OPERATION, SERVICE

AND

ILLUSTRATED

PARTS

LIST

FOR

L-W

224A PROJECTOR.

Aperture

plate-----------------------------------~--------------

14

Bell

-

Drlve

6

Changing---------------------~--------------------

9

Br~~eAssy-----------------------------------------------------

10,11,15

Cam

-

Film

Transport--------------------------------------------

16

Circuit

Description----------------------------------------------

6

Claw

Magnet---------------------------------------------------

10,11,17

Clutch

-

Sprocket

Drive------------------------------------------

11,13,20

Dismantling

Projector--------------------------------------------

8 - 10

Frame

Counter--------------------------------------------------

14

General

Specifications-------------------------------------------

1

Lamps---------------------------------------------------------

4

Lubrication-----------------------------------------------------

21

Magnetic

Pick

-

up----------------------------------------------..;

11,17

Main

Shaft

Assy------------------------------------------

-------

10,11

Maintenance----------------------------------------------------

8

Mechanical

Operating

Principles-----------------------------------

5

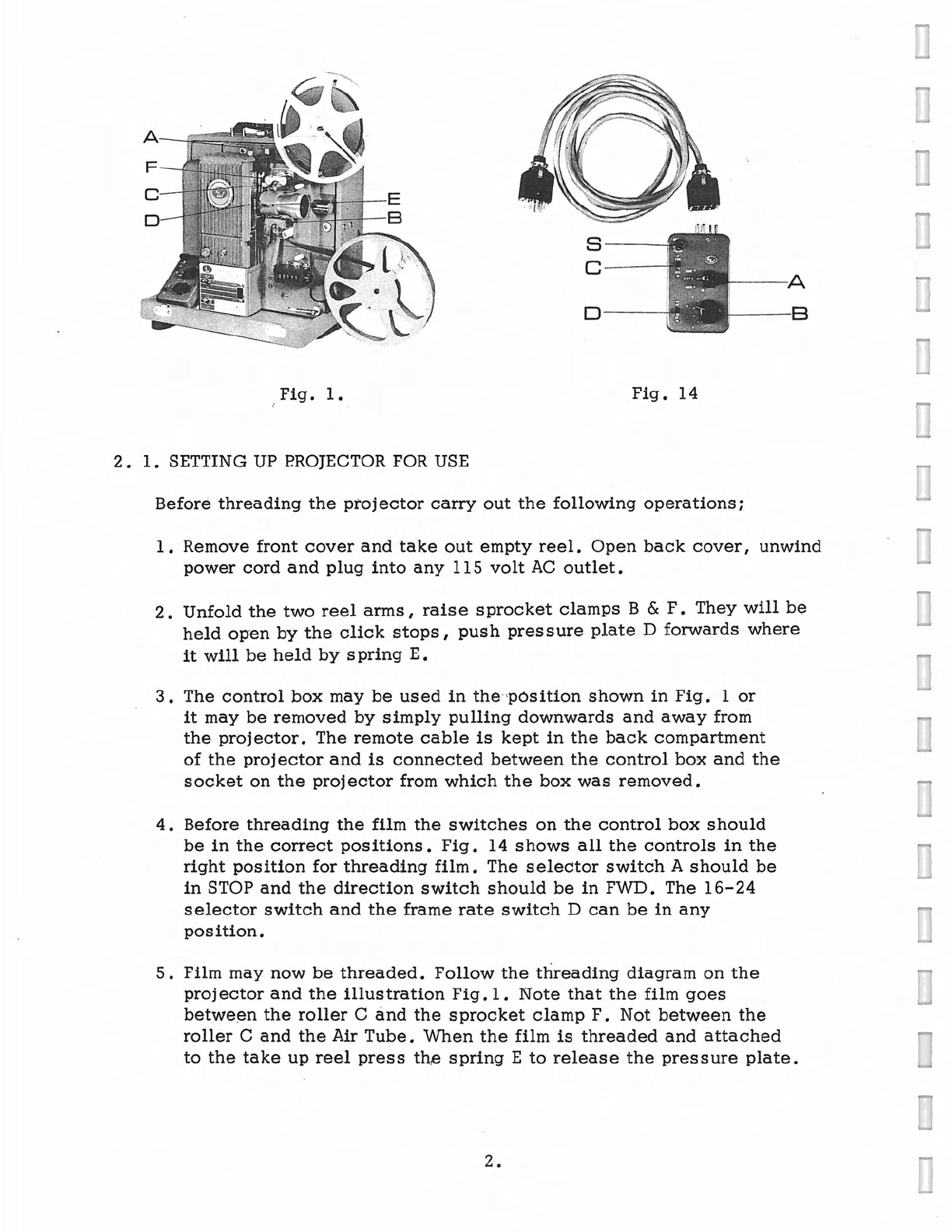

Operating

Instructions--------------------------------------------

2,3

Parts

Illustrations----------------------------------------------

25 -

on

PowerPanel---------------------------------------------------

8,18,19

Rear

Cam

-

timing----------------------------------------------

13

download from : www.olafs-16mm-kino.de