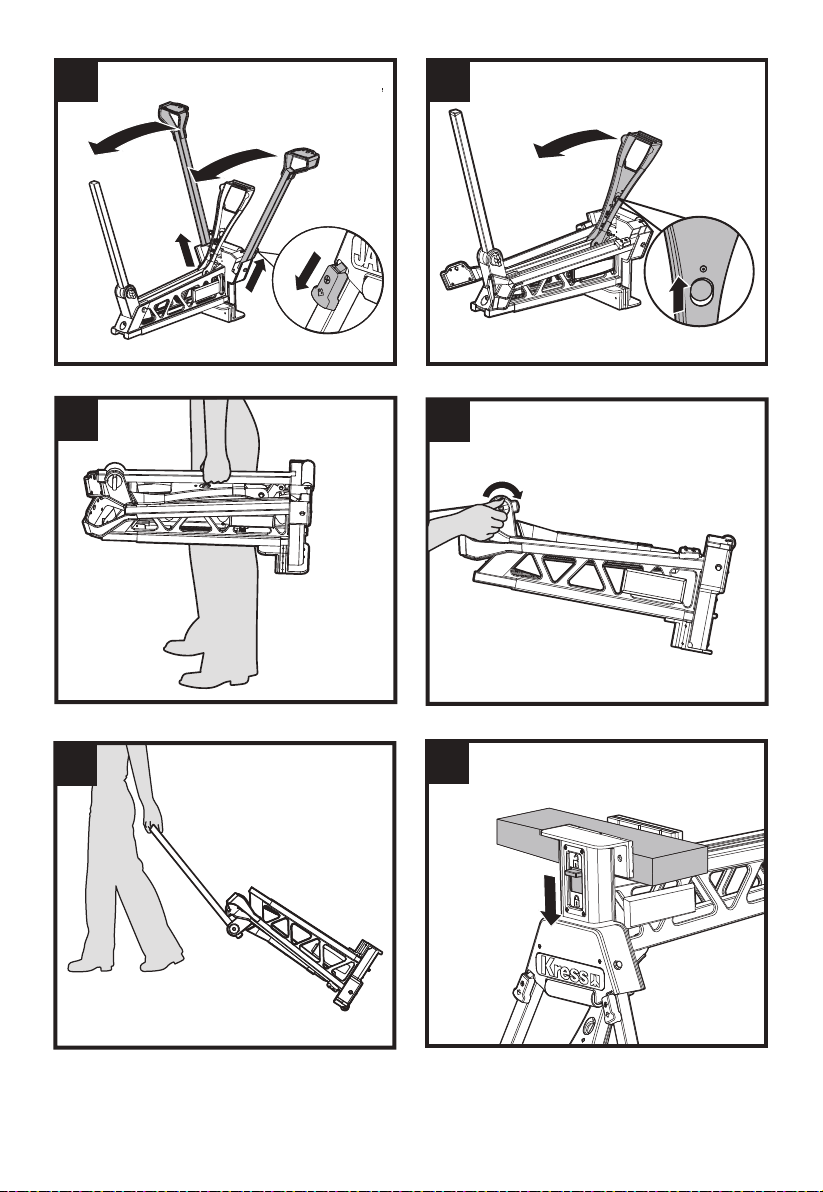

2. FOLDING INSTRUCTIONS

Folding is the reverse procedure of above. (See Fig.

F-K)

1. Ensure that the Lock / Release Switch (13) is in the

“unlock position”. ( See Fig. F)

2. Turn the unit upside down. Slide the front leg latch

and fold the Front Legs (10) into position. ( See Fig. G)

3. Draw the Foot Pedal (9) locking latch and place the

Foot Pedal in folding position. ( See Fig. H)

4. Loosen the Rear Locking Knob(5). Slide the Rear

Leg (6) from housing and back into storage position.

Make sure the Rear Leg is engaged fully into storage

position and the Rear Leg Locking Knob is tightened

rmly.

5. You can carry the Rear Leg as a carry handle when

the workbench is fully folded in its position. (See Fig. I)

6. You can also slide the Rear Leg to use as a handle.

With the Roller (12) on the front, transporting the

workbench is easy and fast. Note that the Roller is

not designed to withstand rigorous transport, such as

bouncing down stairways or traversing rough terrain.

(See Fig. J, K)

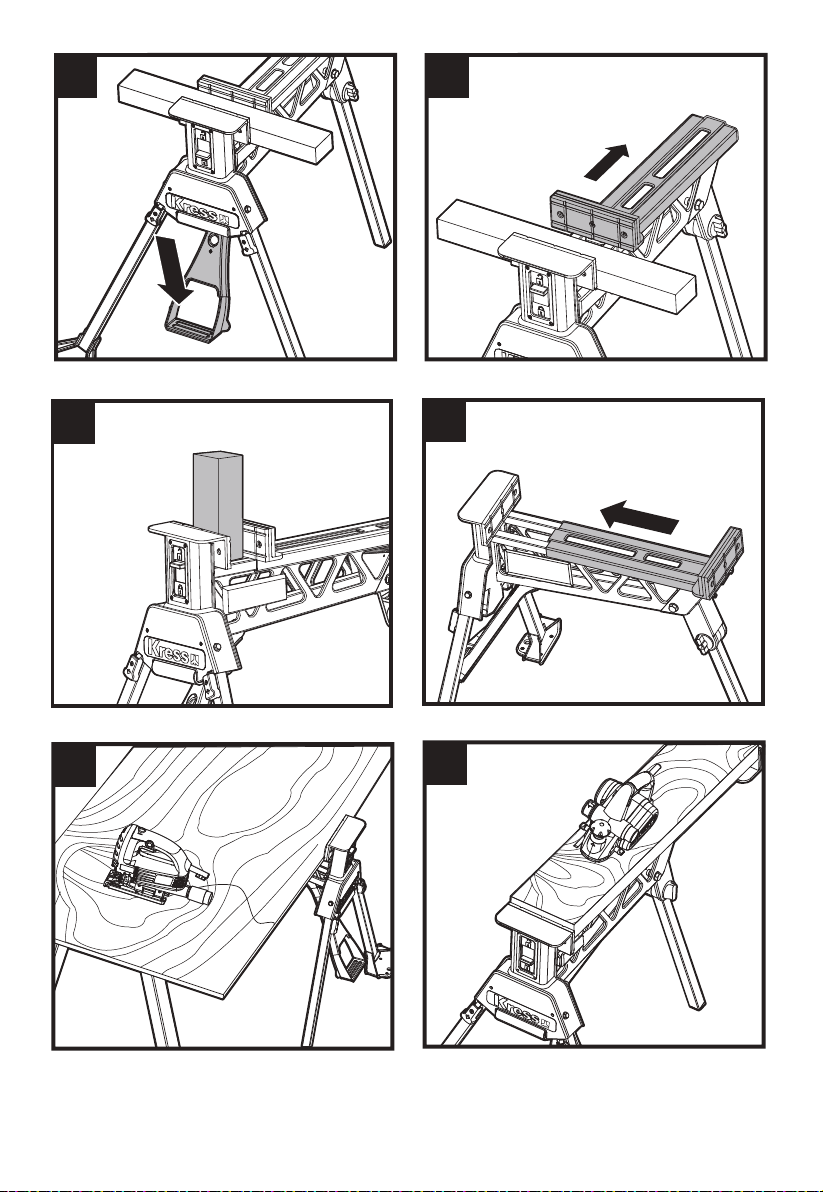

3. CLAMPING

1. Place the workpiece against the Fixed Jaw (14) and

slide the Moving Jaw (1) forward until it touches the

workpiece.

The Foot Pedal (9) can be pressed repeatedly to make

the jaw move forward.

2. Slide the Lock / Release Switch (13) down to the

“lock” position. (See Fig. L)

3. Apply downward pressure on the Foot Pedal until

enough clamping force is applied. (See Fig. M)

WARNING: Maximum allowable force on

the foot pedal is 100kg. Do not stand or

jump on the unit, as you can cause injury or

damage to the unit.

4. RELEASING

1. Slide the Lock / Release Switch (13) up to the

“release” position. (See Fig. F)

2. Push on the Foot Pedal(9), allow it to return up and

release the workpiece. (See Fig. M)

If you have clamped the object very tightly, you must

exert similar pressure on the foot pedal before it will

release.

WARNING: Ensure you are supporting the

workpiece to avoid its falling when the

jaw is released.

3. Slide the moving jaw back and remove your

workpiece. (See Fig. N)

5. CLAMPING ON ONE SIDE OF THE JAW

Sometimes, large or awkward workpieces can only be

clamped on one side of the jaws. In this case, be sure

to avoid excessive clamping force.

6. CLAMPING SQUARE PIECES VERTICALLY

(See Fig.O)

Sometimes, tubing or other square (steel, aluminum

or other) workpieces need to be clamped vertically

on the center of the jaws. The hole on the base plate

under the jaw accommodates pieces up to 6cm in

width.

7. CLAMPING LARGE OBJECTS [450mm TO

940mm]

The move jaw can be reversed to accommodate large

workpieces.

1. Set the Lock / Release Switch (13) to the “release”

position and ensure that the Foot Pedal (9) is released.

2. Slide the Moving Jaw (1) fully from its tracks. (See

Fig. N)

3. Rotate the jaw 180 degrees and re-insert it into the

track. (See Fig. P)

WARNING: Whenever clamping objects

with the moving jaw reversed, ensure the

workpiece sits down onto the sliding jaw, and

is parallel to it. Avoid clamping workpieces at

the top of the jaws (with a gap between the

workpiece and the base of the moving jaw) as

excessive pedal pressure could damage the

unit.

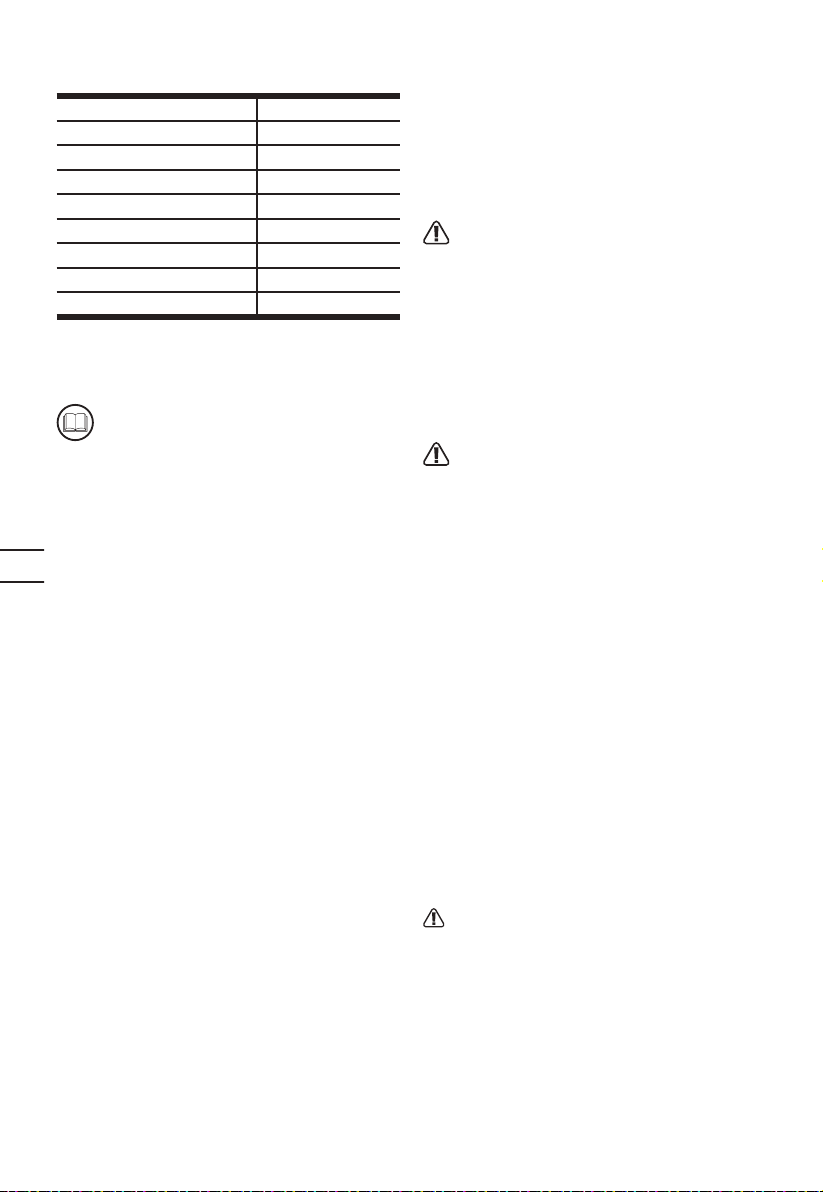

Note: Some operations such as hand sawing

or planing exert enough pressure to cause the

workbench to slide. In these situations, it is

acceptable to hold the workbench in place by

standing on the foot plate. (See Fig. R)

When clamping large or heavy materials,