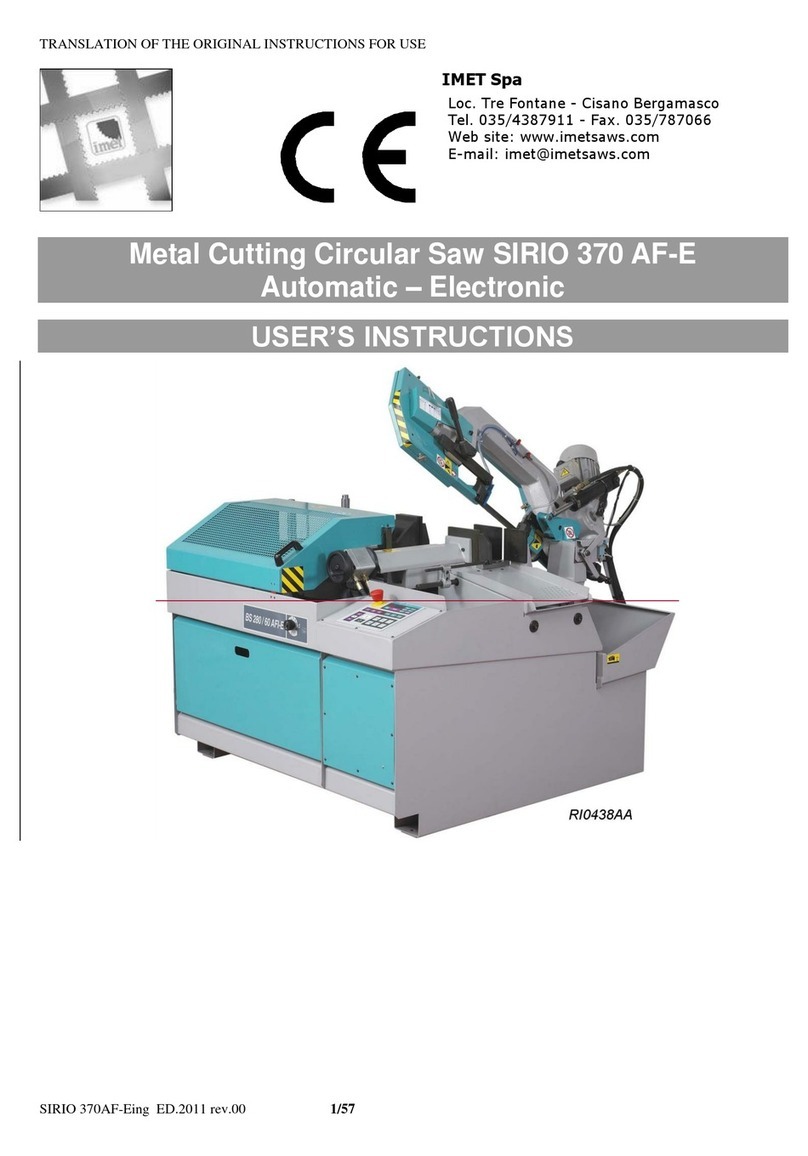

IMET Spa SIRIO 370 AF-NC User manual

TRANSLATION OF THE ORIGINAL INSTRUCTIONS FOR USE

SIRIO 370AF-NCing ED.2010 rev.00 1/81

IMET Spa

Loc. Tre Fontane - Cisano Bergamasco

Tel. 035/4387911 - Fax. 035/787066

Web site: www.imetsaws.com

Metal Cutting Circular Saw SIRIO 370 AF-NC

Automatic –Electronic with Numeric Control

USER’S INSTRUCTIONS

TRANSLATION OF THE ORIGINAL INSTRUCTIONS FOR USE

SIRIO 370AF-NCing ED.2010 rev.00 2/81

TRANSLATION OF THE ORIGINAL INSTRUCTIONS FOR USE

SIRIO 370AF-NCing ED.2010 rev.00 3/81

1

We recommend to read carefully the information here included in order to install, use and maintain correctly and safely

this machine.

Please refer always to this instruction manual in case of assistance service need and keep it carefully for all the machine

life. The reference number in Italy is +39 035 4387918 or +39 035 4397928.

A consequence of the continuous improvement of the product is that some images/descriptions here included could not

correspond to the improved features of the machines.

Your kind collaboration would help us in intevening asap.

In the enclosed Compliance Declaration you will find the Safety and Reference Norms applied during the planning and

construction of this machine.

The choice and the use of the parts have been made by considering the conditions of use and the long machine life.

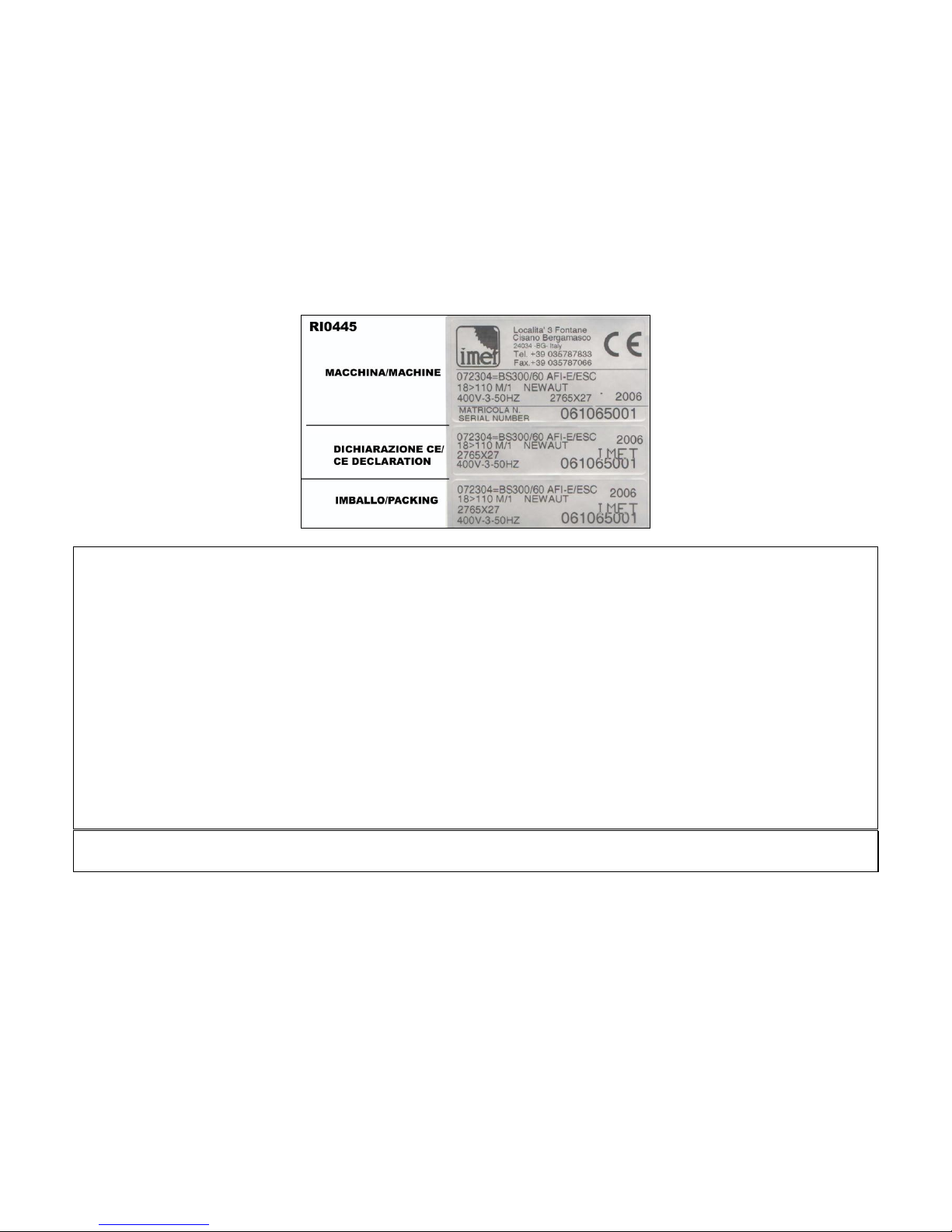

The identification plate, with the serial number, is fixed on the front right angle of the base or on a wall of control box.

1.1 - ATTACHED DOCUMENT FOR E.M.C. ( INDUSTRIAL ENVIRONMENT)

The user is responsible for installation and use of this machine in compliancewith the manifacturer's

instructions shown in this manual. This plant meetsthe protection requirements in accordance with the

Directives 2006/42/EEC,

2004/108/EEC as for electromagnetic compatibility (EMC).

In particular, it follow the technical instructions of the Rules EN55011,EN50082-2 and it has been realized for

industrial and not for household use.

In the event that should be electromagnetic interferences the user is responsible for solving the problem

together with the technical assistance of the manifacturer.

Before installing the machine the user must take into account possible electromagnetic problems of the

working area. In particular, we suggest installing the plant away from:

-signalling, control and telephone cables; -radiotelevision transmitters and receivers;

-computers or controlling and measuring instrument; -safety and protection devices.

The electric supply cable must be kept as short as possible, well right and without wires.

The covers, the door and the frame must be suitably closed when the plant is operating.

Under no circumstances the plant must be modified except for adjusting and changing established by the

manifacturer. Follow the maintenance schedule

TRANSLATION OF THE ORIGINAL INSTRUCTIONS FOR USE

SIRIO 370AF-NCing ED.2010 rev.00 4/81

2

===========================================================================

CE DECLARATION OF CONFORMITY (encl. II A DIR 2006/42/CE) / 02

===========================================================================

THE MANUFACTURER : IMET S.p.A

Località Tre Fontane

24034 - CISANO BERGAMASCO –BG- ITALIA

HEREBY DECLARES THAT

in designing and manufacturing the machine described here below , we have considered the most important requirements

of safety and health dictated by the European Directives of the Machine Security. Remember that this declaration loses its

validity if machine is modified without our agreement.

Trade name CIRCULAR SAWING MACHINE FOR METALS

Code / Model / Type

Manufacturing year

Serial number

IT IS IN COMPLIANCE WITH THE DIRECTIVES

DIRECTIVE 2006/42/CE OF THE EUROPEAN PARLIAMENT AND OF THE COUNCIL OF THE

17TH/05/2006 REGARDING THE MACHINES AND THAT MODIFIES THE DIRECTIVE 95/16/CE;

DIRECTIVE 2004/108/CE OF THE EUROPEAN PARLIAMENT AND OF THE COUNCIL OF THE

15/12/04 REGARDING THE ELECTROMAGNETIC COMPATIBILITY -EMC-

DIRECTIVE 2006/95/CE OF THE EUROPEAN PARLIAMENT AND OF THE COUNCIL OF THE

12/12/06 REGARDING ELECTRICAL EQUIPMENT FOR USE OF LOW VOLTAGE -LVD-

HARMONIZED STANDARDS REFERENCE EN.12100-01; EN 55011, EN50082-2, EN 13898, EN 60204 LEGISLATIVE

DECREE N.17 OF THE 27TH OF JANUARY 2010.

AND AUTHORIZING THE PERSON LISTED BELOW TO ISSUE THE TECHNICAL FILE.

Date : 01.01.2010

The signatory identification The manager

Angelo Meroni

--------------------------------------------------------------------------------------------------------------------------

File : Machine no. Delivery note no Dated

---------------------------------------------------------------------------------------------------------------------------

…………………….

………………..

………………..

TRANSLATION OF THE ORIGINAL INSTRUCTIONS FOR USE

SIRIO 370AF-NCing ED.2010 rev.00 5/81

3 - MACHINE NOISE

The decibel pointed out in the workplace in the conditions under described is appointed to the simoultaneous working of

some machine parts in motion ( it depends on the detailed cycle ) added to that one of the tool when is cutting the

workpiece.

In several moments the decibel are pointed out to note the different using conditions.

The phon-meter is placed at about 1 meter near the machine and at about 1,60 m from the floor.

The results of each test is in dBA and they mean the average of 3 tests made from the: left side, opposite side,

right side.

For any machines the using conditions are the following :

When idle, at the maximum blade speed: dBA 63

During the cut, at a suited blade speed, cutting solid steel (St12=≈C20, 80mm diameter): dBA 75

(tolerance ± 2dB).

In the standard production the test is made by a same machine of above mentioned one, in compliance with E.C. safety

norms 2006/42/EEC and 86/188/EEC .

The use of the machine in bad conditions or the use of the wrong tools cause also sensitive alterations of these tests and

it is prejudicial for the health of the taff and for the good results of the work .

Most of all the noice depends on the cutting material, on its sizes and on the locking system.

By expecting that above mentioned decibels could be exceeded, we recommend the operator the using of the personal

means of protection ( head phones, plugs etc. ) in case of working a long time at highest levels, taking into account

other possible machinery running nearby and the characteristics of the working place

3.1 - ADDITIONAL HEALTH AND SAFETY REQUIREMENTS

This type of machine, manually controlled during some working operations, must respond to further health and safety

requirements as specified by article 2.2 of the Annexed I of the European Directive 2006/42/EEC and following.

In particular, the level of vibrations emitted by the machine while in use must be clearly specified in the instructions.

This machine does not emit vibrations of a level higher than 2,5 m/s 2

The measurement procedure used conforms to the general norms applied to this type of machine.

As in the preceding paragraph, using the machine in unsuitable conditions or using the wrong tools can cause

changes affecting this value, endangering the health of the work force as well as the quality of production.

Vibrations emitted during cutting may be amplified by the material, by its dimensions and its

positioning/clamping in the vice.

Table of contents

Other IMET Spa Saw manuals