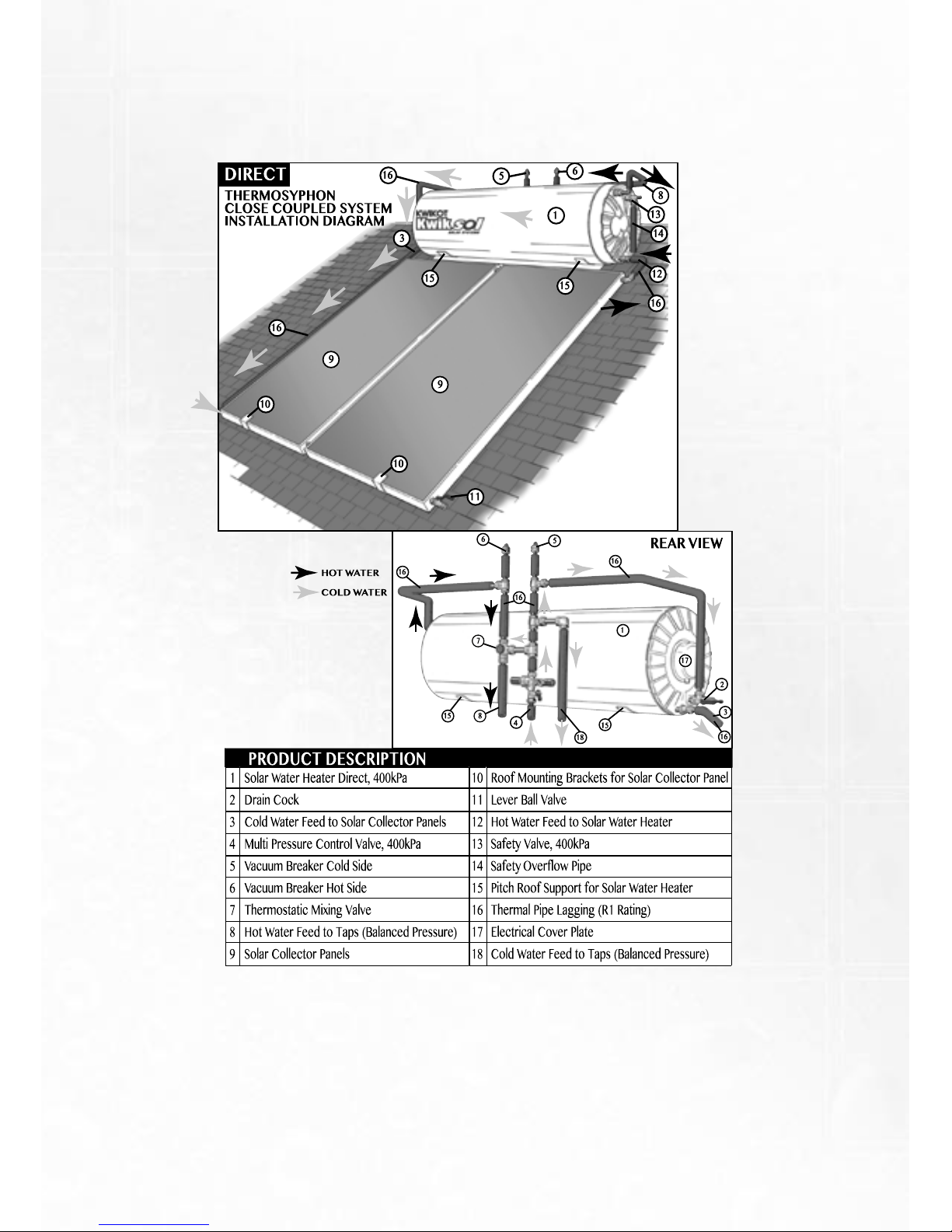

Kwiksol Instruction, Installation & Warranty Manual 7

G. FEATURES OF THE SOLAR VACUUM TUBES

• Consists of two glass tubes (inner

and outer) manufactured from

Borosilicate glass.

• The outer tube is transparent

allowing light rays to pass through it

with minimum reflection.

• The inner tube is coated with a solar

selective coating, which provides

excellent solar radiation absorption.

• The tops of the two tubes are fused

together and the air extracted,

which forms a vacuum.

• To maintain the vacuum between the two tubes a barium layer is used, which

provides a clear visual indication of the vacuum status. The silver coating will turn

white if the vacuum is lost.

• The tubes are installed onto a frame and the tops of the tubes inserted into a

manifold. Both are made from anodized aluminum.

H. ROOF LOCATION OF A SOLAR SYSTEM

1. Roof location and pitch

• For optimum performance the solar flat plate collector

panel/s or solar vacuum tubes with frame, need to face

the equator (facing north for Southern Hemisphere

installations). Installation on angles of up to 45

ໍ

away from

the equator do not have a major effect on the annual solar

output, consequently roof locations which face less than

45

°

away from the equator are acceptable. Solar radiance

from the sun begins at about 10.00 until 16.00 and at its

peak between 12.00 and 14.00.

• If the solar flat plate collector panel/s or solar vacuum tubes are installed with an

east facing bias, the best solar capture is achieved in the morning and if installed

with a west facing bias, in the afternoon.

• The installation location should not be subject to excessive shading from trees

and adjacent buildings and particularly between 9.00 and 15.00. Shadows are

longer in winter than in summer so a location that is free of shadows in summer

may have some shadows in winter.

• The solar flat plate collector panels or solar vacuum tubes should be installed

on a roof pitch greater than 8

ໍ

and less than 30

ໍ

. Where the roof pitch is greater

than 30

ໍ

, the installation will require additional support to prevent it from moving

downwards when installing and after installing. If the pitch is less than 8

ໍ

, the

installation will require a mounting frame to increase the pitch to above 8

ໍ

.

Installations below 8

ໍ

do not thermosyphon effectively and the solar flat plate

collector panel/s or vacuum tubes will not clean properly when it rains.

12 set 16 set 20 set

PERFECT

ORIENTATION

ZONE

GOOD

ORIENTATION

ZONE

GOOD

ORIENTATION

ZONE