Table of Contents Kübler Group

2 - EN HB Modbus Interface - R67048.0002 - 02

Table of Contents

1 Document ........................................................................................................................ 4

2 General Information........................................................................................................ 5

2.1 Target Group........................................................................................................... 5

2.2 Symbols used / Warnings and Safety instructions.................................................. 5

3 Product Description ....................................................................................................... 7

3.1 Technical Data Sendix F58xx ................................................................................. 7

4 Installation....................................................................................................................... 8

4.1 Electrical Installation ............................................................................................... 8

4.1.1 General Information for the Connection.................................................... 8

4.1.2 Information for EMC-Compliant Installation .............................................. 8

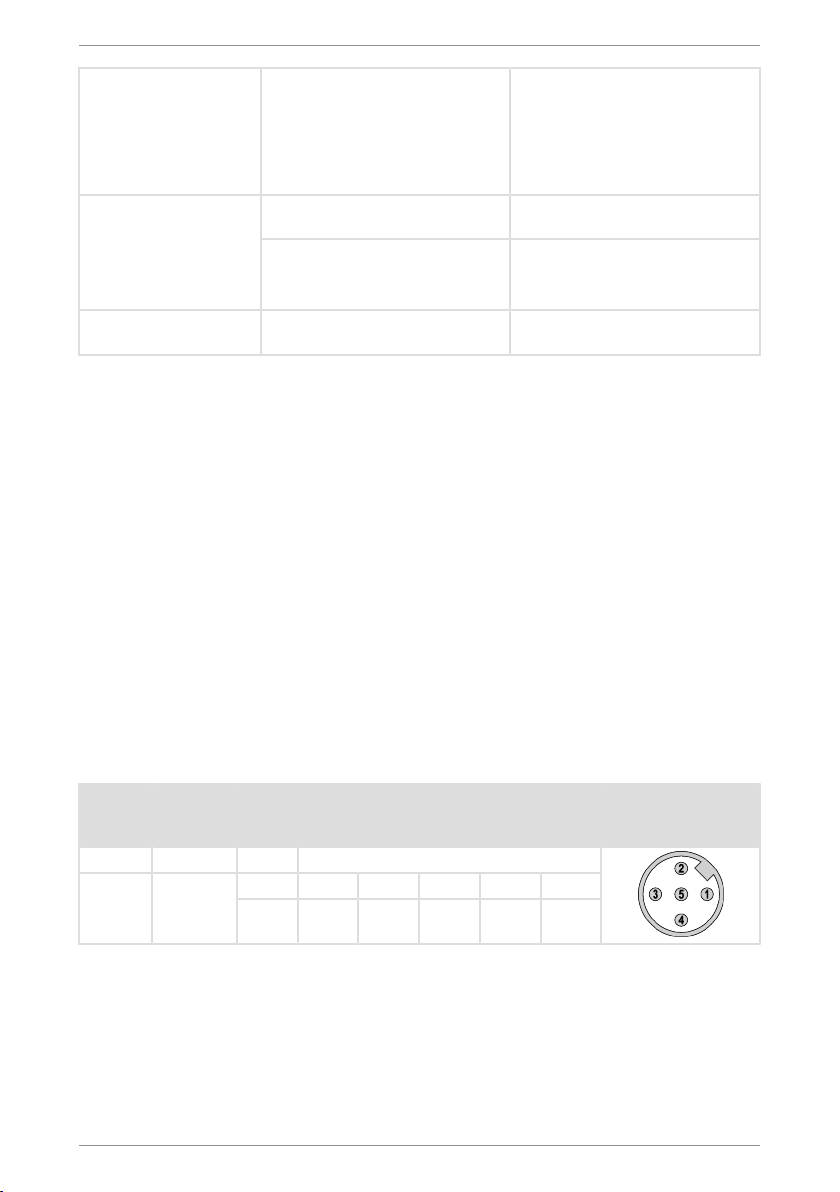

4.1.3 Terminal Assignment ................................................................................ 9

4.1.4 Network topology ...................................................................................... 10

5 Commissioning and Operation ..................................................................................... 11

5.1 Function and Status LED ........................................................................................ 11

5.2 Quick Start Guide.................................................................................................... 11

5.2.1 Changing the parameters ......................................................................... 11

5.2.2 Not supported Modbus function codes ..................................................... 12

5.2.3 Default settings ......................................................................................... 12

5.3 Protocol Features.................................................................................................... 13

5.3.1 Structure of the Modbus RTU frames ....................................................... 13

5.3.2 Function codes.......................................................................................... 14

5.3.3 LRC check................................................................................................. 16

5.3.4 Data Addresses......................................................................................... 16

5.4 Function code 03 - Reading the Holding Register .................................................. 16

5.5 Function Code 16 - Writing the Holding Register.................................................... 18

5.6 Function code 17 - Query of Device-Specific Information....................................... 22

5.7 Description of the Registers.................................................................................... 24

5.7.1 Reading the Holding Register ................................................................... 24

5.7.2 Writing the Holding Register ..................................................................... 27

5.8 Modbus Exception Codes ....................................................................................... 31

5.9 Examples ................................................................................................................ 31

5.9.1 Scaling Setting Example ........................................................................... 31

5.9.2 Count Direction Change Example............................................................. 32

5.9.3 Preset Setting Example ............................................................................ 33

6 Maintenance .................................................................................................................... 34

7 Annex............................................................................................................................... 35

7.1 Decimal / Hexadecimal conversion table ................................................................ 35

8 Contact ............................................................................................................................ 37