Lawn-Boy 522R User manual

Operator’s Manual

Pour

obtenir gratuitement une version en français de ce manuel, écrivez à l’adresse

ci-dessous. N’oubliez pas d’indiquer les numéros de modèle et de série de votre produit.

Lawn-Boy Inc., Attn.: Parts Dept., 81

1

1 L

yndale A

ve S, Bloomington, MN 55420–1

196.

English (EN)

FORM NO. 3323-205 Rev A

522R

Snowthrower

Model No. 28230—200000001 and Up

Lawn Boy, Inc. - 1999

All Rights Reserved Printed in USA

2

Contents

Page

Introduction 2.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Safety 3

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General Snowthrower Safety

3

. . . . . . . . . . . . . . . . .

Lawn-Boy Snowthrower Safety

4

. . . . . . . . . . . . . . .

Safety Decals and Instructions

5

. . . . . . . . . . . . . . . .

Loose Parts

6

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Accessories 7

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Assembly 7

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Install Handle

7

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Install Speed Selector Rod

8

. . . . . . . . . . . . . . . . . . .

Install T

raction Rod

8

. . . . . . . . . . . . . . . . . . . . . . . .

Install Auger Drive Control Linkage

8

. . . . . . . . . . .

Install Chute Control Rod

9

. . . . . . . . . . . . . . . . . . .

Secure Chute Deflector

9

. . . . . . . . . . . . . . . . . . . . .

Check T

ire Pressure

10

. . . . . . . . . . . . . . . . . . . . . . . .

Before Starting

10

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fill Crankcase W

ith Oil

10

. . . . . . . . . . . . . . . . . . . . .

Fill Fuel T

ank With Gasoline

11

. . . . . . . . . . . . . . . . .

Operation 11

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Controls 11

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Starting/Stopping Engine

12

. . . . . . . . . . . . . . . . . . . .

Operating T

ips 13

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Adjusting Skids And Scraper Blade

13

. . . . . . . . . . . .

Maintenance 14

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Draining Gasoline

14

. . . . . . . . . . . . . . . . . . . . . . . . .

Lubricating Snowthrower

15

. . . . . . . . . . . . . . . . . . .

Changing Crankcase Oil

15

. . . . . . . . . . . . . . . . . . . .

Auger Gear Box Grease

16

. . . . . . . . . . . . . . . . . . . . .

Adjusting Auger/Impeller Drive Belt

16

. . . . . . . . . .

Replacing Auger/Impeller Drive Belt

16

. . . . . . . . . .

Replacing T

raction Drive Belt

17

. . . . . . . . . . . . . . . .

Adjusting T

raction Drive

18

. . . . . . . . . . . . . . . . . . . .

Adjusting Speed Selector

18

. . . . . . . . . . . . . . . . . . . .

Replacing Spark Plug

18

. . . . . . . . . . . . . . . . . . . . . . .

Storage 19

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Warranty 20

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

WARNING

The engine exhaust fr

om this pr

oduct contains

chemicals known to the State of California to

cause cancer

, birth defects, or other r

eproductive

harm.

Introduction

Thank you for purchasing a Lawn-Boy product.

All of us at Lawn-Boy want you to be completely satisfied

with your new product, so feel free to contact your local

Authorized Service Dealer for help with service, genuine

Lawn-Boy parts, or other information you may require.

Whenever you contact your Authorized Service Dealer or

the factory

, always know the model and serial numbers of

your product. These numbers will help the Service Dealer

or Service Representative provide exact information about

your specific product. Y

ou will find the model and serial

number decal located in a unique place on the product

(Fig. 1).

m–2592

1

Figure 1

1. Model

and serial number decal

For

your convenience, write the product model and serial

numbers in the space below

.

Model No:

Serial No.

Read

this manual carefully to learn how to operate and

maintain your product correctly

. Reading this manual will

help you and others avoid personal injury and damage to

the product. Although Lawn-Boy designs, produces and

markets safe, state-of-the-art products, you are responsible

for using the product properly and safely

. Y

ou are also

responsible for training persons who you allow to use the

product about safe operation.

The Lawn-Boy warning system in this manual identifies

potential hazards and has special safety messages that help

you and others avoid personal injury

, even death.

DANGER, W

ARNING and CAUTION are signal words

used to identify the level of hazard. However

, regardless

of the hazard, be extremely careful.

DANGER

signals an extreme hazard that will cause

serious injury or death if the recommended precautions

are not followed.

WARNING

signals a hazard that may cause serious injury

or death if the recommended precautions are not followed.

3

CAUTION

signals a hazard that may cause minor or

moderate injury if the recommended precautions are not

followed.

T

wo other words are also used to highlight information.

“Important” calls attention to special mechanical

information and “Note” emphasizes general information

worthy of special attention.

The left and right side of the machine is determined by

standing behind the handle in the normal operator

’s

position.

Safety

T

o ensur

e maximum safety

, best performance, and to

gain knowledge of the pr

oduct, it is essential that you

and any other operator of the snowthr

ower r

ead and

understand the contents of this manual befor

e the

motor is ever started. Pay particular attention to the

safety alert symbol

which means CAUTION,

W

ARNING OR DANGER — “personal safety

instruction.” Read and understand the instruction

because it has to do with safety

. Failur

e to comply with

instruction may r

esult in personal injury

.

The snowthrower is designed and tested to of

fer

reasonably safe service; however

,

failur

e to comply with

the following instructions may r

esult in personal

injury.

General

Snowthrower Safety

The

following instructions have been adapted from the

ANSI/OPEI standard B71.3—1995 and ISO standard

8437:1989. Information or terminology specific to

Lawn-Boy snowthrowers is enclosed in parenthesis.

Training

•

Read the operator

’

s manual carefully

. Be thoroughly

familiar with the controls and the proper use of the

equipment. Know how to stop the unit and disengage

the controls quickly

.

•

Never allow children to operate the equipment. Never

allow adults to operate the equipment without proper

instruction.

•

Keep the area of operation clear of all persons,

particularly small children and pets.

•

Exercise caution to avoid slipping or falling, especially

when operating in reverse.

Preparation

•

Thoroughly inspect the area where the equipment is to

be used and remove all doormats, sleds, boards, wires,

and other foreign objects.

•

Disengage all clutches and shift into neutral before

starting the engine.

•

Do not operate the equipment without wearing

adequate winter garments. W

ear footwear which will

improve footing on slippery surfaces.

•

Handle fuel with care; it is highly flammable.

•

Use an approved fuel container

.

•

Never add fuel to a running or hot engine.

•

Fill fuel tank outdoors with extreme care. Never

fill fuel tank indoors.

•

Replace gasoline caps securely and wipe up spilled

fuel.

•

Use only the power cord supplied with the

snowthrower and a receptacle appropriate for use with

the cord for electric starting motors.

•

Adjust the collector (auger) housing height to clear

gravel or crushed rock surface (this is not necessary on

single-stage snowthrowers).

•

Never attempt to make any adjustments while the

engine is running, except where specifically

recommended by manufacturer (Lawn-Boy).

•

Let engine and machine adjust to outdoor temperatures

before starting to clear snow

.

•

The operation of any powered machine can result in

foreign objects being thrown into the eyes. Always

wear safety glasses or eye shields during operation or

while performing an adjustment or repair

.

Operation

•

Do not put hands or feet near or under rotating parts.

Keep clear of the dischar

ge opening at all times.

•

Exercise extreme caution when operating on or

crossing gravel drives, walks, or roads. Stay alert for

hidden hazards or traf

fic.

•

After striking a foreign object, stop the engine, remove

the wire from the spark plug, thoroughly inspect the

snowthrower for any damage, and repair the damage

before restarting and operating the snowthrower

.

•

If the unit should start to vibrate abnormally

, stop the

engine and check immediately for the cause. V

ibration

is generally a warning of trouble.

•

Stop the engine whenever you leave the operating

position, before unclogging the collector

(auger)/impeller housing or dischar

ge guide (chute),

and when making any repairs, adjustments, or

inspections.

•

When cleaning, repairing, or inspecting, make certain

the collector (auger/rotor blades)/impeller and all

moving parts have stopped. Disconnect the spark-plug

4

wire, and keep the wire away from the plug to prevent

accidental starting. Disconnect the cable on electric

motors.

•

Do not run the engine indoors, except when starting it

and for moving the snowthrower in or out of the

building. Open the outside doors; exhaust fumes are

dangerous.

•

Do not clear snow across the face of slopes. Exercise

extreme caution when changing direction on slopes.

Do not attempt to clear steep slopes.

•

Never operate the snowthrower without proper guards.

plates or other safety protective devices in place.

•

Never operate the snowthrower near glass enclosures,

automobiles, window wells, drop-of

fs, etc. without

proper adjustment of the snow dischar

ge angle. Keep

children and pets away

.

•

Do not overload the machine capacity by attempting to

clear snow at too fast a rate.

•

Never operate the machine at high transport speeds on

slippery surfaces. Look behind and use care when

moving in reverse.

•

Never direct dischar

ge at bystanders or allow anyone

in front of the unit.

•

Disengage power to the collector (auger/rotor

blades)/impeller when snowthrower is transported or

not in use.

•

Use only attachments and accessories approved by the

manufacturer of snowthrower (Lawn-Boy), such as

wheel weights, counterweights, cabs, etc. (Refer to

your Authorized Service Dealer for accessories

available for your snowthrower

.)

•

Never operate the snowthrower without good visibility

or light. Always be sure of your footing, and keep a

firm hold on the handles. W

alk; never run.

Maintenance and storage

•Check

all fasteners at frequent intervals for proper

tightness to be sure the equipment is in safe working

condition.

•

Never store the machine with fuel in the fuel tank

inside a building where ignition sources are present

such as hot water and space heaters, clothes dryers,

etc. Allow the engine to cool before storing in any

enclosure.

•

Always refer to this operator

’

s manual for important

details if the snowthrower is to be stored for an

extended period.

•

Maintain or replace safety and instruction labels, as

necessary.

•

Run the machine a few minutes after throwing snow to

prevent freeze-up of the collector (auger)/impeller

.

(W

ith the engine running, pull the recoil starter handle

several times.)

Lawn-Boy

Snowthrower Safety

The

following list contains safety information specific to

Lawn-Boy products or other safety information that you

must know that is not included in the ANSI or ISO

standards.

•

The r

otating impeller or auger can cut off or injur

e

fingers or hands.

Stay behind the handles and away

from the dischar

ge opening while operating the

snowthrower

.

Keep your face hands, feet, and any

other part of your body or clothing away fr

om

concealed, moving, or r

otating parts.

•

Before adjusting, cleaning, repairing, and inspecting

the snowthrower, and before unclogging the dischar

ge

chute,

stop the engine, r

emove the key

, and wait for

all moving parts to stop

. Also, pull the wire of

f of

the spark plug and keep it away from the plug to

prevent accidental starting.

•

Use a stick,

not your hands

to remove obstructions

from the dischar

ge chute.

•Before

leaving the operator

’

s position behind the

handles, stop the engine, remove the key

, and wait for

all moving parts to stop.

•

Do not wear loose fitting clothing that could possibly

get caught in moving parts.

•

If a shield, safely device, or decal is damaged,

illegible, or lost, repair or replace it before beginning

operation. Also, tighten any loose fasteners.

•

Do not

smoke while handling gasoline.

•

For two-stage snowthrowers, use the lower gear and, if

applicable, the rear wheel position when operating on

slopes.

•

Do not

use the snowthrower on a roof.

•

Do not touch the engine while it is running or soon

after it is stopped because the engine will be hot

enough to cause a burn. Do not add oil or check the

oil level in the crankcase when the engine is running.

•

Perform only those maintenance instructions described

in this manual. Before performing any maintenance,

service, or adjustment, stop the engine, remove the key

and pull the wire from the spark plug, keeping it away

from the plug to prevent accidental starting. If major

repairs are ever needed, contact your Authorized

Lawn-Boy Service Dealer

.

•

Do not over speed the engine by changing the

governor settings.

5

•

When storing the snowthrower for more than 30 days,

drain the gasoline from the fuel tank to prevent a

potential hazard. Store gasoline in a safety approved,

red metal container

. Remove the key from the ignition

switch before storing the snowthrower

.

•T

o ensure the best performance and safety

, purchase

only genuine Lawn-Boy replacement parts and

accessories to keep the Lawn-Boy all Lawn-Boy

.

Do

not use “W

ill Fit” r

eplacement parts and

accessories as they could cause a safety hazard.

""

" " "

#

#

""

"$

!

$

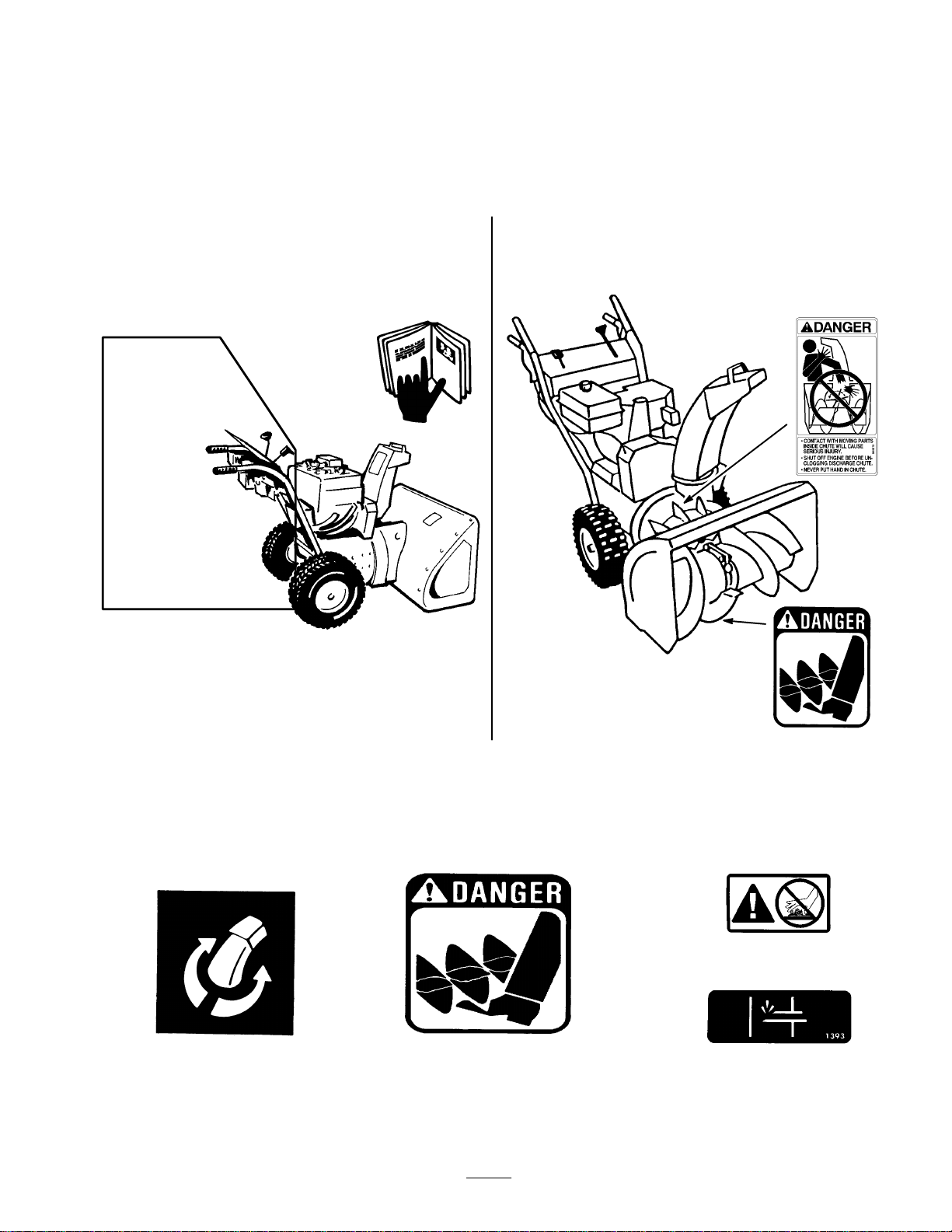

Safety

Decals and Instructions

Safety

decals and instructions are easily visible to the operator and are located near any area of potential danger

. Replace

any decal that is damaged or lost. Decals with T

ecumseh part numbers must be obtained from T

ecumseh Product Company

.

Decals with Lawn-Boy part numbers must be obtained from Lawn-Boy Inc.

ON

AUGER HOUSING

(Lawn-Boy Part No. 53–7670)

ON CHUTE CONTROL BRACKET

(Lawn-Boy Part No. 63–3510)

ON ENGINE

(T

ecumseh Part No. 371

19)

NEXT T

O PRIMER

(T

ecumseh Part No. 36501)

6

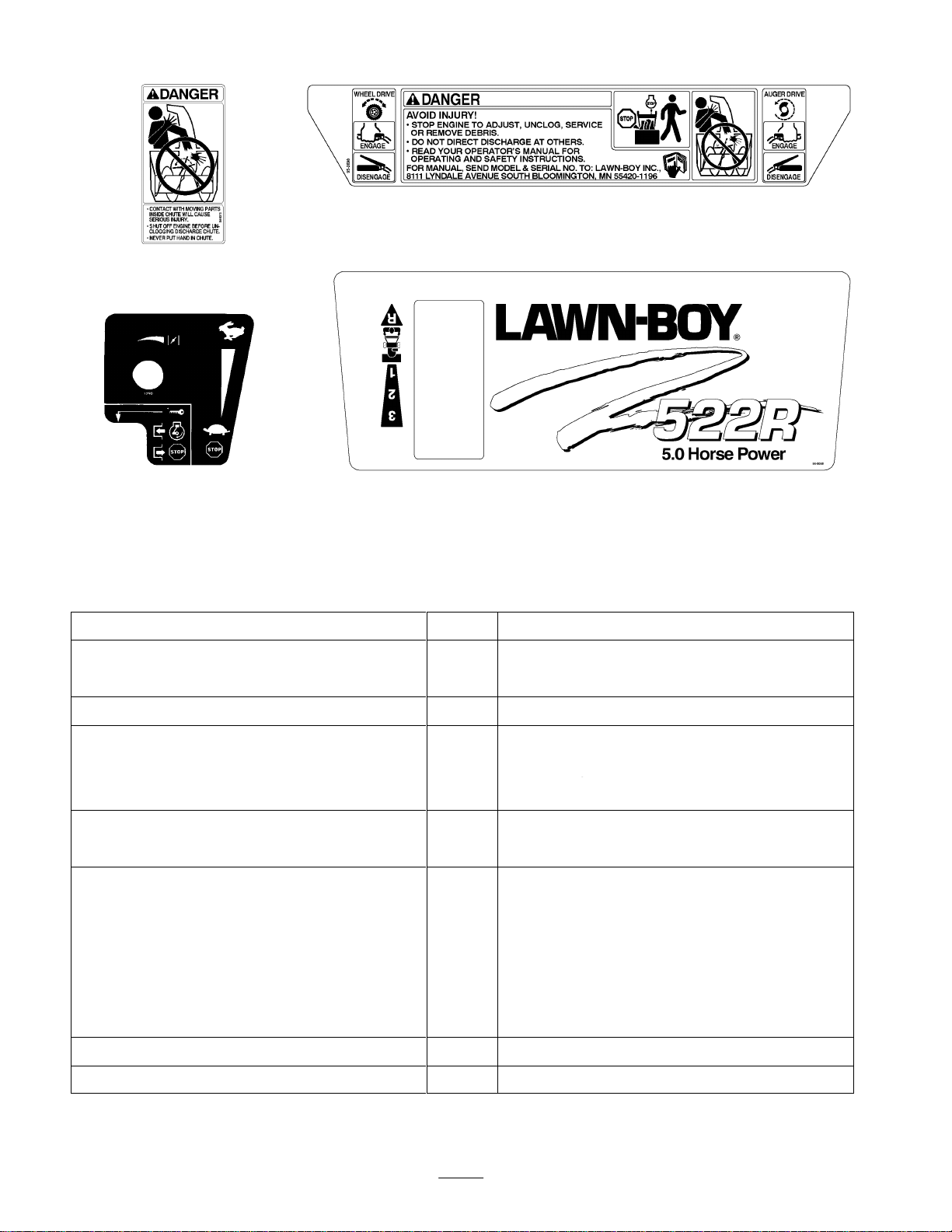

ON CONTROL P

ANEL

(Lawn-Boy Part No. 95–2698)

ON CONTROL P

ANEL

(Lawn-Boy Part No. 94–8098)

ON ENGINE

(T

ecumseh Part No. 35282)

ON DISCHARGE CHUTE

(Lawn-Boy Part No. 94–8079)

Loose

Parts

Part Qty Use

Cotter

Pin

1

Install on Speed Selector Rod

Flat W

asher 1

Install on Speed Selector Rod

Capscrews & Curved W

ashers 4

Install Handle

Clevis Pin

1

Cotter Pin

1

Install Auger & T

raction Drive Control Rod

Flange Nut

2

g

Capscrew & Locknut

1

Install Chute Control Rod

Locknut & Pyramidal W

asher 1

Install Chute Control Rod

Carriage Bolt

1

Rubber W

asher 1

Friction Plate

1

Secure Chute Deflector

Large Flat W

asher 1

Secure Chute Deflector

Curved W

asher 1

Locknut 1

Key 1

Use in Ignition Switch

Registration Card

2

Used to V

alidate Product W

arranty

Specifications

and design subject to change without notice.

7

Accessories

Description Part

Number

110 Vac Electric Starter Kit 38036

Tire Chain Kit 56-2700

Drift Breaker Kit 37-7022

Assembly

Note:

Determine left and right sides of snowthrower by

standing in the normal operating position.

Install

Handle

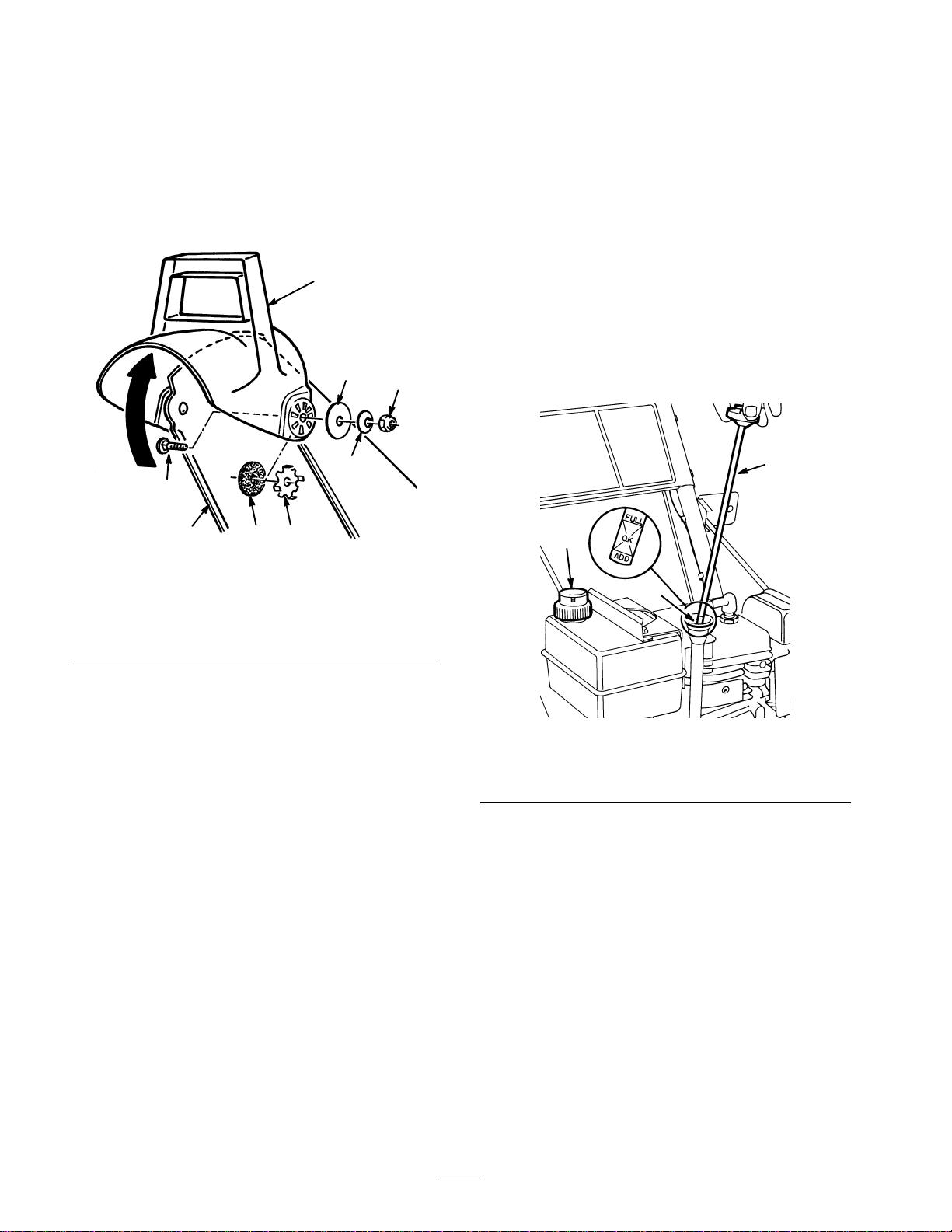

1. Remove

tie straps securing control rods to handle.

2.

Remove the axle pins from both wheels (Fig. 2) and

slide the wheels outward on the axle approximately

one inch to make clearance for assembly of handles.

653

Figure 2

1. Handle

2. Capscrews

and curved

washers

3.

Axle pinf

3. Thread

a flange nut (flange side down) onto traction

rod located on left handle (Fig. 3).

4.

Hold handles in installation position and insert traction

rod through loop in lower traction rod (Fig. 3).

654

Figure 3

1. Traction

rod

2. Loop 3.

Lower traction rod

4.

Flange nuts

5. Position

left handle against side of unit, align handle

mount holes with holes in side plate, and secure with

two capscrews and curved washers until finger tight

(Fig. 2).

Note:

Concave side of curved washer goes against

outside of handle.

Repeat procedure on right side. Make sure handles are

at same height before tightening handle screws on both

sides of unit.

6.

Reinstall the wheels. Note that there are two holes in

each end of the axle. Axle pins are installed through

holes in the wheel hub and through inner

hole of axle

(Fig. 4).

Note:

If snowthrower is to be equipped with optional

tire chains, wheels must be pinned through outer

axle

holes.

473

Figure 4

1. Axle

pin

2.

Outer axle hole

3.

Inner axle hole and wheel

hub

8

Install

Speed Selector Rod

1. Pull

speed selector arm (Fig. 5) to the fully “out”

position and move speed selector (Fig. 6) on control

panel to the R (REVERSE) position to ease assembly

.

648

Figure 5

1. Speed

selector arm

2.

Speed selector rod

3.

Flat washer and cotter pin

879

Figure 6

1.

Auger control lever

2. T

raction control lever

3.

Speed selector

4.

Speed selector rod

2. Install

speed selector rod into selector arm, add one

flat washer on the selector rod and secure with cotter

pin (Fig. 5).

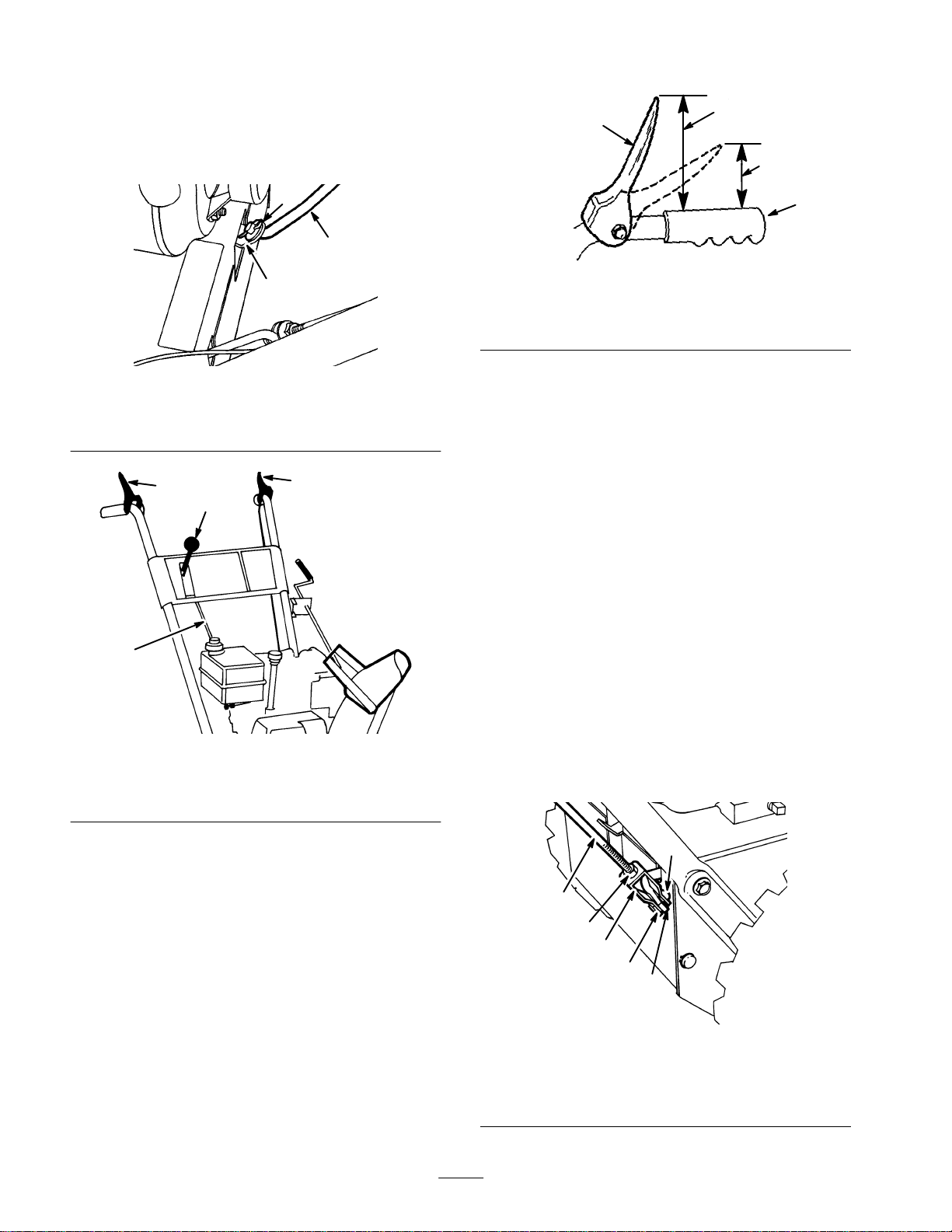

Install

T

raction Rod

1. Thread

a flange nut (flange side up) onto bottom of

traction control rod below loop in lower traction rod

(Fig. 3).

2.

Adjust the two flange nuts up or down on the traction

control rod until the distance between the top of the

handgrip and the bottom of the traction control lever

(Fig. 6 and 7) is approximately 4

#/8

inches.

This is a

pr

eliminary setting only

.T

ighten the two flange nuts

finger tight.

665

Figure 7

1. Traction

control lever

2. Handgrip 3.

Approximately 4

#/8

inches

4.

One to two inches

3. Move

speed selector (Fig. 6) into third gear

.

Note:

If speed selector will not move into third gear

,

an adjustment is necessary: refer to Adjusting Speed

Selector

, page 18. Make the adjustment before

continuing with assembly

.

4.

Slowly pull machine backward while slowly

depressing traction control lever toward handle.

Adjustment is correct when wheels stop turning and

the distance between the top of the handgrip and the

bottom of the traction control lever is one to two

inches (Fig. 7). Readjust the two flange nuts, if

necessary

, to obtain this dimension and then tighten

the two flange nuts securely

.

Install

Auger Drive Control

Linkage

1. Loosen

jam nut above clevis on upper control rod

(Fig. 8).

2.

Align holes in clevis and lower control rod and insert

clevis pin (Fig. 8).

649

Figure 8

1. Jam

nut

2. Clevis

3.

Upper control rod

4.

Lower control rod

5.

Clevis pin

6.

Cotter pin

9

3. Check

the distance between the top of the handgrip

and the bottom of the auger control lever (Figs. 6 & 9).

Distance should be approximately four inches.

This is

a pr

eliminary setting only

.

665

Figure 9

1. Auger

control lever

2. Handgrip 3.

Approximately four inches

4.

One to two inches

4. Compress

auger control lever slowly toward handgrip.

The amount of force to compress the lever will

increase noticeably when slack is removed from the

drive belt (approximately one-half of lever

movement). Adjustment is correct when the force

begins

to increase and the distance between the top of

the handgrip and the bottom of the auger control lever

is one to two inches.

Note:

If force does not noticeably increase, remove the

belt cover (refer to Replacing Auger/ Impeller Drive

Belt, steps 1-2, page 16) and measure the one to two

inch dimension above the handgrip at the point where

the slack is removed from the auger drive belt.

5. T

o adjust the distance, remove clevis pin, loosen jam

nut and thread clevis up or down to increase or

decrease distance between handgrip and auger control

lever (Fig. 8).

6.

When adjustment is correct, install clevis pin and

secure it in place with the cotter pin. T

ighten jam nut

to secure clevis (Fig. 8).

Install

Chute Control Rod

1. Assemble

chute control bracket and rod to left side of

handle with capscrew and locknut. Leave locknut

loose until assembly is completely mounted (Fig. 10).

886

Figure 10

1. Chute

control bracket

and rod

2.

Capscrew and locknut

2. Apply

No. 2 general purpose grease to worm gear

.

Next, mount worm gear and bracket to mounting

flange and secure with pyramidal washer and locknut

(Fig. 1

1).

3.

Slide worm gear into teeth of chute retaining ring and

tighten locknut (Fig. 1

1).

658

Figure 1

1

1. Worm

gear and bracket

2.

Bolt, pyramidal washer

and locknut

3.

Mounting flange

4. Tighten

the locknut securing chute control bracket

against left handle (Fig. 10).

5.

Check operation of chute control rod. Move worm

gear slightly outward if binding is evident.

Secure

Chute Deflector

1. Pivot

deflector upward and back until deflector stop

passes over lip on top of chute.

10

2.

Secure left side of deflector to dischar

ge chute using

parts as illustrated in Figure 12. Make sure rubber

washer and friction plate are positioned between chute

and deflector and friction plate tabs fit into holes in

deflector

. See Figure 12 for proper installation

sequence of parts.

Note:

Concave side of curved washer goes against

lar

ge flat washer

.

667

Figure 12

1. Chute

2. Deflector

3. Carriage

bolt

4.

Rubber washer

5.

Friction plate

6.

Large flat washer

7.

Curved washer

8. Locknut

3. Tighten

nuts on both sides of deflector

. Do not

over

-tighten nuts so that excessive force is required to

change deflector angle.

Check

T

ire Pressure

IMPORTANT:

Check pr

essur

e of tir

es because they

ar

e over

-inflated at the factory for shipping. Ther

efore,

befor

e the snowthr

ower is operated, r

educe pr

essur

e in

both tir

es to 7-15 psi equally

.

Before

Starting

ENGINES

WHICH ARE CER

TIFIED T

O COMPL

Y

WITH CALIFORNIA AND U.S. EP

A EMISSION

REGULA

TIONS FOR ULGE ENGINES:

Are certified

to operate on regular unleaded gasoline. Include the

following emission control system(s): EM, TWC (if so

equipped); Do not include any user adjustable features –

therefore no other adjustments are needed.

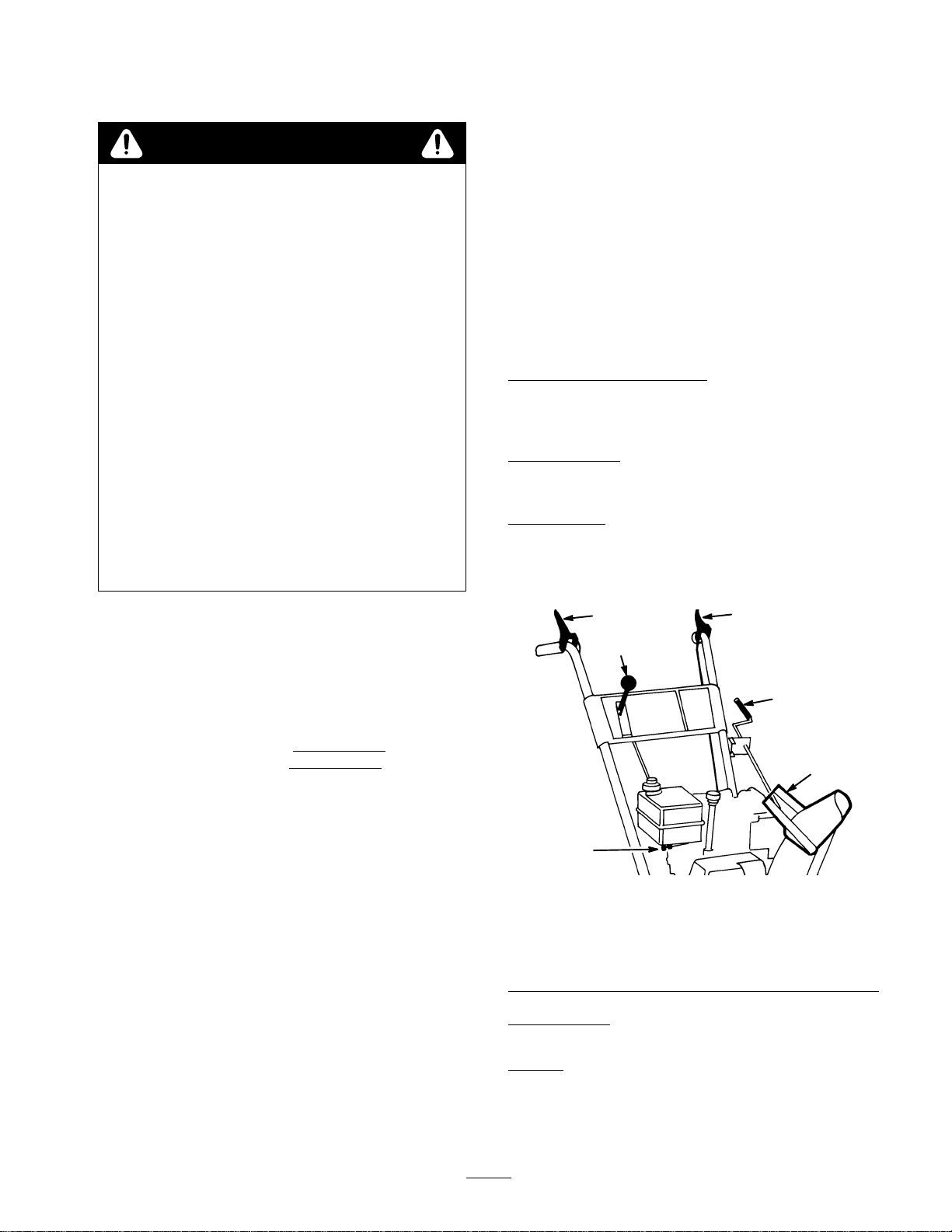

Fill

Crankcase W

ith Oil

The

engine is shipped from the factory without oil in the

crankcase. Therefore, before starting the engine, oil must

be added to the crankcase.

IMPORTANT

: Check level of oil every 5 operating

hours or each time unit is used. Initially, change oil

after the first 2 hours of operation; ther

eafter

, under

normal conditions, change oil after every 25 hours of

operation or annually

, whichever comes first.

1.

Move unit to a level surface to ensure an accurate oil

level reading.

2.

Clean area around dipstick to prevent foreign matter

from entering filler hole when dipstick is removed.

3.

Remove dipstick from crankcase (Fig. 13).

883

Figure 13

1. Filler

hole

2. Dipstick 3.

Fuel tank cap

4. Slowly

pour 21 ounces (0.621 liters) of SAE 5W–30 or

SAE 10 oil into the filler hole. The engine uses any

high-quality deter

gent oil having the American

Petroleum Institute (API) “service classification”—SF

,

SG, SH or SH/CD.

Note:

Dipstick must be fully installed to ensure

accurate gauging of oil level. DO NOT OVERFILL.

POUR OIL SLOWL

Y.

11

Fill

Fuel T

ank W

ith Gasoline

DANGER

POTENTIAL

HAZARD

•

In certain conditions gasoline is extr

emely

flammable and highly explosive.

WHA

T CAN HAPPEN

•

A fir

e or explosion fr

om gasoline can burn you,

others, and cause pr

operty damage.

HOW T

O A

V

OID THE HAZARD

•

Use a funnel and fill the fuel tank outdoors, in

an open ar

ea, when the engine is cold. W

ipe up

any gasoline that spills.

•

Do not fill the fuel tank completely full. Add

gasoline to the fuel tank until the level is 1/4” to

1/2” (6 mm to 13 mm) below the bottom of the

filler neck. This empty space in the tank allows

gasoline to expand.

•

Never smoke when handling gasoline, and stay

away fr

om an open flame or wher

e gasoline

fumes may be ignited by a spark.

•Stor

e gasoline in an appr

oved container and

keep it out of the r

each of childr

en.

•

Never buy mor

e than a 30-day supply of

gasoline.

Use clean, fresh lead-free gasoline, including

oxygenated

or

reformulated

gasoline, with an octane rating of 85 or

higher. T

o ensure freshness, purchase only the quantity of

gasoline that can be used in 30 days. Use of lead-free

gasoline results in fewer combustion chamber deposits

and longer spark plug life. Use of premium grade fuel is

not necessary

.

IMPORTANT

: NEVER USE METHANOL

,

GASOLINE CONT

AINING METHANOL

,

GASOHOL CONT

AINING MORE THAN 10%

ETHANOL, PREMIUM GASOLINE OR WHITE

GAS BECAUSE ENGINE FUEL SYSTEM DAMAGE

COULD RESUL

T.

Lawn-Boy recommends that Lawn-Boy 2+4

r

Fuel

Conditioner be used regularly during operation and

storage. Lawn-Boy 2+4

r

Fuel Conditioner cleans the

engine during operation and prevents gum-like varnish

deposits from forming in the engine during storage.

Note:

A fuel stabilizer/conditioner is most ef

fective when

mixed with fresh gasoline.

DO NOT USE FUEL ADDITIVES OTHER THAN

THOSE MANUF

ACTURED FOR FUEL

STABILIZA

TION DURING ST

ORAGE SUCH AS

LA

WN-BOY 2+4

r

FUEL CONDITIONER.

LA

WN-BOY DOES NOT RECOMMEND

ST

ABILIZERS WITH AN ALCOHOL BASE SUCH

AS ETHANOL OR METHANOL. ST

ABILIZERS

SHOULD NOT BE USED T

O TR

Y T

O ENHANCE

THE POWER OR PERFORMANCE OF MACHINE.

1.

Clean area around the fuel tank cap (Fig. 13). Remove

cap from fuel tank. Using unleaded, regular gasoline,

fill tank to within 1/4” to 1/2” (6 to 13 mm) from the

top of the tank, not into the filler neck. This space is

for expansion of fuel. Do not fill tank full. Reinstall

fuel tank cap.

Operation

Controls

Auger/Impeller Drive Contr

ol

(Fig. 14)—Control has

two positions: ENGAGE and DISENGAGE. T

o engage

both auger and impeller

, compress lever against right

handgrip. T

o disengage, release lever

.

T

raction Contr

ol

(Fig. 14)—T

o engage traction (wheel

drive), lever must be compressed against left handgrip. T

o

stop traction, release lever

.

Speed Selector

(Fig. 14)—The control has four positions:

reverse, 1, 2 and 3. T

o change speeds, move gear shift to

position desired. Lever will lock in notch at each speed

selection. Use positions 1, 2 or 3 depending on snow

conditions.

m–4037

Figure 14

1. Auger/impeller

drive

control

2. T

raction control

3.

Speed selector

4.

Discharge chute control

5.

Fuel shut–of

f valve

6.

Chute deflector handle

Ignition

Switch

(Fig. 15)—Insert key before starting

engine with the recoil starter

. T

o stop engine, remove key

.

Throttle

(Fig. 15)—Moving the throttle upward increases

engine speed.

12

Choke

(Fig. 15)—Rotate choke to FULL choke position

to start a cold engine. As engine warms up, move choke

gradually to OFF

.

Primer

(Fig. 15)—Press primer to pump a small amount

of gasoline into engine for improved cold weather

starting.

m-4045

Figure 15

1. Choke

2. Primer

3. Throttle

4. Recoil

starter

5.

Ignition switch

Fuel Shut-Off Valve

(Fig. 14)—V

alve is located under

fuel tank. Close valve to stop fuel flow from fuel tank and

open valve to allow fuel to flow to the carburetor

. Close

valve when snowthrower is not in use.

Discharge Chute Contr

ol

(Fig. 14)—Rotate dischar

ge

chute control clockwise to move dischar

ge chute to the

left and counterclockwise to move chute to the right.

Recoil Starter

(Fig. 15)—Recoil starter is on back side of

engine. Pull recoil starter to start engine.

Chute Deflector Handle

(Fig. 14)—Deflector handle is

on top of dischar

ge chute, and it is used to control height

of the snow stream.

Starting/Stopping

Engine

If

engine is operated when temperature is +40

_

F (4

_

C) or

higher

, remove carburetor heater box (Fig. 16). However

,

the heater box must be reinstalled when temperature falls

below +40

_

F (4

_

C). T

o remove heater box:

1.

Remove (2) Phillips screws and (1) hex head screw

securing heater box in place (Fig. 16). Pull choke knob

of

f choke rod (Fig. 15).

880

Figure 16

1. Carburetor

heater box

2.

Phillips screws

3.

Hex head screw

2. Lift

heater box up and away from the engine, and

reinstall choke knob on mounting pin.

IMPORTANT

: Check auger and impeller to ensur

e

that both parts ar

e not fr

ozen but fr

ee to r

otate.

Also, make sur

e discharge chute is not obstructed.

USE A STICK, NOT YOUR HAND, T

O REMOVE

ANY OBSTRUCTIONS.

Starting

1.

Move throttle (Fig. 15) to F

AST.

2.

Open fuel shut-of

f valve below fuel tank (Fig. 14).

3.

Rotate choke (Fig. 15) to full choke position.

4.

Insert ignition key (Fig. 15).

5.

Cover hole in center of primer with thumb and push

primer slowly three times.

DO NOT PRIME IF THE

ENGINE HAS BEEN RUNNING AND IS HOT

.

Note:

Excessive priming may cause flooding of engine

and failure to start.

6.

Grasp recoil starter handle (Fig. 15) and pull it out

slowly until positive engagement results; then pull

vigorously to start the engine. Keep firm grip on

starter handle and return the rope slowly

.

Note:

If engine does not start or if temperature is

–10_

F (–23

_

C) or below

, additional priming may be

required. After each additional prime, try to start the

engine before priming again.

7.

After engine starts, immediately rotate choke (Fig. 15)

to 3/4 position. As engine warms up, rotate choke to

1/2 position; then to OFF position. If engine falters,

return choke to 1/2 position. When engine warms

sufficiently

, rotate choke to OFF position.

13

Before Stopping

1. Engage

auger to clear any remaining snow from inside

the housing.

2.

Run engine for a few minutes to help dry of

f any

moisture which may have accumulated on engine.

3. W

ith engine running, pull recoil starter with a rapid,

continuous full arm stroke three or four times. This

helps prevent possible freeze-up of recoil starter due to

extreme snow blowing conditions.

Note:

Pulling of recoil starter rope produces a loud,

clattering sound. This is not harmful to the engine or

the starter

.

Stopping

1.

Release traction and auger drive controls (Fig. 14).

2.

Move throttle (Fig. 15) to slow

.

3.

Remove key from ignition switch to prevent

unauthorized use of snowthrower

.

4. W

ait for all moving parts to stop before leaving the

operator’

s position (behind the handles).

5.

Store key in a memorable place.

Operating

T

ips

1. When

snowthrower is not being used, close fuel

shut-of

f valve and remove key from the switch.

2.

Remove snow as soon as possible after it falls. This

produces best snow removal results.

3.

Adjust skids to match the type of surface being

cleaned; refer to Adjusting Skids, page 13.

4.

The snowthrower is designed to clean snow down to

the contact surface, but there are times when the front

of the snowthrower may tend to ride up. If this

happens, reduce forward speed by shifting into a lower

gear

. If front still tends to ride up, lift up on both

handles to hold down front of snowthrower

.

5. Dischar

ge snow downwind whenever possible, and

overlap each swath to ensure complete snow removal.

If wheels slip, shift into a lower gear to reduce forward

speed.

6.

Run snowthrower for a few minutes after clearing

snow so moving parts do not freeze. Engage auger to

clear any remaining snow from inside housing.

7.

Do not overload snowthrower by clearing snow at too

fast a rate. If engine slows down, shift to a lower gear

to reduce forward speed.

8.

Always use full throttle (maximum engine speed)

when throwing snow

.

DANGER

POTENTIAL HAZARD

•

Rotating impeller or auger can cause injury

.

WHA

T CAN HAPPEN

•

Rotating impeller or auger can cut off or injur

e

fingers or hands.

HOW T

O A

V

OID THE HAZARD

•

Stay behind the handles and away fr

om

discharge opening while operating the

snowthrower.

•

Keep face, hands, feet and any other part of

your body or clothing away fr

om concealed,

moving or r

otating parts.

•Befor

e adjusting, cleaning, repairing and

inspecting the snowthr

ower

, and befor

e

unclogging the discharge chute, shut engine off

and wait for all moving parts to stop.

•

Also, pull wir

e off spark plug and keep wir

e

away fr

om the plug to pr

event accidental

starting.

•

USE A STICK, NOT YOUR HANDS, T

O

REMOVE OBSTRUCTIONS FROM

DISCHARGE CHUTE.

9.

In wet or slushy conditions, clogging of the dischar

ge

chute will be reduced by maintaining maximum

engine speed and by not overloading the engine.

10.

In some snow and cold weather conditions, some

controls and moving parts may freeze. Therefore,

when any control becomes hard to operate, stop the

engine and wait for all moving parts to stop; then

check all parts for freeze up. DO NOT USE

EXCESSIVE FORCE AND TR

Y T

O OPERA

TE THE

CONTROLS WHEN FROZEN. Free all controls and

moving parts before operating.

Adjusting

Skids And Scraper

Blade

For Concrete Or Asphalt Surfaces

1. Pull

wire of

f spark plug and make sure wire does not

contact plug accidentally

.

2.

Check the tire pressure in both tires. Make sure that

they are inflated equally between 7 and 15 psi.

3.

Move snowthrower to a level surface. Next, loosen (4)

flange nuts securing both skids to the auger side plates

(Fig. 17) until the skids can be slid up and down easily

.

14

651

Figure 17

1. Skid

2. Auger

side plate

3.

Flange nuts

4. Support

the auger blades of

f the ground so that both

the scraper and the auger blades (Fig. 18) clear the

level surface by at least 1/16 inch.

m–2843

Figure 18

1. Scraper

2. Mounting screws 3.

Auger blades

Note:

The auger blades and scraper should be higher

above the pavement if the pavement surfaces on which

the snowthrower will be used are cracked, rough or

uneven.

5.

Check the scraper blade adjustment. T

o adjust scraper

,

loosen (5) mounting screws (Fig. 18), pull scraper all

the way down, and retighten screws.

6.

When scraper is adjusted correctly and is supported

above level surface, move the skids down to sit flat on

the ground and tighten the (4) flange nuts securing

both skids to the auger side plates (Fig. 17). Skids will

now support the auger blades and scraper above the

ground.

For Gravel Surfaces

For

gravel or crushed rock surfaces, adjust the skids to

prevent picking up rocks.

1.

Pull wire of

f spark plug and make sure wire does not

contact plug accidentally

.

2.

Loosen the (4) flange nuts securing both skids to auger

side plates (Fig. 17). Next, slide skids down as far as

possible so auger will be supported as far from the

level surface as skid adjustment allows; then tighten

flange nuts.

Maintenance

WARNING

POTENTIAL HAZARD

•

If you leave the wir

e on the spark plug,

someone could start the engine.

WHA

T CAN HAPPEN

•

Accidental starting of engine could seriously

injur

e you or other bystanders.

HOW T

O A

V

OID THE HAZARD

•

Pull wir

e off spark plug and r

emove key fr

om

switch befor

e you do any maintenance. Also

push wir

e aside so it does not accidentally

contact spark plug.

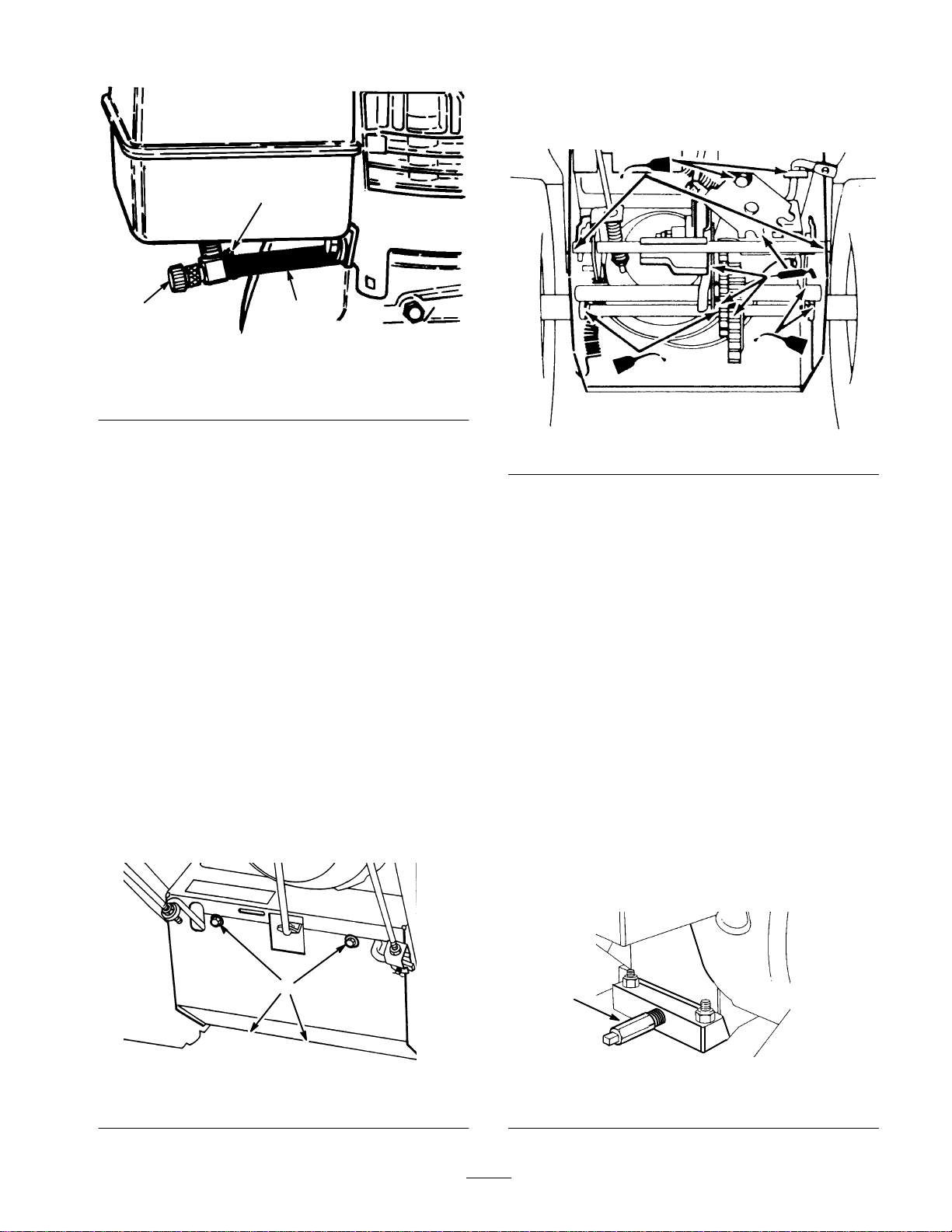

Draining

Gasoline

1. Close

fuel shut-of

f valve located under fuel tank

(Fig. 19).

WARNING

POTENTIAL HAZARD

•

Gasoline is highly flammable.

WHA

T CAN HAPPEN

•

Gasoline can be ignited and cause serious

personal injury

.

HOW T

O A

V

OID THE HAZARD

•

Drain gasoline outdoors.

•

Drain gasoline fr

om a cold engine only

.

•W

ipe up any gasoline that may have spilled.

•

Do not drain gasoline near any open flame or

wher

e gasoline fumes may be ignited by a

spark.

•

DO NOT SMOKE a cigar

, cigar

ette or pipe

when handling gasoline.

15

881

Figure 19

1. Fuel

shut–of

f valve

2.

Hose clamp

3.

Fuel line

2. Place

a clean drain pan under shut-of

f valve.

3.

Loosen hose clamp securing fuel line to valve and

slide line of

f valve (Fig. 19).

4.

Open valve by rotating valve to the right. This allows

fuel to flow into drain pan.

5.

Reinstall fuel line and secure with hose clamp.

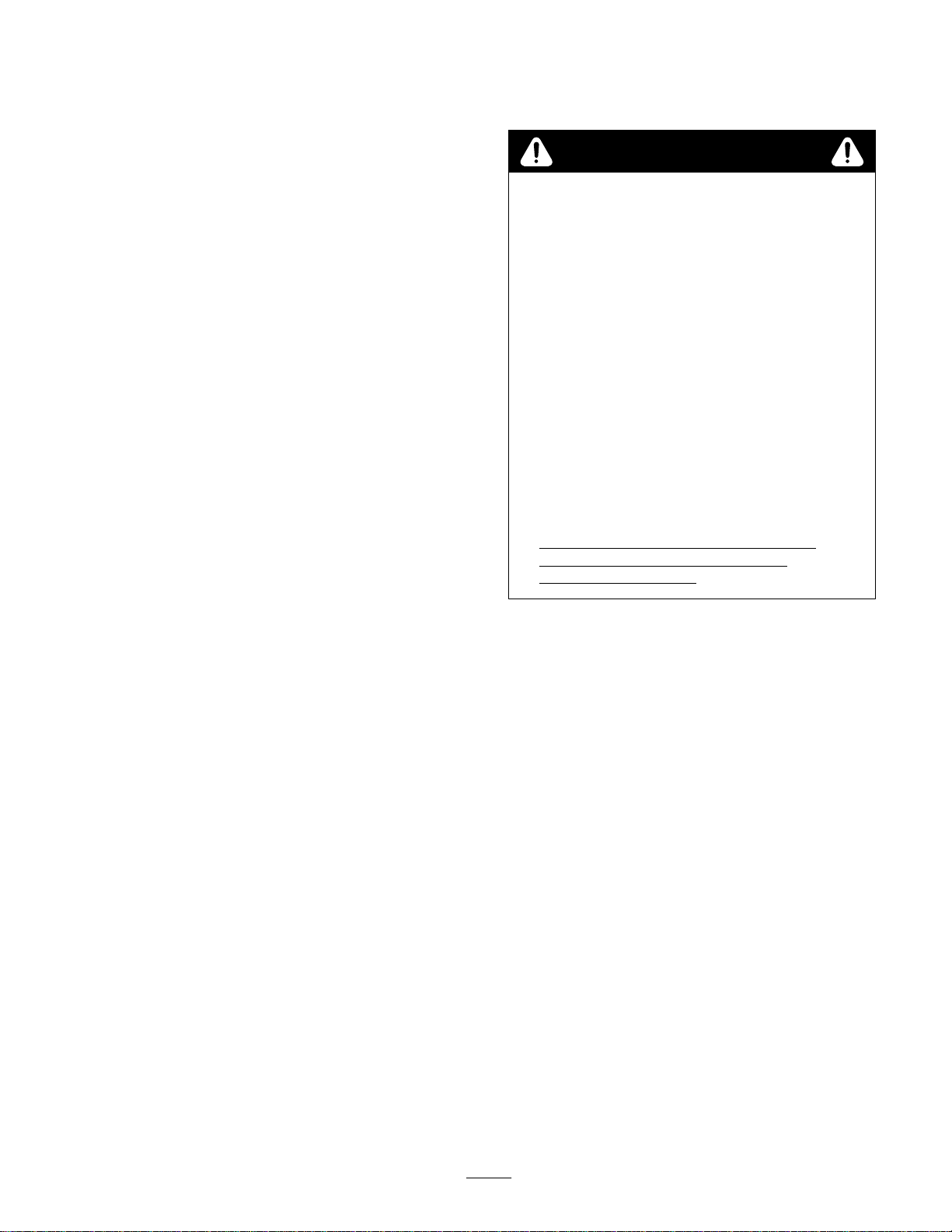

Lubricating

Snowthrower

Lubricate

moving parts of the snowthrower after every

15 hours of operation.

1.

Pull wire of

f spark plug and make sure wire does not

contact plug accidentally

.

2.

Drain gasoline from fuel tank; refer to Draining

Gasoline, page 14.

3. T

ip snowthrower forward onto auger housing and

block it so it cannot fall. Now

, remove four screws

holding bottom cover in place and remove cover

(Fig. 20).

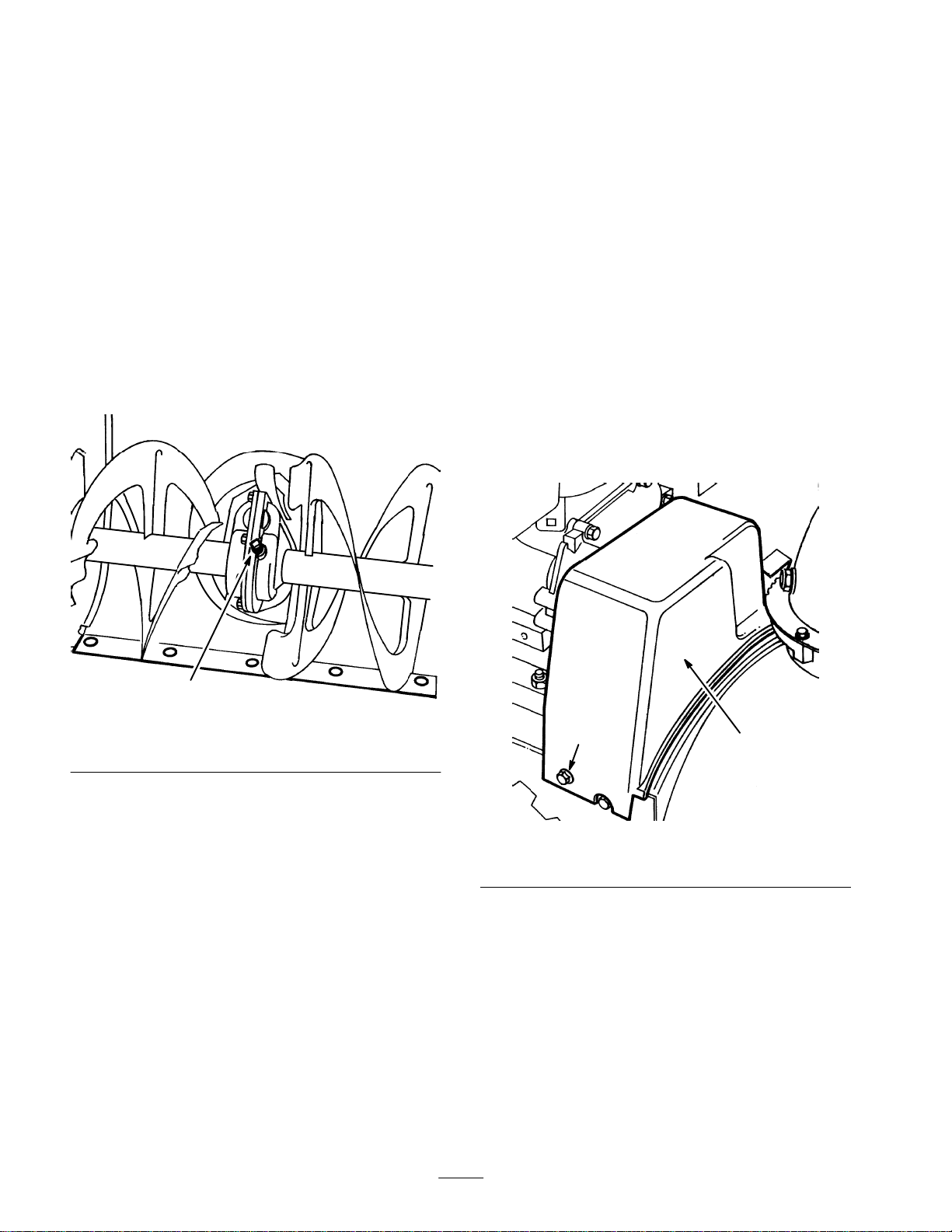

m–2592

Figure 20

1. Four screws

4. Lightly

lubricate snowthrower with light oil and grease

as shown in Figure 21. W

ipe up any excess oil or

grease.

887

Figure 21

IMPORTANT

: Do not get oil or gr

ease on rubber

wheel or friction drive plate because the wheel will slip

and the rubber may deteriorate.

5.

Reinstall bottom cover with (4) screws.

Changing

Crankcase Oil

Initially,

change oil after the first 2 hours of engine

operation; thereafter

, under normal conditions, change oil

after every 25 hours of engine operation or annually

,

whichever comes first. If possible, run engine just before

changing oil because warm oil flows better and carries

more contaminants than cold oil.

1.

Pull wire of

f spark plug and make sure wire does not

contact plug accidentally

.

2.

Block up the rear of the snowthrower chassis and

remove the left wheel.

3.

Clean area around oil drain plug. Next, slide oil drain

pan below drain extension; then remove oil drain plug

(Fig. 22).

m-4041

Figure 22

1. Drain

plug

16

4. After

all oil is drained, reinstall oil drain plug and left

wheel.

5.

Position snowthrower on a level surface. Next, fill

crankcase with oil: refer to Fill Crankcase W

ith Oil,

page 10. W

ipe up any oil that may have spilled.

Auger

Gear Box Grease

The

auger gear box grease level must be checked at time

of snowthrower assembly

, after every 10 hours of use and

upon removal from annual storage. T

o check the auger

gear box grease level:

1.

Position snowthrower on a level surface.

2.

Clean area around pipe plug so dirt is removed.

3.

Remove pipe plug from gear box (Fig. 23).

m–2843

Figure 23

1. Pipe

plug

4. Check

level of grease in gear box. Grease must be

visible through opening.

5.

If level of grease is low

, add MAG-1 grease (a low

temperature, high pressure grease) to the gear box until

point of overflow

.

Note:

Only use low temperature, high pressure grease

in gear box.

6.

Reinstall pipe plug in gear box.

Adjusting

Auger/Impeller Drive

Belt

If

auger/impeller belt slips, resulting in decreased

snowthrowing performance, either an adjustment or a new

belt is required.

1.

Check adjustment per steps 4–6 of Install Auger Drive

Control Linkage, page 8. Make adjustments if

required.

2.

Check tension of belt by operating the auger

.

If belt

still slips, r

eplace the belt. USE ONL

Y GENUINE

LA

WN-BOY REPLACEMENT P

ARTS.

Replacing

Auger/Impeller Drive

Belt

When

auger/impeller drive belt (Fig. 24) becomes worn,

oil-soaked or otherwise damaged, belt replacement is

required.

661

Figure 24

1. Belt

cover

2.

Screw (2)

1. Pull

wire of

f spark plug and make sure it does not

contact the plug accidentally

.

2.

Remove (2) screws holding belt cover in place and set

cover aside (Fig. 24).

3.

Remove auger/impeller drive belt from engine pulley

and lar

ge auger/impeller pulley (Fig. 25).

17

4.

Install new belt around large auger/impeller pulley

(Fig. 25). Next, loop belt over engine pulley

, making

sure that belt is on inside of idler pulley and belt guide

(Fig. 25).

664

Figure 25

1. Traction

drive belt

2.

Auger/impeller drive belt

3.

Belt guide

4.

Idler pulley

5.

Large auger/impeller

pulley

6.

Engine pulley

5. Adjust

auger drive linkage. Refer to steps 4–6 of

Install Auger Drive Control Linkage, page 8.

6.

Reinstall belt cover with (2) screws.

Replacing

T

raction Drive Belt

When

traction drive belt becomes worn, oil-soaked or

otherwise damaged, belt replacement is required.

1.

Pull wire of

f spark plug and make sure it does not

contact the plug accidentally

.

2.

Drain gasoline from fuel tank. Refer to Draining

Gasoline, page 14.

3.

Remove (2) screws holding belt cover in place and set

cover aside (Fig. 24).

4.

Remove auger/impeller drive belt from engine pulley

and lar

ge auger/impeller pulley (Fig. 25).

5. T

ip snowthrower forward and block it so it cannot fall.

6.

Remove (4) screws securing bottom cover to frame

(Fig. 25). Remove bottom cover

.

7.

Disconnect spring from notch in bottom edge of side

plate (Fig. 26).

CAUTION

POTENTIAL HAZARD

•

Spring is under heavy tension.

WHA

T CAN HAPPEN

•

Spring could be thr

own in operator

’

s or

bystander’

s dir

ection.

HOW T

O A

V

OID THE HAZARD

•

Use caution when r

emoving spring.

650

Figure 26

1. Spring

2. Notch

in side plate

3.

Large traction pulley

8. Set

unit upright and remove traction drive belt from

engine pulley and lar

ge traction pulley (Fig. 25).

9.

Install new belt around lar

ge traction pulley

. Next,

loop belt over engine pulley

, making sure that belt is

on inside of belt guide (Fig. 25).

10.T

ip snowthrower forward and block it so it cannot fall.

11.

Hook spring into notch in bottom edge of side plate

(Fig. 26).

12.

Replace bottom cover with four screws and set unit

upright.

13.

Reinstall auger/impeller drive belt around lar

ge

auger/impeller pulley and engine pulley

, making sure

that belt is on inside of idler pulley and belt guide

(Fig. 25).

Note:

If auger/impeller drive belt is replaced with a

new belt, adjust auger drive linkage. Refer to steps 4–6

of Install Auger Drive Control Linkage, page 8.

14.

Reinstall belt cover with (2) screws.

18

Adjusting

T

raction Drive

If

speed selector shifts properly but snowthrower does not

drive in reverse or forward speeds, an adjustment may be

required.

1.

Check adjustment per steps 5 and 6 of Install T

raction

Rod, page 8. Make adjustments if required.

2.

If linkage is adjusted correctly and problem persists,

contact your local Authorized Lawn-Boy Service

Dealer.

Adjusting

Speed Selector

If

there is slow or no ground speed in No.1 speed

selection, or speed selector cannot be moved into No. 3

speed selection, an adjustment of the speed selector

linkage is required.

1.

Pull wire of

f spark plug and make sure wire does not

contact plug accidentally

.

2.

Remove (4) screws securing bottom cover to frame.

Remove cover (Fig. 20).

3.

Loosen flange nuts securing selector plate to control

panel. This allows selector plate to move freely for

adjustment (Fig. 27).

4.

Shift speed selector to third gear and push down on

speed selector plate to move drive assembly to the

right. Drive assembly should be

!/8

” from roll pin; if

not, slide selector plate (Fig. 27) until

!/8

” dimension

is correct (Fig. 28).

659

Figure 27

1. Flange

nuts

2.

Speed selector plate

!8

650/913

Figure 28

1.

Roll pin

2.

Drive assembly

5. With

drive assembly

!/8

” from contacting roll pin,

tighten flange nuts securing speed selector plate.

6.

Shift speed selector to R (REVERSE) and back to

third to check adjustment. If space between roll pin

and drive assembly is more than

#/16

of an inch (4.8

mm), repeat steps 2–4.

7.

Reassemble bottom cover with (4) screws.

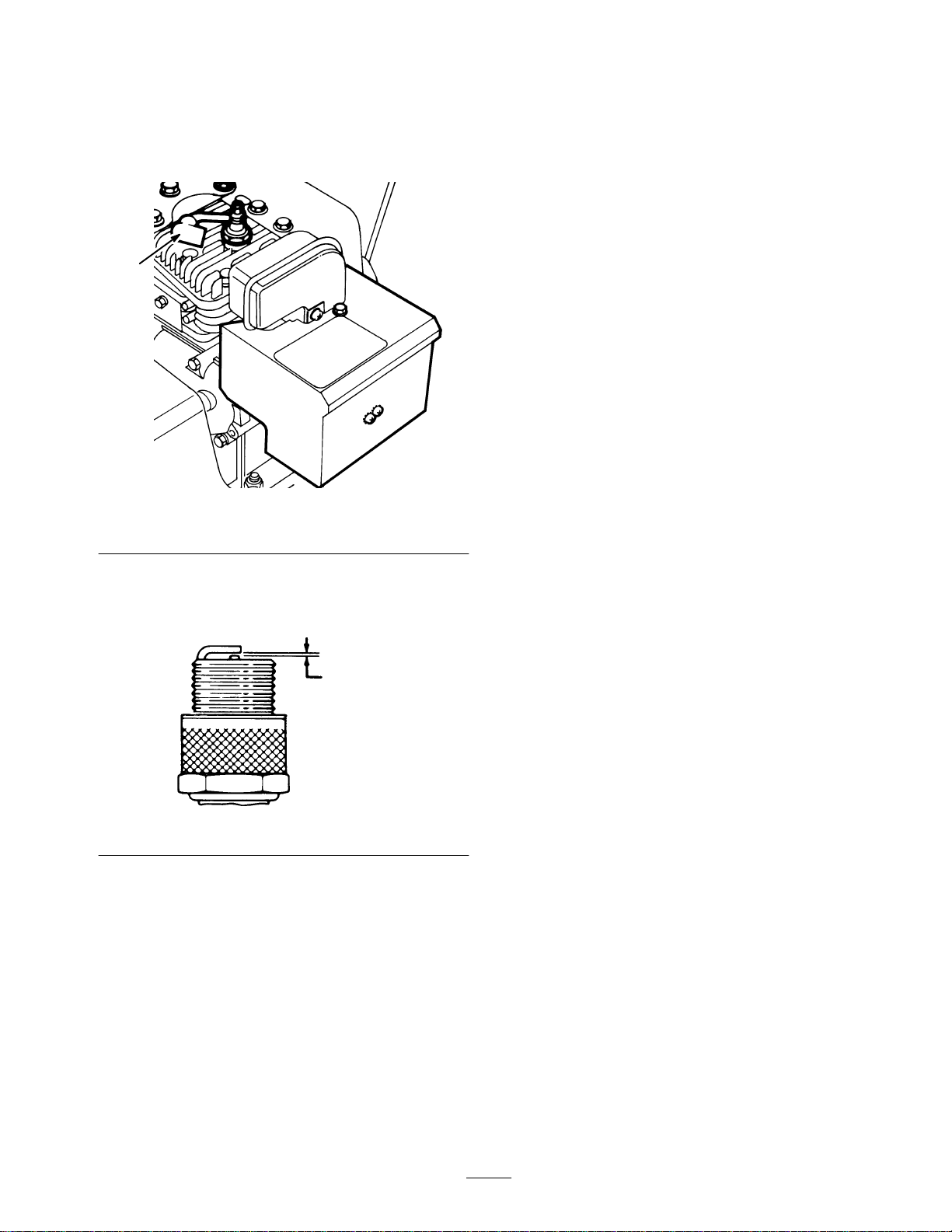

Replacing

Spark Plug

Check

spark plug yearly or every 100 operating hours. If

electrodes in center of plug are dark or have deteriorated,

install a new plug. Use a Champion RJ–19LM spark plug

or equivalent. Set air gap at 0.030” (0.76 mm).

1.

Clean area around spark plug so foreign matter cannot

fall into cylinder when plug is removed.

2.

Pull wire of

f spark plug (Fig. 29) and remove plug

from cylinder head.

19

IMPORTANT

: A cracked, fouled or dirty spark

plug must be r

eplaced. Do not sand blast, scrape or

clean electr

odes because grit may eventually r

elease

fr

om the plug and fall into the cylinder

. The r

esult

will likely be engine damage.

880

Figure 29

1. Spark

plug wire

3. Set

air gap between electrodes of new spark plug at

0.030” (0.76 mm) (Fig. 30). Next, install spark plug in

cylinder head. T

ighten plug to 15 ft–lb (20.4 N

m).

110

Figure 30

4. Push

the wire onto the spark plug (Fig. 29).

Storage

1. PREP

ARE THE FUEL SYSTEM:

Note:

A fuel stabilizer/conditioner is most ef

fective when

mixed with fresh gasoline.

•

Add Lawn-Boy 2+4

r

Fuel Conditioner to the fuel

tank. Refer to fuel conditioner bottle for instructions.

•

Run engine for ten minutes to distribute conditioned

fuel through fuel system.

•

Stop engine, allow it to cool, and drain fuel tank.

•

Restart the engine again and run it until it stops.

•

Either choke or prime the engine, restart it a third

time and run engine until it will not restart.

•

Dispose of fuel properly

. Recycle per local codes.

•

DO NOT stor

e ST

ABILIZED gasoline over 90 days.

2.

Remove spark plug from cylinder head. Next, pour

two teaspoons of engine oil into spark plug hole in

cylinder head. Install spark plug in cylinder head, but

do not install wire on the plug. Then pull recoil starter

slowly to distribute oil on inside of cylinder

.

3.

Lubricate the snowthrower: refer to Lubricating

Snowthrower

, page 15. Change crankcase oil: see

Changing Crankcase Oil, page 15.

4.

Clean the snowthrower

. T

ouch up chipped surfaces

with paint. Sand af

fected areas before painting, and

use a rust preventative to prevent metal parts from

rusting.

5. T

ighten all screws and nuts. If any part is damaged,

repair or replace it.

6. ST

ORE SNOWTHROWER—Cover snowthrower and

store in a clean, dry place out of the reach of children.

NEVER ST

ORE SNOWTHROWER IN HOUSE

(LIVING AREA) OR BASEMENT WHERE

IGNITION SOURCES MA

Y BE PRESENT SUCH

AS HOT W

A

TER AND SP

ACE HEA

TERS,

CLOTHES DR

YERS, AND THE LIKE

BECAUSE

GASOLINE AND FUMES ARE HIGHL

Y

FLAMMABLE, EXPLOSIVE, AND DANGEROUS

IF INHALED.

Allow engine to cool before storing in

any enclosure.

If you have a general understanding of internal combustion engines and wish to repair and service your engine yourself,

refer to the W

arranty and Repair section in your engine owner

’

s manual for information on how to obtain a “MECHANICS

HANDBOOK” from T

ecumseh Products Company

.

Rev. 6/18/97

What Is Covered By This Express Warranty?

LawnĆBoy Inc. promises to repair any LawnĆBoy

snowthrower used for residential purposes if defective

in materials or workmanship for a period of two years

from the date of purchase. Products used for commerĆ

cial, rental or institutional use are warranted for a periĆ

od of 45 days from the date of purchase. he cost of

parts and labor are included. ransportation within a

15 mile radius of the servicing dealer is covered for

twoĆstage snowthrowers. Single stage snowthrowers

are excluded from the transportation coverage proĆ

vided by this warranty.

How Do You Get Warranty Service?

Should you feel your LawnĆBoy product contains a deĆ

fect in materials or workmanship, contact the dealer

who sold you the product or any Authorized LawnĆBoy

Service Dealer. he Yellow Pages of your telephone diĆ

rectory is a good reference source. he dealer will eiĆ

ther arrange service at his/her dealership or recomĆ

mend another Authorized Service Dealer who may be

more convenient. You may need proof of purchase

(copy of registration card, sales receipt, etc.) for warĆ

ranty validation.

If for any reason you are dissatisfied with the Service

Dealer's analysis of the defect in materials or workĆ

manship or if you need a referral to a LawnĆBoy SerĆ

vice Dealer, please feel free to contact us at the followĆ

ing address:

LawnĆBoy Customer Service Department

8111 Lyndale Avenue South

Bloomington, MN 55420-1196

612-888-8801

800-526-6937

What Must You Do To Keep The Warranty

In Effect?

You must maintain your LawnĆBoy Product by followĆ

ing the maintenance procedures described in the opĆ

erator's manual. Such routine maintenance, whether

performed by a dealer or by you, is at your expense.

A TWO YEAR FULL WARRANTY

Snowthrowers

What Does This Warranty Not Cover?

and

How Does Your State Law Relate To This

Warranty?

here is no other express warranty except for special

emission system coverage on some products. his

express warranty does not cover:

DCost of regular maintenance service or parts,

such as filters, fuel, lubricants, and tuneĆup

parts.

DAny product or part which has been altered or

misused or required replacement or repair due

to normal wear, accidents, or lack of proper

maintenance.

DRepairs necessary due to improper fuel, conĆ

taminants in the fuel system, or failure to proĆ

perly prepare the fuel system prior to any periĆ

od of nonĆuse over three months.

All repairs covered by this warranty must be perĆ

formed by an Authorized LawnĆBoy Service Dealer

using LawnĆBoy approved replacement parts.

LawnĆBoy is not liable for indirect, incidental or

consequential dama es relatin to a breach of

this warranty, includin any cost or expense of

providin substitute equipment or service durĆ

in reasonable periods of malfunction or non-

use pendin completion of repairs under this

warranty. Some states do not allow exclusions

of incidental or consequential dama es, so the

above exclusion may not apply to you.

This warranty ives you specific le al ri hts,

and you may also have other ri hts which vary

from state to state.

Customers who have purchased LAWNĆBOY products exported from the United States or Canada should contact their

LAWNĆBOY Distributor (Dealer) to obtain guarantee policies for your country, province, or state. If for any reason you

are dissatisfied with your Distributor's service or have difficulty obtaining guarantee information, contact the LAWNĆBOY

importer. If all other remedies fail, you may contact us at LawnĆBoy Inc.

COUNTRIES OTHER THAN THE UNITED STATES OR CANADA

This manual suits for next models

1

Table of contents

Other Lawn-Boy Snow Blower manuals