Installation, Operating & Maintenance Instructions

W1512 FMOD Moderne Range ood O&M Dec 16.docx

Page 2 Fornair

• A route with more than two 90° bends will significantly

degrade the performance of the extraction system. If

possible, avoid having a 90° bend at the extractor exhaust

spigot; keep bend radii as large as possible to maintain a

smooth airflow without vortices; avoid kinks in flexible

ducting; pull flexible ducting taut over straight runs to

ensure that the internal surface is as smooth as possible.

• Duct runs in excess of 5 metres are not recommended and

will seriously impair efficiency - if you are concerned then

please call for advice.

• The hood can be vented either to the top exhaust or the

rear exhaust position. Use the position which gives the

shortest duct route length and least number of bends. (The

blower will need to be rotated for ducting directly through

the rear exhaust position.)

4. INSTALLATION

Do not throw away the box and any internal packaging

until installation is ully completed - the packaging may be

required in the unlikely event that hood must be returned.

4.1. Remove the Grease Filters

Place extractor on its back plate on a horizontal surface.

To remove the grease filters pull/lift the filter release lever

away from the hood base. This releases the retaining clips

allowing the filter to be carefully lifted away from the hood.

Take care not to scratch the hood.

The internal fixing holes, blower assembly and/or spigot

blanking plate can now be accessed through the opening in

the baseplate.

4.2. Exhaust Position

The hood can be vented either to the top exhaust or the rear

exhaust position. Each exhaust position has 4 fixing points

onto which can be attached either the blower/spigot assembly

or a blanking plate.

Position the blower/spigot assembly in the chosen exhaust

position and the blanking plate in the unused position, using

the original fixings and washers supplied.

When changing the exhaust position, care should be taken not

to excessively pull or twist the cable attached to the blower.

4.3. Duct Installation

Make holes, as necessary, in the walls or ceiling to take the

ducting from the exhaust spigot location to the outside. *

Note: A 175mm diameter hole is suitable for both ducting and

any electrical cables (such as power or remote motor cables)

to pass through.

The duct route length should be kept as short as possible with

as few bends as possible (see Section 3).

If terminating on an outside wall a suitable weather louvre

should be fitted - an airbrick must never be used.

*I you have purchased a bespoke model with two exhaust

spigots itted then two individual 150mm ducts should be

run.

• Recirculating Models

We do not recommend recirculating air installations and they

should be avoided wherever possible (see section 3).

If your extractor has been adapted for recirculation (not our

standard configuration) then adequate provision must be

made for the exhausted air to return into the kitchen

(equivalent to 150mm round duct) - e.g. Purchase of a special

chimney with vents, ducting to a vent in the room, or finishing

the chimney short of the ceiling. Failure to do so may cause

the unit to overheat and fail and will invalidate your warranty.

4.4. Remote Motors

If your extractor has been purchased to operate with a

standard inline or external remote motor (SEM) then you will

find a black plastic box outside the extractor (on flying leads)

containing electrical terminals for connection to the remote

motor cable assembly. This box is referred to as the remote

motor terminal box.

Each terminal inside the remote motor terminal box has one

side connected to a coloured wire, which leads back to the

hood control system. The remote motor cable assembly also

has coloured wires and these are connected to the empty

terminals such corresponding colours are opposite and

connect to each other; i.e. red connects to red, blue to blue,

and so on...

Not all terminals will be used because each remote motor type

is configured differently.

An electrician or Part P registered electrical installer should

undertake any work associated with the electrical installation

of SEM remote motors.

Please refer to Section 9, Remote Motor Wiring

Illustrations, for more information.

If you need to extend the remote motor cable then additional

cable can be purchased. Alternatively, it may be extended

using 7 core x 0.5mm flex. It is vital to ensure that any new

cable is inserted such that the core colour integrity is

maintained; i.e. a core that started as red must terminate as

red, blue as blue, purple as purple, and so on.

Any remote motor should be installed in accordance with the

installation instructions that accompany it. It must be installed

in an easily accessible location for future maintenance. We

are not responsible for providing the means of access (e.g.

scaffolding or any alterations to the building and/or furniture

necessary to make access possible) in the event of any

maintenance requirement.

No separate power supply is required for S M remote

motors.

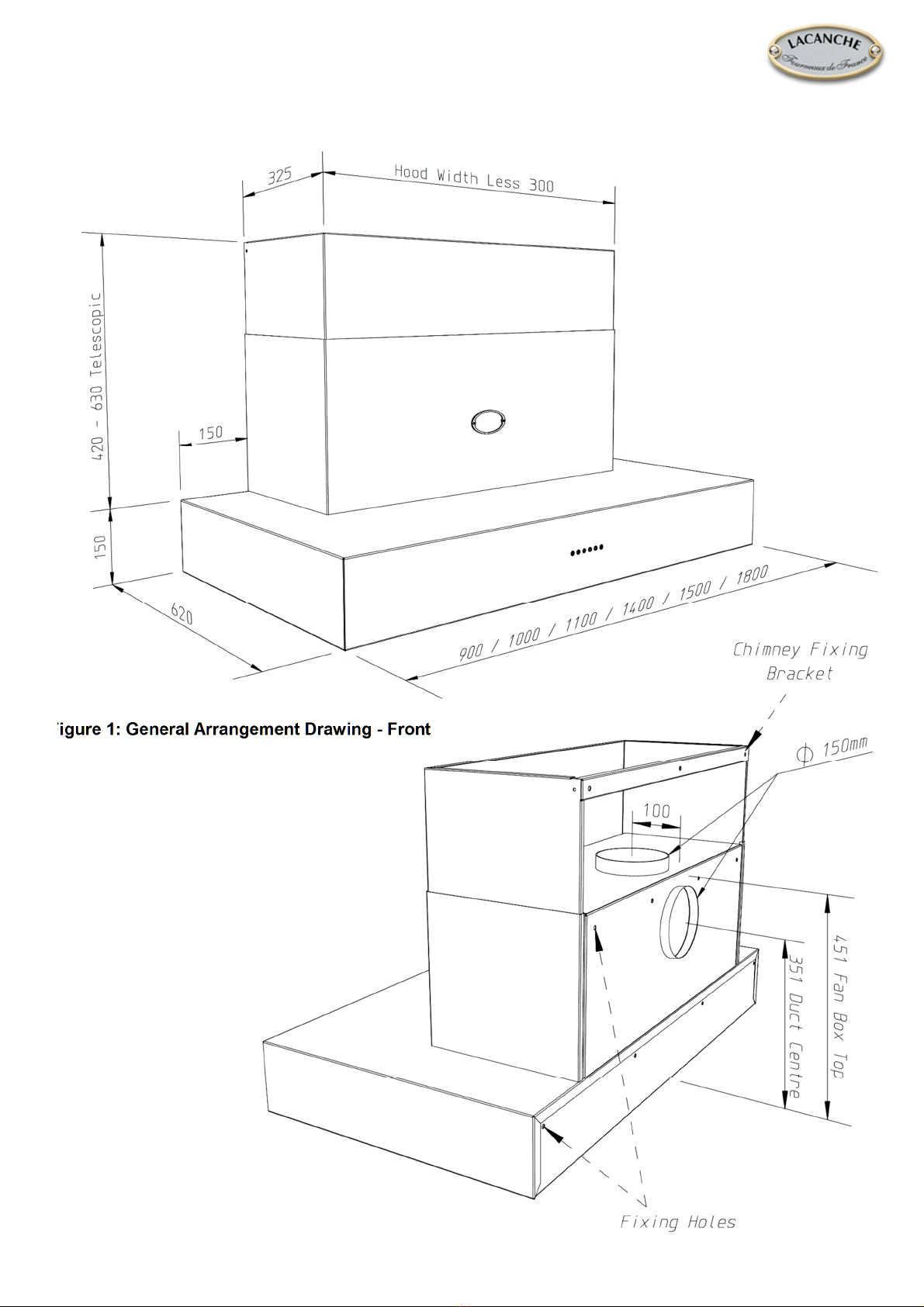

4.5. Fixing the Hood to the Wall

If you are fitting a splashback it is usually best to install it

before the hood.

Important:

• Line drawings re erenced in this section can be ound

in Section 8: General Arrangement Drawings.

• The chimney can be removed to ease handling of the hood

and to provide access to the top outlet duct spigot.

• The supporting wall must be of good quality, have an even

surface and be sturdy enough to support the extractor.

• Fixings must be used which are suitable for the type of wall

construction.

• Fixing the hood to the wall requires a minimum o 2

people.

• No wall fixings are provided.