18. NEVER STAND ON THE SAW. Serious injury could occur if the saw is tipped or if the

cutting blade is unintentionally contacted.

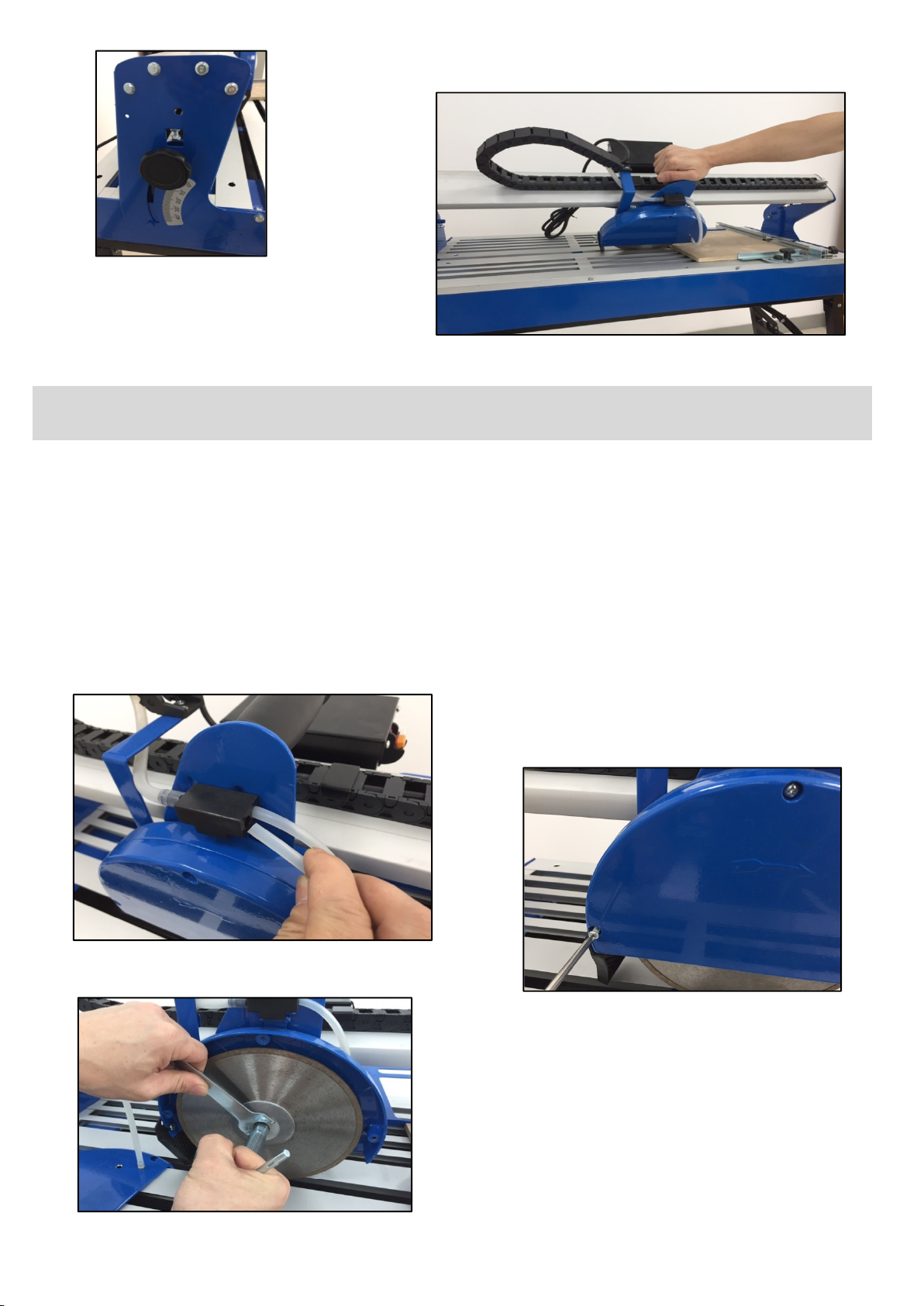

19. CHECK DAMAGED PARTS. Before further use of the saw, the safety guard or any other

part that is damaged should be carefully checked to determine that it will operate

properly and perform its intended funtion. Check for alignment of moving parts,

binding if moving parts, binding of moving parts, breakage of parts, mounting and any

other conditions that may affect its operation. The safety guard or any other part

that is damaged should be properly repaired or replaced.

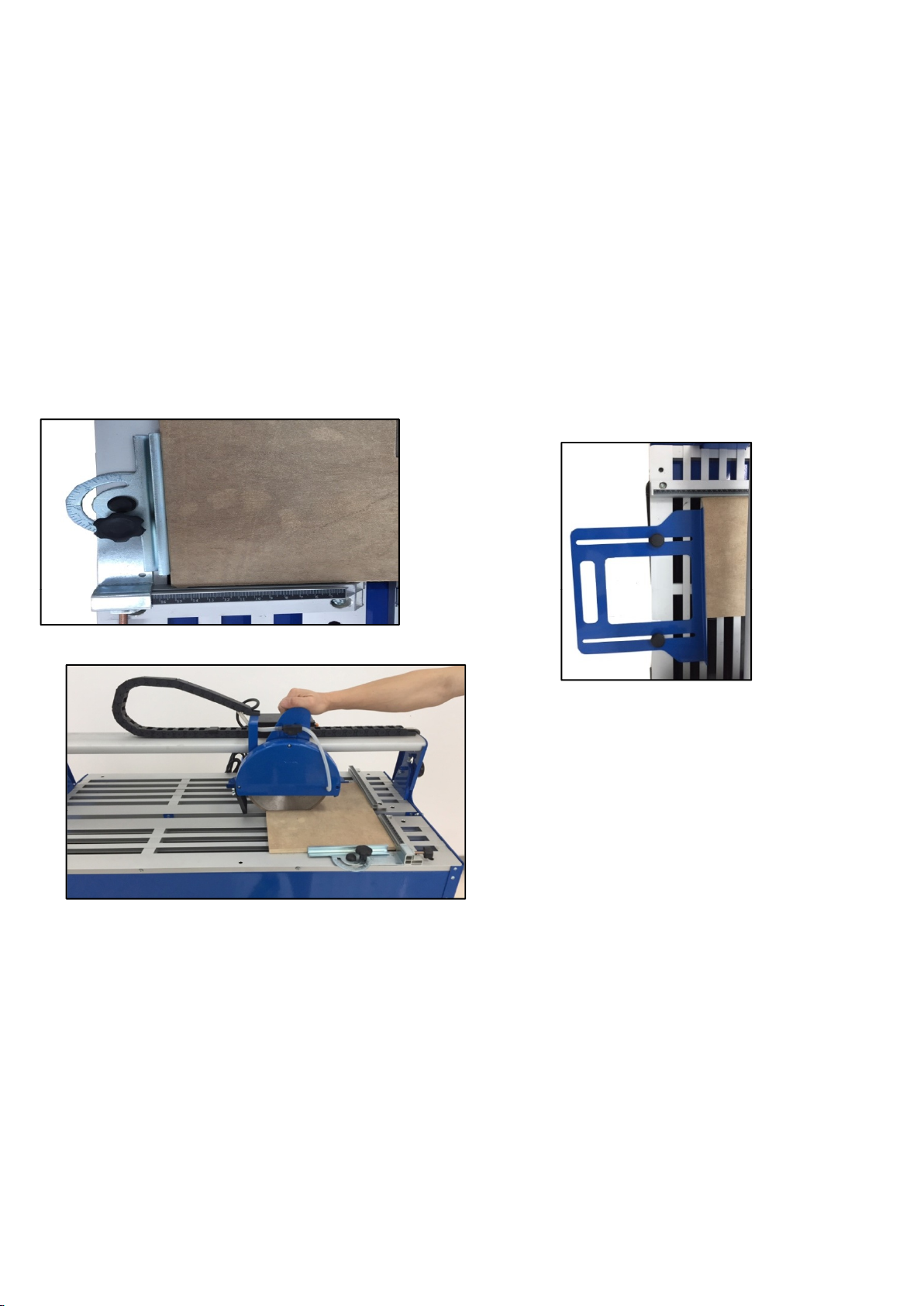

20. DIRECTION OF FEED. Pull the motor trolley towards the materials to be cut.

21. NEVER LEAVE THE SAW RUNNING UNATTENDED. TURN POWER OFF. Do not leave

the saw until it comes to a complete stop.

22. DO NOT use the bridge saw in the prosence of glammable liquids or gases.

23. ALWAYS remove the power cord plug from the electric outlet when making adjusting

changing the parts, cleaning or working on the saw.

24. DO NOT operate the saw if you are under the influence of any drugs, alcohol or

medication that could affect your ability to use the saw properly.

25. WARNING. Dust gengerated from certain materials can be hazardous to your health.

Always operate the saw in well ventilated areas and use a proper dust mask. Use the

dust collection systems wherever possible.

26. NEVER touch the pins of plug while inserting it into the electrical socket.

27. NEVER use the power cord to pull the plug out of the electrical socket.

28. ALWAYS keep the power cord away from sharp objects or any other obstacles that can

28. ALWAYS keep the power cord away from sharp objects or any other obstacles that can

cause damage.

SPECIFIC SAFETY RULES

Read all of the instructions before opearting this bridge saw, and keep them in a safe place

for future reference.

A. GROUD INSTRUCSTION

1. IN THE EVENT OF A MALFUNCTION OR BREAKDWON, grounding provides a path of

least resisdtance for electric current to reduce the risk of electric shock. This saw is equipped

with an electric cord that properly installed and grounded in accordance with all local codes

and ordinances.

2. Do not modigy the plug provided. If it will not fit the outlet, have a proper outlet installed by

a quilified elecrician.

3. improper connection of the grounding conductor can result in a risk of electric shock.

The conductor with insulation having an outer surface that is green with or without yellow

stripes is the grounding conductor. If repair or replacement of the electric cord or

plug is necessary, do not connect the grounding conductor to a live terminal.

4. Check with a qualified electrician or service personnel if the grounding instructions are

not completely understood, or if in doubt as to whether the saw properly grounded.

5. Use only 3-2ire extension cords that have 3-prong grounding plugs and 3-pole receptacles

that accept the saw plug. Repair or replace damaged or worn cords immediately.

6. THIS SAW IS INTENDED FOR USE ON A CIRCUIT that has an outlet that looks like the one

6. THIS SAW IS INTENDED FOR USE ON A CIRCUIT that has an outlet that looks like the one

illustrated in Sketch A of Figure 1. The saw has a ground plug that looks like the plug illustrated

Page 02