3

Contents

FOREWORD ...........................................................................................................2

CONTENTS.............................................................................................................3

PRODUCT IDENTIFICATION...........................................................................7

WORK SAFETY INSTRUCTIONS.....................................................................8

UTILISATION .........................................................................................................8

NOT ALLOWED USE ..............................................................................................8

GENERALLY..........................................................................................................9

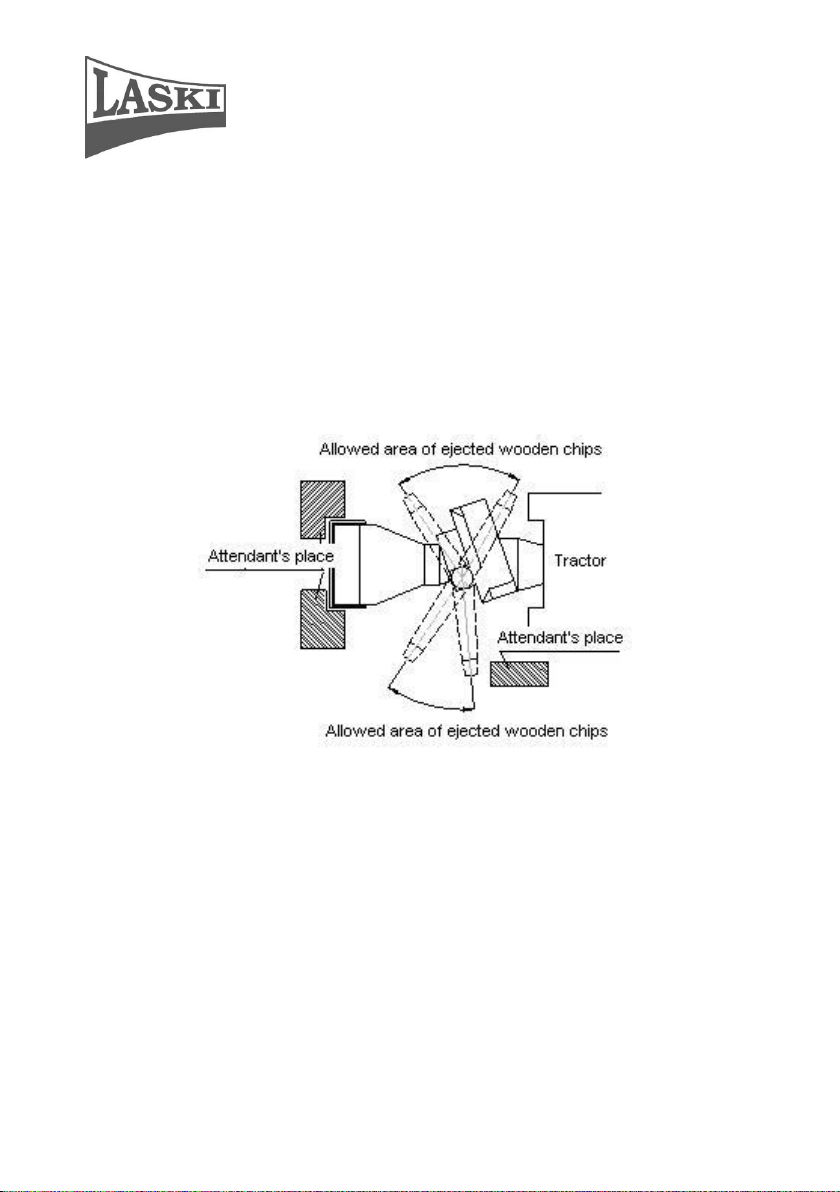

MOTOR VEHICLE CONSTRUCTION AND USE REGULATIONS ................................15

WORK SAFETY SYMBOLS....................................................................................17

RESIDUAL RISKS .................................................................................18

TRANSPORT OF PRODUCT/HANDLING .................................................................20

PRECAUTIONS IN DESIGN ....................................................................................20

CONTROLS ..........................................................................................................23

USE........................................................................................................................25

STORAGE.............................................................................................................25

BEFORE PUTTING INTO OPERATION ....................................................................25

COUPLING TO TRACTORS ....................................................................................26

CARDAN SHAFT ADJUSTMENT ............................................................................28

PUTTING INTO OPERATION..................................................................................29

CHIPPING ............................................................................................................31

PUTTING OUT OF OPERATION ..............................................................................34

EMERGENCY SITUATIONS ...................................................................................34

TECHNICAL DESCRIPTION...........................................................................35

Chipping Device.............................................................................................35

Frame.............................................................................................................36

Technical Parameters.....................................................................................37

MAINTENANCE .................................................................................................37

Lubrication.....................................................................................................38

Blade Grinding...............................................................................................39

Chipping Adjustment......................................................................................40

NOSTRESS System –Speed Regulation .........................................................41

........................................................................................................................41