3 SETUP 7

B01995-10

–Insert the black and violet cables of bulb included in the separate enclosure into

the socket and position it in the turn signal indicator lamp .

–Position the turn signal on each side and mount and tighten nuts .

–Connect the plug-in connector of the right turn signal with the connector

marked green on the wiring harness.

–Connect the plug-in connector of the left turn signal with the connector marked

red on the wiring harness.

–Mount the turn signal relay with the retaining bracket and plug in the connec-

tor.

–Install the front fender. ( p. 16)

–Refit the headlight mask with the headlight. ( p. 16)

800042-10

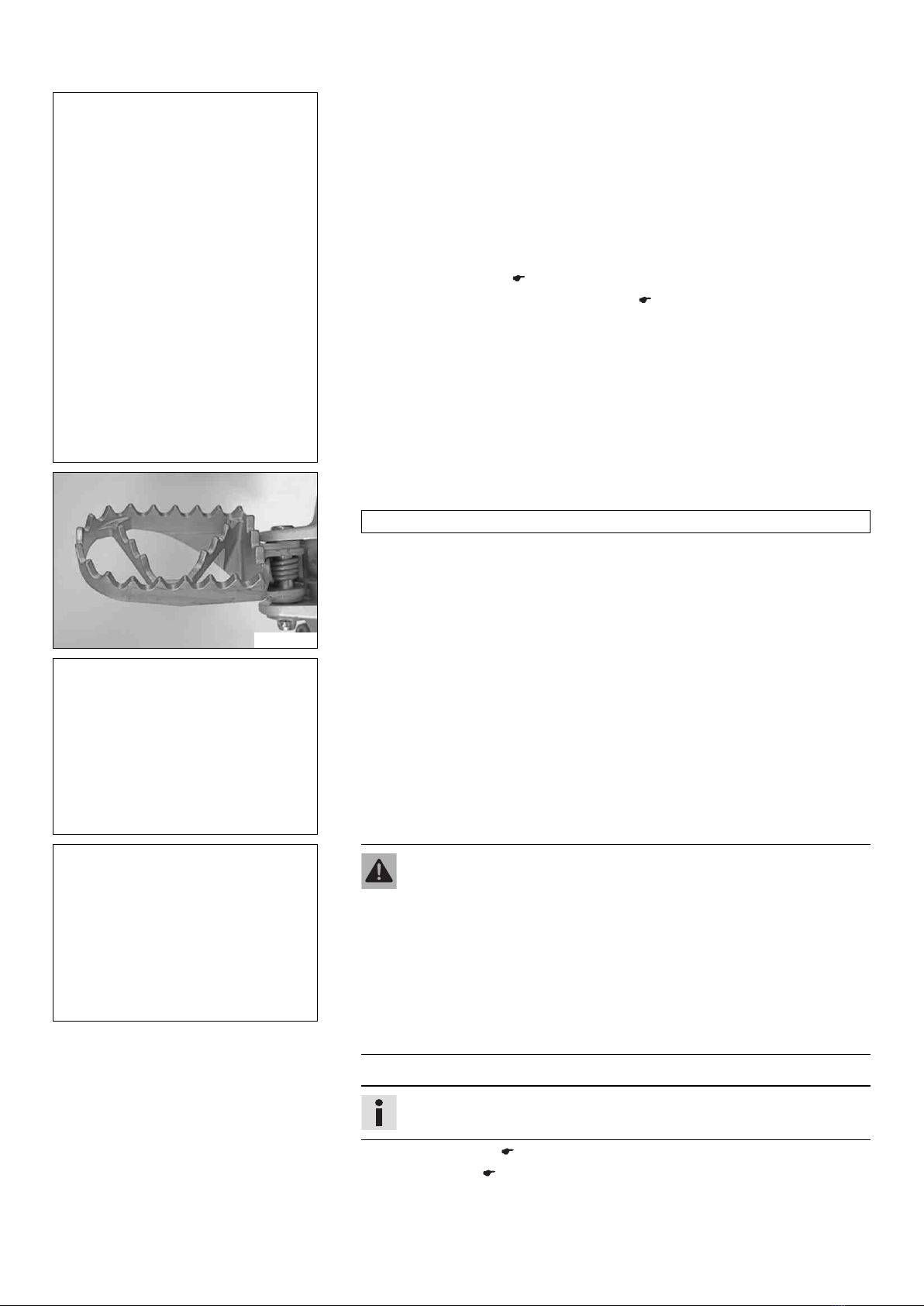

–Mount the footrests with the springs and pins. Secure the pins using the washers

and cotter pins.

Pliers for footrest spring (58429083000)

B01170-01

–Mount the license plate holder with the license plate lamp, turn signals, and reflec-

tor.

–Connect the electrical components.

–Connect the plug-in connector of the right turn signal with the connector marked

green on the wiring harness.

–Connect the plug-in connector of the left turn signal with the connector marked red

on the wiring harness.

B01173-01

Warning

Risk of injury Battery acid and battery gases cause serious chemical burns.

–Keep batteries out of the reach of children.

–Wear suitable protective clothing and goggles.

–Avoid contact with battery acid and battery gases.

–Keep sparks and open flames away from the battery. Only charge in

well-ventilated rooms.

–In the event of skin contact, rinse with large amounts of water. If battery

acid gets in the eyes, rinse with water for at least 15 minutes and con-

tact a physician.

–Fill the battery.

Info

Read the notes in the battery package.

–Recharge the battery. ( p. 14)

–Install the battery. ( p. 15)

–Unpack and mount the KTM PowerParts included in the delivery (optional).