Contents

4

BA BFK457 GB 2.0

1 Preface and general information 6...........................................

1.1 About these Operating Instructions ... 6..................................................

1.1.1 Terminology used 6.........................................................

1.2 Scope of supply 6..................................................................

1.3 Lenze drive systems 7...............................................................

1.3.1 Labelling 7................................................................

1.3.2 Application as directed 7.....................................................

1.3.3 Legal regulations 7..........................................................

2 Safety information 8......................................................

2.1 Persons responsible for the safety 8....................................................

2.2 General safety information 8..........................................................

2.3 Layout of the safety information 9......................................................

3 Technical data 10.........................................................

3.1 Product description 10...............................................................

3.1.1 General 10.................................................................

3.1.2 Braking 11.................................................................

3.1.3 Brake release 11............................................................

3.2 Kenndaten 11......................................................................

3.3 Switching times 13..................................................................

3.4 Operating frequency / friction work 14....................................................

3.5 Emission 15.......................................................................

4 Installation 16............................................................

4.1 Required tools 16...................................................................

4.2 Assembly 17.......................................................................

4.2.1 Preparation 17..............................................................

4.3 Installation 17......................................................................

4.3.1 Installation of the hub onto the shaft 17...........................................

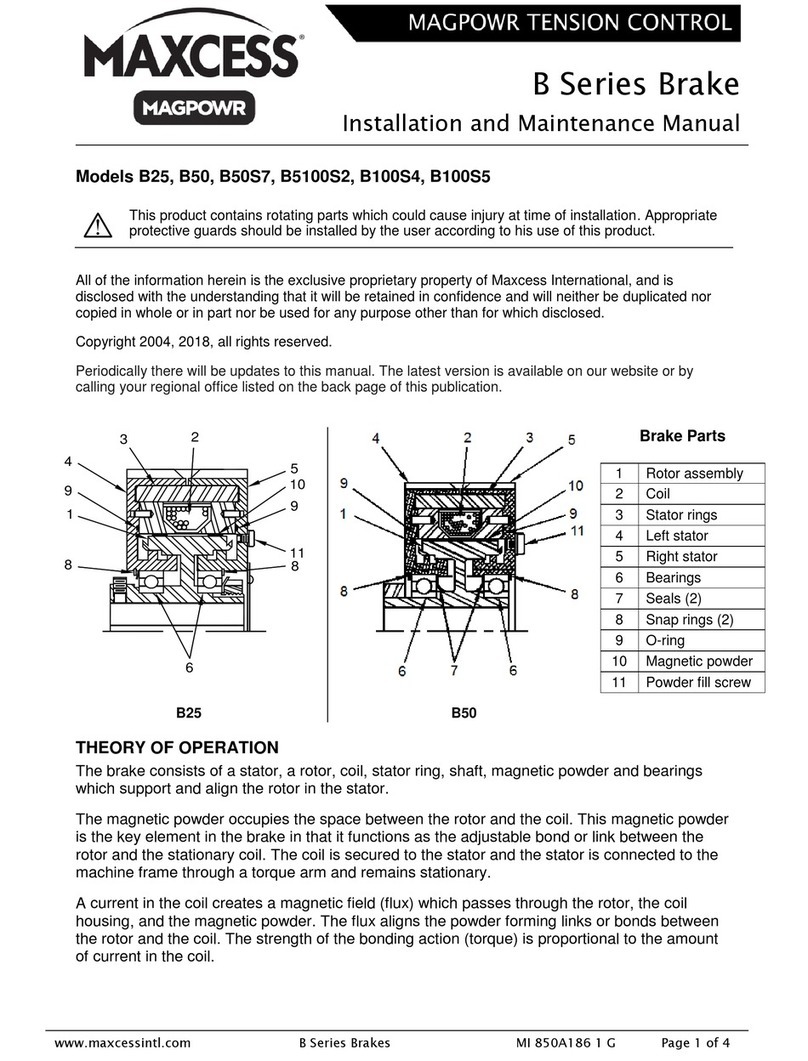

4.3.2 Installation of the brake BFK457-03...05 18........................................

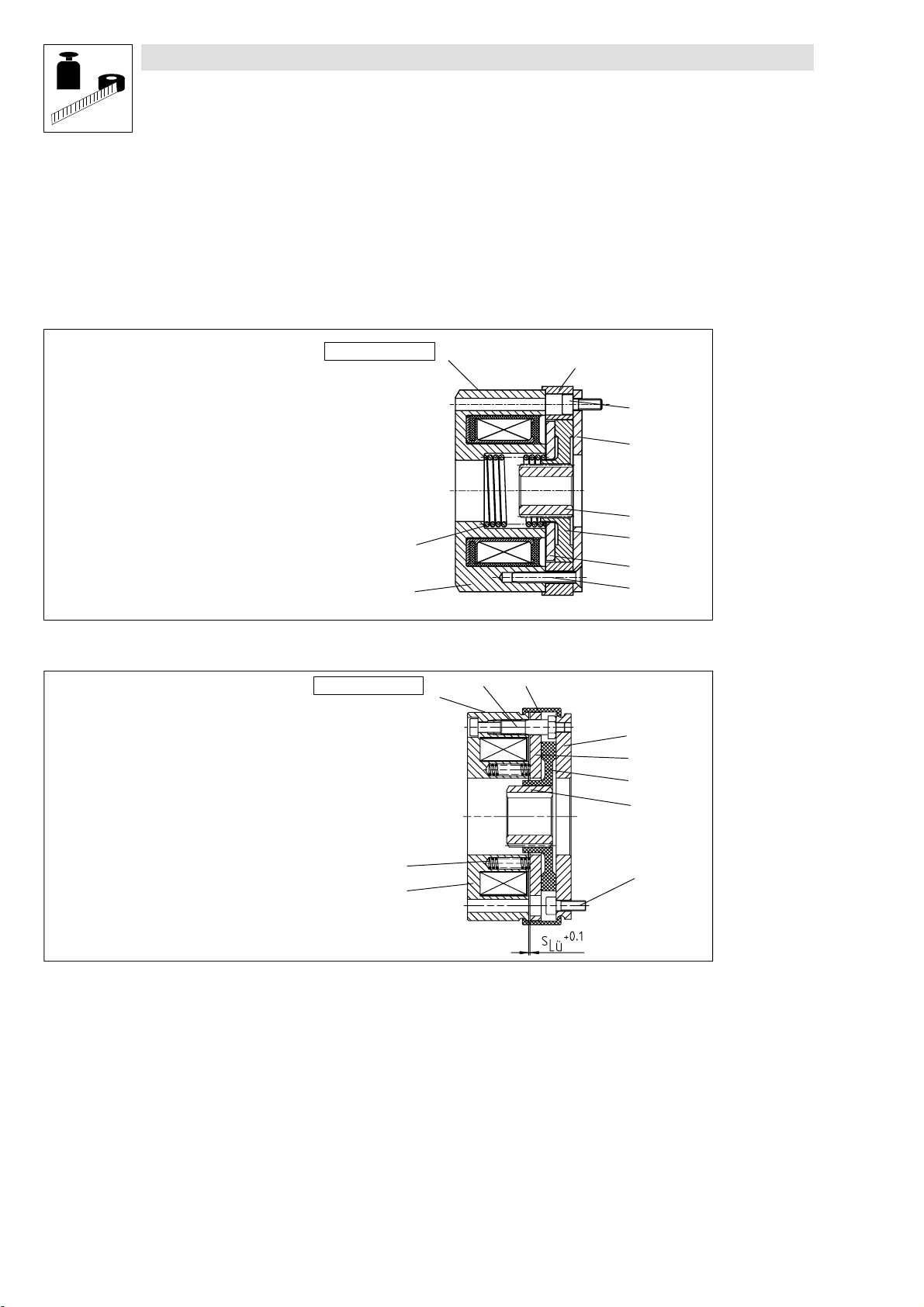

4.3.3 Installation of the brake BFK457-06+08 18.........................................

4.3.4 Installation of cover seal for brake sizes 06+08 19...................................

4.4 Electrical connection 20..............................................................

5 Commissioning and operation 22.............................................

5.1 Operational test 22..................................................................

5.1.1 Release / voltage check 22.....................................................

5.2 During operation 22.................................................................