NOTICE TO: OWNERS, OPERATORS AND DEALERS

IMPROPER INSTALLATION AND INADEQUATE MAINTENANCE, POOR HOUSEKEEPING AND WILLFUL NEGLECT OR

BYPASSING OF SAFETY DEVICES MAY RESULT IN SERIOUS ACCIDENTS OR INJURY. TO ASSURE THE SAFETY

OF CUSTOMERS AND/OR OPERATORS OF YOUR MACHINE, THE FOLLOWING MAINTENANCE CHECKS MUST BE

PERFORMED ON A DAILY BASIS.

NOTICE À L’ATTENTION DES PROPRIÉTAIRES, UTILISATEURS ET REVENDEURS

UNE INSTALLATION INCORRECTE ET UN ENTRETIEN INADÉQUAT, DE MÊME QUE LA NÉGLIGENCE OU LA

NEUTRALISATION DÉLIBÉRÉES DES DISPOSITIFS DE SÉCURITÉ, PEUVENT ÊTRE CAUSES DE BLESSURES OU

D’ACCIDENTS SÉRIEUX. POUR ASSURER LA SÉCURITÉ DES CLIENTS ET/OU DES UTILISATEURS DE VOTRE

MACHINE, IL EST INDISPENSABLE DE PROCÉDER CHAQUE JOUR AUX CONTRÔLES DE ROUTINE CI-APRÈS.

1. Prior to operation of the machine, check to make certain that all operating instructions and warning signs

of the signs.) Missing or illegible ones must be replaced immediately. Be sure you have spare signs and

labels available at all times. These can be obtained from your distributor or from Laundrylux.

2. Check the door safety interlock, as follows:

(a) RAISE THE LID of the machine and attempt to start in the normal manner:

For coin-operated models, insert the proper coins to start the machine.

For card-operated models, insert the card to start the machine.

THE MACHINE MUST NOT START

(b) CLOSE THE LID, start the machine operation and, while it is operating, open the lid.

THE MACHINE MUST COME TO A COMPLETE STOP

If the machine can start with the lid raised, or can continue to operate with the lid raised,

the door interlock is no longer operating properly. The machine must be placed out of order until this

condition is corrected.

3. DO NOT UNDER ANY CIRCUMSTANCES ATTEMPT TO BYPASS OR REWIRE ANY OF THE MACHINE

SAFETY DEVICES AS THIS CAN RESULT IN SERIOUS ACCIDENTS.

4. Be sure to keep the machine(s) in proper working order. Follow all maintenance and safety procedures.

Further information regarding machine safety, service and parts can be obtained from your dealer or from

Laundrylux through its Technical Support Hotline - (516) 371-0700.

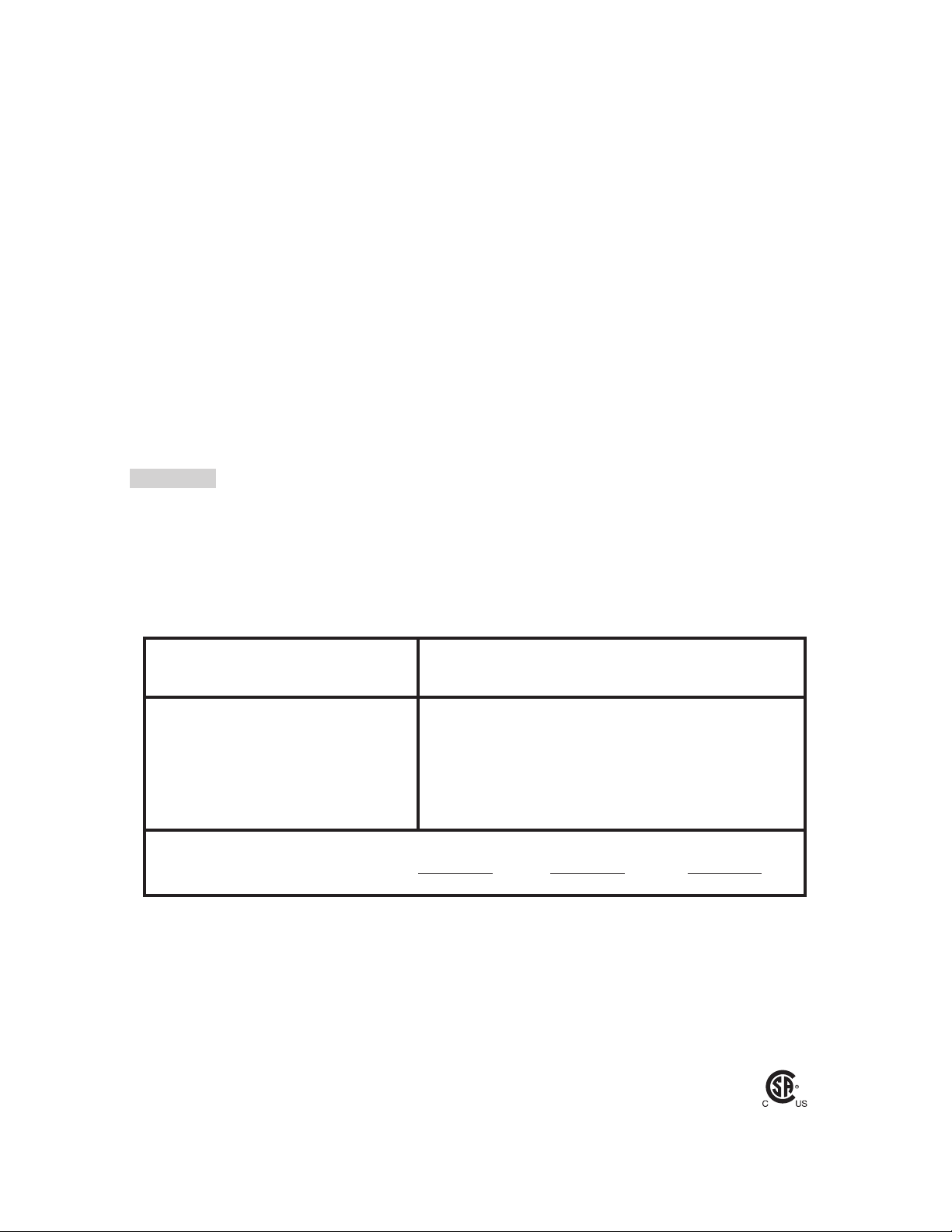

All requests for assistance must include the model, serial number and electrical characteristics as

previous page of this manual.

5. WARNING: DO NOT OPERATE MACHINE(S) WITH SAFETY DEVICES BYPASSED, REWIRED OR

INOPERATIVE! DO NOT OPEN MACHINE DOOR UNTIL DRUM HAS STOPPED ROTATING!

AVERTISSEMENT: NE PAS FAIRE FONCTIONNER LA (LES) MACHINE(S) AVEC UN DISPOSITIF

DE SÉCURITÉ NEUTRALISÉ, RECÂBLÉ OU NON OPÉRATIONNEL! NE PAS OUVRIR LA

MACHINE TANT QUE LE TAMBOUR NE S’EST PAS IMMOBILISÉ!