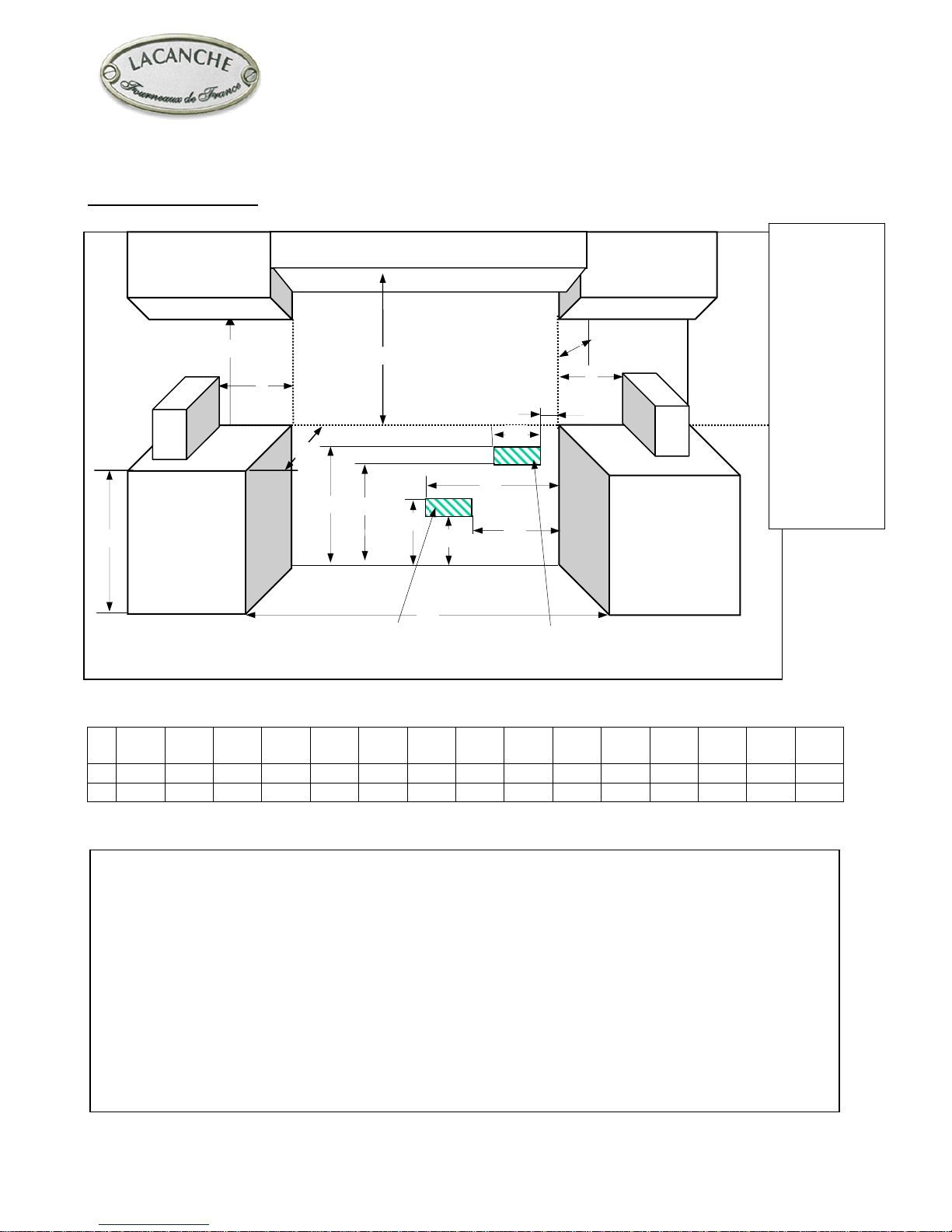

TECHNICAL DATA

CORMATIN

Page 3 of 40

Static electric oven (option) :

Same dimensions as gas oven.

Thermostatically controlled roof and base heating elements, safety cut-out by safety thermostat.

Rating : 3400 W – Power supply : 240 Volts 60Hz.

Ventilated electric oven (option)

Heating provided by two circular heating elements each surrounding a reaction-type fan. Dimensions W x H x D : 530 mm

(20.8’’) x 305 mm (12’’) x 405 mm (15.9’’). This can optionally be fitted with an electric.

Thermostatically controlled heating elements, safety cut-out by safety thermostat.

Rating : 3700 W – Power supply : 240 Volts 60Hz.

Accessories

One drip tray, one shelf, one pastry tray per oven.

Shipment-Packaging

Unpack and check the appliance is in good condition. In case damage, note any reservations on the delivery note and confirm

them within 48 hours by registered letter with confirmation of delivery to the carrier.

Appliance Width Depth Height mm Weight Gross/Net

LG 731 G 850 mm / 33.4’’ 840 mm / 33.1’’ 1070 mm / 42.1’’ 105 kg / 89 kg – 233 / 197 lb

Gas connection :

1/2” ID NPT (Sch 40) inlet, on male coupling (Figures 1, 2 and 3). Sealant on all pipe joints must be resistive to LP gas.

If used, a flex gas line for the gas supply must be metal of at least 1/2” ID NPT approved by an approved certifying agency

(A.G.A., C.G.A,. etc.) in compliance with ANSI Z21.41 and Z21.69. Never use a hose made of rubber or other synthetic

material.

Gas supplying :

Appliance gas supplying can be switched, please refer to rating plate and marking at the rear of the appliance.

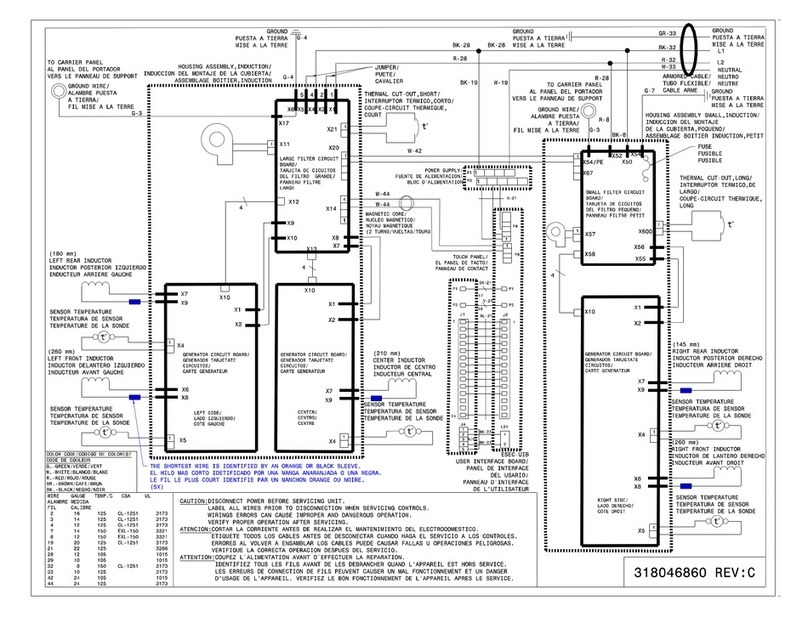

Electrical connection :

On terminal block at the rear of the appliance. Use flexible cord in accordance with standard N.E.C., AINSI/NEMA 70-1996

or latest edition (not cord provided) (Figures 1 & 3).

Pressures and hourly consumption :

Appliance gas supplying can be switched (table 1).

Table 1

PRESSURE 6’’ WC 10’’ WC

GAS Natural Gas L.P. Propane

Burner Btu / hr Btu / hr

Oven 13,000 13,000

Ultra fast (UF) Tradition (T) 18,000 17,000

Intensive (I) 13,000 13,000

Fast (F) 10,500 10,000

Semi fast (SF) 5,000 5,000