Lawn-Boy 63600 User manual

Operator’s Manual

Original Instructions (EN)

Register your product at www.lawnboy.com

Form No. 3353-338 Rev A

48in Snow Blade

Precision Series Riding Mowers

Model No. 63600—Serial No. 250000001 and Up

2

W2005 by Lawn-Boy Inc.

8111 Lyndale Avenue South

Bloomington, MN 55420-1196

Contact us at www.lawnboy.com

All Rights Reserved

Printed in the USA

Contents

Page

Introduction 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Loose Parts 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removing the Mower 4. . . . . . . . . . . . . . . . . . . . .

Assembling the Blade 4. . . . . . . . . . . . . . . . . . . . .

Preparing the Machine 6. . . . . . . . . . . . . . . . . . . . .

Installing the Extension Spring 6. . . . . . . . . . . . . .

Installing the Snow Blade 8. . . . . . . . . . . . . . . . . .

Operation 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Lowering and Raising the Blade 10. . . . . . . . . . . . .

Adjusting the Blade Angle 10. . . . . . . . . . . . . . . . . .

Setting the Blade Height 11. . . . . . . . . . . . . . . . . . .

Adjusting the Blade Trip Springs 11. . . . . . . . . . . .

Tips for Using the Blade 11. . . . . . . . . . . . . . . . . . .

Maintenance 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Recommended Maintenance Schedule 12. . . . . . . .

Greasing and Lubricating the Blade 12. . . . . . . . . .

Reversing the Scraper 13. . . . . . . . . . . . . . . . . . . . .

Removing the Blade 13. . . . . . . . . . . . . . . . . . . . . . .

Storing the Blade 15. . . . . . . . . . . . . . . . . . . . . . . . .

Introduction

Read this manual carefully to learn how to operate and

maintain your product properly. The information in this

manual can help you and others avoid injury and product

damage. Although Lawn-Boy designs and produces safe

products, you are responsible for operating the product

properly and safely.

Whenever you need service, genuine Lawn-Boy parts, or

additional information, contact an Authorized Service

Dealer or Lawn-Boy Customer Service and have the

model and serial numbers of your product ready. Figure 1

illustrates the location of the model and serial numbers on

the product.

m–7049 1

Figure 1

1. Location of the model and serial numbers

Write the product model and serial numbers in the space

below:

Model No.

Serial No.

This manual identifies potential hazards and has special

safety messages that help you and others avoid personal

injury and even death. Danger, Warning, and Caution are

signal words used to identify the level of hazard.

However, regardless of the hazard, be extremely careful.

Danger signals an extreme hazard that will cause serious

injury or death if you do not follow the recommended

precautions.

Warning signals a hazard that may cause serious injury or

death if you do not follow the recommended precautions.

Caution signals a hazard that may cause minor or

moderate injury if you do not follow the recommended

precautions.

This manual uses two other words to highlight

information. Important calls attention to special

mechanical information and Note: emphasizes general

information worthy of special attention.

3

Installation

Note: Determine the left and right sides of the machine from the normal operating position of the machine.

Note: Some parts will not be used on all machines.

Loose Parts

Description Qty. Use

Blade assembly

Rod

Cotter pin, 1 inch

Skid

Carriage bolt, 3/8 x 1 inch

Flat washer, 3/8 inch

Locknut, 3/8 inch

Frame assembly

Bolt, 3/4 x 3-3/4 inch

Locknut, 3/4 inch

Index lever

Bolt, 1/4 x 2 inch

Locknut, 1/4 inch

Cotter pin, 1-1/4 inch

1

1

2

2

4

4

4

1

1

1

1

1

1

1

Assembling the blade

Lift arm

Bolt , 5/16 x 3/4 inch

Nut, 5/16 inch

1

4

4

Preparing the machine

Support rod bracket

Front spring mount

Bolt, 3/8 x 1-1/4 inch

Extension spring

Rear spring mount

Bolt, 1/4 x 3/4 inch

Locknut, 1/4 inch

1

1

2

1

1

1

1

Installing the extension spring1

Side plate

Bolt, 3/8 x 1 inch

Flat washer, 3/8 inch

Flange nut, 3/8 inch

Lift mount assembly

Lift rod

Clevis pin

Cotter pin, 3/4 inch

Shoulder bolt,

2

6

3

7

1

1

1

2

1

Installing the snow blade

4

Description UseQty.

Operator’s manual 1Read before installing the snow blade

Registration card 1Fill out and return to Lawn-Boy

1Parts not used on machines with Model number 81250.

Removing the Mower

Note: Retain all parts for installing the mower on the

machine in the future.

1. Park the machine on a level surface and disengage the

blade control (PTO).

2. Move the motion control levers to the brake position,

stop the engine, remove the key, and wait for all

moving parts to stop before leaving the operating

position.

3. Lower the height-of-cut lever to the lowest position.

4. Remove the hairpin cotter and clevis pin from the

front support rod on each side of the mower (Fig. 2).

m–6431

1

2

Figure 2

1. Hairpin cotter and clevis

pin

2. Support rod

5. Remove the nuts on support rods in the front and then

remove them by guiding them out of the machine from

the back.

6. Remove the hairpin cotter and washer from the

adjusting rod (Fig. 3) on each side of the mower.

Note: Some machines leveling bracket may have a

different orientation than depicted in Figure . Make sure to

note the orientation of the bracket for your machine and

apply it when installing the mower deck. Refer to your

Operator’s Manual for more information.

m–6432

2

1

2

3

Figure 3

1. Leveling bracket

2. Hairpin cotter and washer

3. Adjusting rod

7. Remove the hairpin cotter and washer at the mower

leveling brackets (Fig. 3) on each side of the mower.

8. Slide the brackets off of the mounting pin.

9. Slide the mower rearward and remove the mower belt

from the engine pulley.

10. Slide the mower out from underneath the tractor.

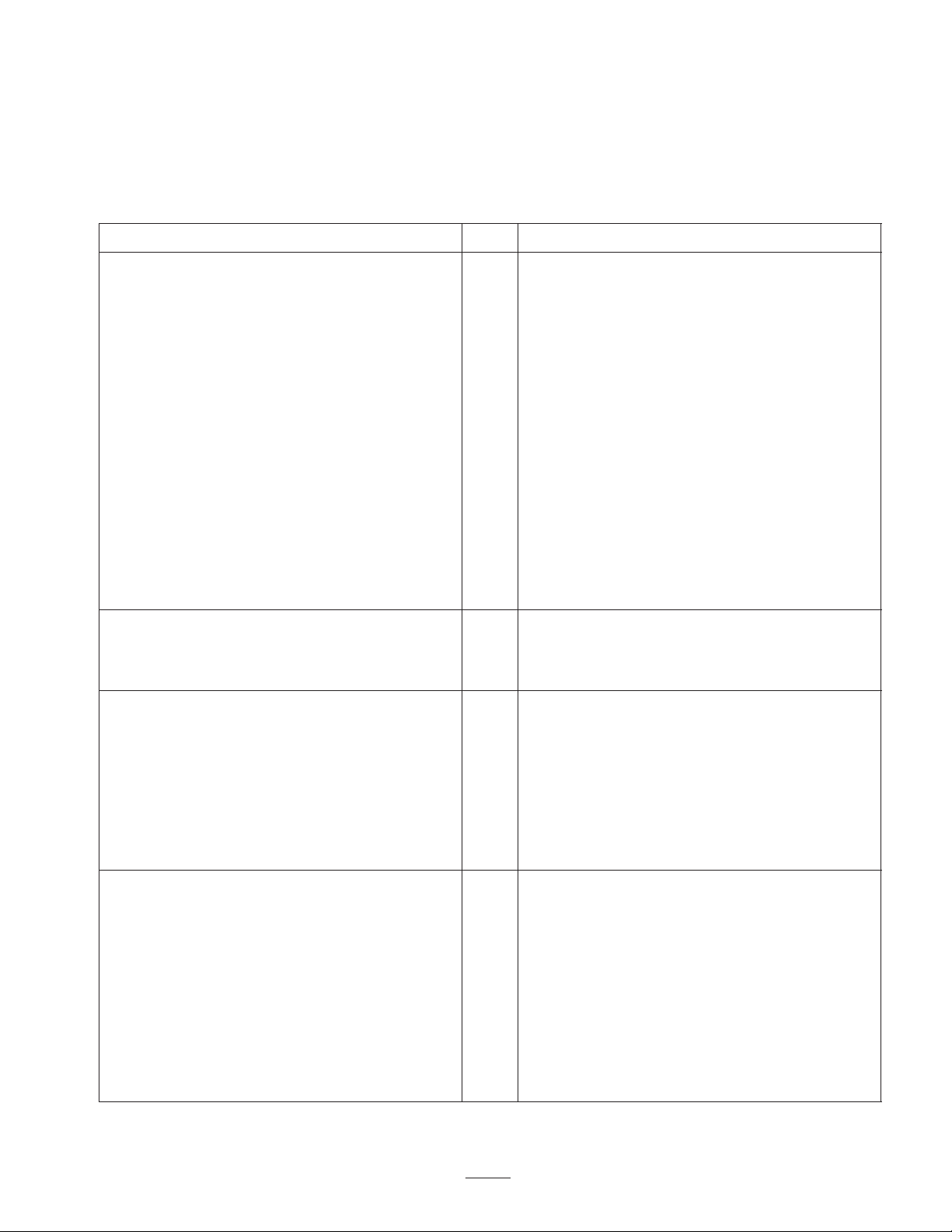

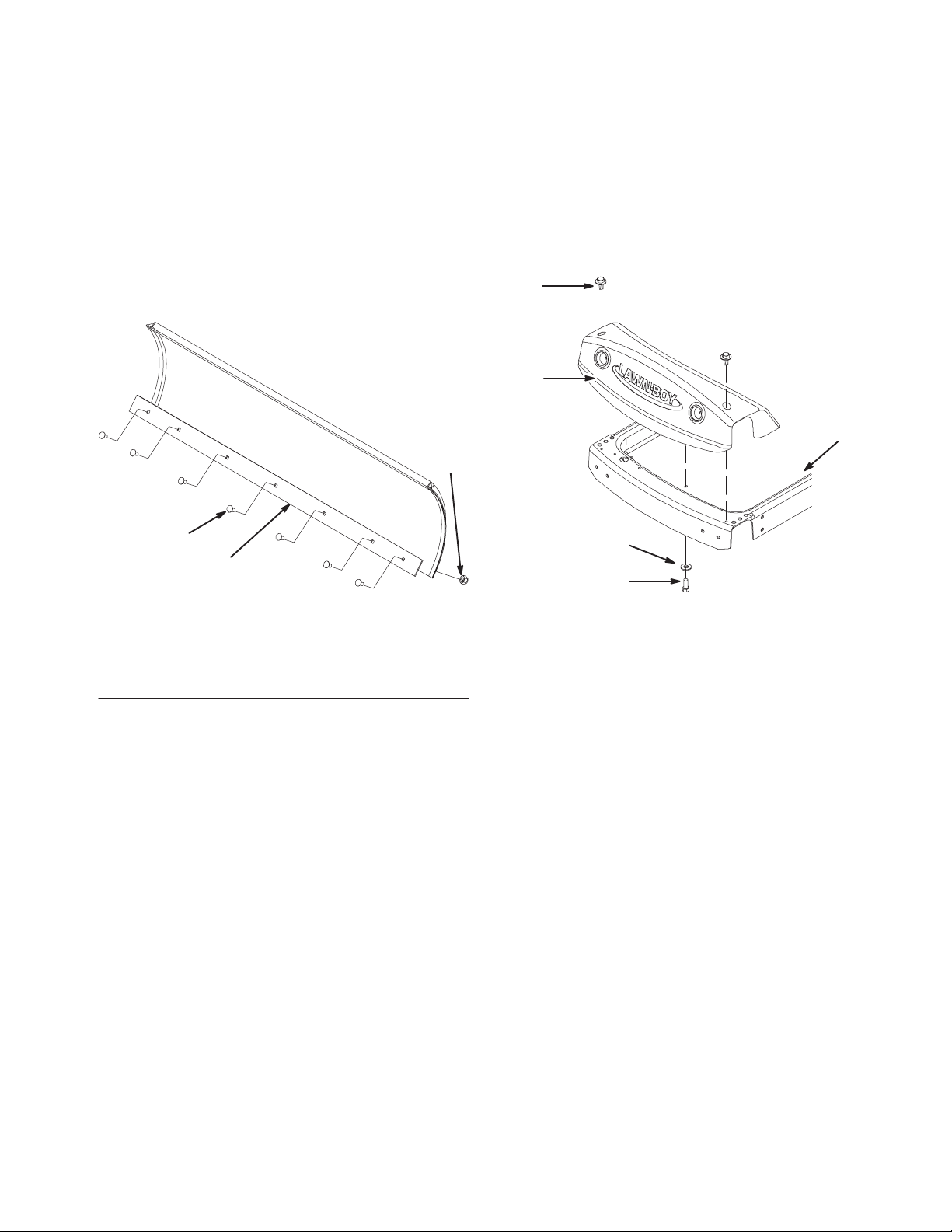

Assembling the Blade

1. Lift and rotate the channel assembly (Fig. 4) so that

the holes align with the lower blade mounts.

2. Slide the rod through the holes and secure it with two

cotter pins (1 inch) (Fig. 4).

5

m–3269

1

3

2

3

4

5

Figure 4

1. Channel assembly

2. Rod

3. Cotter pin, 1 inch

4. Lower blade mounts

5. Upper rod

3. Bend the ends of the cotter pins to secure the rod.

4. Attach the skids to both sides of the blade with 4

carriage bolts (3/8 x 1 inch), flat washers (3/8 inch),

and locknuts (3/8 inch) (Fig. 5).

m–5559

1

2, 3, 4

Figure 5

1. Skid

2. Carriage bolt, 3/8 x 1 inch

3. Flat washer, 3/8 inch

4. Locknut, 3/8 inch

Note: Use the slotted holes to position the skid height

according to what type of surface you will be plowing.

Position the skids lower for plowing rough surfaces or

higher for plowing smoother surfaces.

5. Apply a general purpose grease to the pivot area of the

frame and channel (Fig. 6).

6. Slide the blade channel assembly between the frame

mount and secure it with a bolt (3/4 x 3-3/4 inch) and

locknut (3/4 inch) (Fig. 6).

Note: Do not tighten the nut and bolt excessively; this

avoids binding on the channel weldment as it pivots from

side to side.

m–5567

12

3

4

5

6

7

8

Figure 6

1. Channel assembly

2. Grease here

3. Bolt, 3/4 x 3-3/4 inch

4. Locknut, 3/4 inch

5. Index lever

6. Bolt, 1/4 x 2 inch

7. Locknut, 1/4 inch

8. Cotter pin, 1-1/4 inch

7. Attach the index lever to the frame assembly with a

bolt (1/4 x 2 inch) and locknut (1/4 inch) (Fig. 6).

8. Connect the index lever to the angle pin with a cotter

pin (1-1/4 inch) (Fig. 6).

9. Bend the end of the cotter pin to secure the lever.

6

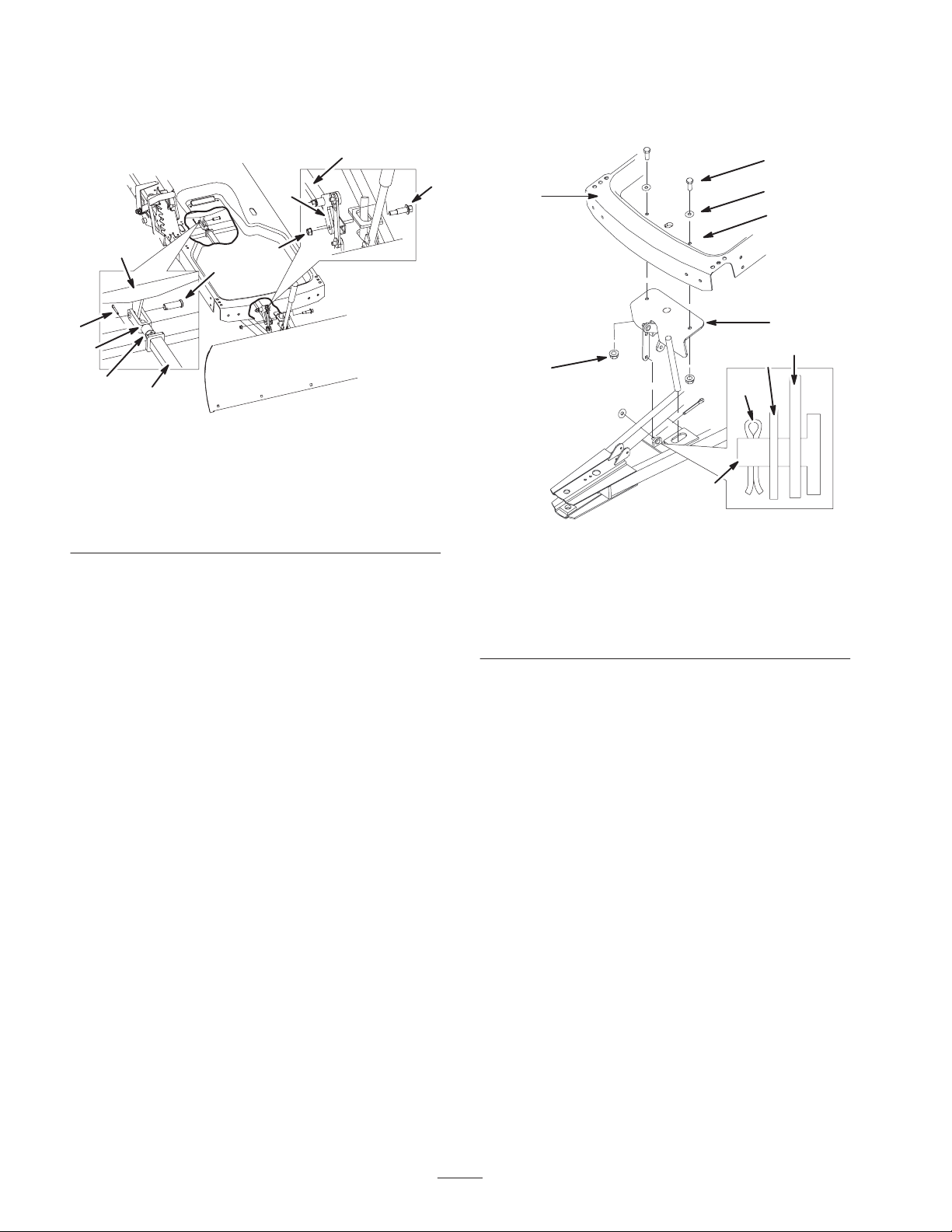

Preparing the Machine

1. Move the lift lever into the lowest position to install

the lift arm (Fig. 7).

1

Figure 7

1. Lift lever

2. Attach the lift arm to the the machine lift arm

assembly using 4 bolts (5/16 x 3/4 inch) and 4 nuts

(5/16 inch) as shown in figure 8. The nuts are to be

installed on the outside to prevent interference when

operating the blade.

2

1

3

4

m–8193

Figure 8

1. Lift arm

2. Bolts, 5/16 x 3/4 inch

3. Locknuts, 5/16 inch

4. Lift lever

Installing the Extension Spring

Note: Machines with Model number 81250 have an

extension spring assembly installed and therefore the

following procedure does not need to be performed.

Please move ahead to Installing the Snow Blade on

page 8.

1. Locate the support rod securing the right side cover to

the machine frame.

2. Remove the screw securing the support rod to the right

side cover.

3. Remove the support rod and retain all parts.

m–8194

1

2

3

Figure 9

1. Right side cover

2. Support rod

3. Screw

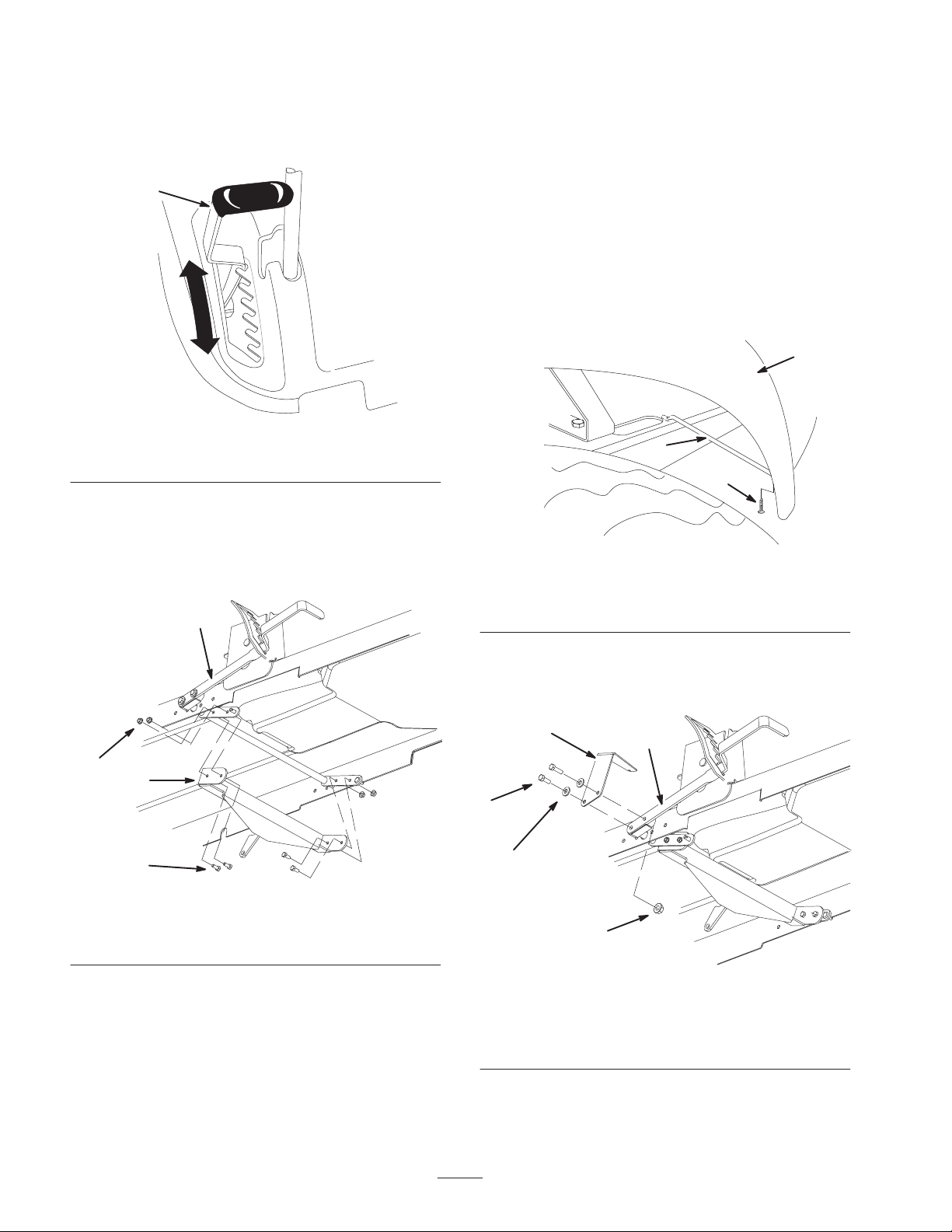

4. Remove the 2 bolts, 2 washers, and nut connecting the

lever to the lift block. Discard the 2 bolts and retain

the washers and locknut.

5

2

3

1

m–8195

4

Figure 10

1. Lift arm

2. Bolt, 3/8 x 1-1/4 inch

3. Washer

4. Locknut

5. Front spring mount

5. Attach the front spring mount to the lift lever using 2

bolts (3/8 x 1-1/4 inch) and the washers and locknut

removed in step 4 (Fig. 10).

7

6. Lift the seat forward to access the interior of the

machine.

7. Remove the bolt and locknut securing right side of the

seat brace to the frame. Retain all fasteners

8. Install the support rod bracket over the hole in the seat

brace. Secure the bracket and brace to the frame using

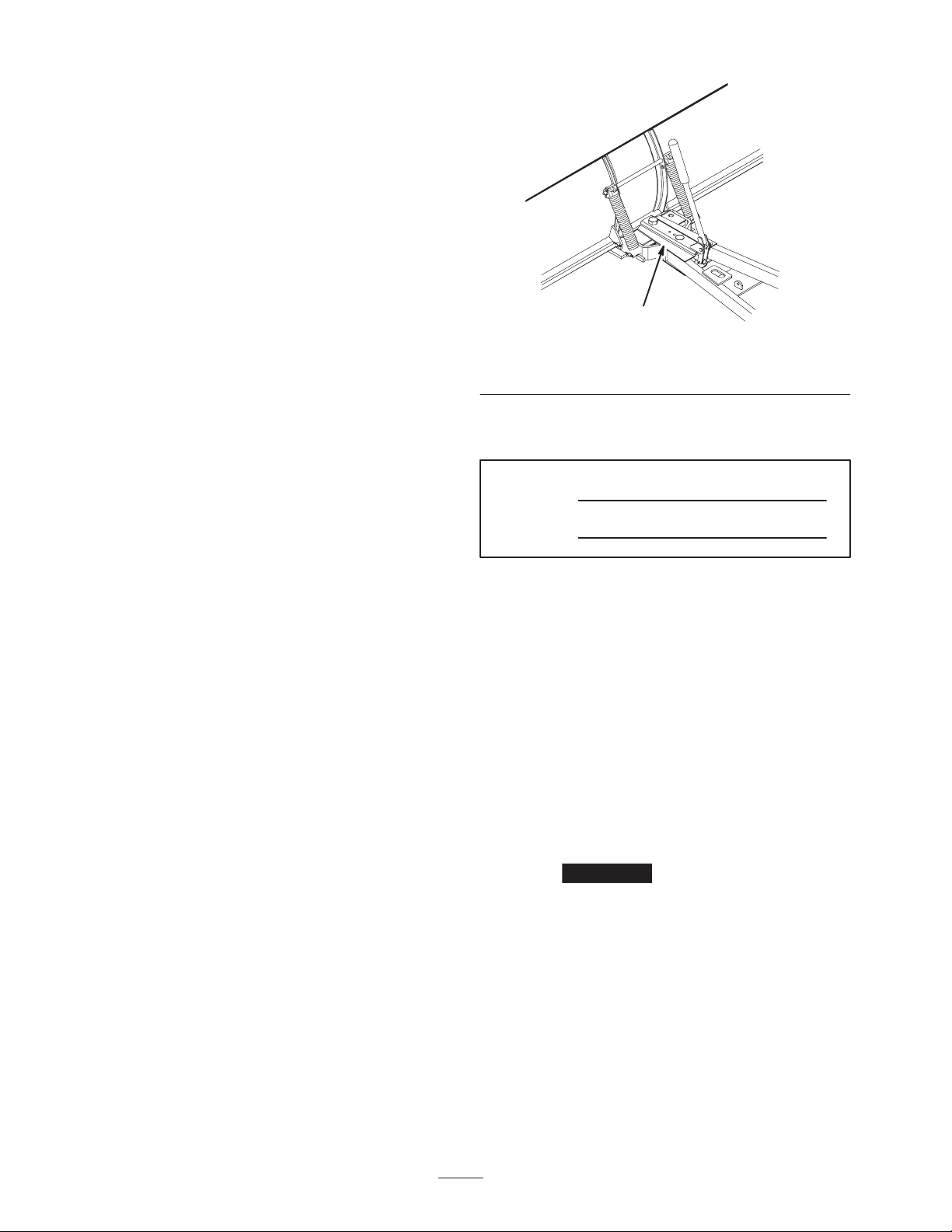

the bolt and locknut removed previously (Fig. 11).

1

2

3

4

m–8196

Figure 11

1. Bolt

2. Bracket

3. Seat brace

4. Locknut

9. Install the support rod into the support rod bracket as

shown in Figure 12.

Note: The orientation of the Z bend in the support rod has

flipped to accommodate the new support rod bracket.

10. Secure the rod to the right side cover using the screw

removed previously.

m–8197

1

2

3

5

4

Figure 12

1. Right side cover

2. Support rod

3. Screw

4. Z bend, flipped orientation

5. Front spring mount

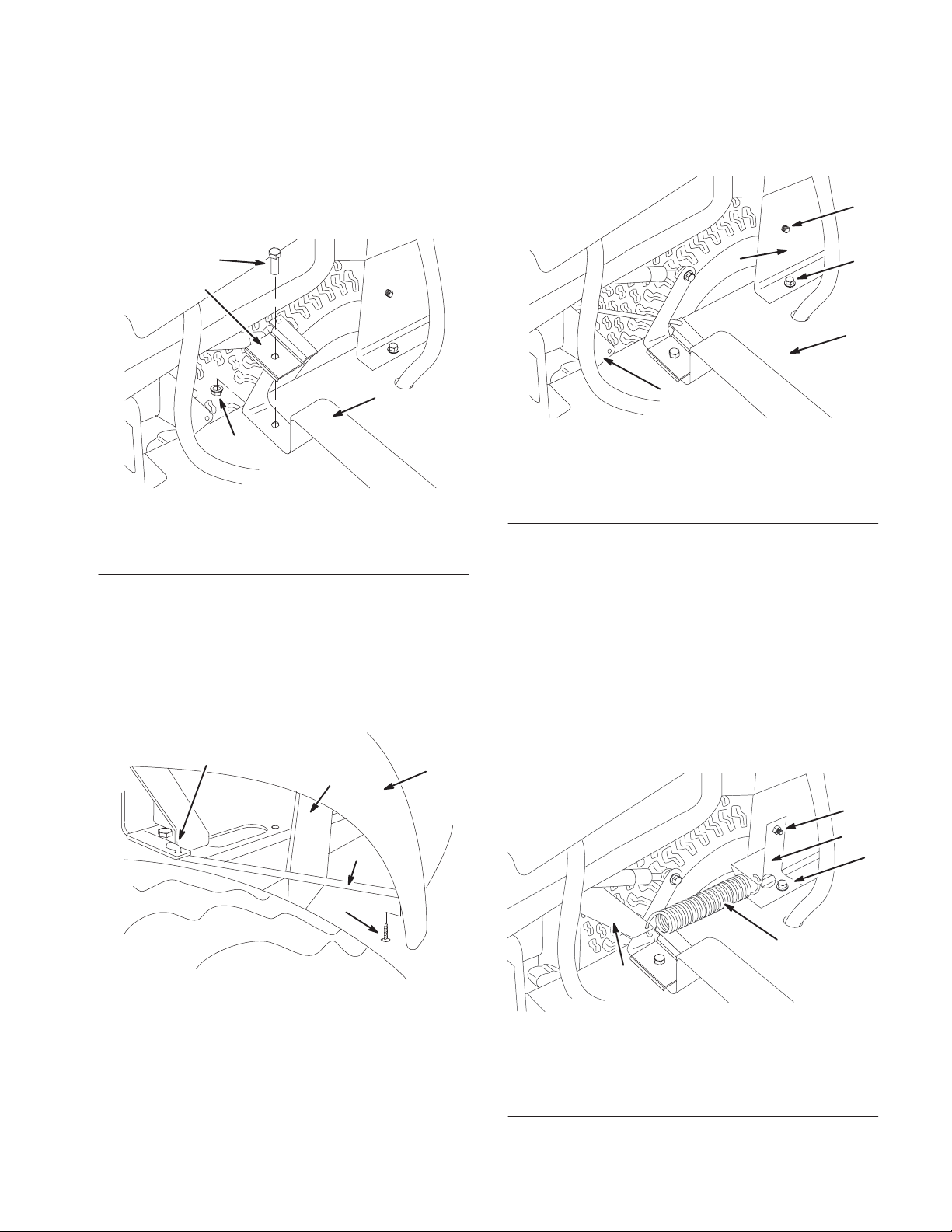

11. Remove the front bolt and nut in the base of the gas

tank plate (Fig. 13). Retain these fasteners.

12. Remove the upper screw in the gas tank plate and

discard (Fig. 13).

3

4

5

1

2

m–8198

Figure 13

1. Tractor frame

2. Gas tank plate

3. Front bolt

4. Upper screw

5. Front spring mount

13. Install the rear spring mount to the gas tank plate using

the front bolt removed in step 11 (Fig. 14).

14. Secure the rear spring mount to the gas tank plate

using a bolt (1/4 x 3/4 inch) and locknut (1/4 inch)

(Fig. 14).

15. Raise the lift lever to the highest possible position.

16. Attach one end of the spring to the front spring mount

and the other to the rear spring mount (Fig. 14).

Note: This will require the spring to be partially extended

during this step.

5, 6

1

2

3

4

m–8199

Figure 14

1. Rear spring mount

2. Spring

3. Front spring mount

4. Front bolt

5. Bolt, 1/4 x 3/4 inch

6. Locknut, 1/4 inch

8

17. Lower the seat back into position.

Installing the Snow Blade

1. Attach a side plate to the right side of the machine

frame using 2 bolts (3/8 x 1 inch) and 2 flange nuts

(3/8 inch) (Fig. 15).

Note: Torque the side plate bolts to 30 ft.-lb. (41 N⋅m).

m–7044

1

2

3

4

Figure 15

1. Side plate

2. Bolt, 3/8 x 1 inch

3. Flange nut, 3/8 inch

4. Tractor frame

2. Lift the blade assembly off the ground and slide the

frame assembly beneath the machine as depicted by

the arrows shown in figure 16.

m–8174

1

2

4

3

Figure 16

1. Lift the blade assembly

2. Slide the frame assembly

under the tractor

3. Snow blade assembly

4. Rear shaft

Note: The snow blade is in position when the rear shaft of

the frame assembly has moved past the lift arm and is

lined up with the hole in the side plate.

3. Lift the rear shaft of the frame assembly up and into

the side plate hole (Fig. 17).

m–7046

1

2

Figure 17

1. Rear shaft 2. Side plate hole

4. Install the other side plate on the left side of the unit

over the rear shaft using 2 bolts (3/8 x 1 inch) and 2

flange nuts (3/8 inch).

Note: Torque the side plate bolts to 30 ft.-lb. (41 N⋅m).

5. Remove 2 bolts (1/4 inch), securing the foot plate to

the frame (Fig. 18). Remove the bolt and washer from

under the foot rest. Retain all fasteners.

m–8175

3

1

2

4

5

Figure 18

1. Foot rest

2. Frame

3. Bolt (1/4–20 inch)

4. Washer

5. Bolt (1/4–10 inch)

6. Remove the foot plate to access the existing holes in

the machine frame (Fig. 19).

9

m–8176

5

2

4

6

1

3

10 7

8

9

Figure 19

1. Existing hole

2. Bolt, 3/8 x 1 inch

3. Washer, 3/8 inch

4. Flange nut, 3/8 inch

5. Tractor frame

6. Lift mount assembly

7. Lift link

8. Frame assembly post

9. Cotter pin, 3/4 inch

10. Washer, 3/8 inch

7. Install the lift mount assembly using 2 bolts

(3/8 x 1 inch), 2 washers (3/8 inch) and 2 flange nuts

(3/8 inch) as shown in figure 19.

Note: Move the lift mount assembly into position from the

side of the unit in order to install it in the correct

orientation.

8. Place the link lift over the frame assembly post and

use a washer (3/8 inch) and cotter pin (3/4 inch) to

hold it in place (Fig. 19).

9. Bend the end of the cotter pin to secure the lift link.

Connecting the Lift Rod

1. Move the lift rod into position beneath the machine

and above the frame assembly (Fig. 20).

m–7048

1

7

5

1

3

4

9

8

2

6

Figure 20

1. Lift rod

2. Shoulder bolt

3. Flange nut

4. Pivot arm

5. Lift arm

6. Clevis pin

7. Cotter pin, (3/4 inch)

8. Yoke

9. Jam nut

2. Attach the lift rod to the pivot arm of the lift mount

using the shoulder bolt and flange nut (3/8 inch) as

shown in figure 20.

3. Line up the holes in the lift rod yoke and the lift arm

(Fig. 20).

Note: If needed, adjust the length of the lift rod arm by

loosening the jam nut and turn the yoke to either lengthen

or shorten the lift rod.

4. Set the blade height to ensure the full range of motion

with the lift lever. See Setting the Blade Height on

page 11.

5. Install the lift rod to the lift arm using a clevis pin and

cotter pin (3/4 inch) as shown in figure 20.

6. Bend the ends of the cotter pins to secure the clevis

pin.

7. Replace the foot plate with the fasteners removed

previously (Fig. 18).

10

Operation

Important This snow blade should be used for

plowing snow only.

If you hit fixed objects with the blade, the

machine could stop abruptly, causing you to lose

control, sustain personal injury, and equipment

damage.

•Travel at a safe, slow speed.

•Check the area to be plowed and mark all fixed

objects so that you can avoid them.

Caution

Lowering and Raising the

Blade

Use the lift lever to lower and raise the blade (Fig. 21).

To rest the blade on the ground, put the lift lever in the

lowest position.

1

Figure 21

1. Lift lever

Note: Raise the lift lever to highest position when

transporting the blade.

Adjusting the Blade Angle

There are five positions for the side to side angle of the

blade. To change the blade angle, perform the following

procedure:

1. Raise the blade.

2. Push the index lever forward with one hand (Fig. 22)

while positioning the blade with the other hand until

you have reached the desired blade angle.

3. Release the index lever.

Note: The angle pin must snap into the hole in the channel

to retain the blade position.

1

m–5566

Figure 22

1. Index lever

11

Setting the Blade Height

Set the operating height using the following procedure.

1. Move the lift lever into the second lowest position.

2. Remove the cotter pin and clevis pin attaching the lift

rod to the lift arm.

3. Move the lift rod down and out of the lift arm so that

the yoke can turn freely (Fig. 23) and loosen the jam

nut.

m–7052

1

3

2

4

Figure 23

1. Lift rod

2. Lift arm

3. Yoke

4. Jam nut

4. Move lift rod forward as far as possible and hold it in

that position (Fig. 23).

5. Turn the yoke to adjust the length of the lift rod

(Fig. 23). The lift rod is in position when the holes in

the yoke line up with the lift arm.

6. Install the lift rod to lift arm using the clevis pin and

cotter pin removed previously.

7. Bend the end of the cotter pin to secure the clevis pin.

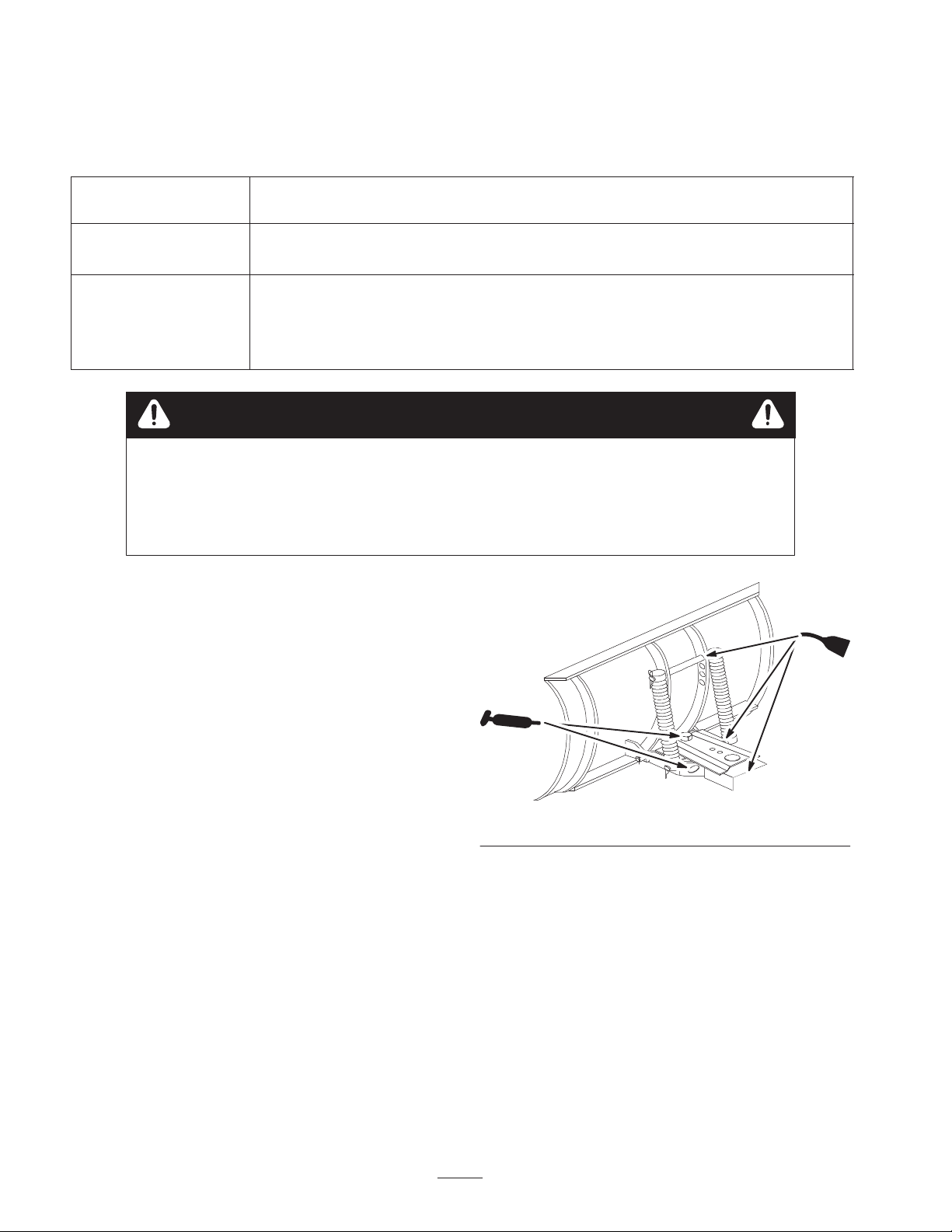

Adjusting the Blade Trip

Springs

The blade trip springs can be mounted in four positions.

The top hole provides the greatest scraping pressure and

the bottom hole provides the least scraping pressure

(Fig. 24).

1. Remove the hairpin cotter and slide the rod from the

blade and springs (Fig. 24).

2. Slide the rod through the springs and the new hole

position in the blade (Fig. 24).

m–3395

1

2

3

4

Figure 24

1. Hairpin cotter

2. Rod

3. Spring

4. Top hole

Tips for Using the Blade

To obtain the best possible results with your blade, follow

these tips:

•Remove snow as soon as possible after it falls.

•Remove snow from a driveway by making one pass

down the center and then plowing snow to either side

on successive passes.

12

Maintenance

Recommended Maintenance Schedule

Maintenance Service

Interval Maintenance Procedure

25 hours

•Grease the channel pivot.

•Oil the linkages.

Yearly/Storage Service

•Grease the channel pivot.

•Oil the linkages.

•Examine the scraper for wear and replace if necessary.

•Paint any chipped surfaces.

Caution

If you leave the key in the ignition switch, someone could accidently start the engine and

seriously injure you or other bystanders.

Remove the key from the ignition and disconnect the wire from the spark plug before you do

any maintenance. Set the wire aside so that it does not accidentally contact the spark plug.

Greasing and Lubricating the

Blade

Grease and oil the blade after every 25 operating hours or

once a year, whichever occurs first.

Grease type: general-purpose grease

Oil type: SAE 10W or 10W30

Greasing the Channel Pivot

1. Lower the blade.

2. Set the parking brake, stop the engine, and remove the

ignition key.

3. Clean the area around the channel pivot with a rag.

Apply grease to the pivot bolt, frame, and channel

indexing holes (Fig. 25).

4. Wipe off excess grease.

m–1473

Figure 25

Oiling the Linkages

1. Set the parking brake, stop the engine, and remove the

ignition key.

2. Place a few drops of oil on all movable linkages

(Fig. 25).

3. Wipe off excess oil.

13

Reversing the Scraper

Periodically inspect the scraper blade for wear. Reverse

the scraper blade when it becomes worn and before the

working surface contacts the housing.

1. Raise the blade and support the housing off of the

ground.

2. Remove the carriage bolts and locknuts securing the

scraper (Fig. 26).

3. Reverse the scraper and install it with the previously

removed hardware (Fig. 26).

m–5568

1

2

3

Figure 26

1. Scraper

2. Carriage bolt

3. Locknuts

Removing the Blade

Note: Retain all parts for installing the snow blade on the

machine in the future.

1. Move the lift lever into the lowest position to remove

the blade.

2. Remove 2 bolts (1/4 inch), securing the foot plate to

the frame (Fig. 27). Remove the bolt and washer from

under the foot rest. Retain all fasteners.

m–8175

3

1

2

4

5

Figure 27

1. Foot rest

2. Frame

3. Bolt (1/4–20 inch)

4. Washer

5. Bolt (1/4–10 inch)

3. Remove the foot plate to access the existing holes in

the machine frame (Fig. 27).

14

4. Remove the shoulder bolt and flange nut (3/8 inch)

attaching the lift rod to the pivot arm of the lift mount

as shown in figure 28.

m–7048

1

7

5

1

3

4

9

8

2

6

Figure 28

1. Lift rod

2. Shoulder bolt

3. Flange nut

4. Pivot arm

5. Lift arm

6. Clevis pin

7. Cotter pin, (3/4 inch)

8. Yoke

9. Jam nut

5. Remove the cotter pin (3/4 inch) and washer (3/8 inch)

securing the lift mount to the frame assembly

(Fig. 29).

6. Remove the clevis pin and cotter pin (3/4 inch)

securing the lift rod to the lift arm (Fig. 28).

7. Remove the lift rod from the machine.

8. Remove the 2 bolts (3/8 x 1 inch), 2 washers (3/8 inch)

and 2 flange nuts (3/8 inch) securing the lift mount

assembly to the tractor frame (Fig. 29).

m–8176

5

2

4

6

1

3

10 7

8

9

Figure 29

1. Existing hole

2. Bolt, 3/8 x 1 inch

3. Washer, 3/8 inch

4. Flange nut, 3/8 inch

5. Tractor frame

6. Lift mount assembly

7. Lift link

8. Frame assembly post

9. Cotter pin, 3/4 inch

10. Washer, 3/8 inch

9. Remove the lift mount from the machine.

Note: Move the lift mount assembly out of position from

the side of the machine.

10. Remove the 4 bolts (3/8 x 1 inch) and 4 flange nuts

(3/8 inch) securing side plates to the tractor frame.

11. Remove the side plates and lower the frame assembly

to the ground.

12. Remove the 4 bolts (5/16 x 3/4 inch) and 4 nuts

(5/16 inch) securing the lift arm to machine.

13. Remove the lift arm.

14. Slide the snow blade assembly out from under neath

the machine.

15. Replace the foot plate with the fasteners removed

previously.

15

Storing the Blade

1. Before long-term storage, wash the entire blade

assembly with mild detergent and water to remove dirt

and grime.

2. Check the condition of the scraper; refer to Reversing

the Scraper Blade, page 13.

3. Grease and oil the blade; refer to Greasing and

Lubricating the Blade, page 12.

4. Check and tighten all bolts, nuts, and screws. Repair or

replace any part that is damaged.

5. Paint all scratched or bare metal surfaces. Paint is

available from your Authorized Lawn-Boy Dealer.

6. Store the blade in a clean, dry garage or storage area.

7. Cover the machine to protect it and keep it clean.

Table of contents

Other Lawn-Boy Snow Blower manuals