Index

1General Description ........................................................................................................................1

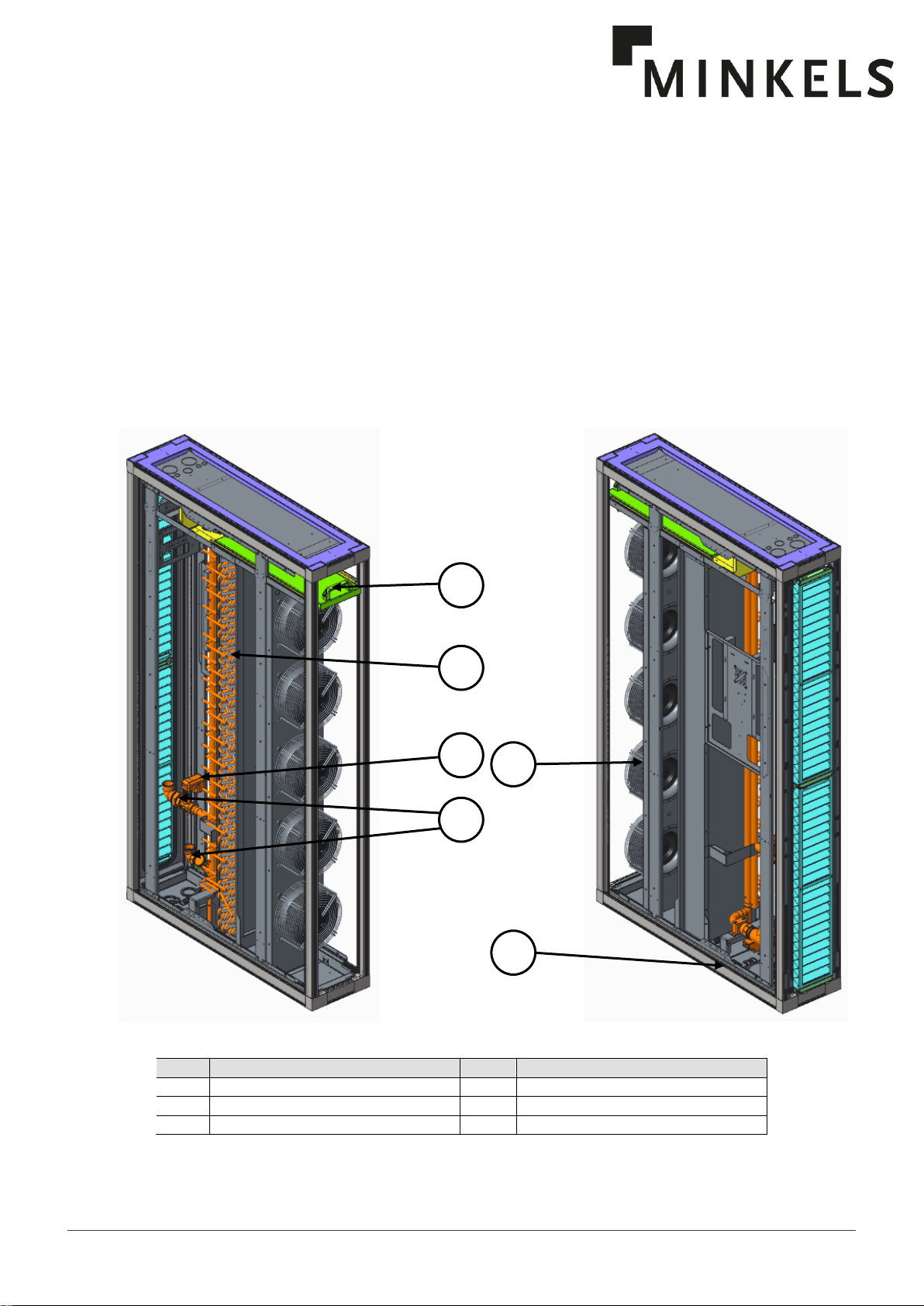

1.1 Structure....................................................................................................................................................................2

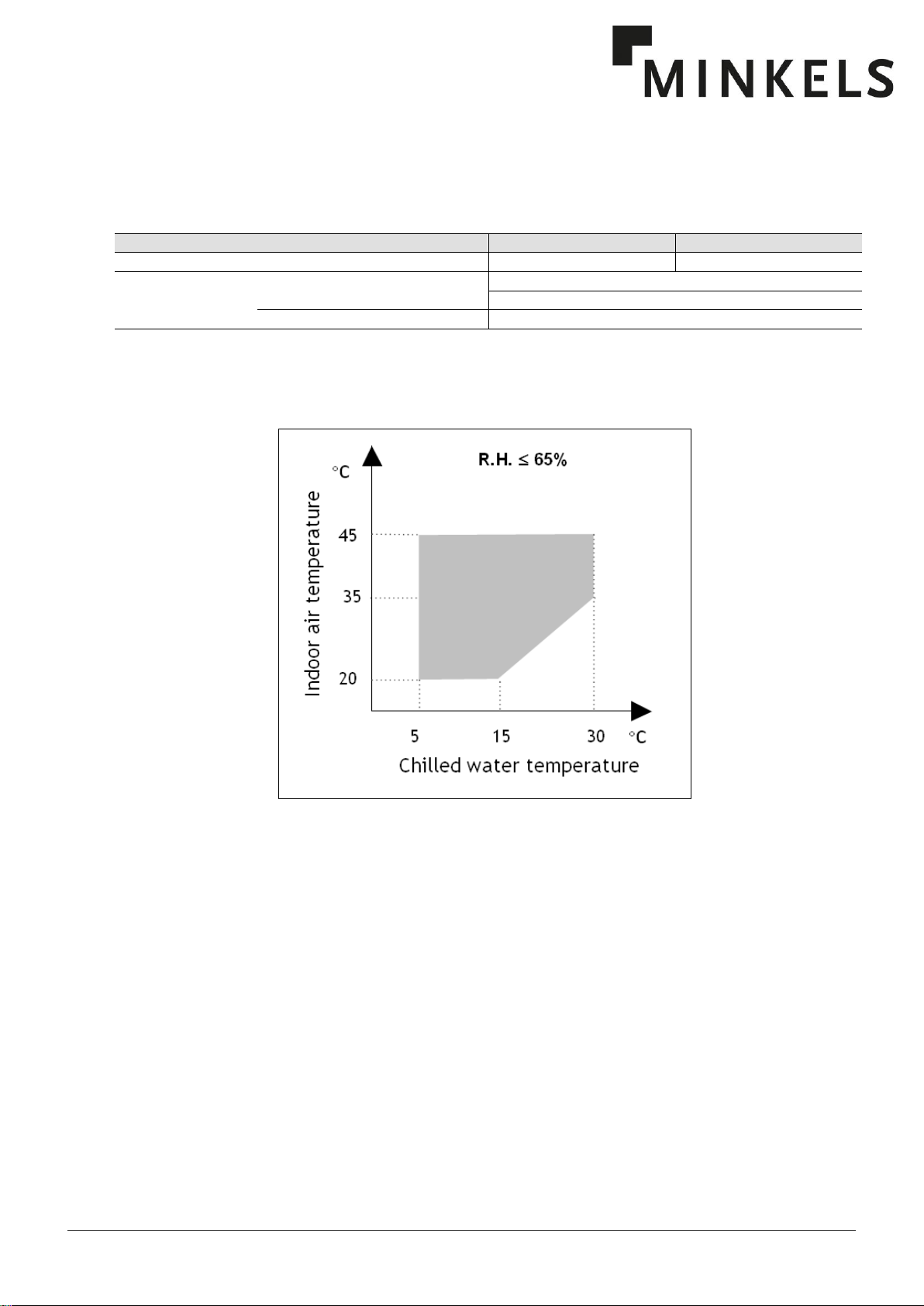

1.2 Application limits .......................................................................................................................................................3

1.3 Components..............................................................................................................................................................3

1.4 Installation warnings..................................................................................................................................................5

2Inspection / Transport / Positioning...............................................................................................6

2.1 Inspection on receipt.................................................................................................................................................6

2.2 Lifting and transport ..................................................................................................................................................6

2.3 Unpacking .................................................................................................................................................................6

2.4 Positioning.................................................................................................................................................................6

3Installation.......................................................................................................................................7

4Electrical Connections....................................................................................................................8

4.1 Generalities...............................................................................................................................................................8

5Operating Diagrams......................................................................................................................10

6Start-Up..........................................................................................................................................11

6.1 Preliminary checks..................................................................................................................................................11

6.2 Starting operations..................................................................................................................................................11

7Setting Operating Parameters......................................................................................................12

7.1 Generalities.............................................................................................................................................................12

8Maintenance ..................................................................................................................................13

8.1 Warnings.................................................................................................................................................................13

8.2 Generalities.............................................................................................................................................................13

9Troubleshooting............................................................................................................................15