Blue I HYDROGUARD HG-202 User manual

1 Water. Quality. Secured.

HYDROGUARD HG-202

Water Quality Analyzer

User manual

Version 4.1

2 Water. Quality. Secured.

Rev.

By

Changes made

Date

4.0

BM

Update to pictures, logo, chlorine electrode

31.7.19

1.4

BM

Installation Section Updated

11.8.19

3 Water. Quality. Secured.

Table of Contents

1 General Safety Precautions ...................................................................................4

2 Preface...................................................................................................................5

2.1 Intended Use ...................................................................................................5

2.2 Safety Precautions ..........................................................................................5

3 Overview.................................................................................................................6

3.1 Features and Modules.....................................................................................6

3.2 Remote Communications................................................................................6

3.3 System Components .......................................................................................6

4 Installation .............................................................................................................8

4.1 Selecting a Location ........................................................................................8

4.2 Mounting the controller and connecting the electrodes ................................8

4.3 Plumbing Requirements and Installation .......................................................9

4.3.1 Water Supply.......................................................................................... 10

4.3.2 Water Return.......................................................................................... 10

4.4 Electrical Requirements and Installation ..................................................... 10

4.4.1 NTU card Electrical Installation ............................................................ 11

4.4.2 Input Switches........................................................................................ 11

4.5 Wiring to Dosing Systems ............................................................................. 12

4.5.1 Wiring the Turbidity Relay...................................................................... 12

5 First Time Operation and Calibration .................................................................. 14

5.1 HydroGuard Control Panel ............................................................................ 14

5.2 Menus and Settings....................................................................................... 15

5.2.1 Configuration Setting ............................................................................. 16

5.2.2 Technician’s Menu ................................................................................. 16

5.2.3 Operation Checklist................................................................................ 17

5.2.4 Turbidity Relay and External Equipment Operation .............................. 17

6 Calibration............................................................................................................ 18

6.1.1 pH Calibration ........................................................................................ 18

6.1.2 ORP Calibration...................................................................................... 19

6.1.3 Chlorine/Turbidity Calibration ............................................................... 19

7 Optional Controller Features............................................................................... 21

7.1 Flow Meter .................................................................................................... 21

8 Routine Operation and Maintenance ................................................................... 23

9 Relays, Menus and Alarms .................................................................................. 24

9.1 Relays ............................................................................................................ 24

9.2 Operator’s Menu............................................................................................ 24

9.3 Monitoring HydroGuard Alarms .................................................................... 25

10 Troubleshooting................................................................................................... 26

4 Water. Quality. Secured.

1General Safety Precautions

This section presents important information intended to ensure safe

and effective use of this product.

Read the following carefully before handling the product. These

warnings and cautions must be followed carefully to avoid injury to

yourself or damage to equipment.

Warning: Only properly trained and licensed electricians should attempt to wire or service the electronic

components of the analyzer/controller.

There is an Electrical Shock Hazard when servicing this system.

Always verify that all electrical power source(s) are off before opening the analyzer/controller unit or

attempting to service electronic components or wiring.

Caution: Extreme caution should be used when installing, operating, and maintaining the HYDROGUARD®

Analyzer. Only properly trained technicians are authorized to install and maintain the

analyzer/controller.

Only properly trained and licensed swimming pool operators should attempt to make any changes to

chemical dosing levels.

Always follow local health and safety regulations when performing any service on the

analyzer/controller unit or when changing chemical dosing settings.

The main power supply may be connected to either 110-120 or 220-240VAC 50/60Hz. Switching between

voltages is accomplished by changing two (2) jumpers located above the main power connection, to the

left of the transformer. For 110-120VAC, a 1amp fuse should be use; for 220-240VAC, a 0.5amp fuse

should be used. These changes must be completed prior to wiring.

Caution: Before connecting to a power source, confirm that both jumpers are located on the correct

voltage and that the appropriate fuse is in place.

Remote control of pool water chemistry is potentially dangerous to bathers. The HYDROGUARD remote

monitoring and control service is set by default to monitoring and reporting only.

Each relay connection is limited to 4 amps, to prevent overheating. The relays may show a higher rating

but do not connect equipment exceeding 4 amps.

All electrical connections should comply with National Electrical Code (NEC) and all local regulations.

Caution: Do not use chemicals that reduce the surface tension. When using hydrochloric acid, observe

all safety regulations.

Electrodes:

Warning: Do not swallow the electrolyte. Avoid electrolyte contact with skin or eyes. In case of

accidental contact, wash with a lot of cold water! In case of eye inflammation, contact a doctor

immediately. Wear safety glasses and gloves when working with the electrolyte solution.

Caution: Do not touch or damage the electrodes. The electrolyte is sensitive to oxidation: Always keep

the electrolyte bottle closed after use. Do not transfer the electrolyte to other containers. The

electrolyte should not be stored for more than one year and should be clear (not yellow) in appearance

(for use by date, see label). Avoid forming air bubbles when pouring the electrolyte into the measuring

chamber.

Caution: HYDROGUARD's control board unit should not be opened except for initial installation and

troubleshooting, and should only be opened by a trained and approved technician.

5 Water. Quality. Secured.

2Preface

The HydroGuard HG-202 Water Quality Controller continuously monitors and

automatically controls chemical levels in pool water. HydroGuard automates pH,

Chlorine, temperature, turbidity, and other water quality tests, administering pool

chemicals as required, according to the results of these tests. This manual includes

installation instructions. For more detailed information, please refer to the

technician guide.

2.1

Intended Use

This manual is for qualified and trained service technicians who will install and

service the HydroGuard HG-202 Water Quality Analyzer. It provides instructions on

how to install the HydroGuard system, how to integrate it with external chemical

dosing systems, as well as how to calibrate, operate, and maintain the system.

This document is not intended to teach swimming pool operation. Local regulations

supersede the information provided in this document and should always be used to

determine the correct course of action.

2.2

Safety Precautions

WARNING

Only properly trained and licensed electricians should attempt to wire or

service the electronic components of the analyzer. There is an Electrical Shock

Hazard when servicing this system. Always verify that all electrical power

source(s) are off before opening the analyzer unit or attempting to service

electronic components or wiring.

CAUTION

Extreme caution should be used when installing, operating, and maintaining

the HydroGuard HG-202 Water Quality Analyzer and Controller. Only properly

trained technicians are authorized to install and maintain the analyzer. Only

properly trained and licensed electricians should attempt any change to the

system’s electrical components. Only properly trained and licensed operators

should attempt to make any changes to chemical dosing levels.

NOTE

Always follow local health and safety regulations when performing any service

on the HydroGuard unit or changing chemical dosing settings.

6 Water. Quality. Secured.

3Overview

3.1

Features and Modules

The HydroGuard unit has many different configurations and can be setup to measure

up to 5 basic parameters that indicate pool water quality (some are optional):

1. Free Chlorine

2. pH

3. Temperature

4. Turbidity

5. ORP

* - Input from an external flow meter is possible

(flow meter supplied by others)

3.2

Remote Communications

Water Guard OL (Online) is an optional web based monitoring system of up to 5

analyzers using cellular communication. The Water Guard OL communicator accepts

HydroGuard's alarms and readings and transmits them to a web based application

server. The information is easily accessible remotely through the Internet or mobile

telephone. Additional information is provided with the remote communication

package.

CAUTION

Remote control of water chemistry is potentially dangerous; therefore, the Water

Guard OL remote monitoring and control service is set by default to monitoring and

reporting only.

3.3

System Components

HydroGuard has two primary units: the analyzing unit and the control unit.

The analyzing unit performs the actual measurements and contains the following

components:

Filter –130 micron filter meant as additional protection for the measuring

equipment

Acrylic cell - holds all the electrodes / probes (some are optional): pH, ORP, Free

Chlorine and Temperature

Turbidity Module - Measures turbidity levels

Sockets –powers the dosing systems (dosing systems not included)

The control unit includes the electronics and software that control the

measurements performed in the analyzing unit and the chemical dosing by external

dosing systems. It includes the following components:

7 Water. Quality. Secured.

Control Panel - calculates the measurement results and determines the required

chemical dosing to maintain an appropriate chemical balance and provides data to

devices such as a PC or communicator.

Keyboard Panel - mounted on the cover of the control module, it functions as

HydroGuard’s user interface. The control panel displays current measurements and

indicates alarms. All settings and adjustments are performed through the control

panel.

I/O Module (Input/Output) - holds the relays that control external dosing systems

and power supply.

Note: color of components in the above picture may vary from the actual product

Control Panel

Door

Enclosure and

Electronic

Cards

Acrylic Cell with

Free Cl, pH,

Temperature sensors

Turbidity

module

Filter

Dosing equipment

sockets

8 Water. Quality. Secured.

4Installation

4.1

Selecting a Location

Convenient Access

HydroGuard should be installed where it can be easily viewed and operated by pool

personnel.

Dry Area

It is best to install the HydroGuard in a dry area. The unit includes electronic circuitry

that may short circuit and is susceptible to corrosion over long periods in high

ambient moisture levels.

Pool Chemicals

Pool chemicals can be corrosive to HydroGuard’s electronic circuitry. It is highly

recommended that HydroGuard is not installed adjacent to the pool chemicals

storage area or the dosing systems themselves.

Distance from sampling line

The water sampling line that is tapped into main circulation pipe, feeding the

HydroGuard, should be as short as possible. A long sample line from the main

circulation pipe to HydroGuard creates an unnecessary delay between supply,

measurement, analysis, and chemical dosing.

4.2

Mounting the controller and connecting the electrodes

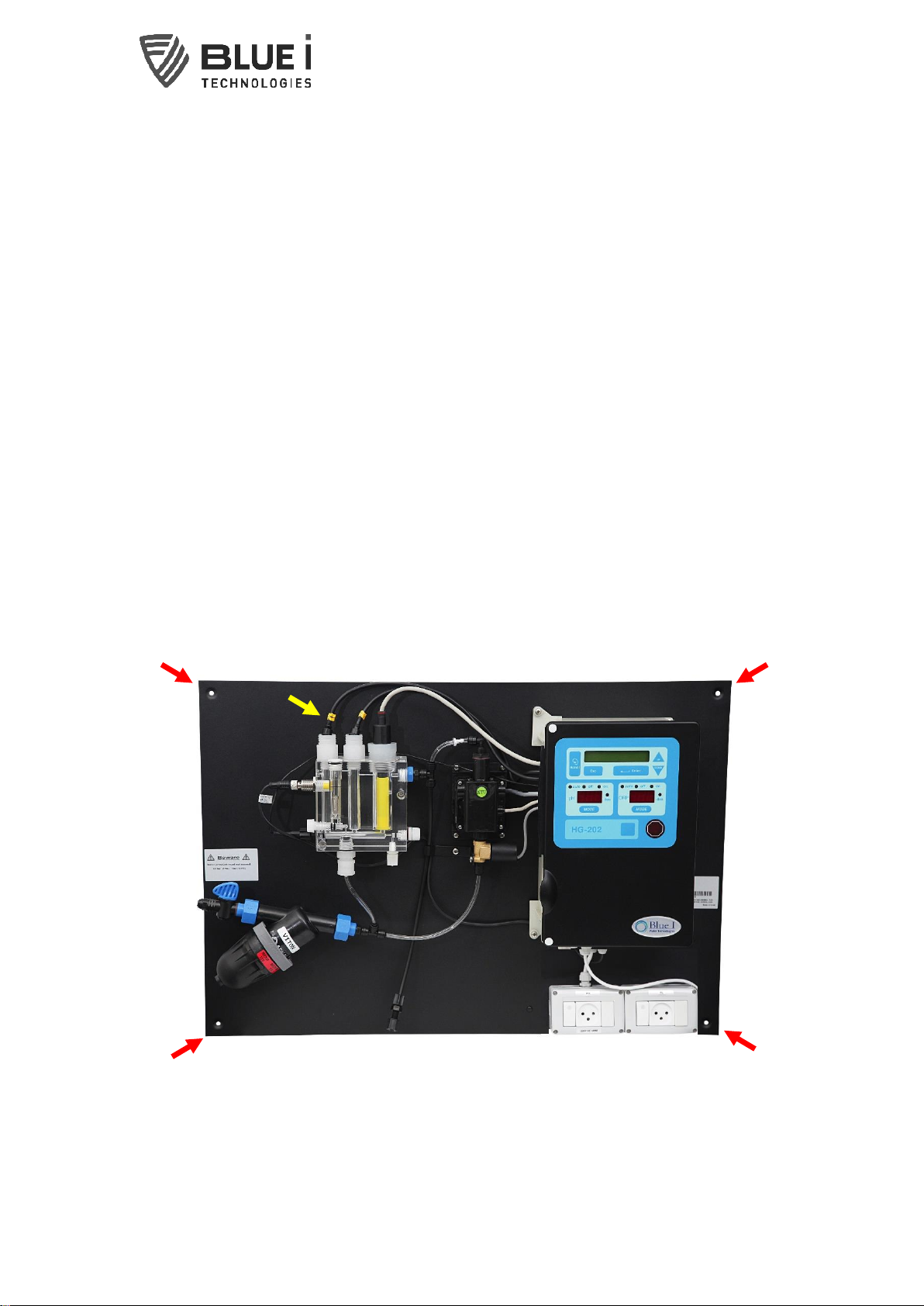

Mounting the controller

Hold the controller (with use of a level) up against the mounting surface upon which

you wish to place the controller and mark the drilling locations through the locations

marked by the red arrows in the above picture.

9 Water. Quality. Secured.

Drill four 5/16” holes in the mounting surface and use appropriate items in order to

fasten the controller securely to the wall.

Connecting the electrodes

Once the controller has been mounted, unscrew the chlorine electrode from the flow

cell and remove the electrolyte cap from its tip. Screw back in and tighten by hand.

The pH and ORP electrodes are shipped separately for preservation purposes. After

removing them from their packaging, the electrolyte caps should be removed and the

electrodes screwed in by hand. Next, connect the appropriate cable to the respective

electrode (cables are marked with yellow indicators for recognition, see yellow arrow

in the above picture).

4.3

Plumbing Requirements and Installation

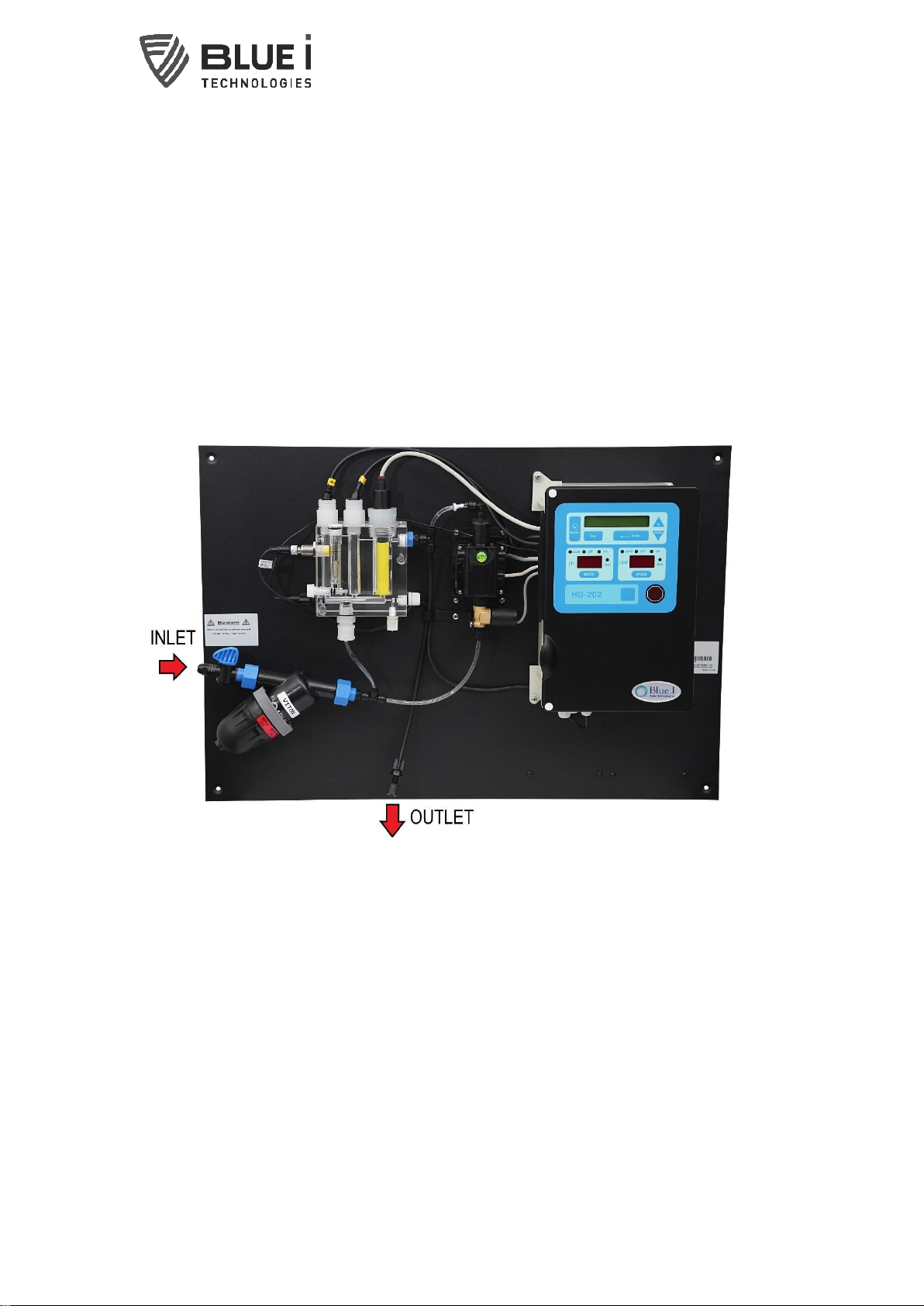

Connect ¼” tubing to inlet and outlet as in the picture above.

HydroGuard requires an inlet water supply and a water return outlet. A shut-off valve

must be installed in the main circulation pump line, between the pump and the

Hydroguard. A ½” OD tube is required from the shut-off valve to the Hydroguard. The

tube should be as short as possible, in order to minimize the delay time between the

pool water being sampled and adjusting dosing levels (see section above). A ½” OD

return line is also required. The distance to the return is not as important as the

distance to the HydroGuard but must return to a lower pressure than the inlet to allow

for sufficient flow.

10 Water. Quality. Secured.

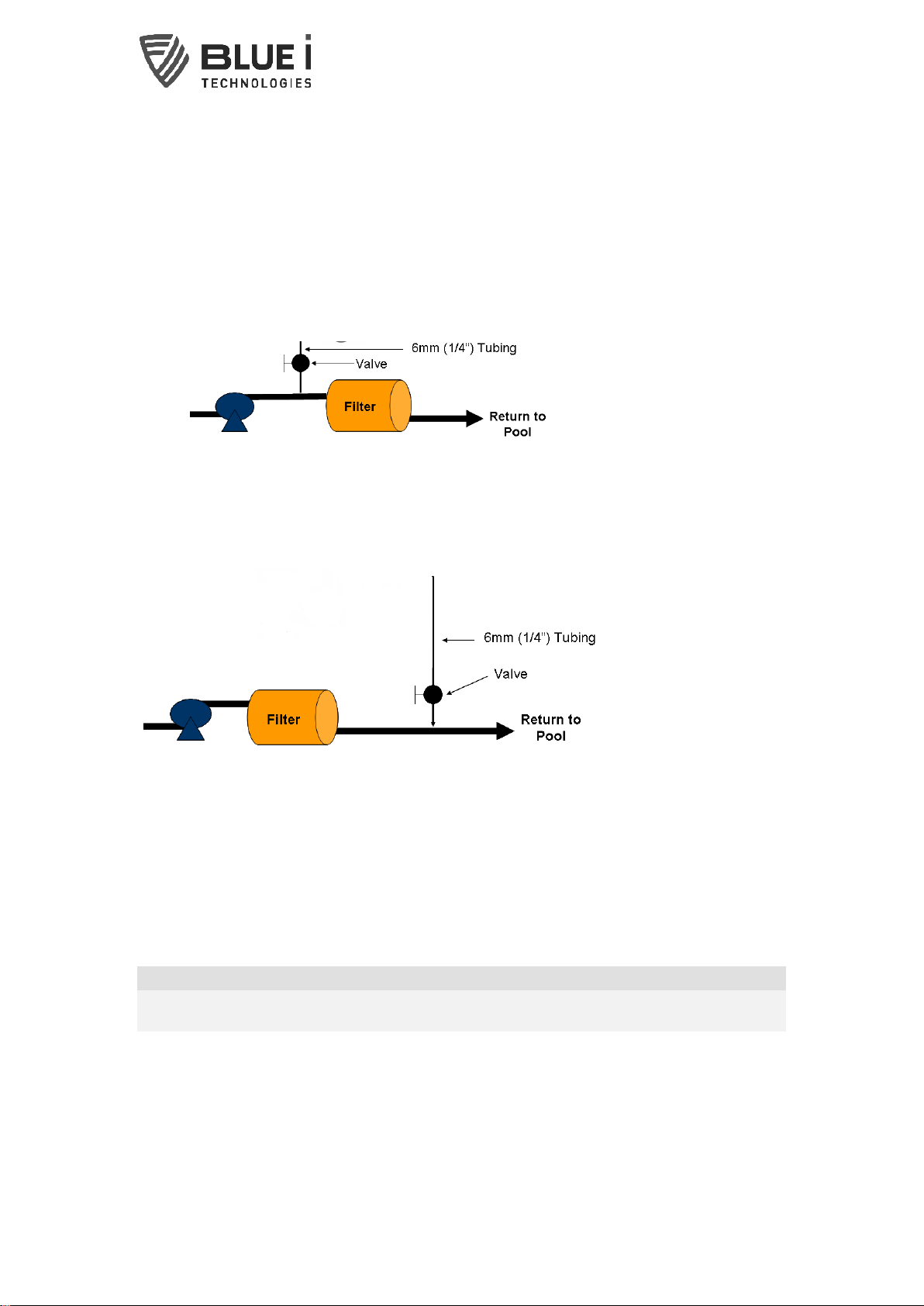

4.3.1 Water Supply

HydroGuard should receive its water supply either directly from the pool, or from the

main circulation pipe between pump and filter. HydroGuard requires a pressurized

water supply to the flow cell. A fitting is supplied for 6mm (1/4”) tubing; however other

tubing and fittings may be attached to the 3/8” FNPT connector. The distance from the

main process pipe should be as short as possible, in order to minimize the delay time

between the water being sampled and HydroGuard testing the water.

Max inlet Pressure: 1 Bar (~15 psi)

Flow Rate: 30-120 L/hr (~0.15-0.6 gpm)

4.3.2 Water Return

The water can be returned to the circulation system at any point with lower pressure

than the water supplied to the HydroGuard. Connect the water return to the ¼” NPT

outlet fitting on the right side of the flow cell.

Return pressure should be at least 0.5 Bar (~psi) below Inlet

Suggested connection scheme

4.4

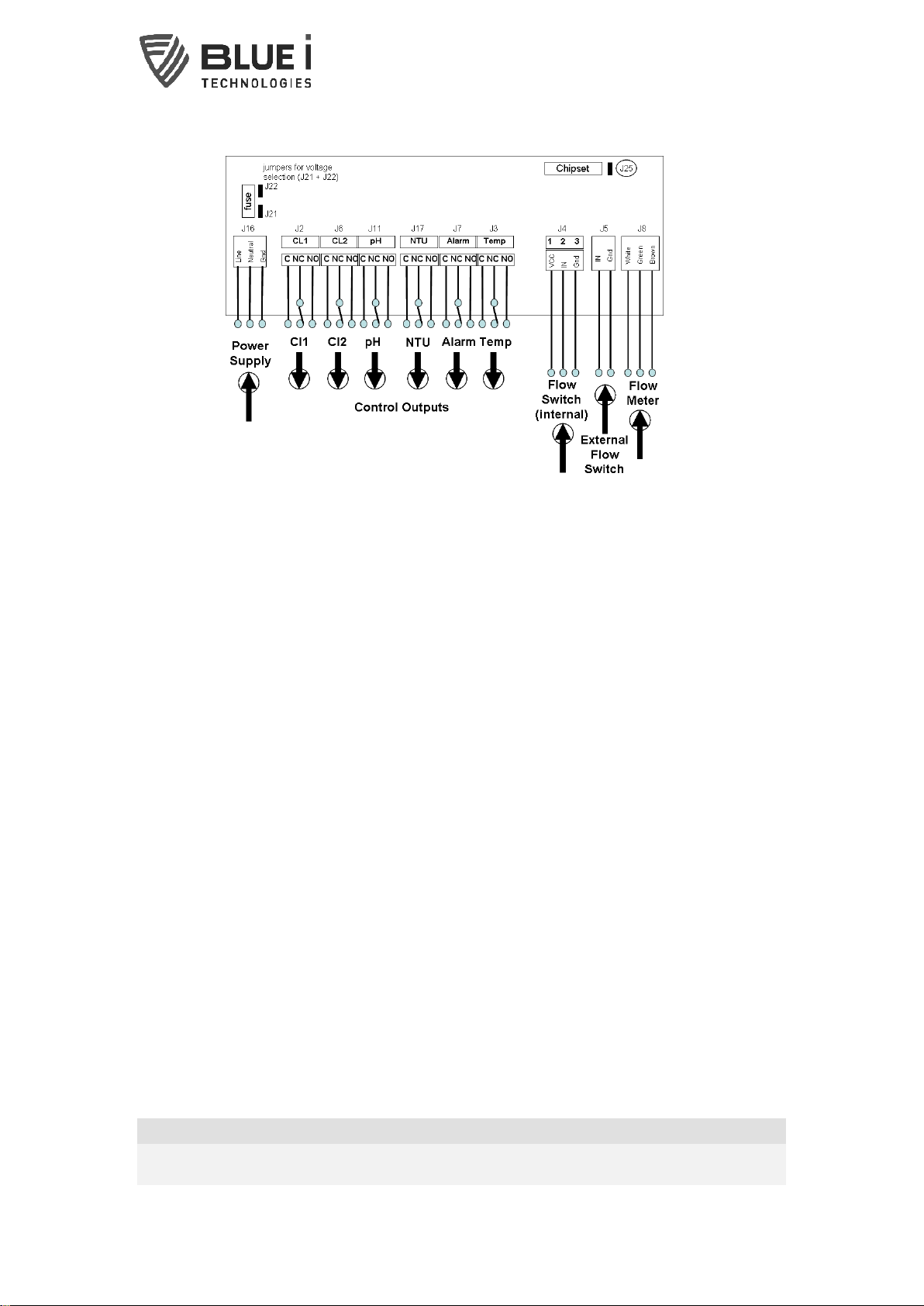

Electrical Requirements and Installation

HydroGuard requires a 100-240 VAC, 50/60 Hz electrical power source on a separate

16A circuit in the plant room’s electrical board. The main HydroGuard power supply

should be connected to a non-dependent power supply, so that the unit remains

powered constantly. Any relays used to directly activate equipment should be

powered by a dependent power supply (interlocked power supply).

CAUTION

Before making a connection to a power source, confirm that both jumpers are

located on the correct voltage and that the appropriate fuse is in place.

1) Verify that the power switch or circuit breaker to the non-dependent power

source is off.

2) Connect the line (live) wire to the I/O board connector marked Line.

3) Connect the neutral wire to the I/O board connector marked Neutral.

4) Connect the earth wire to the I/O Module connector marked Ground.

5) Continue with the other electrical connections.

To Water Inlet

From Water Outlet

11 Water. Quality. Secured.

6) Turn on electrical power only after all electrical connections have been

completed.

4.4.1 NTU card Electrical Installation

1) Install the NTU card on the inside, bottom of the control panel door using the

supplied screws.

2) Connect the NTU card to the I/O module using the supplied ribbon cable and any

open connector (the connectors on both boards operate in parallel).

4.4.2 Input Switches

Flow input switches provide additional layers of security against accidental chemical

additions when there is no flow. If a connection is expected but not detected at each

input, the controller will indicate an alarm and will open all relays (and close the

alarm relay).

Two flow switches and one flow meter may be connected:

Flow Switch (internal): Flow switch connected to flow cell of analyzer. Supports

both 2 and 3 wire flow switches.

oIf a 2 wire switch is used, it should be connected to the “In” and “GND”

connections.

oIf a 3 wire switch is used, the “VCC” connection will also be used.

External Flow Switch: Connection for external 2-wire flow switch. If an external

switch is not connected, a jumper must be installed for the analyzer to operate

properly.

Flow Meter: Connection for 2 or 3 wire flow Meter. The analyzer will not look for

the flow meter connection unless the option is turned ON in technician menu;

therefore, no jumper is required if a meter is not installed.

It is highly recommended for an external flow switch or flow meter to be installed on

the main pipe line.

NOTE

A flow switch is attached to the water inlet of the acrylic cell. This flow switch

determines if enough water is reaching the HydroGuard and adds a layer of safety

12 Water. Quality. Secured.

against chemical additions to a pool in the case of no flow; however, this flow switch

alone does not eliminate the need for additional safety equipment on the dosing

systems directly.

CAUTION

Electrical connections in this section are ONLY recommendations. All electrical

connections should comply with National Electrical code (NEC) and all local

regulations.

4.5

Wiring to Dosing Systems

HydroGuard controls chemical dosing systems using a series of electronic relays

that start and stop the dosing pumps. Each relay opens and closes a switch that

activates a separate pump or piece of equipment.

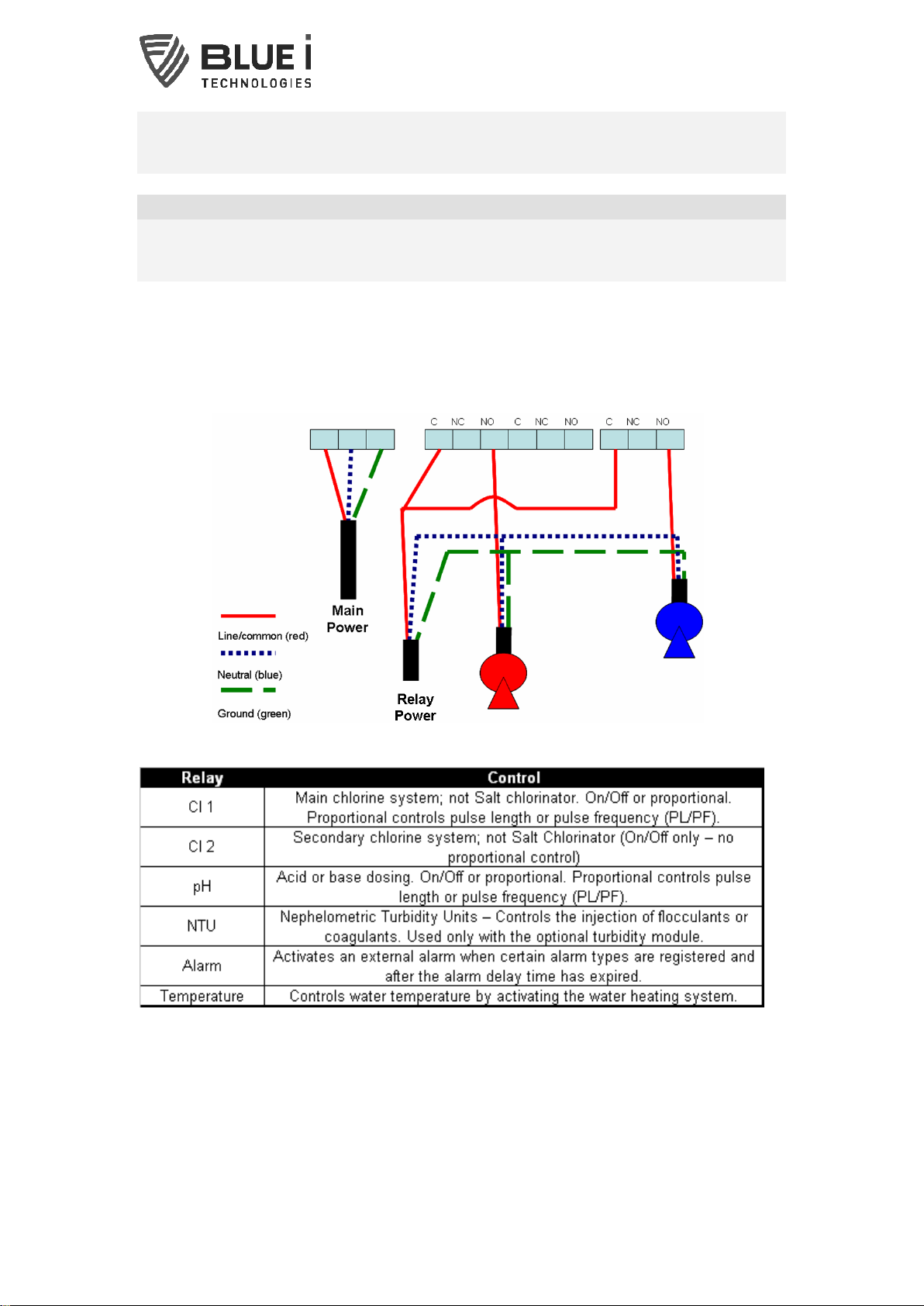

The following table lists the relays and the systems that they activate:

4.5.1 Wiring the Turbidity Relay

Turn off all power supplies to the controller.

Wiring of the NTU (turbidity relay) is identical to wiring of all other relays and should

be connected to a pump-dependent (interlocked) power supply.

The line (live) wire of the pump-dependent power source connects to the connection

labeled Common on the NTU relay. The line wire of the controlled external turbidity

13 Water. Quality. Secured.

equipment is connected to the normally open (NO) or normally closed (NC) connection

of each relay as appropriate. Normally Open means that the relay will be open (i.e. no

power from the relay) until the controller calls for power; Normally Closed means that

the relay will be closed (i.e. power from the relay) until the controller calls to stop

power.

3) Verify that the power switch or circuit breaker to the pump-dependent power

source is off.

4) Connect the earth ground wire of the power supply to the ground return wire from

the controlled external turbidity equipment.

5) Connect the neutral wire of the power supply to the neutral wire from the

controlled external turbidity equipment.

6) Connect the line (live) wire of the power supply to the connector marked ‘C’

(common) on the NTU terminal block.

7) Connect the line (live) wire of the controlled external turbidity equipment to the

normally open (NO) or normally closed (NC) connection on the NTU terminal block.

14 Water. Quality. Secured.

5First Time Operation and Calibration

5.1

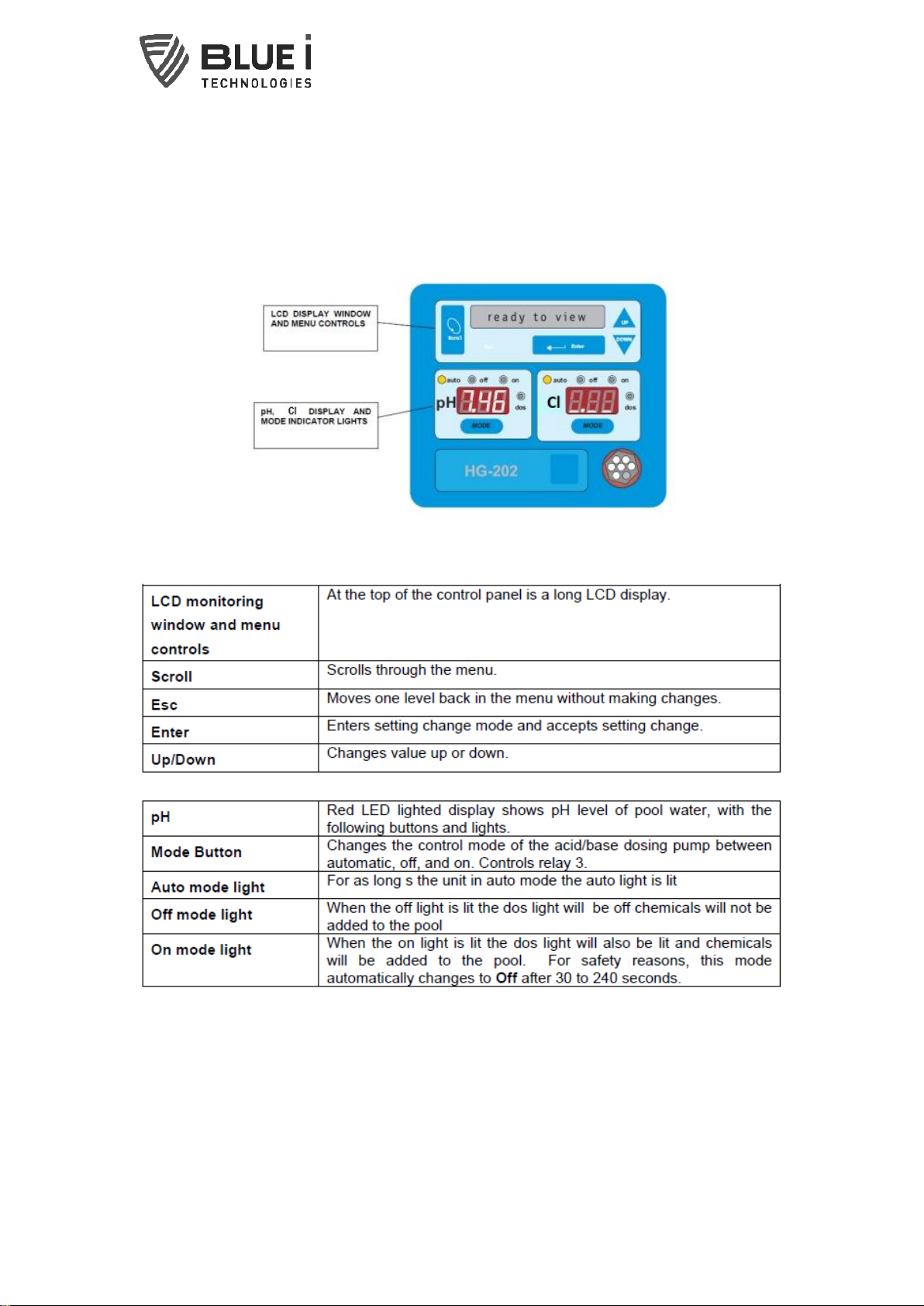

HydroGuard Control Panel

The HydroGuard control panel, displayed below, is a simple, intuitive interface for

monitoring and controlling pool water quality.

The control panel is separated into several distinct areas:

15 Water. Quality. Secured.

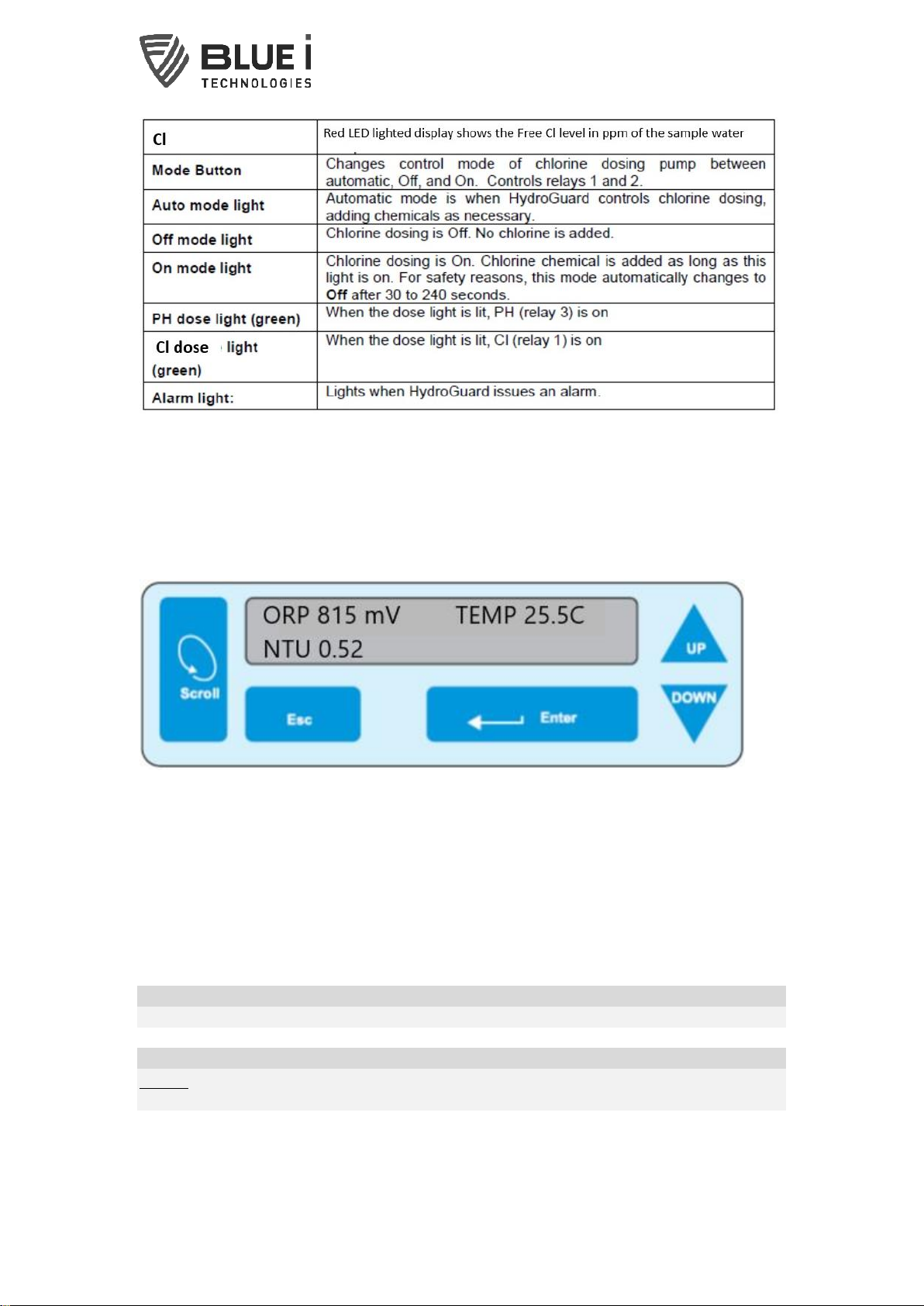

LCD Display

The LCD display in the HydroGuard control panel displays current water conditions in

two rows of data. The top data row displays the water temperature and the ORP

reading. The bottom row shows the Turbidity reading. When an alarm is issued, the

bottom row toggles between the turbidity displays the alarm.

5.2

Menus and Settings

HydroGuard has two menu levels: Operator and Technician. The Operator menu

includes settings that may be controlled by on-site operators. The Technician menu

includes settings and calibrations that should be restricted to specially trained

HydroGuard maintenance technicians. Each menu has a separate password. The

technician level password may be used whenever a password is required, however

the operator password will only be accepted in the operator menu.

NOTE

The default Operator Password is: 123 and the default Technician Password is: 456.

CAUTION

Do not forget your password! There is no way to reset the technician password

without a complete reprogramming of the HydroGuard System.

16 Water. Quality. Secured.

5.2.1 Configuration Setting

Each of the parameters in the operator menu is configured in the same way. The

following procedure describes how to configure a typical setting:

8) Locate the desired parameter in the menu:

9) Press SCROLL until the desired parameter name appears in the LCD display.

10) Press ENTER. “Enter Password 100” appears in the LCD display.

11) Enter the Operator password (or technician password; both are accepted) by

pressing the up arrow or down arrow until the password number is reached.

NOTE

Holding SCROLL why pressing up or down will advance the first digit. Holding up

or down for an extended period of time will proceed through the numbers more

quickly.

12) Press ENTER to accept the password. The parameter name and current setting

appear in the LCD display.

13) Press ENTER, again. The LCD display shows the parameter and the current

setting.

14) Enter the new parameter setting:

15) Press the up arrow or down arrow until the desired value is reached.

16) The second row of the menu display, below the value that is being changed,

shows the current value.

17) Press ENTER to save the new setting or ESC to abort without saving the new

setting.

To change the settings of additional parameters, press Menu until the desired

parameter appears in the LCD display and repeat steps 6-8 above to set the new

parameter.

5.2.2 Technician’s Menu

Configuring each of the technician menu settings is similar to configuring settings in

the Operator menu:

To enter the Technician menu, press (Scroll) and then the up arrow and down arrow

together simultaneously (+) until the menu display changes.

18) Locate the desired parameter in the menu:

19) Press (Scroll) until the desired parameter name appears in the LCD display.

20) Press (Enter). “Enter Password 100” appears in the LCD display.

21) Enter the Technician menu password:

A. Press the up arrow or down arrow until the password number is reached.

B. Press (Enter)

The parameter name and current setting appear in the LCD display.

22) Continue changing the parameter setting, as described in the Operator menu.

23) To set up turbidity measurement, press Scroll until “Turbidity ON/OFF” appears in

the display and press enter.

a) Enter the technician password and press enter.

b) Press up to turn the turbidity sensor on and press enter.

c) Press Scroll until “Turbidity Wiper Interval” appears in the display and press

enter.

d) Enter the technician password and press enter.

17 Water. Quality. Secured.

e) Enter the wiper interval (2 minutes is recommended) and press enter.

f) The turbidity unit should now be active. Confirm that the turbidity value

appears on the LCD display. If it is not active, perform a system reset.

5.2.3 Operation Checklist

Before leaving the site, perform the procedure in this section and record the

requested values.

24) Calibrate the following HydroGuard parameters: pH, ORP, Turbidity

25) Perform the following tests:

a) Press the pH Mode button on the control panel to change the mode to On.

b) Check that the dosing system is adding acid or base chemicals to the pool

water.

c) Press the pH Mode button on the control panel to return the pH mode to Auto.

d) Press the Cl Mode button on the control panel to change mode to On.

e) Check that the dosing system is adding chlorine to pool water.

f) Press the Cl Mode button on control panel to return chlorine mode to Auto.

g) Turn off the main circulation pump.

h) Check that the dosing systems are not adding any chemicals to the pool

water.

26) If the NTU (turbidity) relay is connected to external equipment:

a) Press Scroll until “Turbidity Set Point” appears on the display and press

enter.

b) Enter the operator or technician password and press enter.

c) Enter the turbidity set point value and press enter.

27) With or without the NTU (turbidity) relay connected to external equipment:

a) Press Scroll until “Turbidity High Alarm” appears on the display and press

enter.

b) Enter the operator or technician password and press enter.

c) Enter the turbidity high alarm value and press enter.

5.2.4 Turbidity Relay and External Equipment Operation

The relay will operate in an ON/OFF mode. Whenever the measured turbidity is below

the set point, the relay will remain open (no power to normally open connection).

Whenever the measured turbidity is above the turbidity set point, the relay will close

(power will be supplied to the normally open connection).

If the measured turbidity is above the turbidity high alarm, the alarm on the controller

will be activated. The NTU relay will remain closed (power to the normally open

connection) even during alarm.

18 Water. Quality. Secured.

6Calibration

Parameters must be calibrated with measurements taken with external testing

devices. Always use digital calibration devices, not the less accurate visual test kits.

Alternatively, standard solutions may be used. Make sure the standard solution is

not expired or contaminated prior to using. Follow the procedures below EXACTLY

as instructed.

CAUTION

ALWAYS take water for calibration from the sampling valve, NOT from the process

line directly. The analyzer should always be calibrated with water from the same

source.

6.1.1 pH Calibration

pH is calibrated using a Phenol Red or Buffer 7 solution.

28) Shut off the water inlet and outlet from the flow cell

29) Remove the pH sensor and temperature probe from the flow cell.

30) Wipe sensor probe with a dry cloth and submerge it and the (PT-100)

temperature probe into a cup with the Phenol Red or Buffer 7 solution and wait

for the reading to stabilize.

NOTE

The reading will not stabilize if the temperature probe is not also in the buffer

solution

31) Press (Scroll) until “pH Calibrated”appears in the LCD display.

32) Press (Enter).

33) Enter the password. Press the up arrow or down arrow until the password is

reached.

34) Press (Enter).

35) Press (Enter) again.

36) Press the up arrow or down arrow until the value is the same as the value printed

on the label of the Phenol Red or Buffer 7 Solution.

37) Press (Enter) to save the new calibration or (Esc) to abort without saving.

38) Press (Esc) to return to the main display.

NOTE

pH and Redox (ORP) sensors tend to be slightly erratic in the first 24 hours they

operate. If the above calibrations are performed immediately after these sensors are

installed or replaced, repeat the calibration procedure in approximately 24 hours.

The (PT-100) temperature probe provides grounding and stabilizes the pH and ORP

readings.

19 Water. Quality. Secured.

6.1.2 ORP Calibration

ORP is calibrated using an ORP Standard Solution. A standard closest to the normal

operating value should be used for calibration.

39) Shut off the water inlet and outlet from the flow cell

40) Remove the ORP sensor and (PT-100) temperature probe from the flow cell.

41) Wipe sensor probe with a dry cloth and submerge it and the temperature prove

into a cup with the ORP Standard Solution and wait for the reading to stabilize.

NOTE

The reading will not stabilize if the temperature probe is not also in the buffer

solution

42) Press (Scroll) until ORP Calibrated to appears in the LCD display.

43) Press (Enter).

44) Enter the password. Press the up arrow or down arrow until the password is

reached.

45) Press (Enter).

46) Press (Enter) again.

47) Press the up arrow or down arrow until the value is the same as the value

printed on the label of the standard solution.

48) Press (Enter) to save the new calibration or (Esc) to abort without saving.

49) Press (Esc) to return to the main display.

6.1.3 Chlorine/Turbidity Calibration

50) Take a sample of water from the flow cell

51) Take a reading using a calibrated handheld instrument

52) Press (Scroll) until the relevant menu appears in the LCD display.

53) Press (Enter).

54) Enter the password. Press the up arrow or down arrow until the password is

reached.

55) Press (Enter).

56) The value that appears is the last calibrated value.

57) Press (Enter) again.

58) Press the up arrow or down arrow until the value is the same as the handheld

instrument

59) Press (Enter) to save the new calibration or (Esc) to abort without saving.

20 Water. Quality. Secured.

60) Press (Esc) to return to the main display.

NOTE

When the HydroGuard is initially turned on, the pH and ORP readings will continue to

rise for the first 24-48 hours. If calibration is required, it is best to recalibrate when

the readings have stabilized.

Table of contents

Other Blue I Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

janitza

janitza UMG 604-PRO User manual and technical data

Lighthouse Worldwide Solutions

Lighthouse Worldwide Solutions ApexZ Operator's manual

ST

ST Beta 20P Series operating manual

VOLTCRAFT

VOLTCRAFT VC-330 operating instructions

LaMotte

LaMotte SMART3 Operator's manual

PCB Piezotronics

PCB Piezotronics IMI SENSORS M629A31 Installation and operating manual