Lit. No. 49513, Rev. 04 June 15, 2022

TABLE OF CONTENTS

Snowplow Owner Data Sheet ...............................3

Preface ..................................................................7

Safety ....................................................................8

Vehicle Application Information...........................15

Ballast Requirements .......................................16

Getting to Know Your Snowplow.........................17

UltraMount®Snowplow ....................................17

Blades ..............................................................18

A‑Frame/T‑Frame, Quadrant & Lift Frame.......19

Straight & WIDE‑OUT Blades.......................19

MVP PLUS Blades........................................19

NIGHTHAWK™ Snowplow Headlamps...........20

Vehicle Mount...................................................21

Cab Controls ................................................... 22

Straight Blade Controls.................................23

MVP PLUS & WIDE‑OUT

Blade Controls.............................................24

Accessories and Options ....................................25

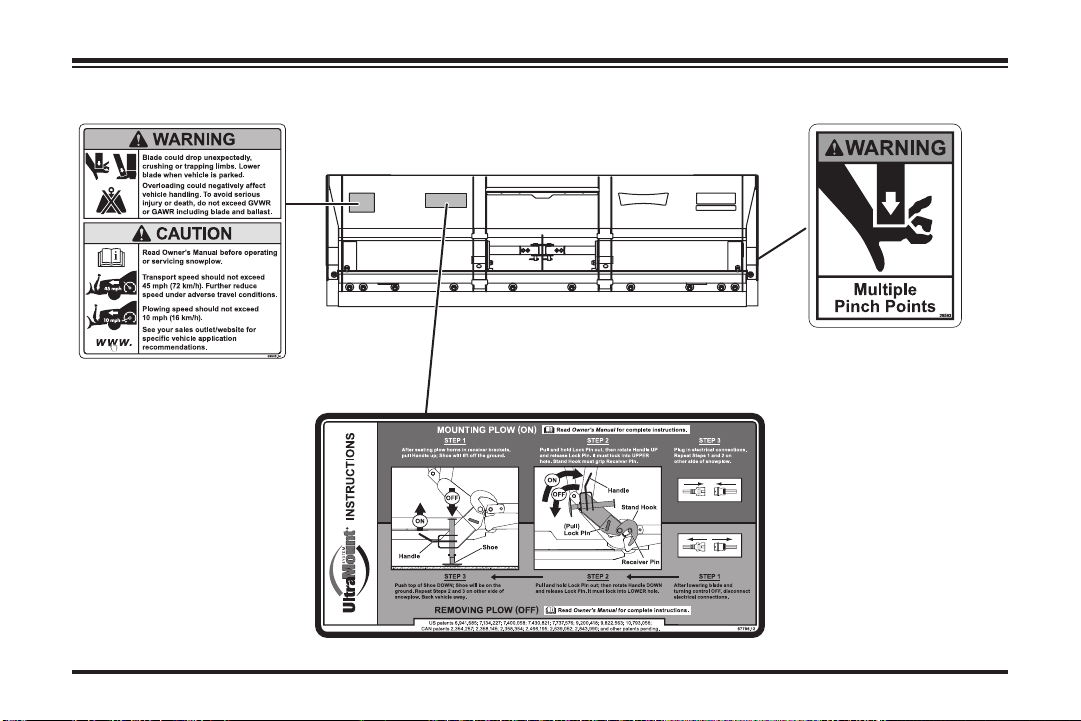

Mounting Snowplow to Vehicle ...........................26

Operating Your Snowplow...................................28

Straight Blade Hand‑Held Control ...................28

Straight Blade Joystick Control ........................31

MVP PLUS & WIDE‑OUT

Hand‑Held Control ........................................ 35

MVP PLUS & WIDE‑OUT

Joystick Control ............................................. 39

FLEET FLEX Electrical System ...................... 44

SECURITY GUARD™ System .................... 45

Smooth Stop .................................................49

One‑Touch FLOAT ....................................... 50

MVP PLUS Blade Positions .............................51

WIDE‑OUT Blade Positions............................ 54

Snowplow Headlamp Check ............................57

Shoe Adjustment............................................. 58

Hydraulic System ............................................ 60

Blade Drop Speed Adjustment.........................61

Transporting the Snowplow............................. 63

Driving and Plowing on Snow and Ice ............ 64

Plowing Snow.................................................. 65

General Instructions..................................... 66

Hard‑Packed Snow.......................................67

Deep Snow ...................................................67

Clearing Driveways ...................................... 68

Clearing Parking Lots .................................. 68

Parking with Snowplow Attached.................... 69

Towing a Disabled or Stuck Vehicle................ 69