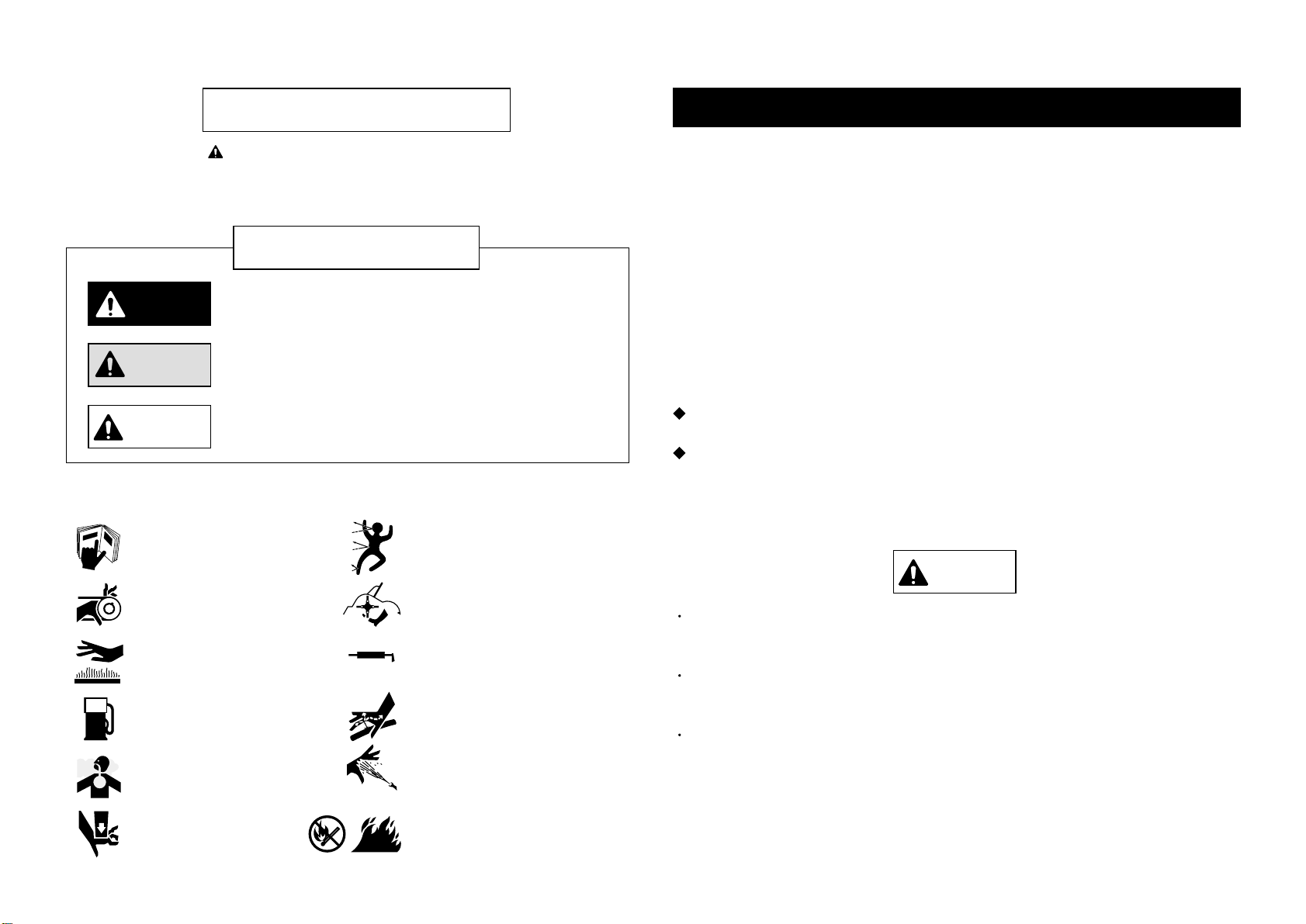

2. Safety operation

Blades rotate at high speed in the mowing machine under severe conditions such as vibration,

slope, and dust. Operation conditions are subject to the place of use, existence of obstacles,

condition of grass, etc. We sincerely desire that users should inspect and maintain the

machine completely, make efforts to master the machine operation skill, take measures for

safety, use the machine correctly so as not to do harm to others, and give top priority to safety

operation.

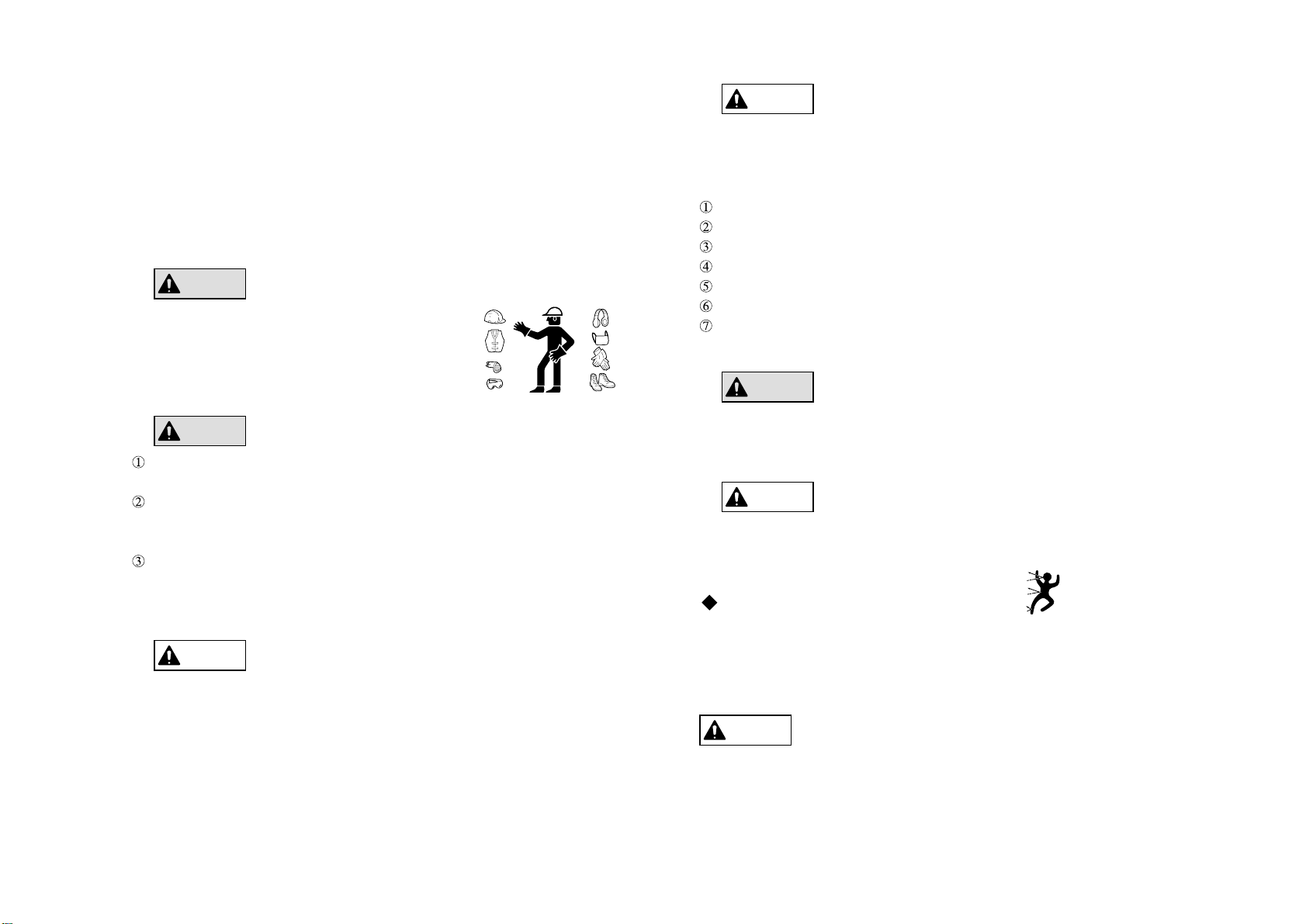

Wear proper clothes that will not be caught in the

machine, and wear protective gear, goggles, shoes,

helmet, and gloves. Provide a first aid kit and secure a

means of communication to deal with an emergency.

Clothes for safety

Avoid such operation

2-1

Do not use the machine when you are tired. When you feel tired while using the

machine, stop the work and take a rest.

Sick people, drunken people, and people under the influence of drugs are not

allowed to use the machine. The visual sense, nimbleness in action, and judgment

will be adversely affected.

When you are unfamiliar with machine operation, read the handling method and

safety precautions to understand them well before operating the machine. Do not

allow children to use the machine.

2-2

When lending the machine to others, an unexpected accident may occur because they

have no knowledge about the safety precautions and handling method shown in the

operation manual. Hand over the operation manual and tell them to read it carefully

before using the machine, explaining the handling method well.

When lending the machine to others2-3

Do not operate the machine with mown grass, dust, etc. accumulated in the cover or around

the engine or the transmission, otherwise fire or other trouble may result. Remove them

carefully. Improper maintenance and incorrect operation and dry grass mowing might

cause fire. Clean and check the machine as shown below before and during work.

Remove dry grass, dust, and other obstacles from around the muffler and engine.

Check the fuel hose for cracks due to deterioration.

Check for fuel leakage during fuel supply.

Fuel supply during engine operation is prohibited.

Check the wiring to prevent fire due to a short circuit.

Inspect the fuel tank and carburetor for fuel leakage due to operation on a slope.

Be sure to carry a fire extinguisher and water etc. when mowing dry grass.

Prohibition of nighttime traveling and work

The machine is not provided with any lighting equipment. Do not operate the machine at

nighttime or when the visibility is poor due to bad weather, etc.

2-5

Do not remodel the machine. Use genuine parts for maintenance to ensure safety.

Remodeling of the machine prohibited2-6

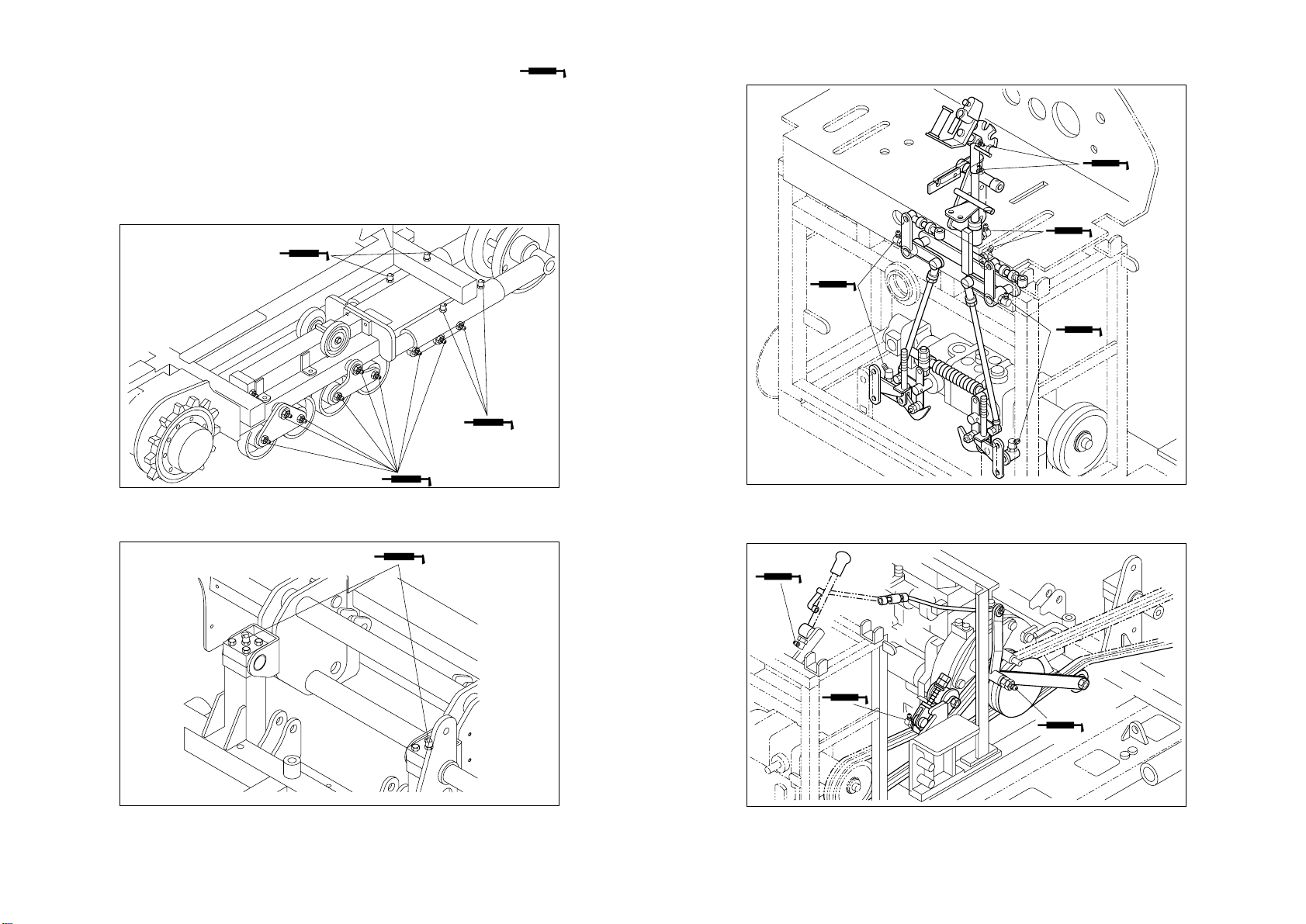

The antiscattering chain is used to prevent stones, etc. from scattering forward during

mowing, thereby preventing damage to human beings, buildings, vehicles, etc. Refer to "6.

Knife frame" in the parts catalog for the installation method.

Antiscattering chain

Fire prevention2-4

Observe the precautions in "1. Precautions as to use" and "2. Safety operation" and pay

sufficient attention to the area around the machine during operation.

- -5

CAUTION

WARNING

WARNING

CAUTION

CAUTION

WARNING

CAUTION