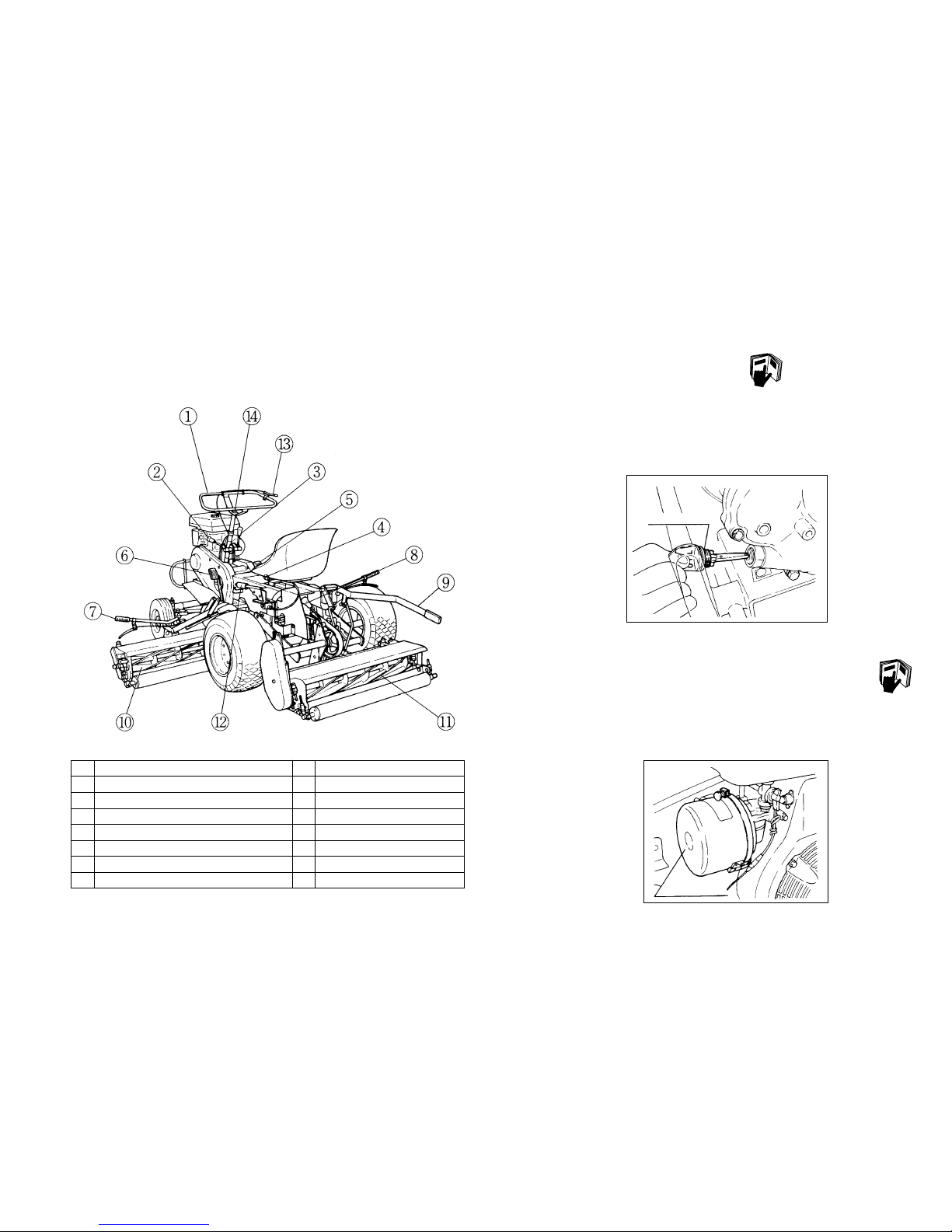

① Wearclothesthatfityourbody.

Wearprotectors(goggles,

safetyshoes,helmet,gloves,etc.)thatsuitthework.

② Learnhowtostoptheengineinanemergency.Whentheengineis

started,putthechangeleverintheneutralposition.

③ Belts,pulleys,rotatingshafts,etc.areverydangerous

whenexposed.Checkthatallthecoversareinstalledatspecifiedpositions.

④ Checkthatthebrake,steeringwheel,tiresarenormal.

⑤ Checkthatboltsandnutsarenotloose.Iftheyare,tightenthem.

1)Cautionswhenengineisstarted

① Checkthatthesidebrakeispulled.

② Keepawayfromchildrenandotherpersons,andoperatethemachinealone.

③ Starttheengineonlyfromthedriver'sseat.

④ Donotoperatetheengineinapoorly-ventilatedplace.

Theexhaustgascontainsnoxiouscarbonmonoxide.

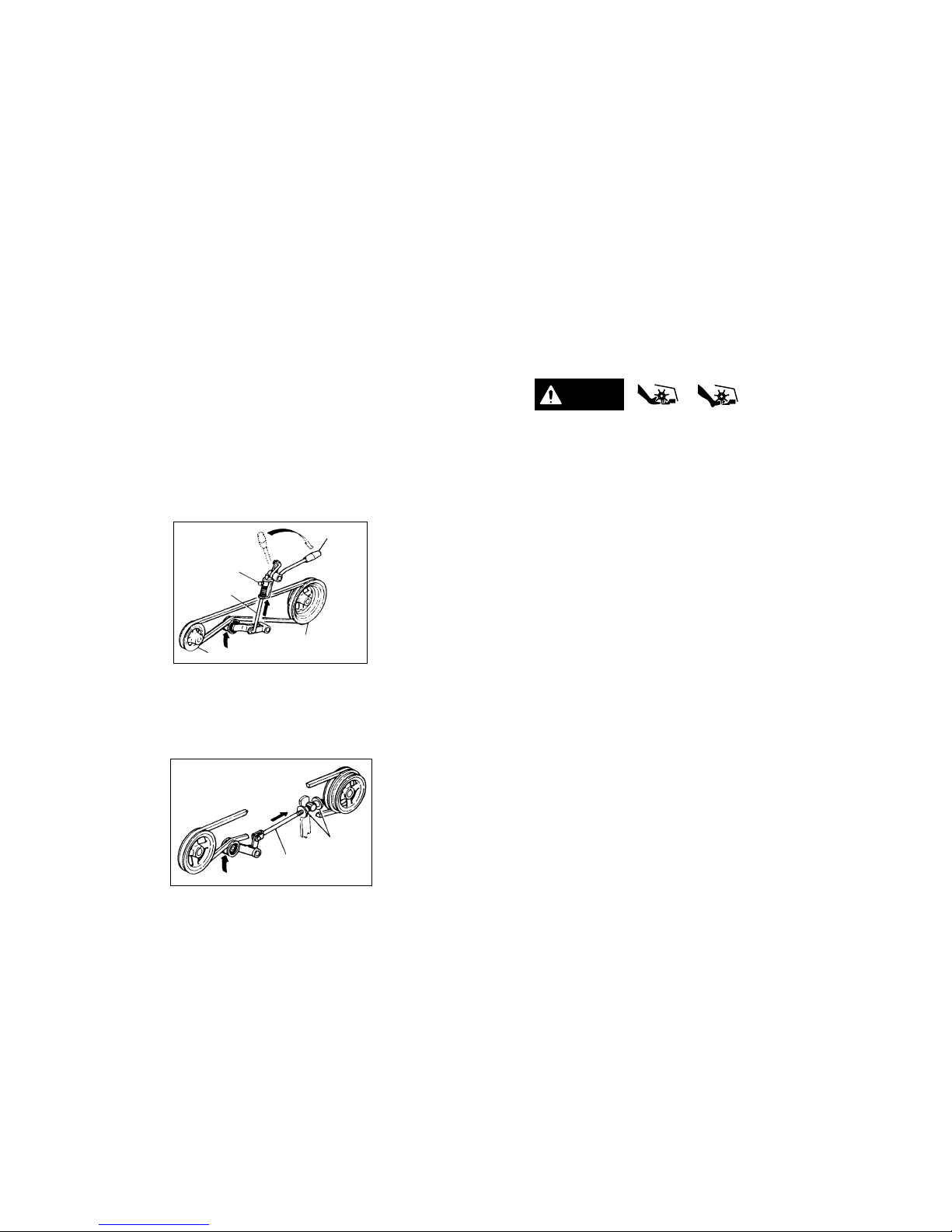

③ Donotputyourhandorfootneartheblade

reelcylinderswhentheyarerotating.

④ Thebladereelcylindersand

bottombladesareverysharp.Handlethemcarefully.

⑤ Fireisstrictlyprohibitedduringfuelsupply.Supplyfuel

outdoorsaftertheengineisstoppedandcooled.

⑥ Theengineisveryhotduringoperation.Donotputyour

handorcombustiblesnearthemufflerandengine.

⑦ Alwaysoperatethemachineataspeedthatallowsemergencystopping.Avoidsudden

startingorsuddenturning.Travelatlowspeedespeciallywhentravellingdownhill.

⑧ Donotoperateataplaceindangeroffallingorslipping.

⑨ Whenleavingthedriver'sseat,parkthemachineataflatplace,stop

theengine,andpullthesidebrake.

⑩ Ifanymachineabnormalitysuchasabnormalvibrationorabnormalnoiseisnoticed

duringoperation,immediatelystoptheengine,investigatethecauseandcompletely

repairbeforerestarting.

1.SafetyPrecautions

Beforeoperating,understandcorrectoperatingproceduresand

safetyprecautions.

1-1SafetyCheck

beforeWork

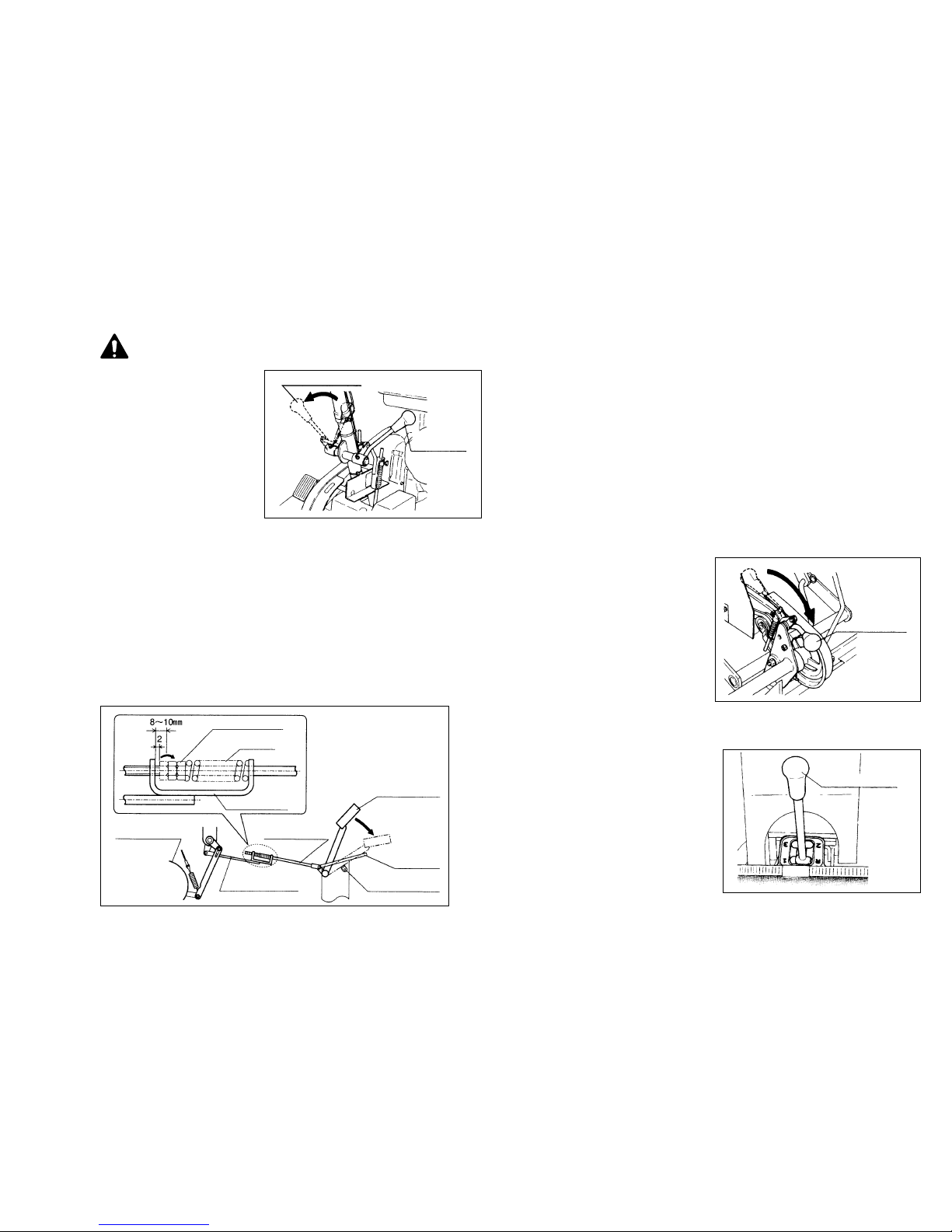

① Pullthetravelingleverslowlytopreventsuddenstarting.

② Becarefulnottodropthemowerwhenliftingit.

1-2SafetyCheckduringWork

① Foradjusting,repairingorcleaning,chooseaflatplaceandpulltheparkingbrake.

② Whendoinganyworkundertheraisedmowerportionormachine,useproper

supportstoholditup.

③ Keepthecautionmarksandexplanationscleanatalltimes.Iftheyarelostor

damaged,attachnewlabels.

④ Donotremodelthemachinewithoutpermission,otherwisemalfunctionor

dangerwillresult.

⑤ Donotstorethemachineindoorswiththefuelleftinthetank.

⑥ Cooltheenginebeforecoveringthemachinewithasheet,etc.

1-3SafetyCheckafterWork

DANGER

DANGER

DANGER

DANGER

WARNING

CAUTION

CAUTION

-3-