Digital Pressure Indicator DPI - Bedienungsanleitung

2 Friedrich Leutert GmbH & Co. KG

Content

1 Safety instructions .............................................................................4

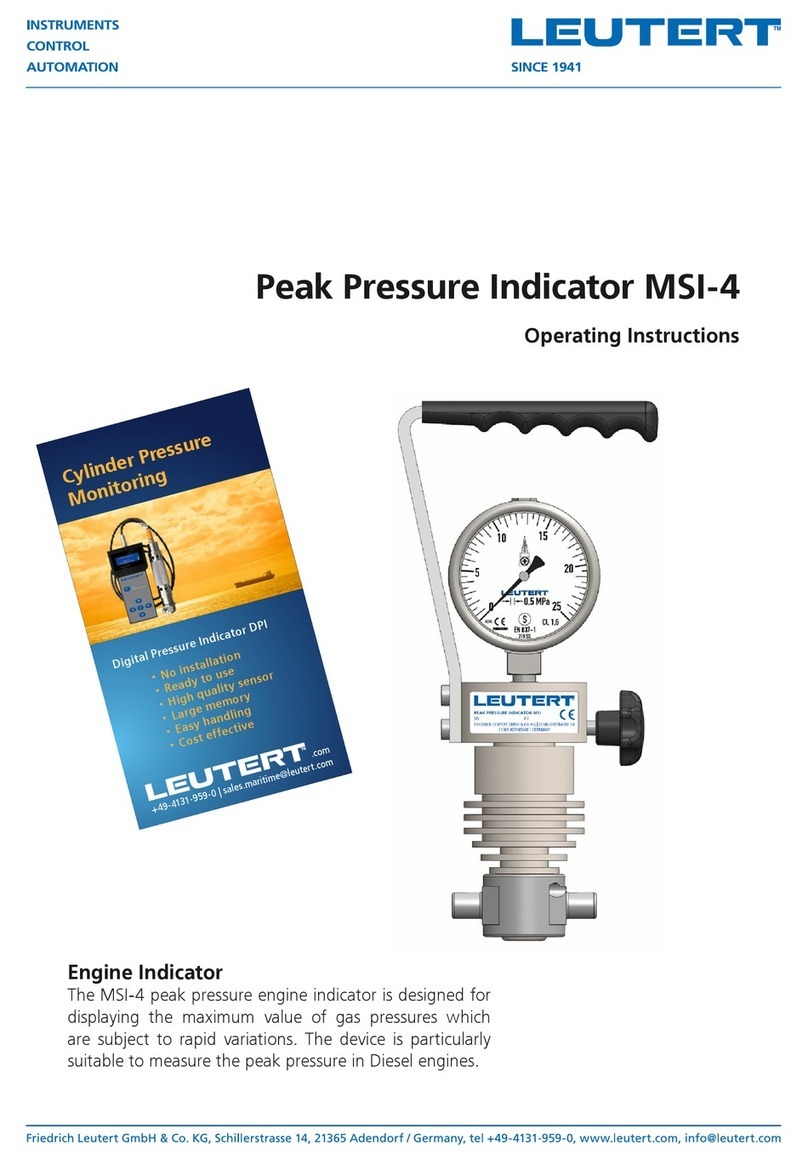

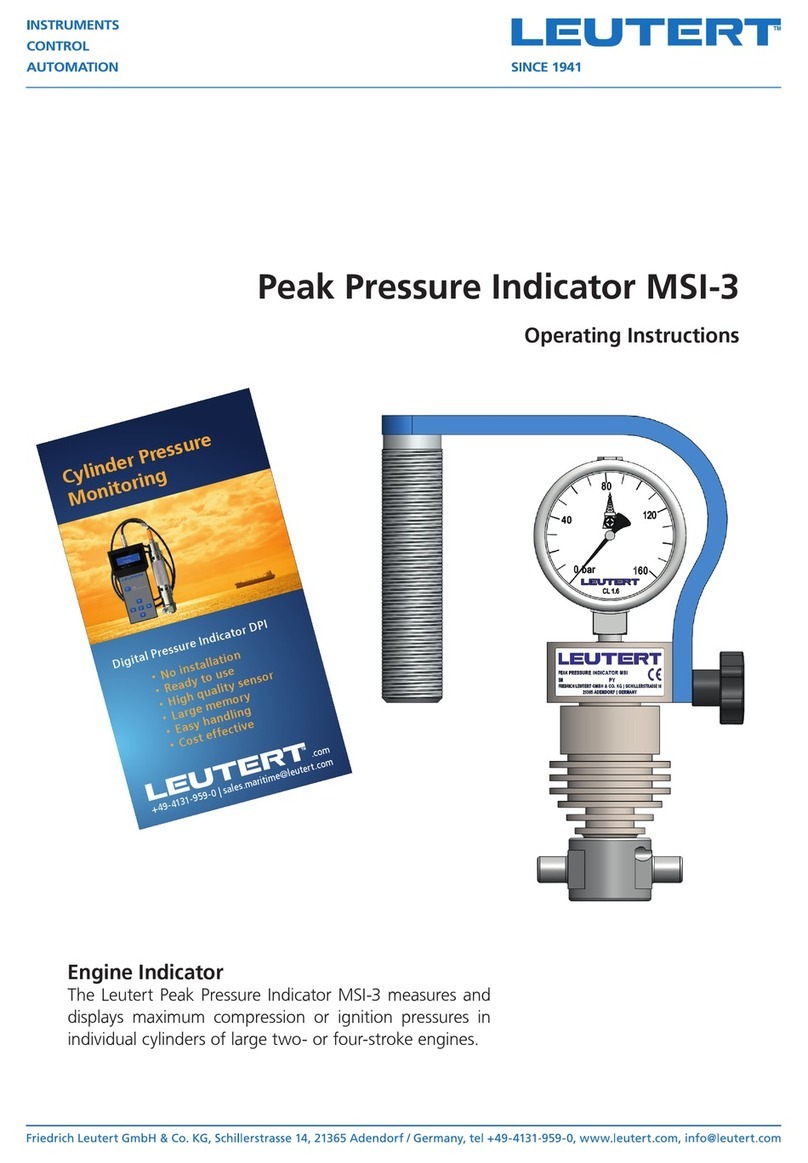

2 Product description............................................................................5

2.1 Application and function ..........................................................5

2.2 Handheld device.......................................................................6

2.2.1 Design..........................................................................6

2.2.2 Technical data ..............................................................7

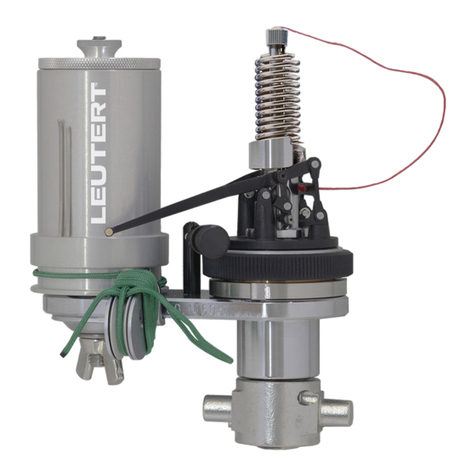

2.3 Pressure sensor.........................................................................8

2.3.1 Design..........................................................................8

2.3.2 Technical data ..............................................................8

2.4 Software ..................................................................................9

2.4.1 Description...................................................................9

2.4.2 Requirements for the PC ..............................................9

3 Prepare the DPI system for use.........................................................10

3.1 Software installation...............................................................10

3.2 Prepare the handheld device for the measurement.................. 12

3.2.1 Enter motor parameters.............................................. 12

3.2.2 Transfer motor parameters to the handheld device .....14

3.3 Set date and time of the handheld device ...............................16

4 Perform measurement on the motor................................................ 17

5 Display measurement results ............................................................21

5.1 Transfer data records from the handheld device to the PC....... 21

5.2 Analyzing measurement data with the DPI software ...............23

5.2.1 Pressure Plot...............................................................24

5.2.2 TDC Correction ..........................................................28

5.2.3 PV Plot .......................................................................30

5.2.4 Bar Graph ..................................................................32

5.2.5 Data Info ....................................................................34

5.2.6 Raw Data ...................................................................35

5.3 Sending and receiving measurement data by email .................36

6 Organize measurement data in the handheld device ........................38

6.1 View data records on the handheld device..............................38

6.2 Delete data records in the handheld device.............................39

7 Maintenance....................................................................................40

7.1 Maintenance of the pressure sensor........................................40

7.2 Cleaning the pressure sensor ..................................................40

7.3 Charging the handheld batteries............................................. 41

7.4 Changing batteries .................................................................42

7.5

Setting the contrast, background lighting of the handheld device

.43