3 Installation Manual 2014 - Riv 2

Contents

General Information..............................................................................................5

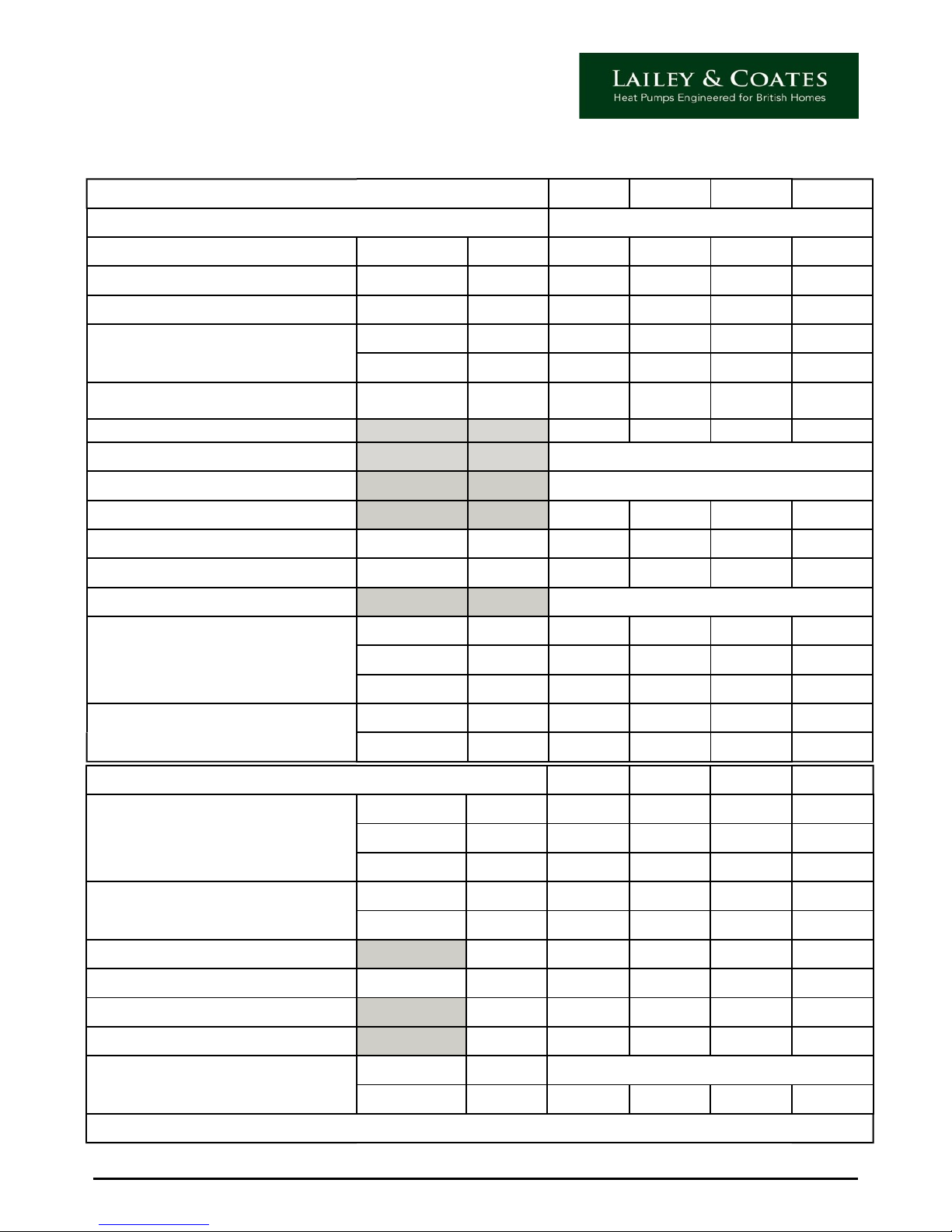

Technical Specification ..........................................................................................6

Installation of External Unit...................................................................................7

Installation of Internal Unit...................................................................................8

Wiring Instructions................................................................................................9

Rated power input and fuse information............................................................10

Indoor Electrical Connections..............................................................................11

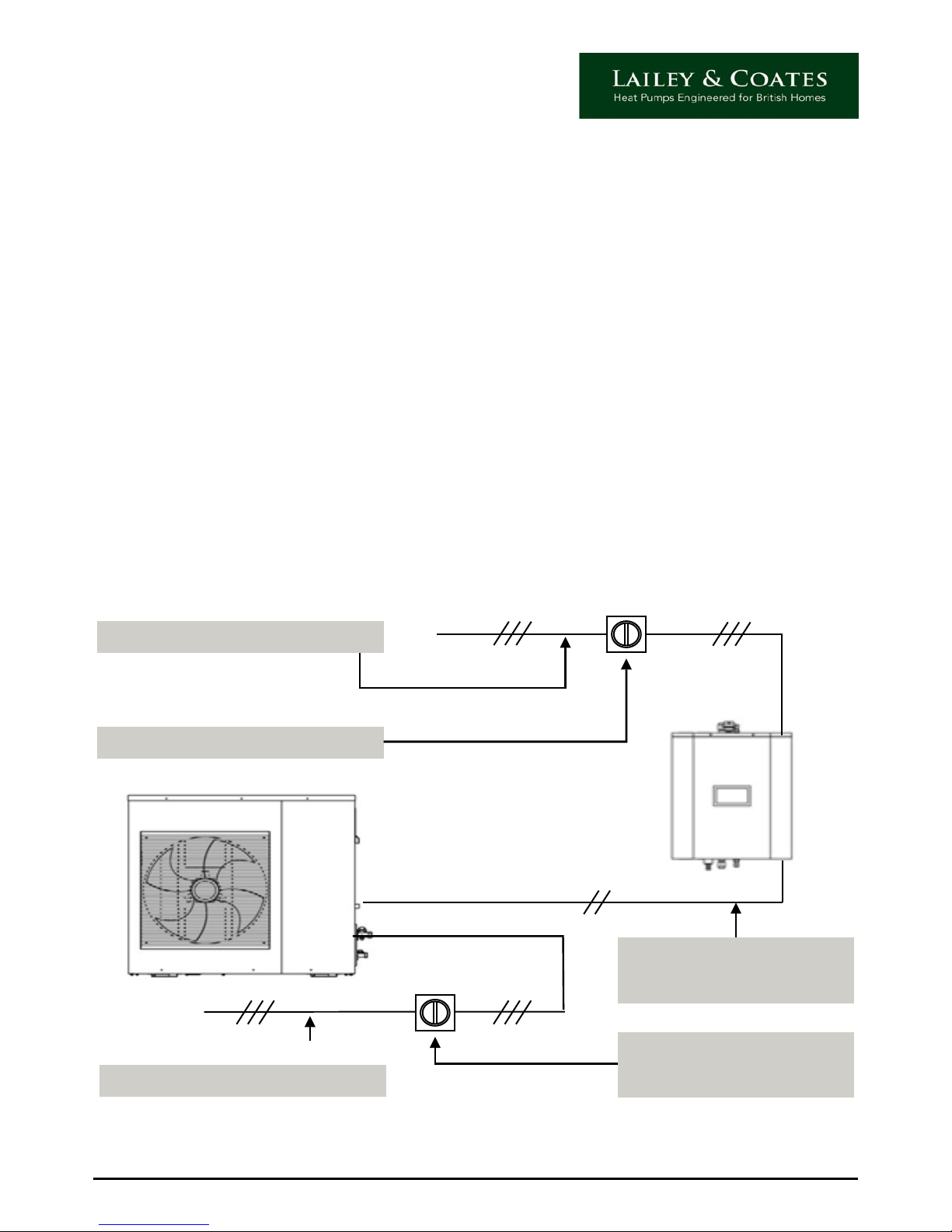

Plumbing Installation...........................................................................................12

Refrigeration Installation.....................................................................................14

Dip Switch Settings..............................................................................................16

Pre-Operation Checklist.......................................................................................17

Commissioning ..................................................................................................18

LCD controller......................................................................................................19

How to set up LCD controller...............................................................................20

Setting the Hot Water Temperature....................................................................21

Setting the Heating Water Temperature..............................................................22

Setting the Heat Pump Timer..............................................................................23

Holiday Timer......................................................................................................26

Simple Trouble Shooting Guide.........................................................................27

Access to change system parameters..................................................................27

Fault / Error Codes...............................................................................................30

Commissioning Sheet..........................................................................................34