PRO-TEK 9216A User manual

PROTEK 9216A

Digital LCR Meter

User’s Manual

Volume1: BasicOperation Rev.3.0

2

Table of contents

Introduction...........................................................................................................................................................4

Warranty.........................................................................................................................................................4

General Safety Summary..............................................................................................................................5

Preventing Injury.....................................................................................................................................5

Preventing Instrument Damage..............................................................................................................5

Maintenance, Repair, and Storage...................................................................................................5

Product Damage Prevention............................................................................................................6

Line Voltage Requirements..............................................................................................................6

Fuse Requirements..........................................................................................................................6

Conventions Used in This Manual .................................................................................................................7

Safety Terms...........................................................................................................................................7

Product Familiarization.........................................................................................................................................8

Front Panel Components...............................................................................................................................8

Fixture Inputs...........................................................................................................................................8

Measurement Modes and the Mode Selection Keys...............................................................................9

Alphanumeric Displays and Parameter Indicators..................................................................................9

Programming and Operator Interface Keys..........................................................................................10

Rear Panel Components..............................................................................................................................12

Specifications...............................................................................................................................................13

Display...................................................................................................................................................13

Test Conditions......................................................................................................................................13

Accuracy................................................................................................................................................13

Features and Options...................................................................................................................................14

General Features...................................................................................................................................14

Options..................................................................................................................................................15

Basic Operations.................................................................................................................................................16

Operation of the LCR Meter For the First Time...........................................................................................16

Unpacking and Inspection.....................................................................................................................16

Installation .............................................................................................................................................16

Startup Procedures......................................................................................................................................17

Before Applying Power..........................................................................................................................17

Before Using the Test Fixture................................................................................................................17

Fixture Options...............................................................................................................................17

Null Calibration Procedure..............................................................................................................18

Changing Test Setup Parameter Settings....................................................................................................18

3

.

.

.

.

.

.

.

.

.

Default Setup.........................................................................................................................................19

Changing, Storing, and Recalling Custom Setups................................................................................20

Measurement Mode........................................................................................................................20

Frequency.......................................................................................................................................20

Drive Voltage..................................................................................................................................21

Bias.................................................................................................................................................22

Measurement Rate.........................................................................................................................24

Settling Time..................................................................................................................................25

Triggering........................................................................................................................................25

Store and Recall.............................................................................................................................26

Range.............................................................................................................................................26

Series and Parallel Equivalent Circuits..........................................................................................29

Display Types.................................................................................................................................29

4

Introduction

ImportantBackgroundInformation

The PROTEK 9216A DIGITAL LCR Meter is a high quality instrument that gives you

many years of good service. Please read the information in this chapter before using or

applying power to the meter. Information on operating and using the meter is given in

the following chapters.

Warranty

PROTEK warrants that this product will be free from defects in materials and

workmanship for a period of one year from the date of purchase. If any such product

proves defective during this warranty period, PROTEK, at its option, either will repair the

defective product without charge for parts and labor, or will provide a replacement in

exchange for the defective product.

In order to obtain service under this warranty, the customer must notify PROTEK of

the defect before the expiration of the warranty period and make suitable arrangements

for the performance of service. The customer shall be responsible for packaging and

shipping the defective product to the service center designated by PROTEK, with

shipping charges prepaid. PROTEK shall pay for the return of the product to customer if

the shipment is to a location within the country in which the PROTEK service center is

located. The customer shall be responsible or paying all shipping charges, duties, taxes,

and any other charges forproducts returned to any other locations.

This warranty shall not apply to any defect, failure or damage caused by improper

use or improper or inadequate maintenance and care. PROTEK shall not be obligated

to furnish service under this warranty:

To repair damage resulting from attempts by personnel other than PROTEK repre-

sentatives to install, repair or service the product;

To repair damage resulting from improper use or connection to incompatible

equipment; or

To service a product that has been modified or integrated with other products when

the effect of such modification or integration increases the time or difficulty of

servicing the product.

This warranty is given by PROTEK with respect to this product in lieu of any other

warranties, expressed or implied. PROTEK and its vendors disclaim any implied

warranties of merchantability or fitness for a particular purpose.

Chapter

1

5

.

.

.

.

.

.

.

.

.

PROTEK’s responsibility to repair or replace defective products is the sole and

exclusive remedy provided to the customer for breach of this warranty. PROTEK

and its vendors will not be liable for any indirect, special, incidental, or

consequential damages irrespective of whether PROTEK or the vendor has

advance notice of the possibility of such damages.

General Safety Summary

Review the following safety precautions to avoid injury and prevent damage to this

product or any products connected to it.

NOTE: Only qualified personnel should perform service procedures.

Preventing Injury

Use Proper Power Cord. To avoid fire hazard, use only the power cord specified for this

product.

Avoid Electrical Overload. To avoid electric shock or fire hazard, do not apply a voltage

to a terminal this is outside the range specified for that terminal.

Ground the Product. This product is grounded through the grounding conductor of the

power cord. To avoid electric shock, the grounding conductor must be connected to

earth ground. Before making connections to the input or output terminal of the product,

ensure that the product is properly grounded.

Do Not Operate Without Cover. To avoid electric shock or fire hazard, do not operate

this product with covers or panels removed.

Use Proper Fuse. To avoid fire hazard, use only the fuse type and rating specified for

this product.

Do Not Operate in Wet/Damp Conditions. To avoid electric shock, do not operate this

product in damp or wet conditions.

Do Not Operate in an explosive atmosphere. To avoid injury or fire hazard, do not

operate this product in an explosive atmosphere.

Keep Probe Surface clean. To avoid electric shock and erroneous readings, keep the

probe surface clean.

Preventing Instrument Damage

Maintenance, Repair, and Storage

This equipment is composed of many high-precision components and components

which require high internal pressure. Care is required when handling or storing this

equipment.

Occasionally, if the surface of the panel is dirty, rub the affected area lightly with a

soft cloth soaked in a light neutral detergent or alcohol. Never use highly volatile

material such as benzene or paint thinner.

The ideal ambient temperature range for storing this equipment is 10C to 60C

(14F to 140F).

6

To avoid personal injury, do not remove the product covers. Do not operate the

product without the covers properly installed.

Two spare fuses are shipped with this equipment.

In order to maintain this equipment in a stable and efficient operating condition,

calibrate the equipment after every 1,000 hours operating time or every 6 months,

whichever is shorter.

Product Damage Prevention

Use Proper Power Source. Do not operate this product from a power source that

applies more than the voltage specified.

Provide Proper Ventilation. To prevent product overheating, provide proper ventilation.

Do Not Operate With Suspected Failures. If you suspect there is damage to this

product, have it Suspected Failures inspected by qualified service personnel.

Do not immerse in Liquids Clean the probe using only a damp cloth. Refer to the

cleaning instructions.

Line Voltage Requirements

Refer to the following table for the correct operating voltage ranges for this LCR meter.

Check the line voltage prior to connecting to the power source, and verify that it is within

a voltage range listed below.

Rating

Operating Voltage Range

AC 115 V

AC 98 V–132 V

AC 230 V

AC 196–253 V

If the LCR meter is to be used at a voltage other than 230V AC, the operating voltage

may be changed by the following procedure ·

Remove the power cable from AC input.

Insert a flat-bladed screwdriver into the slot located on right side of the fuse holder

cap; remove the cap by pressing and then pulling up the screwdriver.

Rotate the cap on the fuse holder to set the voltage to the desired level.

Connect power cable to the AC input.

If a voltage below AC 115 V is required, the power cable and fuse may need to be

changed. In such case, contract your nearest dealer for appropriate service.

After use, disconnect the equipment from the AC outlet.

Fuse Requirements

In order to prevent circuit damage resulting from over current, use the correct fuse value.

The fuse ratings are as follows.

7

.

.

.

.

.

.

.

.

.

Circuit No.

Shape (diameter length) mm

Rating

Remarks

F1101

5.2 20

250 V T500 mA

For AC l15V

250 V T250 mA

For AC 230 V

F601

5.2 20

250 V F250 mA

The internal fuse rating is as follows:

Circuit No.

Shape (diameter length) mm

Rating

Remarks

F602

5.2 20

250 V F250 mA

Note: Refer to the section on troubleshooting in the Reference Manual for instructions

on replacement of the internal fuse.

Conventions Used in This Manual

In this manual, you will find various procedures, which contain steps of instructions

for you to perform. To keep these instructions clear and consistent, this manual

uses the following conventions:

Operating procedures and names of front panel controls are in uppercase and

boldface print.

The case of each name used in the manual is the same (Initial Capitals or

UPPERCASE) as that used on the instrument itself.

Instruction steps are numbered (1, 2, 3, ), unless there is only one step.

When steps require that you make a sequence of selections using front panel

controls and keys, an arrow () is used in the text to indicate an LED result when a

front panel entry is made. Also, whether a name is a key or LED display reading is

clearly indicated:

Example: Press DISP (Entry) ENTER

Safety Terms

The following terms are also used in this manual:

WARNING identifies conditions or practices that could result in injury.

CAUTION identifies conditions or practices that could result in damage to this

product or other property.

NOTICE identifies conditions or practices that could result in incorrect test

data.

8

Product Familiarization

DescriptionoftheLCRMeterandItsFeatures

In this chapter, the controls and connections of the LCR Meter are described, and its

basic operation is summarized in terms of the meter’s specifications, features and options,

and operating modes.

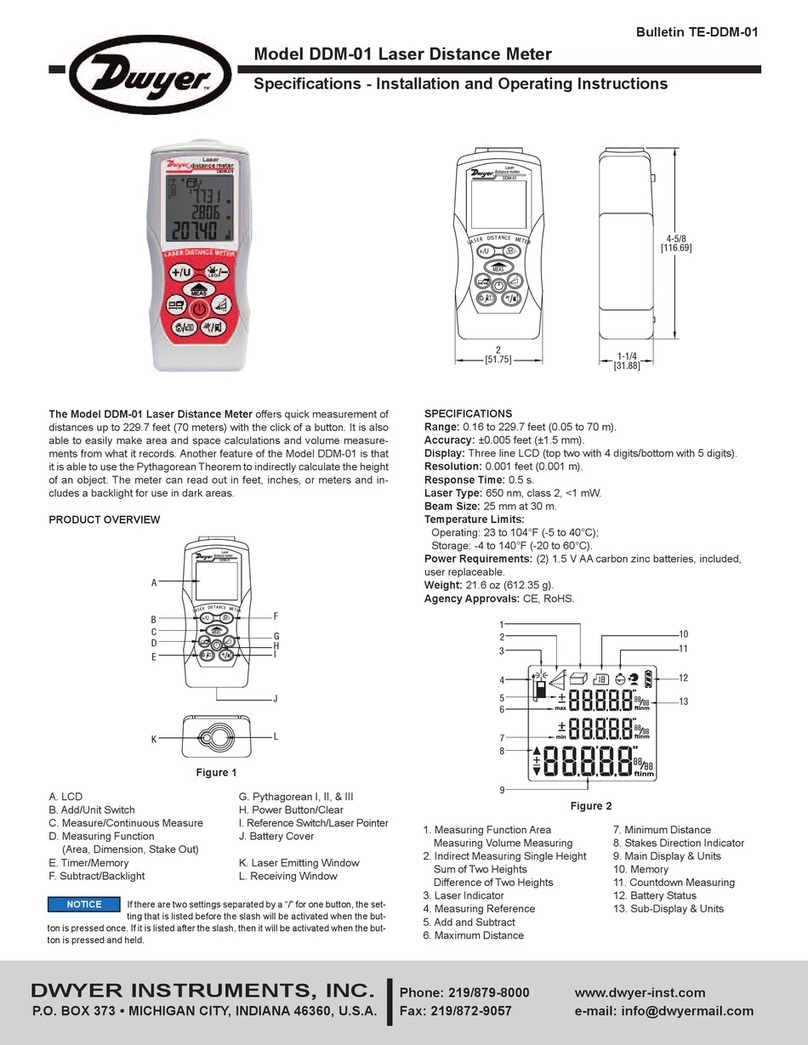

Front Panel Components

The front panel and its displays, controls, and connections are shown in the following

illustration:

Test Frequency Measurement Rate

Bias

Test Voltage Display option Back space

Measurement modeFixture inputs Trigger

Setup Key pad Enter

First, the displays, controls, and connections on the left side of the front panel are ex-

plained, and thenthe many buttons and keysonthe right side are described.

Fixture Inputs

The input terminals labeled IL, PL, PH, and IH connect the test fixture or adapter to the

instrument, as discussed in the section in Chapter 3 on “Connecting a Component.” Two

of the terminals provide a current source to the component under test, and the other two

terminals provide a high impedance connection to measure the voltage across the device.

This four-wire or “Kelvin” type of measurement setup is designed to increase accuracy by

reducing the amount of current in the voltage-sensing wires. Warning: Do not connect

any active voltage source to these terminals, especially high voltages.

Measurement Modes and the Mode Selection Keys

These keys select the measurement to make on the component under test. One of five

measurement modes may be selected: Auto, R+Q, L+Q, C+D or C+R. The selected

Chapter

2

9

mode is indicated by LEDs above the alphanumeric displays. The operation of each

mode can be explained as follows:

AUTO In this mode, the meter automatically selects the most appropriate

measurement on the device. The selection is made according to the following

criteria:

If |Q| < 0.125, the meter selects the R+Q measurement mode.

If Q > +0.125, the meter selects the L+Q measurement mode.

If Q < 0.125 and the meter is in the series equivalent circuit mode, the C+R

measurement mode is selected.

If Q < 0.125 and the meter is in the parallel equivalent circuit mode, the C+D

measurement mode is selected.

R+Q In this mode, resistance is displayed on the main parameter display

and the Q (quality factor) is displayed on the secondary parameter display. The R-

value is either the series or parallel equivalent resistance of the component under test.

The unit for R is , k, or M. The Q value is the dimensionless ratio of the

imaginary part of the component’s impedance to its real part. If Q has a positive (+)

value, the reactive component of the device under test is inductive. If Q has a

negative () value, it is capacitive.

L+Q In this mode, the series or parallel equivalent inductance value of a

component under test is displayed on the main parameter display units in units of µH,

mH, or H, and its dimensionless Q value is displayed on the secondary parameter

display.

C+D In this mode, the series or parallel equivalent capacitance value of a

component under test is displayed on the main parameter display in units of pF, nF,

or µF. On the secondary parameter display, the dimensionless ratio D 1/Q is given.

D is normally a smallvaluefora good capacitor.

C+R In this mode, the capacitance is displayed on the main parameter

display and the equivalent resistance is displayed on the secondary parameter

display. The unitfor resistance is unless the kindicator LED is lit.

Alphanumeric Displays and Parameter Indicators

The two 5-digit (plus sign) LED

1

-segmented alphanumeric displays provide measurement

results, entered parameter values, and status messages. The left display gives the value

of the main parameter of the component under test (L, R, C) and the right display gives

the value of its secondary parameter (Q,D, R, %). Above and next to these two

alphanumeric displays are various LEDs that, when lit, indicate something about the

measurement:

1

LED = light-emitting diode

10

AUTO, R L, C, % LEDsthat indicate the measurement type forthe main parameter

Q, D,R, % LEDs that indicate the measurement type for the secondary

parameter

, k, MLEDs indicating the unitsof the value being displayed on the left

µH, mH, H

pF, nF, F

kThe right-side display is dimensionless or has units of ohms

unless thisLEDis on.

REM, ACT, ERR These LEDs give information on the status of the remote control

(computer) interface operations.

REM: Indicates that the display is being controlled remotely via the interface

connector on the rear panel.

ACT: Indicates that the remote control interface isactive.

ERR: Indicatesthat a remote command contained an error.

NOM, LIM, LIM Indicates which Binning

2

parameter is being entered

Programming and Operator Interface Keys

On the right side of the front panel of theLCR meter, there are many buttons and keys for

programming test conditions and for general operator interface. These keys are grouped

according to function, and some groups have LED indicators associated with them show

which option has been selected.

Frequency The 9216A has five selectable fixed frequencies with an accuracy to

100ppm (0.01%). 100Hz, 120Hz, 1kHz, 10kHz or 100 kHz may be selected by

pressing the up/down keys on the front panel keypad until its corresponding LED is

illuminated.

Drive Voltage

VOLT Pressing the VOLT key, the output voltage will cycle through three

fixed output drive voltages (0.1V, 0.25V, 1.0V). An LED indicates the selected

drive voltage. If NO LED is lit, then the output drive voltage is in the vernier

mode.

CONS This key sets the meterto the constant voltage mode.

BIAS Thebias mode isused onlyfor capacitance measurements. Pressing

these keys for any other measurement will generate the “bias for c” error message.

INT Selects a 2.0 VDC internal bias.

EXT Selects a voltage from an external source to be applied to the

capacitor under test.

2

Binning is explainedlater.

11

MEAS RATE Selects the measuring rate. At frequencies of 1 kHz or greater, slow

(2 measurements per second), medium (10 measurements per second, and fast

measurements (20 measurements per seconds) may be selected.

DISPLAY

Average The average of 2 to 20 measurement readings will be displayed.

The numberof measurements in the average is selected fromthe keypad.

HOLD This key holds the meter in its current measurement range. Pressing

the hold key a second time returns the meter to the Auto-Range mode. A

specific range mayalso be entered from the numeric keys on the keypad.

EQU This key toggles the equivalent circuit for the component under test

between a series or parallel circuit.

DISP The DISP key cycles through the display parameters that may be

selected. The display parameters that may be selected are:

VALUE The measured value of the device under test is displayed.

DEV The deviation from a value previously entered is displayed.

% DEV The percent deviation from a previously entered value is

displayed.

ENTRY Usedfor entering parameter values.

BINS Selectsthe bin number when Binning is enabled.

Note: Certain displays are not available unless data has been entered. For example,

DEV and % DEV are not available unless a nominal value has already been entered.

Also, BINS is notavailable unlessbinning data has previously been entered.

Backspace key used for correcting mistakes when entering

numeric data. This key also serves as the “Local” function.

[0]...[9] These keys are used to enter parameters and are only active

when the meter is in the ENTRY mode.

ENTER [, µH, pF], [k, mH, n F], [M, H, µF]. These three keys are

used for entering numeric parameters in the entry mode (e.g. R, L, C

values). The bottom-most key (M, H, µF) may be used as a general

entry key for entering parameters not listed on the keypad, such as

percent %.

SETUP

STO, RCL The 9216A can store up to nine setups in the memory. To

store the present configuration in memory location #n, press STO [n]

ENTER. To recall a setup, press RCL [n] CAL ENTER.

CAL Enables a series of internal calibration routines, including

open/short and settling time calibration, output amplitude drive, and

internal self-tests.

BIN#, NOM, LIM These keys are used to enter Binning parameters.

The BINNING LED is on when Binning is enabled and the optional

handler is active.

12

TRIGGER

MODE This key toggles between continuous (CONT) or TRIGGERED

measurements .

TRIG When TRIGGER mode is selected, measurements are initiated when this

key is pressed or by the handler or computer interfaces. The TRIG LED will flash

when this mode is enabled.

Rear Panel Components

The rearpanel and its controls and connections are shown in thefollowing illustration:

[1] AC POWER CONNECTOR The AC power cord is inserted into this connector. The

fuse and line voltage selectorare located in the connectorhousing.

[2] POWER SWITCH Turns the meter on and off.

[3] EXTERNAL BIAS INPUT Two banana plugs are used to input an external bias

voltage. The bias supply voltage must be floating and well filtered. Neither input

connector can be referenced to ground.

[4] EXTERNAL BIAS FUSE Protects external bias circuit from currents greater than 250

mA.

[5] RS232 DB25 This connector allows the meter to communicate as a DCE (data

communications equipment, e. g. a modem) to a DTE (data terminal equipment, e.g.,

a computer) using the RS-232C protocol. For further information, refer to the

material on remote programming inthe Reference Manual.

[6] SW1 The switches set the RS232C protocol parameters. The Baud rate, word

length and parity may be set.

13

Specifications

Display

Measurement Modes: Auto, R+Q, L+Q, C+D, C+R

Equivalent Circuit: Series or Parallel

Parameters Displayed: Value, Deviation, % Deviation or Bin Number. Deviation

and % deviation are calculated from a stored relative value

Averaging: 2–10 Measurements

Measurement Range: R+Q: R: 0.0001–2000 M

Q: 0.00001–50

L+Q: L: 0.0001 µH–99999 H

Q: 0.00001–50

C+D: C: 0.0001 pF–99999 µF

D: 0.00001–10

C+R: C: 0.0001 pF–99999 µF

R: 0.00001–99999 k

Test Conditions

Test Frequency: 100 Hz, 120 Hz, 1 kHz, 10 kHz, 100 kHz

Frequency accuracy: ±100ppm.

Drive Voltage: Preset Levels: 0.10, 0.25, and 1.0 Vrms.

Vernier: 0.1 to 1.0 Vrms with 50 mV resolution.

Drive level accuracy: ±2%.

Measurement Rates: (a) Slow(2 meas./sec.), Medium (10 meas./sec.), orFast

(20 meas./sec.) for test frequencies of 1 kHz and above.

(b) Approx. 0.6, 2.4, or 6 measurements per second at

100 Hz and120 Hz.

Ranging Auto or Manual

Triggering Continuous, Manual, or Remote over RS232 or

Handler Interface

Bias Voltage Internal: 2.0 VDC ±2%

External: 0 to +40 VDC (fused @ 0.25 A)

Accuracy

Conditions: Allow 30 minutes of warmup before measurements; all accuracies are at

23°C (73F) ±5°C

Basicaccuracy0.05%. Refer to the accuracy section in the Reference Manual for

detailed specifications.

The following summarizes typical accuracy specifications:

14

Accuracy Value

better than 1% for R > 0.125 and R < 16 M

L > 2.5 H and L < 25 kH

C > 1.25 pF and C < 12.8 mF

better than 5 % for R > 21 mand R < 96 M

L > 420 nHand L <l50 kH

C > 0.21 pF and C < 77 mF

at the following conditions:

1.0V, 0.5V, or 0.25V output voltage

Slowor medium measurement speed

Q and D < 0.1 for R and C

Q > 10 for L

100Hz, 120Hz or 1 KHz test frequency for R

100 Hz test frequency for Lmax and Cmax

10 KHz test frequency for Lmin and Cmin

Features and Options

General Features

Feature

Specification

Fixture

4-wire Kelvin fixture for parts with radialand axial leads

Protection

Protected up to 1 Joule of stored energy, 200 V DC for charged capacitors;

fusedat 0.25 A output currentfor biased measurement

Zeroing

Open and short circuit compensation. Compensation Limits: short circuit:

R<20, Z<50, open circuit: Z>10k

Binning

Up to 8 Pass Bins, QDR and General Fail Bins, all defined by the front panel or

computer interface. Binning setups may be stored in nonvolatile memory

Self Test

Tests the ROM, CPU, nonvolatile RAM, clock generator, A/D converter,

internal bias, multiplier, output drive circuitry, gain circuitry, and source

resistances.

Store and Recall

memory

Stores and recalls nine complete instrument setups. Recall 0 recalls the default

setup.

RS232 Interface

All instrument functions can be controlled or read over the interface.

Operating Conditions

0 to 50°C at a relative humidity of 0 to 80%

Power

20 Watts, 110/220 VA, 50/60 Hz

Dimensions

4 ¼ " H 14 ¼ " W 15" D

Weight:

12 ¾ lbs

Warranty

Two year parts and labor on materials and workmanship

15

Options

Feature

Specification

IEE-488 interface

Instrument functions can be controlled and read over this interface

Handler/sorter interface

DB male connector provides the signal linesforbinning, instrument

status and input trigger.

Note: option consists of both interfaces

Kelvin clips

Provides connection to devices that are not easily accommodated by the

test fixture. Polarity is indicated for biased measurements.

SMD Tweezers

Provides connection to surface mount components

BNC fixture adapter

Connects remote fixtures or devices to the 9216A

16

Basic Operations

Howthe9216AOperatesandWhatItCanDo

The 9216A LCR meter is very versatile in that the user can customize the

measurement and operating modes to obtain the best results in a particular

situation. In this chapter, the basics of the meter’s operation are summarized.

Operation of the LCR Meter For the First Time

Before using 9216A LCR Meter, ensure that it is properly installed, and powered

on.

To get the maximum accuracy for your most critical measurements you

should know how to select the various options and to set up the test conditions

and the proper use of the test fixture you have chosen to use with your meter.

Unpacking and Inspection

After unpacking the 9216A LCR Meter, verify that all parts are included and have

not been damaged during transportation. Retain the packing materials.

Packing Contents:

9216A LCR Meter

Radial Fixture

Power Cord

User Manuals

Installation

To properly installand poweronthe meter, perform the following steps:

Be sure you have the appropriate operating environment.

Leave a space of at least 5.1 cm (2 in) on each side of the meter for proper

ventilation.

Check the fuse for proper type and rating.

Checkfor proper electricalconnections.

Connect theproper powercord to thepower connector on the rear panel.

Chapter

3

17

Startup Procedures

When turned on, the meter will first enter the self-test mode and perform the

following procedure: first, it will display the program version “0X” and the model

number “HC9216” for about three seconds. Next, the meter will display “test” and

“…..” while it performs the self-test. If all tests are successful, “test pass” will be

displayed as a result. In order for the self-test to operate correctly, it is important

to followcertain startup procedures.

Before Applying Power

Prior to turning the unit on, be sure there are no components in the input fixture.

Components in the fixture will cause the self-test to fail and display an error code.

Before Using the Test Fixture

When the self-test is completed, “over range” will be displayed, and the user can

proceed to set up the test conditions and to make measurements. For maximum

accuracy, however, a “null calibration” of the test fixtures needs to be performed

before taking any measurements.

Fixture Options

On the frontpanelof the instrument there are four BNC connectorsdesignated IL,

PL, PH, IH. In what is known as a “4-wire Kelvin connection,” two of these

terminals provide current to and from the device under test, and two of the

terminals sense the potential (voltage) across the device. Separate wires are

used for sensing thevoltage so to minimize the effect of the current in the sensing

wires inside the meter and to minimize stray impedance that can cause

measurement errors.

There are several fixtures available for special measurements: Radial fixture

(standard), Kelvin clips, SMD tweezers, and BNC adapter. The optional fixtures

may be purchased through our distributors.

The standard 9216A test fixture attaches to the four input terminals on the front

panel of the meter and provides two polarized, spring-loaded connection slots to

secure radial-leaded components under test while they are being measured. The

fixture also accommodates axial-leaded components whose leads are bent to

enable insertion into the fixture. Most components will plug into this test fixture,

therebyeliminating the need for special fixtures.

18

Null Calibration Procedure

Whenever the test configuration is changed, including a change of the fixture,

open and short circuit “null” calibrations should be made prior to taking

measurements to compensate for stray impedances, such as component lead

impedance, andfixture, cable and other stray capacitance. Null calibration should

be performed after any change in fixture configuration or for changes in the drive

amplitude. This calibration corrects for all frequencies and all ranges-it is not

necessary to re-calibrate for changes in frequency. For critical measurements,

null calibration should be performed frequently at some interval during the course

of measurements.

The LCR meter store open and short circuit calibration data in nonvolatile

memory. These data values are stored with the STO key and recalled using the

RCL key, allowing null calibration data to be saved for different fixtures.

The null calibration procedure is on the menu that is invoked by pressing the

CAL (Calibrate) key in the SETUP group of keys on the front panel of the meter.

To perform a null calibration, press the CAL key until the message “nuLL cAL”

appears on the alphanumeric display. Pressing the ENTER key while this

message is being displayed causes the message to change to “Short cAL.”

The short-circuit null calibration is done by placing a wire in the fixture

(thereby shorting the fixture’s terminals) that is between 26 to 16 AWG (0.02" to

0.05" or 0.51 to 1.30 mm dia.). The calibration proceeds automatically after the

user presses the ENTER key and moves hands and any miscellaneous objects

away from the fixture. When the short circuit calibration is finished, the meter

prompts the user for the next operation by displaying the message “oPEn cAL.”

To perform the open-circuit null calibration, remove the shorting wire, press

ENTER and again move hands away from the fixture. When the unithas finished,

it displays the message “cAL donE.” To dismiss this message and return to a

normal display mode, press the DISP (Display) key.

Changing Test Setup Parameter Settings

When powered on, the 9216A LCR Meter initially uses the default test setup

parameters, which include selection of the automatic (AUTO) measurement

mode, and the result of the measurement is displayed on the alphanumeric

readout. For most measurements, the test conditions in the automatic mode are

sufficient. However, by pressing the parameter keys on the front panel, the user

may enter customized test setup parameter selections, and by pressing the

keypad keys, enter the desired values of test parameters. Test parameters that

are not associated with dedicated keys on the front panel or keypad, such as the

number of measurementsbeing averaged, deviationmeasurements, etc., may be

entered by pressing the DISP key to enter the ENTRY mode. Table 3-1 below

shows appropriate settings for typical component values.

19

Table 3-1 Test Setup Parameter Settings for Typical Component Values.

Component

Value

Meas. Mode

Equiv. Circuit

Frequency

Unknown

Any

AUTO

Series

1 kHz

Resistor

< 1 k

> 1 k

R+Q

Series

1 kHz

100 or 120 Hz

Inductor

< 10 H

10 H–1 mH

1 mH–1H

> 1H

L+Q

Series

100 kHz

10 kHz

1 kHz

100 or 120 Hz

Capacitor

< 10 pF

10 pF–400 pF

400 pF–1 F

> 1 F

C+D

C+D

C+D

C+R or C+D

Parallel

Series or parallel

Series

Series

10 kHz

10 kHz

1 kHz

100 or 120 Hz

Default Setup

Holding down the backspace key () key while turning on the power to the meter

causes the meter to have the default setup values as listed in the table below.

Note: Alluser calibration settings and values will be lost.

To prevent the user calibration settings from being destroyed, after turning on

the meter without pressing the backspace key,press RCL [0] ENTER. This

key sequence will reset the meter to the default settings listed in the table below

without affecting user-entered calibration values. See the sections that follow for

more details on the settings listed in the table below.

Table 1-1: 9216A default settings

Setting

Value

Parameter

AUTO

Frequency

1KHz

Drive Voltage

1.0Vrms.

Bias

OFF

Measurement Rate

SLOW

Averaging

OFF

Range Hold

OFF

Equivalent Circuit

SERIES

Display

VALUE

Trigger Mode

CONT

Binning

OFF

Table of contents

Other PRO-TEK Measuring Instrument manuals

PRO-TEK

PRO-TEK B-810 User manual

PRO-TEK

PRO-TEK A734 User manual

PRO-TEK

PRO-TEK Z9216 User manual

PRO-TEK

PRO-TEK A434L User manual

PRO-TEK

PRO-TEK A734 User manual

PRO-TEK

PRO-TEK 3201 User manual

PRO-TEK

PRO-TEK 1006 User manual

PRO-TEK

PRO-TEK WI Series User manual

PRO-TEK

PRO-TEK 3290N User manual

PRO-TEK

PRO-TEK B8000FD Series User manual

Popular Measuring Instrument manuals by other brands

Seaward

Seaward Solar Survey 200R manual

Honeywell

Honeywell Touchpoint Plus quick start guide

Siemens

Siemens SIPROCESS GA700 Compact operating instructions

Dwyer Instruments

Dwyer Instruments DDM-01 Installation and operating instructions

QUINN

QUINN 57460 Owner's manual & safety instructions

Keysight

Keysight M9602A PXIe Startup guide