5, Set the recovery machine for liquid recovery and start

the recovery machine. Open the gauge set valves to

allow the recovery machine to pull a vacuum on the ex-

isting system line set and indoor coil,

6. Invert the cylinder of clean R-22 and open its valve to

allow liquid refrigerant to flow into the system through

the vapor line valve. Allow the refrigerant to pass from

the cylinder and through the line set and the indoor coil

before it enters the recovery machine,

7, After all of the liquid refrigerant has been recovered,

switch the recovery machine to vapor recovery so that

all of the R-22 vapor is recovered,

NOTE -A single system flush should remove all of the

mineral oil from the existing refrigerant lines and in-

door coil, A second flushing may be done (using clean

refrigerant) if insufficient amounts of mineral oil were

removed during the first flush, Each time the system

is flushed, you must allow the recovery machine

to pull a vacuum on the system at the end of the

procedure.

8. Close the valve on the inverted R-22 drum and the

gauge set valves. Pump the remaining refrigerant out

of the recovery machine and turn the machine off,

9, Use nitrogen to break the vacuum on the refrigerant

lines and indoor coil before removing the recovery ma-

chine, gauges and R-22 refrigerant drum, Reinstall

pressure tap valve cores into SPA service valves,

10, Install the provided check/expansion valve (approved

for use with R-410A refrigerant) in the liquid line at the

indoor coil,

AIMPORTANT

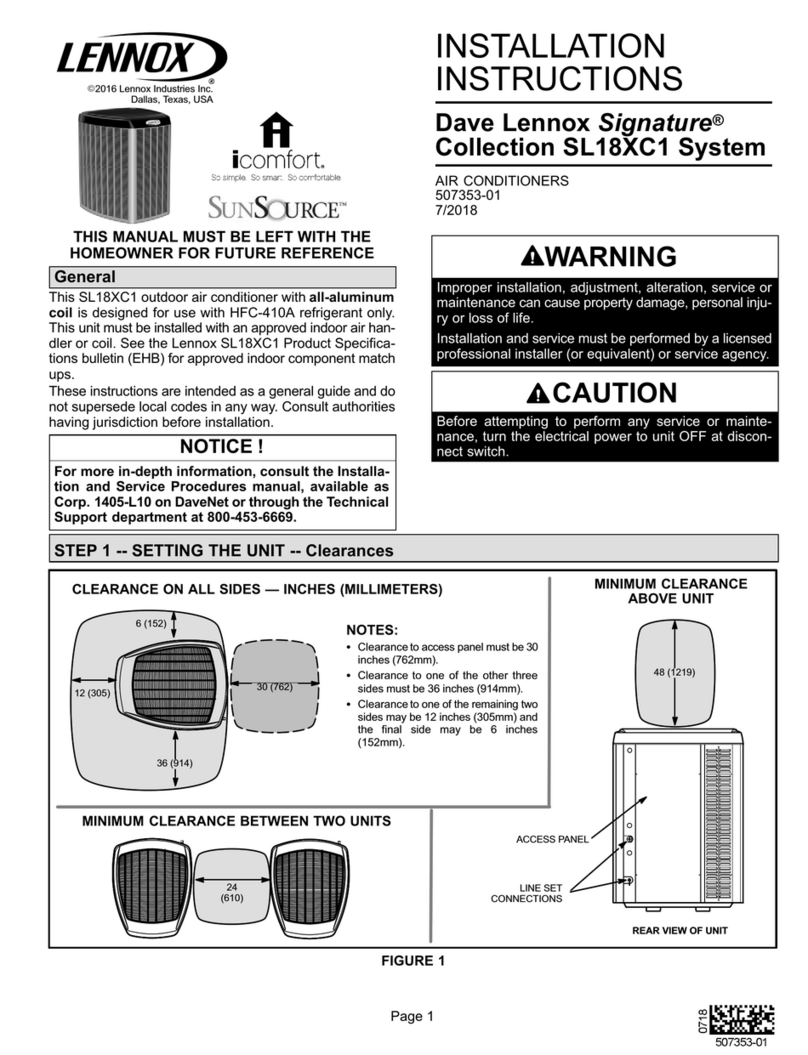

Liquid Line Service Valve

SERVICE PORT

SERVICE

PORT CAP

Insert hex

STEM

CAP To

indoor coil

(Valve Closed) To outdoor coil

SERVICE PORT

SERVICE

PORT CAP

VALVE

CORE

wrench here

STEM

CAP To

indoor coil

Service port Is open to line

set when valve is closed

(front seated) To outdoor coil (Valve Open)

Figure 14

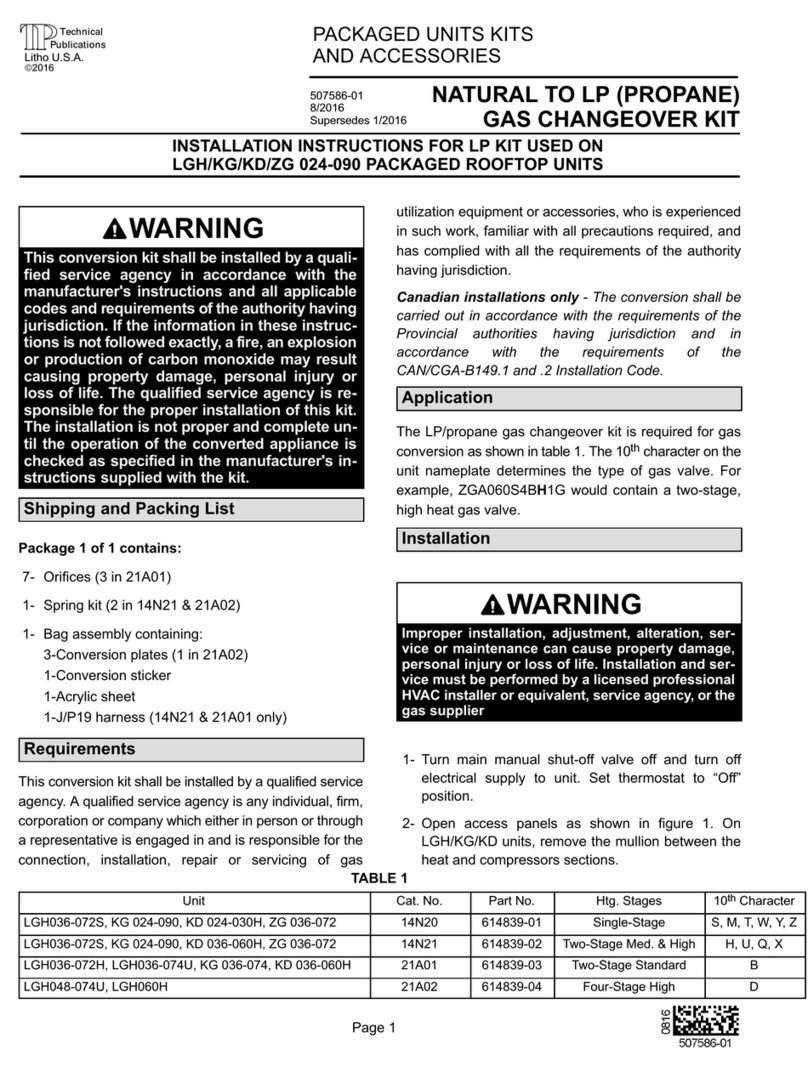

Table 2

Torque Requirements

Part Recommended Torque

Service valve cap 8 ft.- lb. 11NM

Sheet metal screws 16 in.- lb. 2 NM

Machine screws #10 28 in.- lb. 3 NM

Compressor bolts 90 in.- lb. 10 NM

Gauge portseal cap 8 ft.- lb. 11NM

AIMPORTANT

The service valves (liquid line - figure 14, vapor line - fig-

ures 15 and 16) and gauge ports are used for leak testing,

evacuating, charging and checking charge. Each valve is

equipped with a service port which has a factory-installed

Schrader valve. A service port cap protects the Schrader

valve from contamination and serves as the primary leak

seal.

To Access Schrader Port:

1, Remove service port cap with an adjustable wrench,

2. Connect gauge to the service port.

3, When testing is complete, replace service port cap,

Tighten finger tight; then tighten per table 2,

To Open and Close Service Valve:

1. Remove stem cap with an adjustable wrench.

2, Using service wrench and hex head extension (3/16"

extension for liquid line sizes), back the stem out coun-

terclockwise as far as it will go.

3, Replace stem cap and tighten it firmly, Tighten finger

tight; then tighten per table 2,

504867M 06/06

Page 10