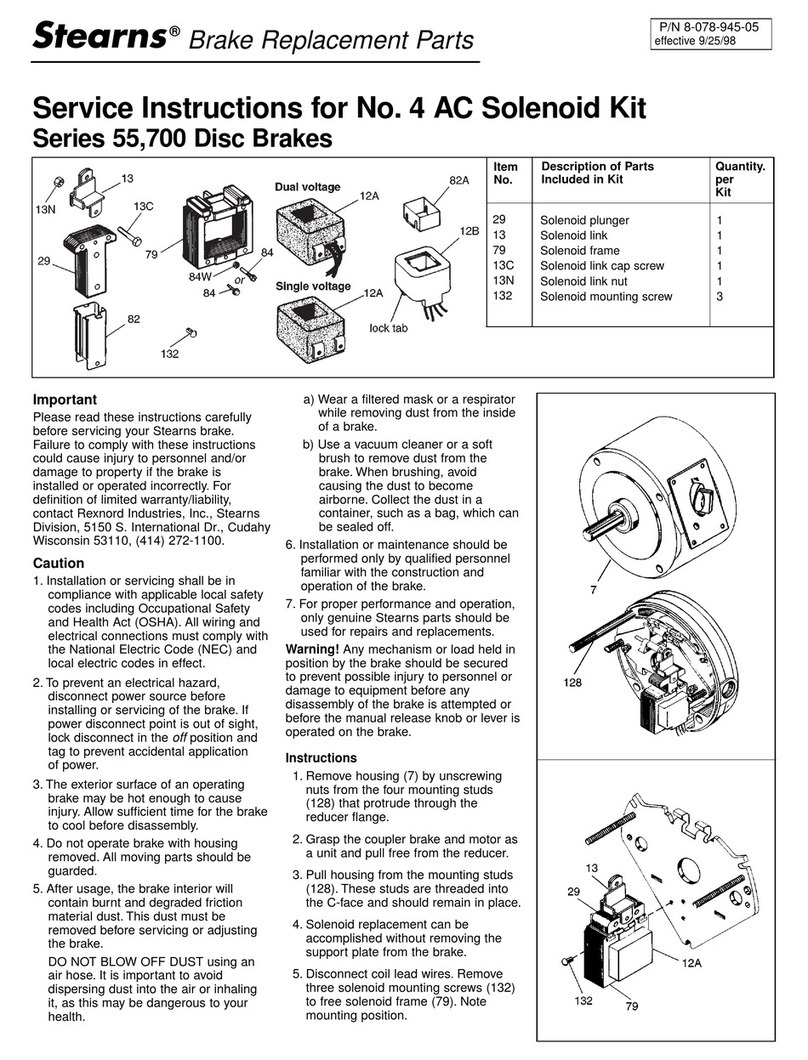

6 Electrical installation ............................................................................................................................................... 49

6.1 Electrical connection .......................................................................................................................................... 49

6.2 AC switching at the motor – extremely delayed engagement............................................................................ 50

6.3 DC switching at the motor – fast engagement ................................................................................................... 51

6.4 AC switching at mains – delayed engagement .................................................................................................. 52

6.5 DC switching at mains – fast engagement......................................................................................................... 53

6.6 Minimum bending radius for the brake connection line...................................................................................... 54

6.7 Technical specifications for the micro-switch..................................................................................................... 54

6.8 Bridge/half-wave rectifier (optional).................................................................................................................... 55

6.8.1 Assignment: Bridge/half-wave rectifier – brake size.............................................................................. 55

6.8.2 Technical specifications......................................................................................................................... 55

6.8.3 Reduced switch-off times ...................................................................................................................... 56

6.8.4 Permissible current load at ambient temperature.................................................................................. 56

7 Commissioning and operation ............................................................................................................................... 57

7.1 Protect the electrical connections against any contact or touching.................................................................... 57

7.2 Function checks before initial commissioning.................................................................................................... 58

7.2.1 Function check of the brake .................................................................................................................. 58

7.2.2 Release / voltage control....................................................................................................................... 58

7.2.3 Testing the hand-release functionality................................................................................................... 59

7.3 Commissioning................................................................................................................................................... 60

7.4 Operation ........................................................................................................................................................... 60

7.4.1 Brake torque reduction (for the optional adjustable braking torque)...................................................... 61

8 Maintenance and repair........................................................................................................................................... 62

8.1 Wear of spring-applied brakes ........................................................................................................................... 62

8.2 Inspections......................................................................................................................................................... 63

8.2.1 Maintenance intervals............................................................................................................................ 63

8.3 Maintenance....................................................................................................................................................... 63

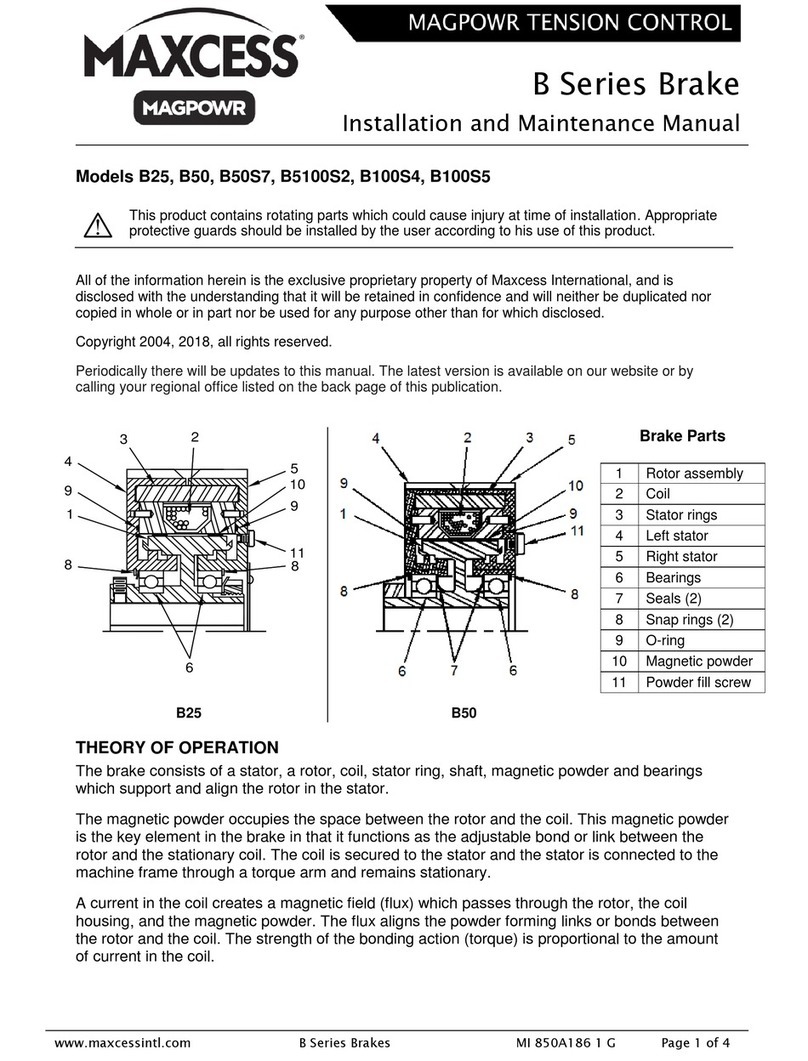

8.3.1 Checking the components..................................................................................................................... 64

8.3.2 Check the rotor thickness...................................................................................................................... 64

8.3.3 Checking the air gap.............................................................................................................................. 65

8.3.4 Release / voltage................................................................................................................................... 65

8.3.5 Adjusting the air gap.............................................................................................................................. 66

8.3.6 Replace rotor......................................................................................................................................... 66

8.4 Spare parts list ................................................................................................................................................... 68

9 Troubleshooting and fault elimination................................................................................................................... 71

INTORQ | BA 14.0168 | 11/2018 8