Landustrie versie 01-21 | Operation & maintenance manual DCP22

Subject to modifications

Checkpoint first pump start:

Before installing and start operating the pump following checkpoints are involved:

Check on delivery

Remove the pump from the packing and check for transport damage, such as material

errors, cracks of bended cable.

Check for completeness of the delivery.

If the delivery is incomplete, or damaged, please contact your supplier immediately.

Check oil level

Verify the oil level in the seal housing (according to procedures on page 12)

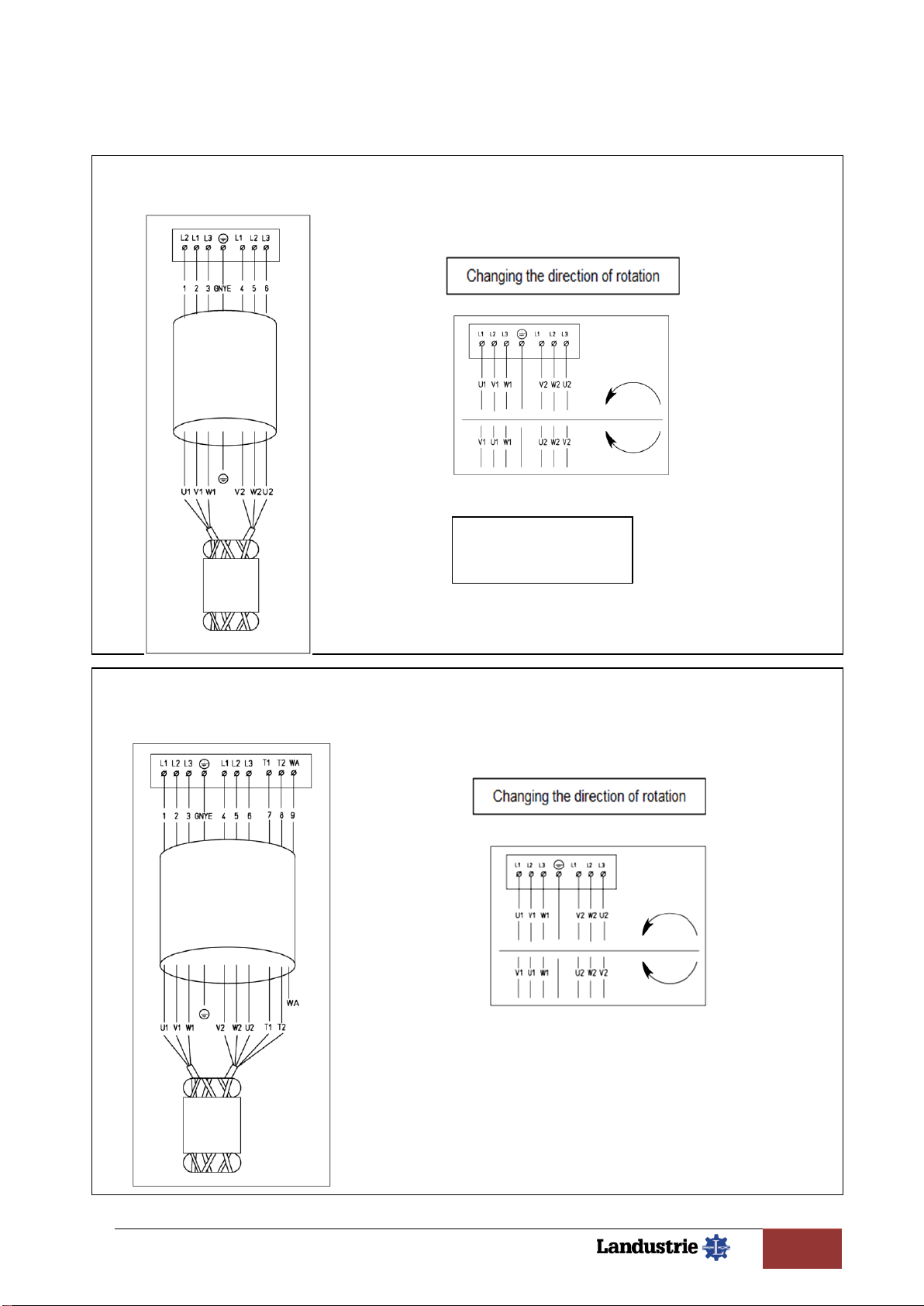

Check Power supply.

Verify if voltage, frequency and starting method are according to the data as specified on

the pump data plate.

Connect the pump according to the wiring diagram of the electrical cabinet.

Information about the pump cable codes can be find on page 8, 9 or 10.

Thermal protection (klixons)

Check the pump for the presence of thermal protection, the connection values for the

standard thermal protection are max. 250V-1.6A. In ‘cold’ condition the switch is closed.

Thermistors (PTC), if thermistors are supplied: Resistance cold: 200-500 Ohm

Resistance at switching temperature: 1650-4000 Ohm.

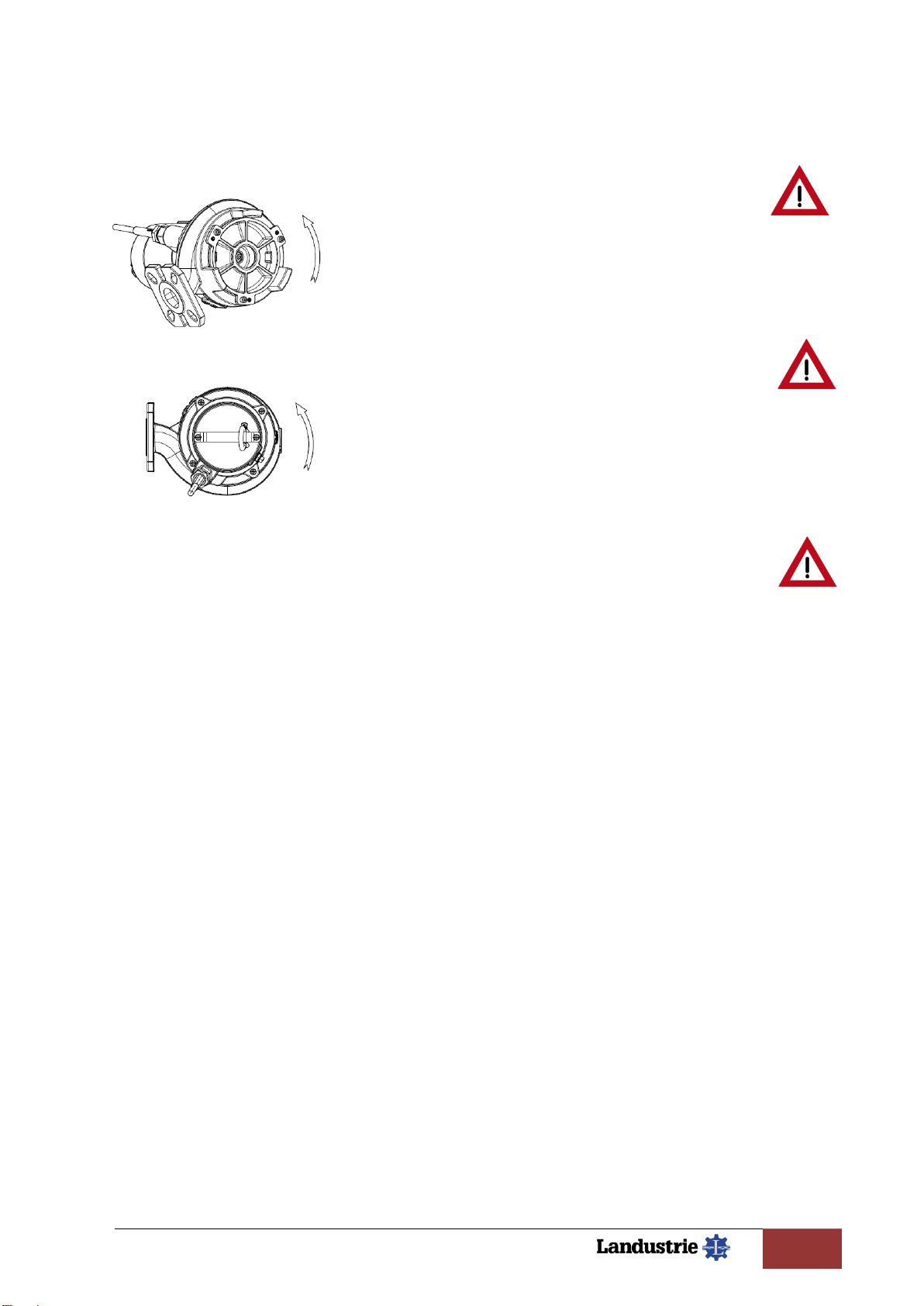

Cable entry

Especially when the pump has been stored for a long time. Turn the cable entry, if

necessary to tighten the rubber gland of the cable entry.

Motor protection

Verify the presence of the motor protection circuit breaker.

At direct start (DOL) the motor circuit breaker should be set at the current value given on

the data plate of the pump.

At star delta start (YD) the setting of the motor circuit breaker should be 0.6 of the current

value on the data plate of the pump.

Maintenance:

Before taking out the pump from the installation, please switch of the mains, according to the

instructions on page 4.

Clean the pump adequately!

Take care! The surface of the pump can be hot, especially when is just switched off.

Maintenance schedule:

After the first 100 operating hours; Check the condition of the oil.

If too much water is mixed with the oil, please contact your supplier.

Every 1000 operating hours or each year; - Check both the condition of the oil and the oil

level. If too much water is included, please contact your supplier.

Change the oil if not transparent.

Lubricants:

The bearings of the pump are greased for life.

Standard oil type for the mechanical seals: Shell Tellus 32, viscosity 32 cSt.