20

TRUCLIMATE 700 90-140 TON INSTALLATION MANUAL

Water Quality

1.0. Minimum Fluid Volume

A. Water-to-water heat pumps require a minimum amount

of source and load side fluid volume to ensure accurate

and stable temperatures during system operation.

For normal air conditioning type applications, it is

recommended to use at least 7 gallons/ton.

B.

Applications that require more precise temperature

control or low loading will occur the minimum

fluid volume shall be no less than 10 gallons/ton.

Installation of a buer tank that will properly mix the

fluid is recommended.

1.1. Water-to-Water Heat Pump Sizing

A. Heat pumps should be adequately sized for optimal

system eciency and run time. Oversizing by more

than 15% can diminish performance resulting in higher

power consumption, short cycling of compressors, and

unstable conditioning temperatures.

B. In applications where the minimum load is significantly

less than the design condition, it is better to install 2

smaller heat pumps for load matching rather than a

single large heat pump.

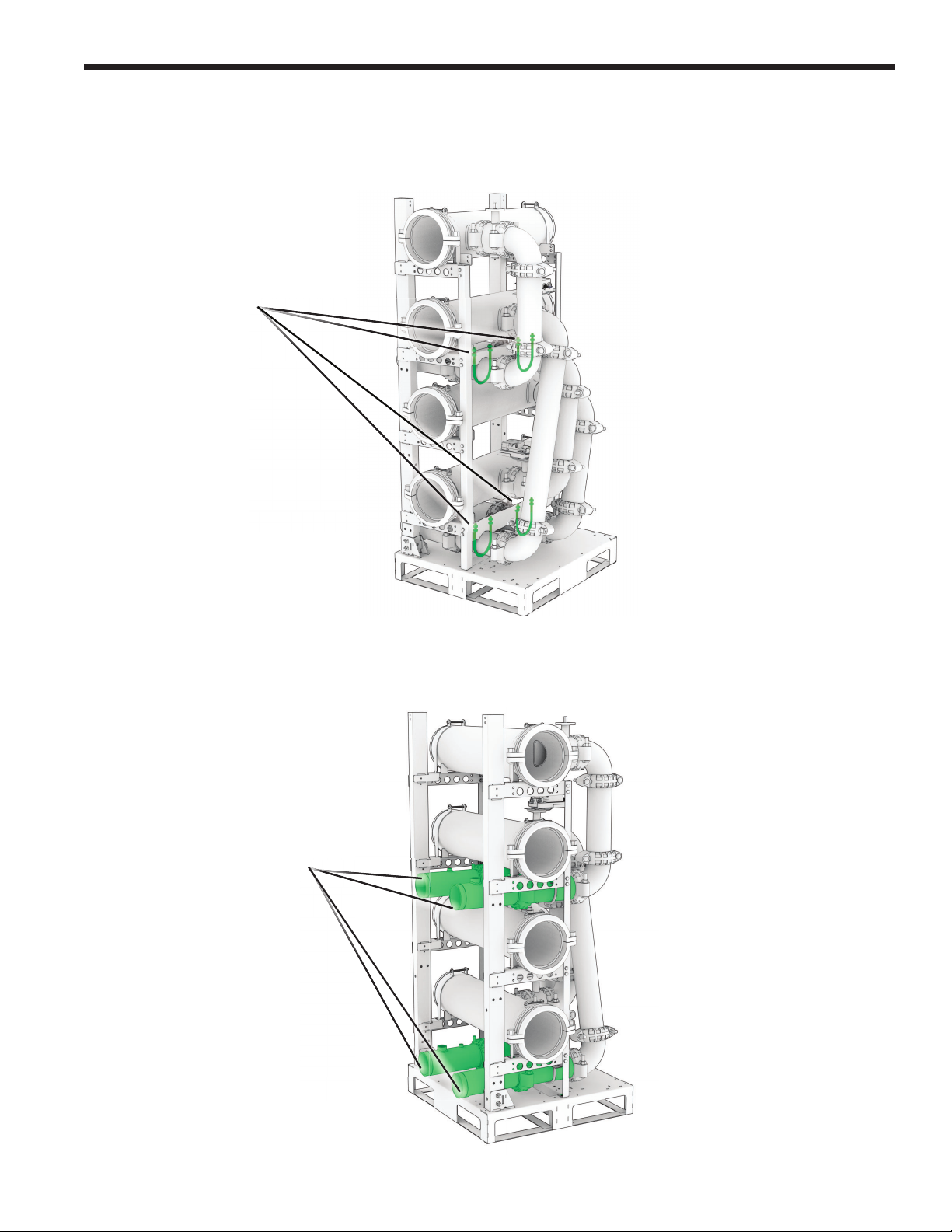

1.2. Heat Pump Piping

A. Multiple heat pumps can be installed in series or

parallel configurations. The preferred system design is

to pipe the equipment in parallel due to its simplicity

and flexibility. In parallel systems, the heat pump

equipment can vary in size as long as flow rate and

system volume are accounted for.

B. Piping equipment in series is not desired; however,

it can be done if proper guidelines are followed.

Always observe proper temperature and flow rate

requirements for each unit. Sometimes this method is

desired to achieve larger temperature dierences.

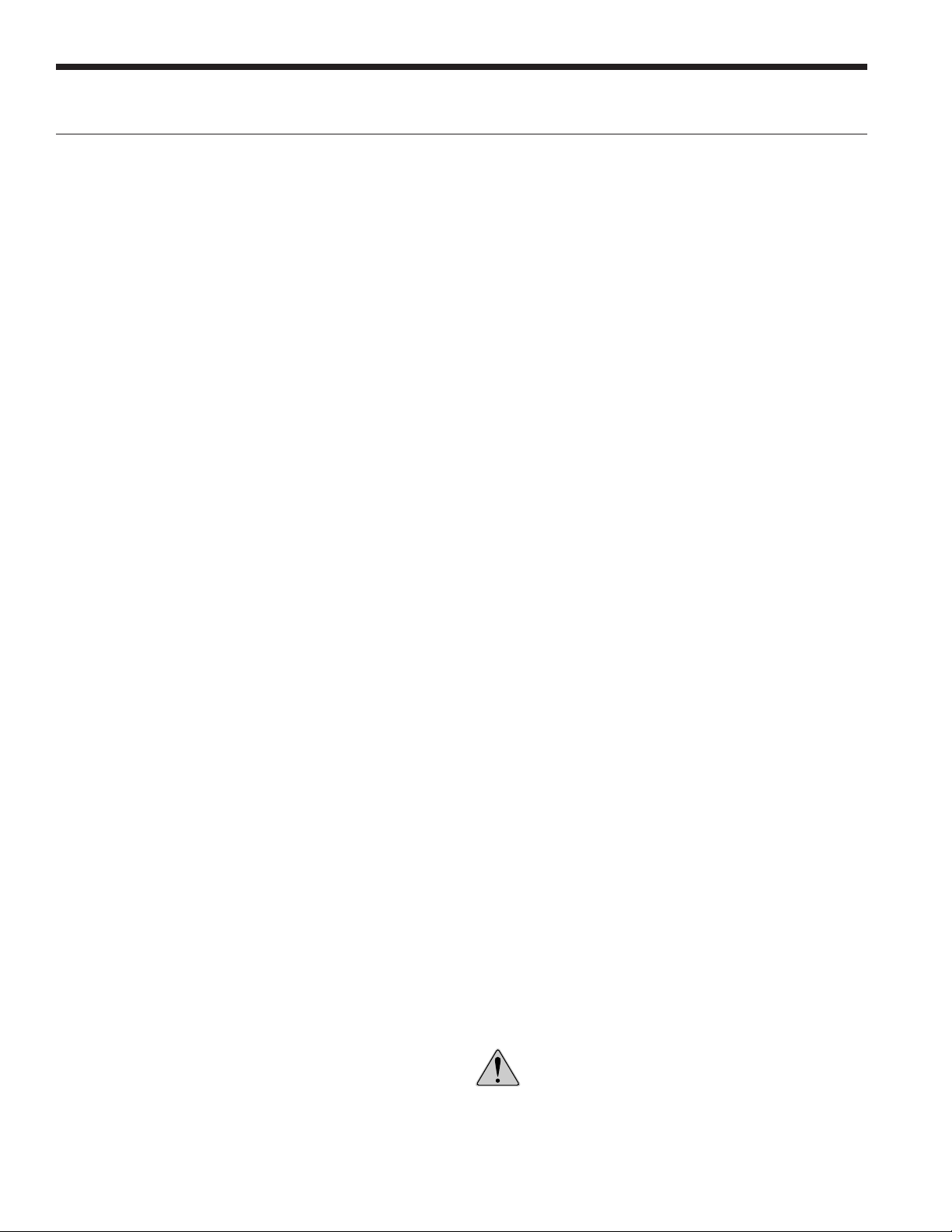

1.3. Strainers

A. All brazed-plate heat exchangers shall have a

strainer within 8 ft of the water/brine inlet. It is highly

recommended to use a minimum of 60 mesh in order

to provide maximum filtration. In any case, the strainers

should never have a mesh size less than 20.

B. Failure to install proper stainers and perform regular

service can result in serious damage to the unit, and

cause degraded performance, reduced operating life

and failed compressors. Improper installation of the

unit (which includes not having proper strainers to

protect the heat exchangers) can also result in voiding

the warranty.

C. Strainers should be selected on the basis of acceptable

pressure drop, and not on pipe diameter. The strainers

selected should have a pressure drop at the nominal

flow rate of the units; low enough to be within the

pumping capacity of the pump being used.

1.4. Flow Sensing Devices

A. A flow switch or equivalent must be installed on the

evaporator for each unit to be installed. If the unit is to

operate as both modes (heating/cooling), a flow switch

is needed on both heat exchangers.

B. A dierential pressure switch can be used in place of a

flow switch. The dierential switch must be capable of

pressure range as indicated in the pressure drop tables.

1.5. Water Quality

A. General: Reversible chiller systems may be successfully

applied in a wide range of commercial and industrial

applications. It is the responsibility of the system

designer and installing contractor to ensure that

acceptable water quality is present and that all

applicable codes have been met in these installations.

B. Water Treatment: Do not use untreated or improperly

treated water. Equipment damage may occur. The

use of improperly treated or untreated water in this

equipment may result in scaling, erosion, corrosion,

algae or slime. The services of a qualified water

treatment specialist should be engaged to determine

what treatment, if any, is required. The product

warranty specifically excludes liability for corrosion,

erosion or deterioration of equipment.

The heat exchangers in the units are 316 stainless steel

plates with copper brazing. The water piping in the

heat exchanger is steel. There may be other materials

in the building’s piping system that the designer may

need to take into consideration when deciding the

parameters of the water quality.

If an antifreeze or water treatment solution is to be

used, the designer should confirm it does not have a

detrimental eect on the materials in the system.

C. Contaminated Water: In applications where the

water quality cannot be held to prescribed limits, the

use of a secondary or intermediate heat exchanger

is recommended to separate the unit from the

contaminated water.

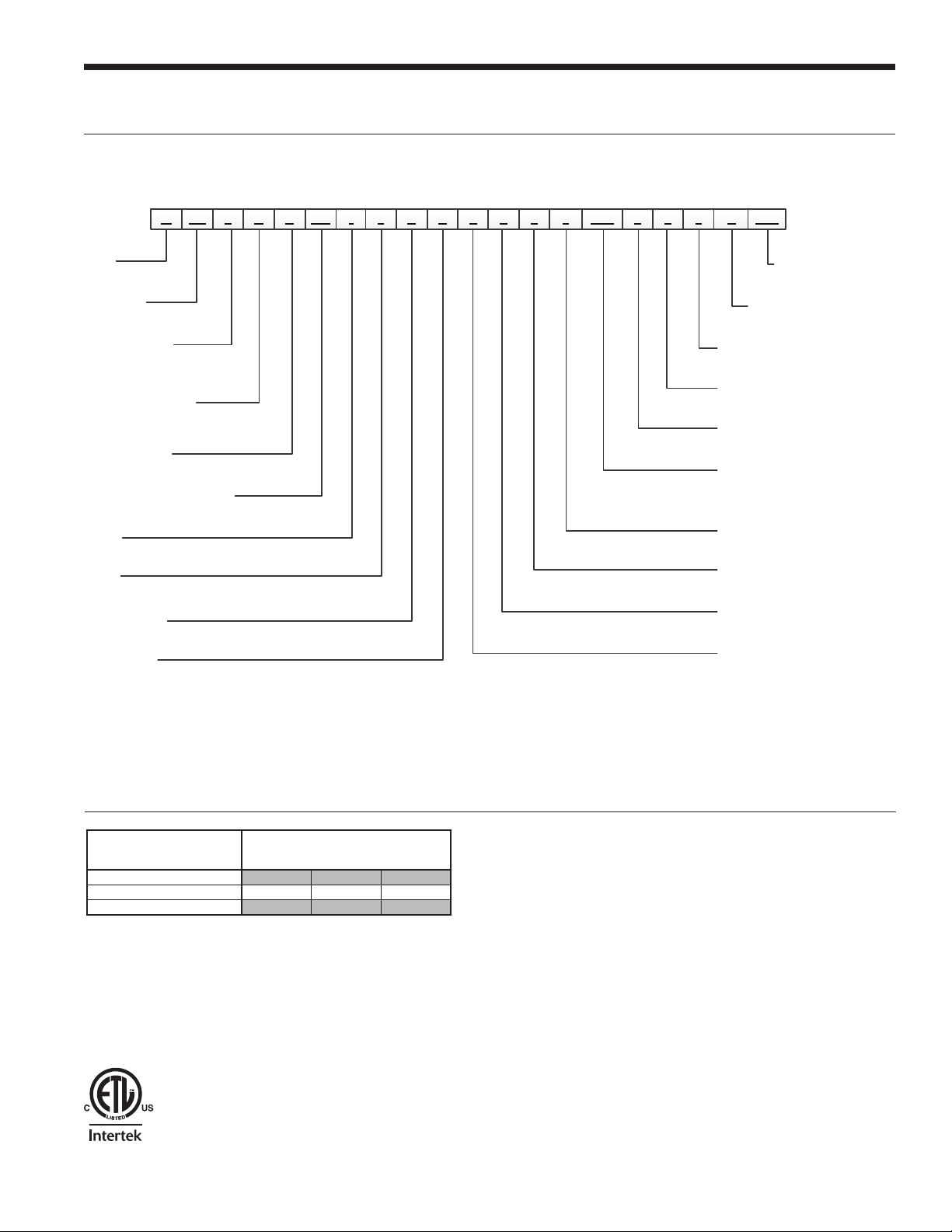

The following table outlines the water quality

guidelines for unit heat exchangers. If these conditions

are exceeded, a secondary heat exchanger is required.

Failure to supply a secondary heat exchanger where

needed will result in a warranty exclusion for primary

heat exchanger corrosion or failure.

WARNING: Must have intermediate heat exchanger

when used in pool applications.