2009-2013 FLH RENEGADE

2009-2010 MODELS

1. See Fig. 1. Remove (2) bolts to free swingarm

fork bracket from left side of motorcycle frame.

2. Release rear brake line hose and rear wheel speed

sensor (if ABS equipped) from cable clips on right

side of swingarm.

3. Remove decorative chrome plug from right side.

NOTE: For best results, use an air impact

wrench to remove right-side nut. Applying heat

to right-side nut may also improve removal. If

left-side nut loosens first, remove left-side nut

and use double nuts to hold pivot shaft while

removing right-side nut.

4. See Fig. 2. Hold left-side nut and remove right

side nut from end of pivot shaft. Remove and

discard cup washer.

5. Using a suitable punch, tap pivot shaft toward

left side of motorcycle.

6. See Fig. 1. Pull pivot shaft assembly with nut,

cup washer, rubber mount and outer spacer out

of transmission mount and left side fork. Hold

shaft in padded vise and remove LH nut. Dis-

card LH cup washer.

7. Remove outer spacer from right side of swin-

garm.

8. Remove rubber mount from right side.

2011+ MODELS

1. See Fig. 1. Remove (2) bolts to free swingarm fork bracket from left side of motorcycle frame.

2. Release rear brake line hose and rear wheel speed sensor (if ABS equipped) from cable clips on

right side of swingarm. Remove black plastic plug from right side.

NOTE: For best results, use an air impact wrench to remove right-side bolt. Applying heat to

right-side bolt may also improve removal. If left-side bolt loosens first, use a ¾” socket to

hold LH pivot shaft outer spacer while removing right-side bolt.

3. See Fig. 2. Hold left-side bolt and remove right side bolt from end of pivot shaft.

4. Using a suitable punch, tap pivot shaft toward left side of motorcycle.

5. See Fig. 1. Pull pivot shaft assembly with outer spacer and rubber mount out of transmission mount

and left side fork. Hold shaft in padded vise and remove LH bolt.

6. Remove outer spacer from right side of swingarm. Remove rubber mount from right side.

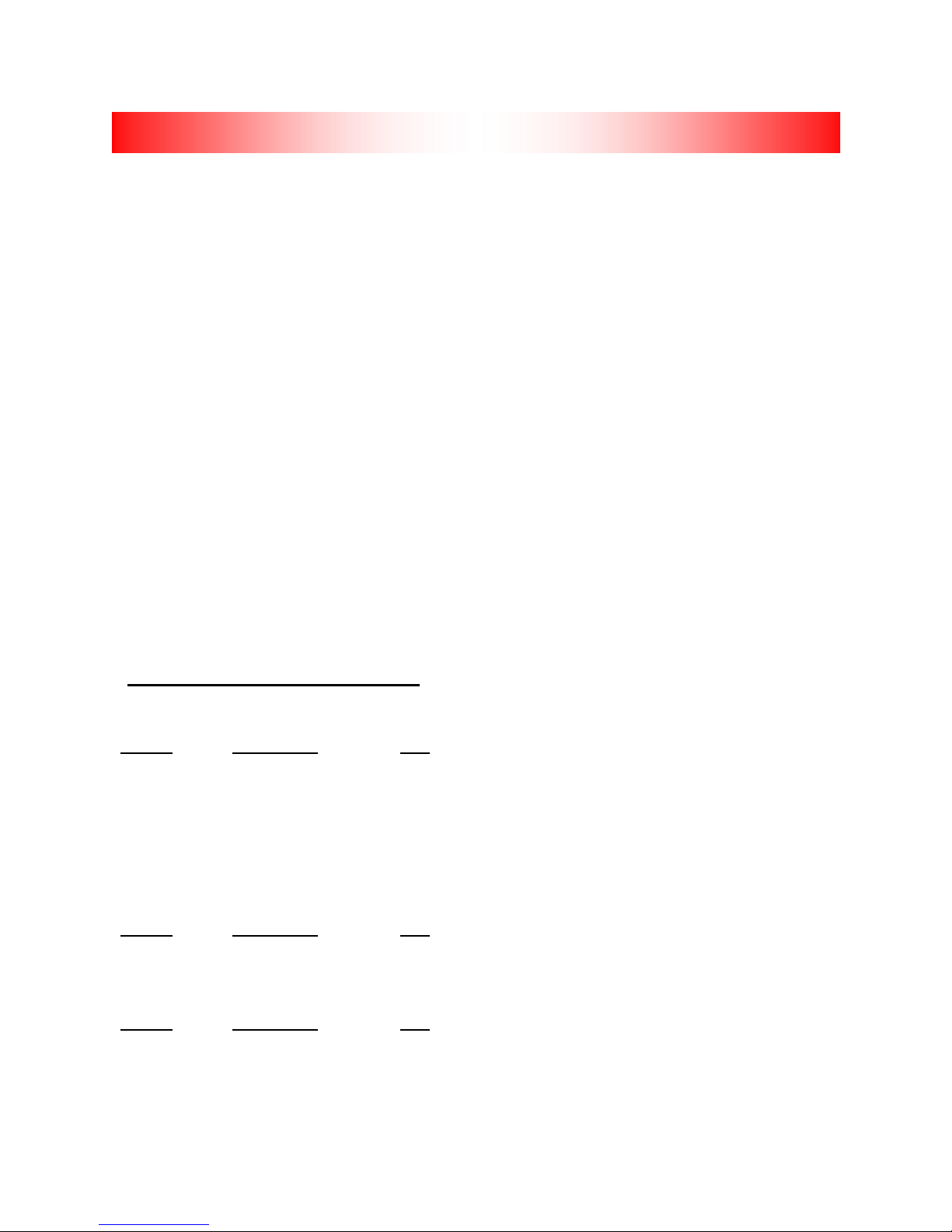

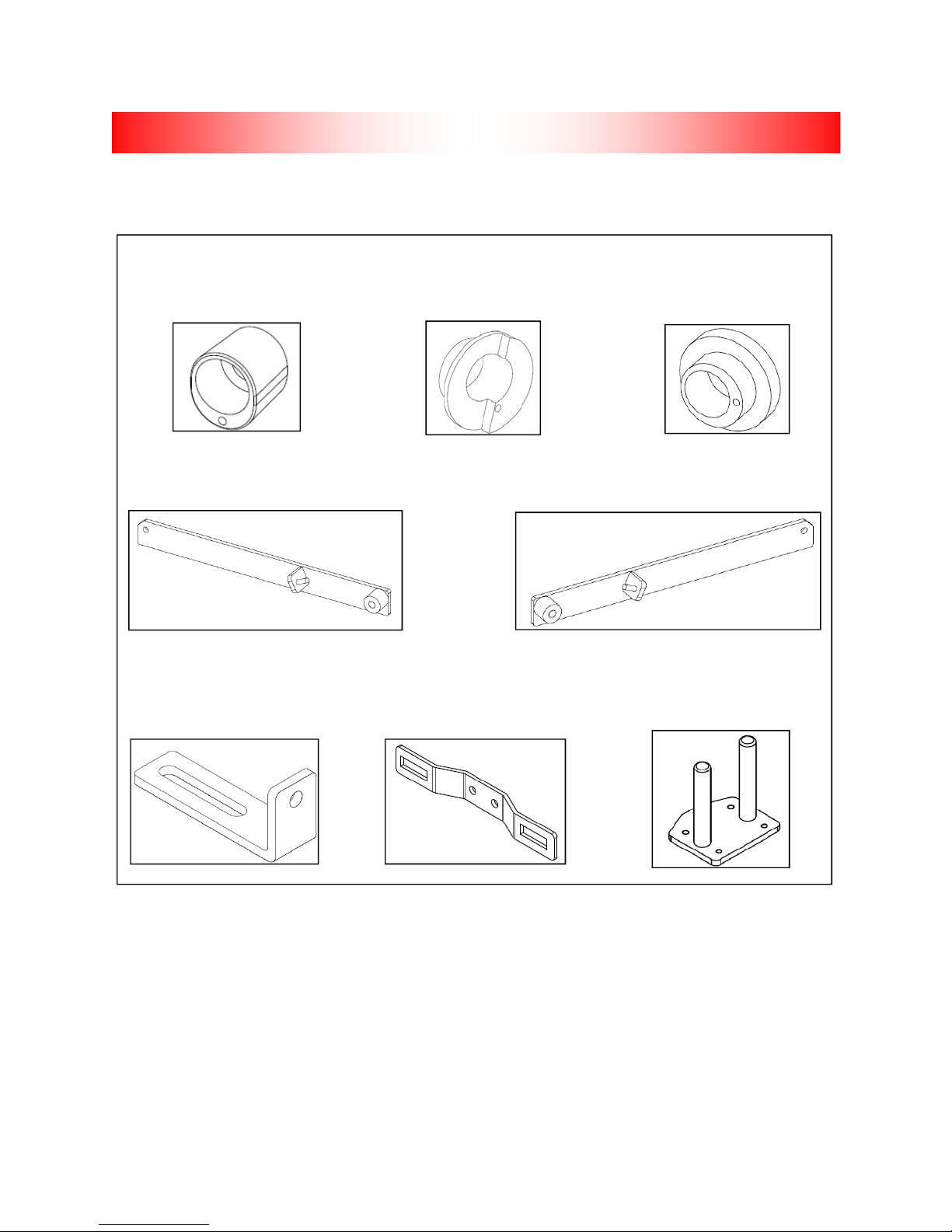

Fig. 1

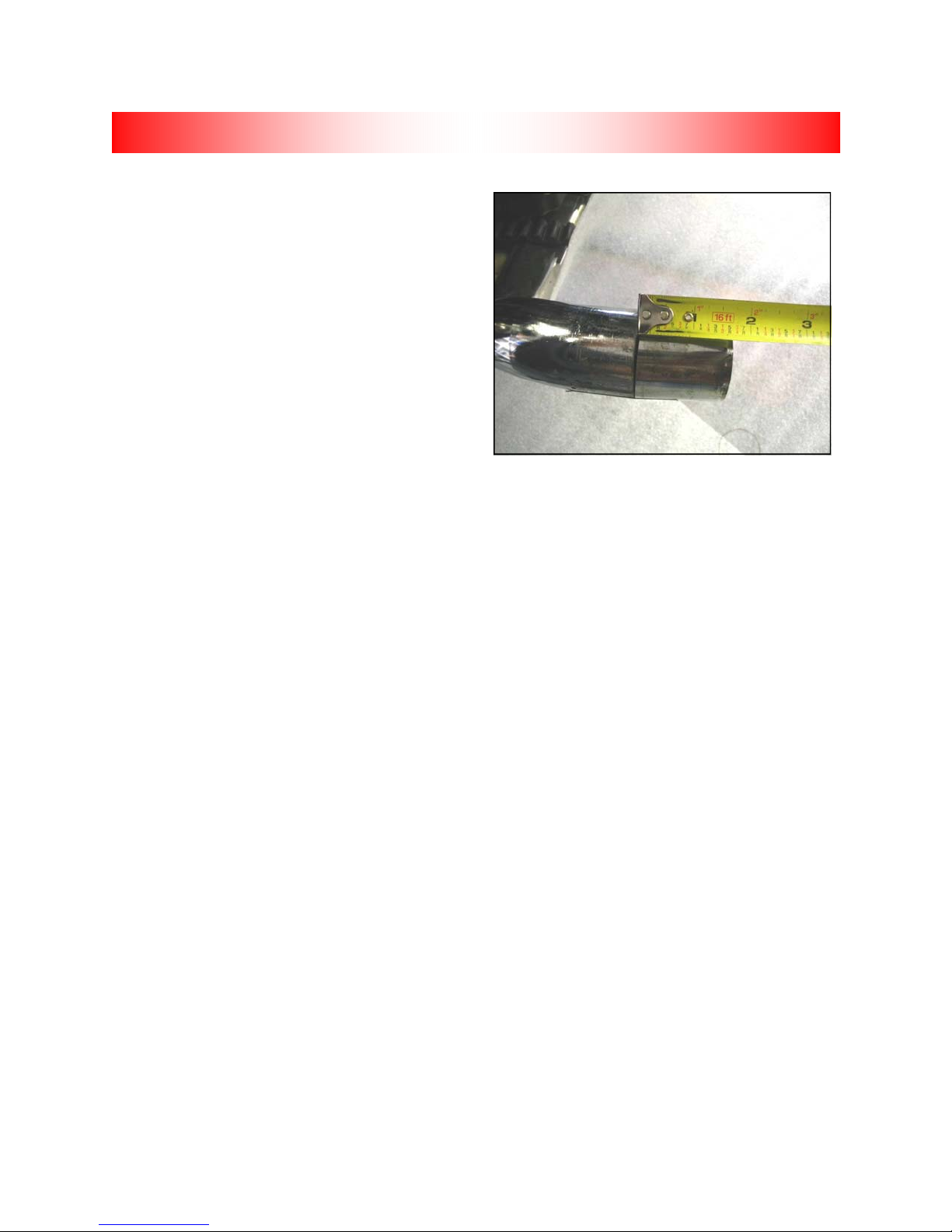

Fig. 2

Right-side mount

LH Fork bracket bolts

REMOVING HD SWINGARM

Pivot shaft nut

9