Leroy Merlin 4226 User manual

4226

Please Read The User Manual Carefully!

2

1 Safety instructions 4

1.1 Operating instructions 4

1.2 Instructions employed 4

1.3 Children, persons with special needs 5

1.4 Intended use 5

1.5 Risk of re 6

1.6 Power supply 6

1.7 Defective equipment 6

2 Unpacking and assembly 7

2.1 Unpacking 7

2.2 Assembly and electrical connection 7

3 Operation 13

3.1 Performance level select fan 13

3.2 Automatic trailing system 13

4 Maintenance 16

4.1 General maintenance instructions 15

4.2 Cleaning the extraction hood 16

4.3. Clean the metal grease lter 17

4.4 Removing and inserting the metal grease lter 18

4.5 Maintenance intervals 19

4.6 Replacing the light source 19

4 Malfunctions 20

5 Malfunctions/Causes/Solutions 21

3

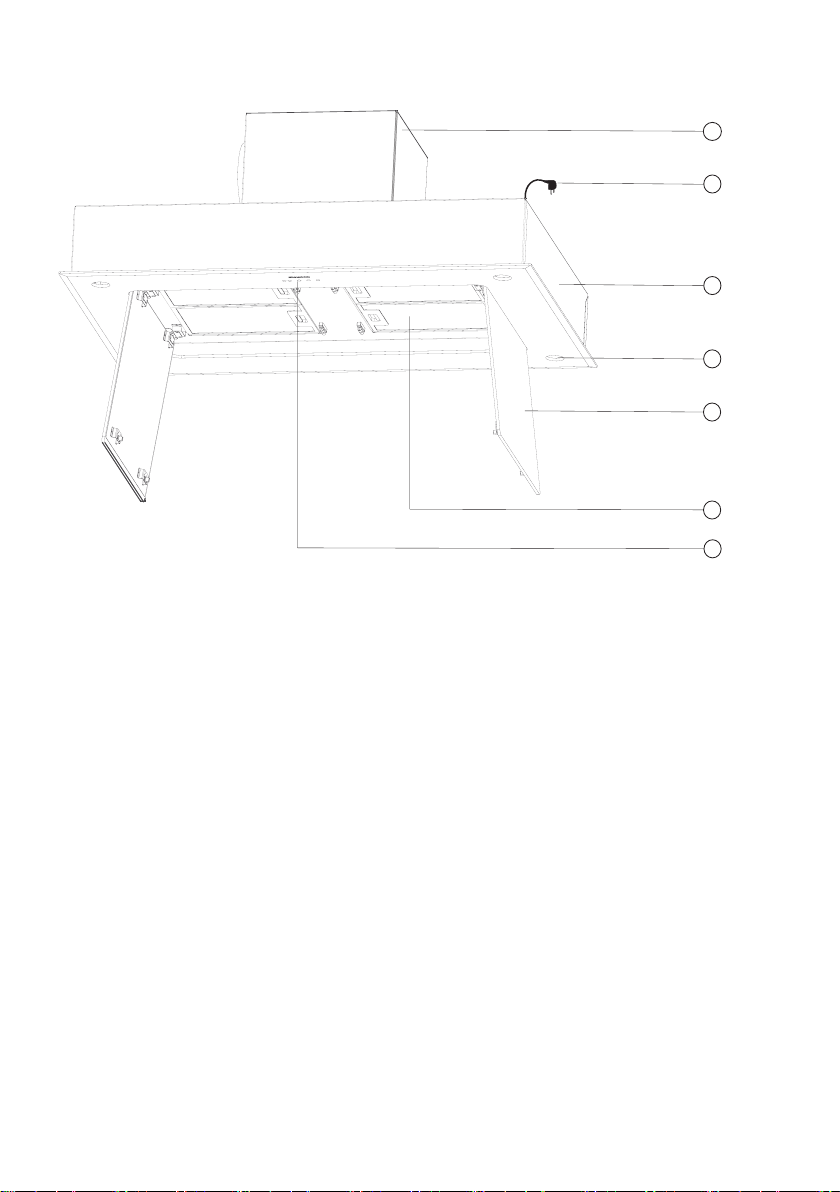

Overview of extraction hood

Figure 1: Overview 1 Motor box

2 Power plug

3 Cover housing

4 Lighting

5 Side suction-plate is removable.

6 Metal grease lter

7 Light diodes of hood remote control

1

2

3

4

5

6

7

4

Read through these operating instructions

completely before working with the extraction

hood.

Store these operating instructions carefully.

When forwarding the equipment to a third

party, deliver the operating instructions.

It is imperative to respect instructions to avoid

injuries to persons and damage to equipment.

No liability is assumed of the manufacturer

for damages arising from non-compliance of

these operating instructions.

Important instructions for your safety are spe-

cically identied. It is imperative to respect

instructions to avoid accidents and damage to

equipment.

1 Safety instructions

WARNING!

Warns of risks to health and shows potential

risks of injury.

CAUTION!

Indicates the dangers of the device or other

objects

CAUTION!

Indicates a potential danger, which can lead to

material damage if it is not avoided.

INSTRUCTION!

Shows tips and information.

Refers to another chapter, a section or inst-

ruction.

1.1 Operating instructions

1.2 Instructions employed

5

1 Safety instructions

Persons (including children), who are not ca-

pable of using the equipment safely (persons

with special needs) due to mental, physical or

motor capacities, may not use the equipment

without the supervision or only with the inst-

ructions of a competent person.

Do not leave the equipment unattended. Use

is only with greatest caution when children

or persons with special needs, who cannot

assess the risks correctly, are in the vicinity.

Packaging material:

- not used for games. There are

Risk of suffocation.

- Appropriate packaging material

dispose of ( spare parts and disposal).

The extraction hood is only intended for

cleaning of cooking vapours rising from

the cooking site and for private use in the

household.

- Only use the equipment in the household.

- The equipment is not intended for commer-

cial

use.

- Extraction hood only for the use over

electrical or gas cooking sites.

- Any other use is not considered as

conditional and is prohibited.

In particular, refrain from:

- Operating the extraction hood without the

metal grease lter. Missing the metal grease

lter leads

to massive grease accumulation in the extrac-

tion hood and the exhaust ducts.

- Flames under the extraction hood. It

may result in ignition of the grease accumu-

lation

.

- The operation of the cooking pot (all types of

heating: gas, electricic, etc.) without

cookware.

1.3 Children, persons with spe-

cial needs

1.4 Intended use

6

1 Safety instructions

- Open ames can lead to ignition

in the extraction hood.

- Cleaning the extraction hood with

unapproved means or

equipment, e. g. with a steam cleaner

( Maintenance).

- Repairs by an

unauthorised person ( Customer ser-

vice).

WARNING!

Risk of combustion Combustion may result

during faulty operation of the extraction

hood.

-Maintenance and cleaning instructions are

correctly complied with ( 4.6 Maintenance

intervals).

Basically refrain from:

- cook, roast and grill with open

ames due to the risk of re.

1.5 Risk of re

In the case unauthorised personnel inter-

vene, warranty and guarantee claims expire (

Warranty)

1.7 Defective equipment

WARNING!

Electric shock The extraction hood is opera-

ted with electricity. If the assembly, handling

and operation are wrong, it can result in

severe or fatal injury. Observe safety instruc-

tions.

1.6 Power supply

CAUTION!

Do not install or operate a defective extrac-

tion hood. Repairs are performed by specia-

lised personnel authorised by the manufactu-

rer ( Customer service).

7

2 Unpacking and assembly

The packaging material is recyclable. Save

the raw material and reduce the volume of

waste. Resupply package in the material cyc-

le. Your technician will revoke the packaging.

( 6.2 Disposal).

Observe the safety instructions for the as-

sembly and electrical connection ( Safety

instructions). Read the assembly instructions

completely before assembling.

It is imperative to respect instructions to

avoid injuries to persons and damage to

equipment.

No liability is assumed of the manufacturer

for damages arising from non-compliance of

these assembly instructions.

2.1 Unpacking

2.2 Assembly and electrical con-

nection

2.3.1 Testing the extraction hood

parts

These consist of:

- Extraction hood with motor box

Accessories:

- 10 screws and washers

8

2.3.2 General information on

assembly

WARNING!

Risk to life due to damage of supply lines. Du-

ring boring, supply lines (electricity, gas and/

or water lines) can be damaged. Before boring

be informed of the route of the supply lines (e.

g. with a search tool for metal and liv wires).

2 Unpacking and assembly

The extraction hood is attached ush-

mounted at the surface in the centre over the

cooktop.

9

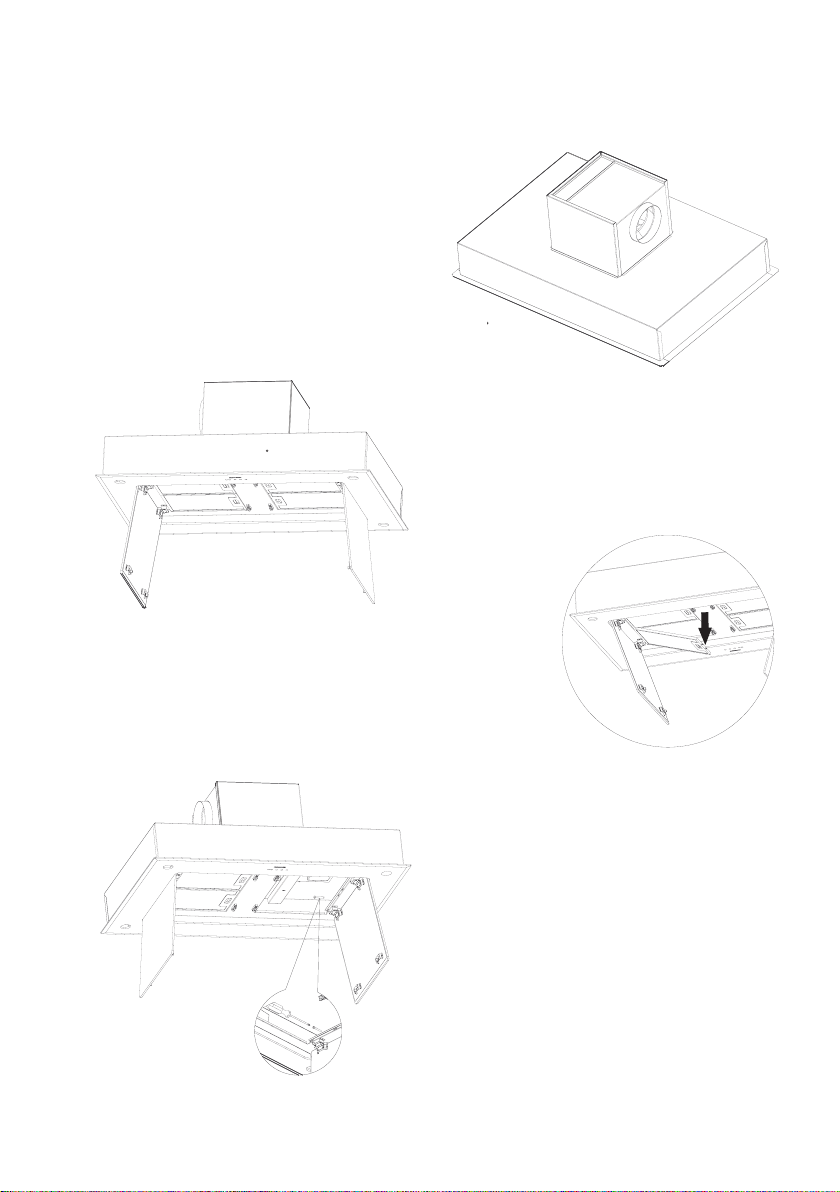

2.3.3 Assembly diagrams

Figure M3

Figure

M2a

Figure M1

Figure

M2b

2 Unpacking and assembly

10

2 Unpacking and assembly

2.3.4 Preparations for hood as-

sembly

- They require a ceiling section with a stable

wooden frame made of square timber or the

like.

The section dimensions are:

Vega interior: 1000 mm

(VGID 104) 958 mm x 656 mm

Vega interior: 1200 mm

(VGID 124) 1158 mm x 656 mm

- They can connect the exhaust air in all direc-

tions to the motor box (g.1). By turning the

motor box, you bring the air vents with a Ø

of 150 mm in the desired direction to the wall

sleeve or other part.

- Before installing the hood, transfer and join

the exhaust duct with a diameter of 150 mm

up to the wall sleeve or other part

1. Ceiling section

2. Exhaust air duct connection

direction

3. Installation of the exhaust air

duct from the hood to the wall slee-

ve or the like

Table of contents

Popular Ventilation Hood manuals by other brands

Gorenje

Gorenje S3 IHGC963S4X manual

KOBE

KOBE ISX2136SQB-1 Installation instructions and operation manual

U.S. Products

U.S. Products ADVANTAGE-100H Information & operating instructions

Kuppersberg

Kuppersberg DUDL 4 LX Technical Passport

Framtid

Framtid HW280 manual

Thermador

Thermador HGEW 36 FS installation manual