Contents

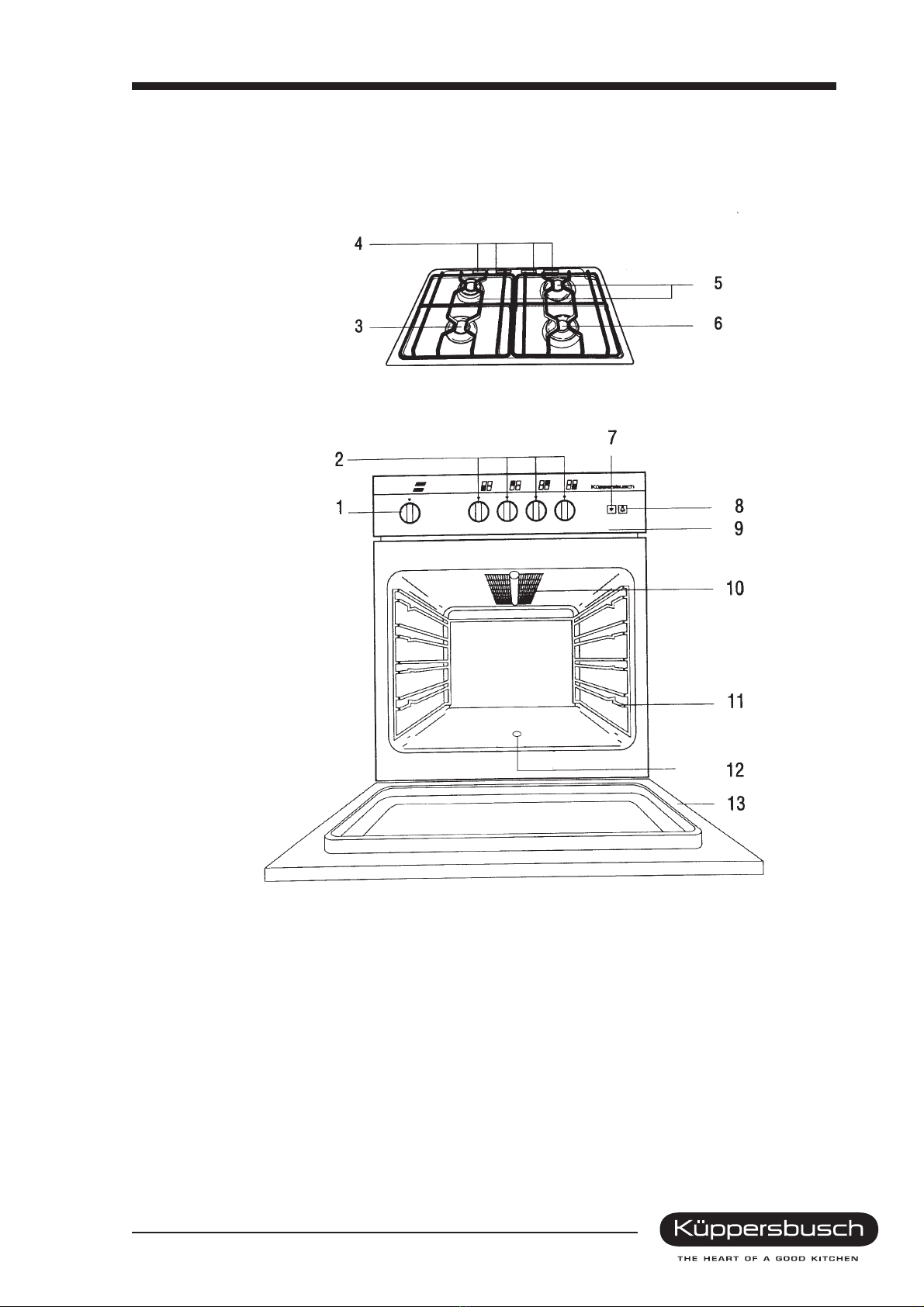

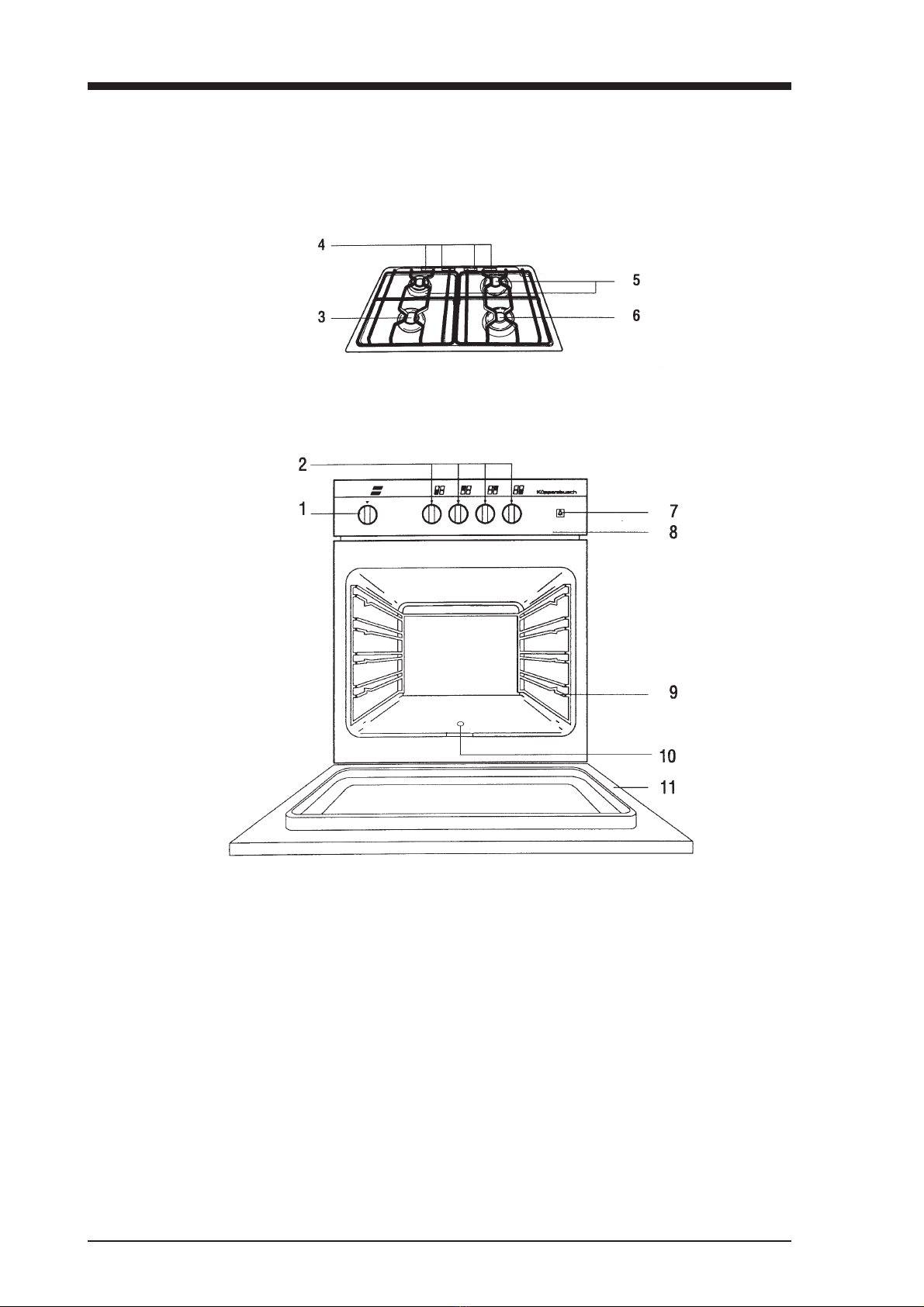

1. Your appliance at a glance ...........................................................................................................4

1.1 GH 606.0 E............................................................................................................................4

1.2 GH 506.0 E............................................................................................................................5

1.3 GH 505.0 E............................................................................................................................6

1.4 GKH 507.0 E .........................................................................................................................7

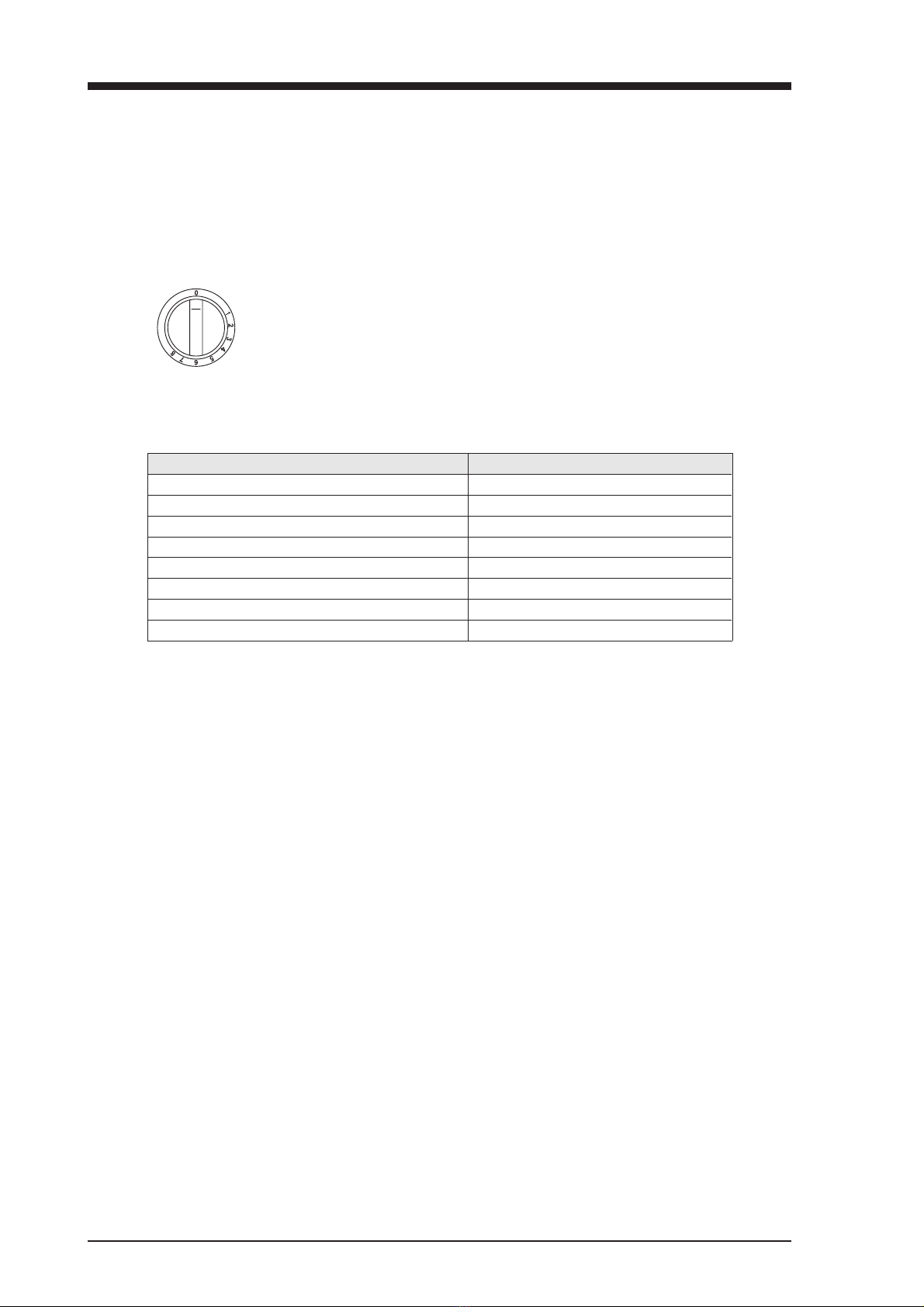

2. The individual functions ..............................................................................................................8

2.1 GH 505.0 E............................................................................................................................8

2.2 GH 505.0 E / GH 606.0 E......................................................................................................9

2.3 GKH 507.0 E .......................................................................................................................12

3. Appliance connection and first use 14

3.1 Gas connection ...................................................................................................................14

3.2 Operation at different setting ..............................................................................................14

3.3 First use ..............................................................................................................................14

3.4 Checking the heat load for LPG .........................................................................................15

3.5 Checking the supply lines ...................................................................................................15

3.6 Functional check ...............................................................................................................15

3.7 Installing the appliance .......................................................................................................15

4. General technical information ..................................................................................................16

5. Injector tables ..............................................................................................................................18

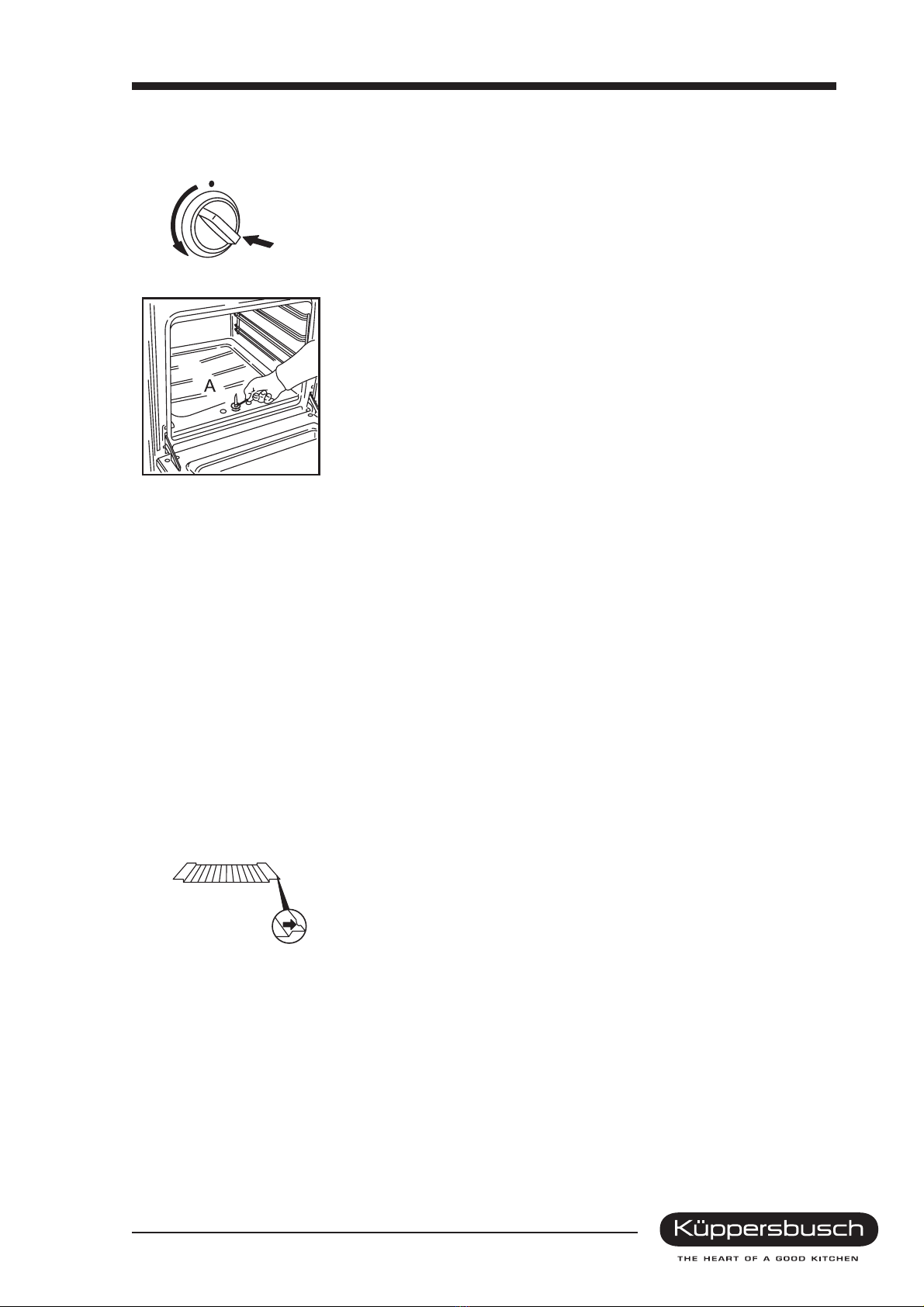

6. Changing and setting the burner injectors ............................................................................ 19

6.1 Cooking zone burners .........................................................................................................19

6.2 Regulating the primary air ..................................................................................................19

6.3 Adjusting the low-setting screws ........................................................................................20

6.4 Oven burner .......................................................................................................................20

6.5 Grill burner .........................................................................................................................23

7. Dismantling the housing parts...................................................................................................21

8. Dismantling the parts..................................................................................................................23

8.1 Oven door ..........................................................................................................................23

8.2 Oven internals ................................................................................................................23

8.3 Gas fittings...........................................................................................................................24

8.4 Electric spark ignition...........................................................................................................26

8.5 Electric oven ......................................................................................................................27

9. Wiring diagrams ..........................................................................................................................29

Technical manual GH 606.0 E/GH 506.0 E/GH 505.0 E/GKH 507.0 E 3

For internal use only