Page 7

Electrical Connections − Power Supply

Do not apply power or close isconnect switch until

installation is complete. Refer to start−up irections. Refer

closely to unit wiring iagram.

Refer to unit nameplate for minimum circuit ampacity an

maximum overcurrent protection.

1− All units are factory wire . For 208V supply,

isconnect the orange wire (230V) at control power

transformer. Reconnect the re wire (208V). Tape the

expose en of the 230V orange wire.

Units Wit out Optional Disconnect

1− The unit is provi e with power entry knockouts

through the base an the blower section mullion (see

page 1).

2− Horizontal Power Entry − Remove necessary

electrical knockouts on blower section mullion.

Bottom Power Entry −

Route wires through knockout on power entry cover.

NOTE − It may be necessary to punch larger holes for

power wiring (refer to current NEC/CEC requirements).

3− Install a equate isconnect switch external to unit in

accor ance with local or national co es as

applicable.

Units Wit Factory−Installed GFI

1− Remove necessary electrical knockouts in unit.

2− Make power wiring connections in bottom power

entry box.

3− Connect separate 120v wiring to GFCI outlet pigtails

in han y box on front left corner mullion.

Electrical Connections − Control Wiring

A−T ermostat Location

Room thermostat mounts vertically on any

non−con uctive flat surface.

Locate thermostat approximately 5 feet (1.5m) above the

floor in an area with goo air circulation at average

temperature. Avoi locating the room thermostat where it

might be affecte by:

− rafts or ea spots behin oors an in corners

−hot or col air from ucts

−ra iant heat from sun or units

−conceale pipes an chimneys

B−Control Wiring

1− Route thermostat cable or wires from subbase

through con uit provi e in unit. Refer to wiring

iagram on unit. For thermostat wire runs up to 60 feet

(18m), use 18 gauge wire. For 60 to 90 feet (18 to

27m) runs, use 16 gauge wire.

2− Install thermostat an humi ity sensor in

accor ance with instructions provi e with

thermostat or sensor. See figure 11 to wire units set

in local thermostat mo e. See figure 12 for units

wire in zone sensor mo e.

2− Install thermostat assembly in accor ance with

instructions provi e with thermostat.

IMPORTANT−Terminal connections at the wall plate or

subbase must be made securely. Loose control wire

connections may allow unit to operate but not with proper

response to room demand.

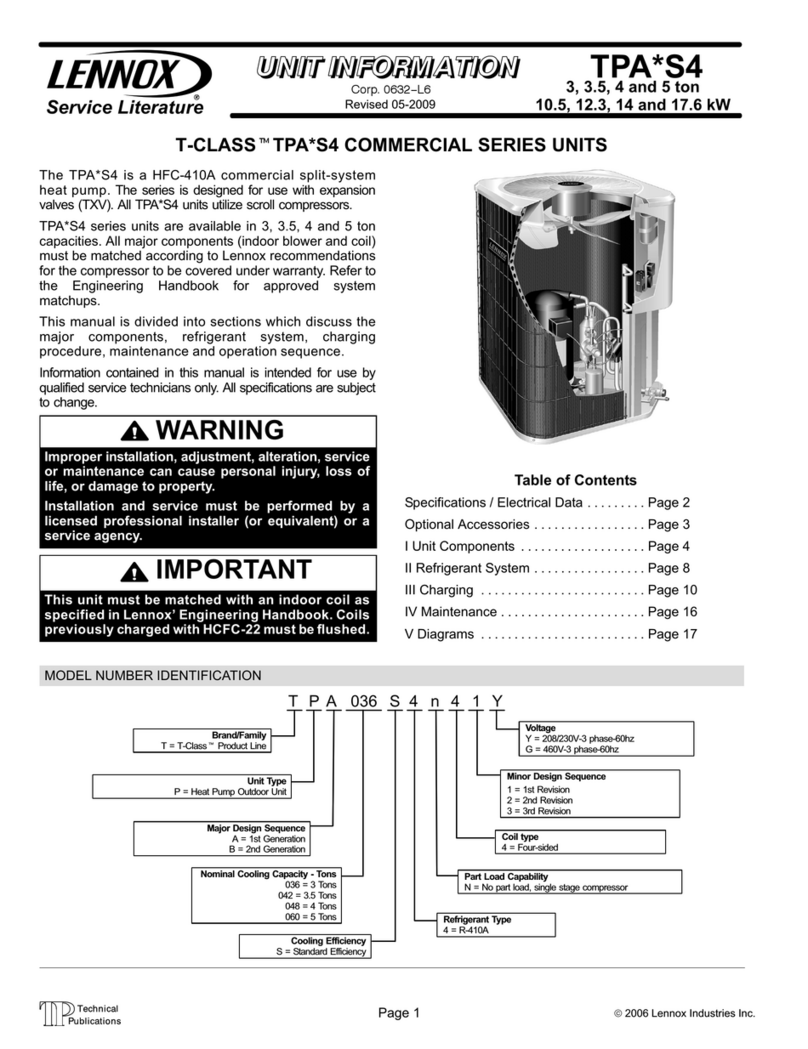

C−Commercial Controls Platform

Units without an optional factory−installe control system

may use a variety of ifferent temperature control systems.

The unit has a pre−wire jack−plug platform allowing a

variety of control systems to plug−in" to unit jack−plugs.

Control systems which have the mating commercial

controls platform jack−plug contain a control system wiring

iagram C" section. This iagram section is use with unit

an accessory iagram sections for total system

operation. Affix iagrams to unit in alpha−numeric or er as

shown in figure 10. Refer closely to installation instructions

provi e with each temperature control system for proper

unit operation.

FIGURE 10

COMPLETE SYSTEM DIAGRAM

A"

Heating

Section

B"

Unit

Section

C"

Control

Section

D"

Economizer

Section