Page 4

©2013 Technical Marine Service, Inc. LC-100 V2.97

SPECIFIC GRAVITY SETUP .....................................................................................................41

CONFIGURING OUTPUT LIGHTS ..............................................................................................43

SETTING ALARM SETPOINTS..................................................................................................44

ALARM TIMEOUT...................................................................................................................44

SERIAL PORT SETUP AND DIAGNOSTICS .................................................................................45

ADVANCED PROGRAMMING.............................................................................................48

ENTERING THE PROGRAM MODE............................................................................................48

ENTERING THE PROGRAM MODE WITH AHOT MENU ESTABLISHED ...........................................48

TANK TABLE EXPLAINED........................................................................................................49

PROGRAMMING A TANK TABLE...............................................................................................50

PASSWORD ..........................................................................................................................51

HOT MENU...........................................................................................................................52

LEVELCOM OUTPUTS............................................................................................................52

LIGHTS.................................................................................................................................53

HORN OUTPUT .....................................................................................................................53

RELAY OUTPUTS ..................................................................................................................54

PROGRAMMING RELAY OUTPUTS ...........................................................................................55

ALARM RELAY CONFIGURATION .............................................................................................55

CONTROL RELAY CONFIGURATION .........................................................................................55

ANALOG OUTPUT..................................................................................................................58

CONFIGURE AS A GAUGE OUTPUT..........................................................................................58

SPECIFIC GRAVITY GAUGE OUTPUT SETUP.............................................................................59

CONFIGURE AS A CONTROL OUTPUT ......................................................................................60

MANUAL ANALOG OUTPUT.....................................................................................................61

DIGITAL COMMUNICATION INTERFACE.....................................................................................62

CONFIGURATION WORKSHEET EXPLAINED ..................................................................65

DISPLAY SETUP....................................................................................................................65

SPECIFIC GRAVITY................................................................................................................66

TANK TABLE.........................................................................................................................66

TIMING.................................................................................................................................67

OUTPUTS.............................................................................................................................68

ALARM SETPOINTS (IN DISPLAY UNITS) ..................................................................................68

HOT MENU...........................................................................................................................69

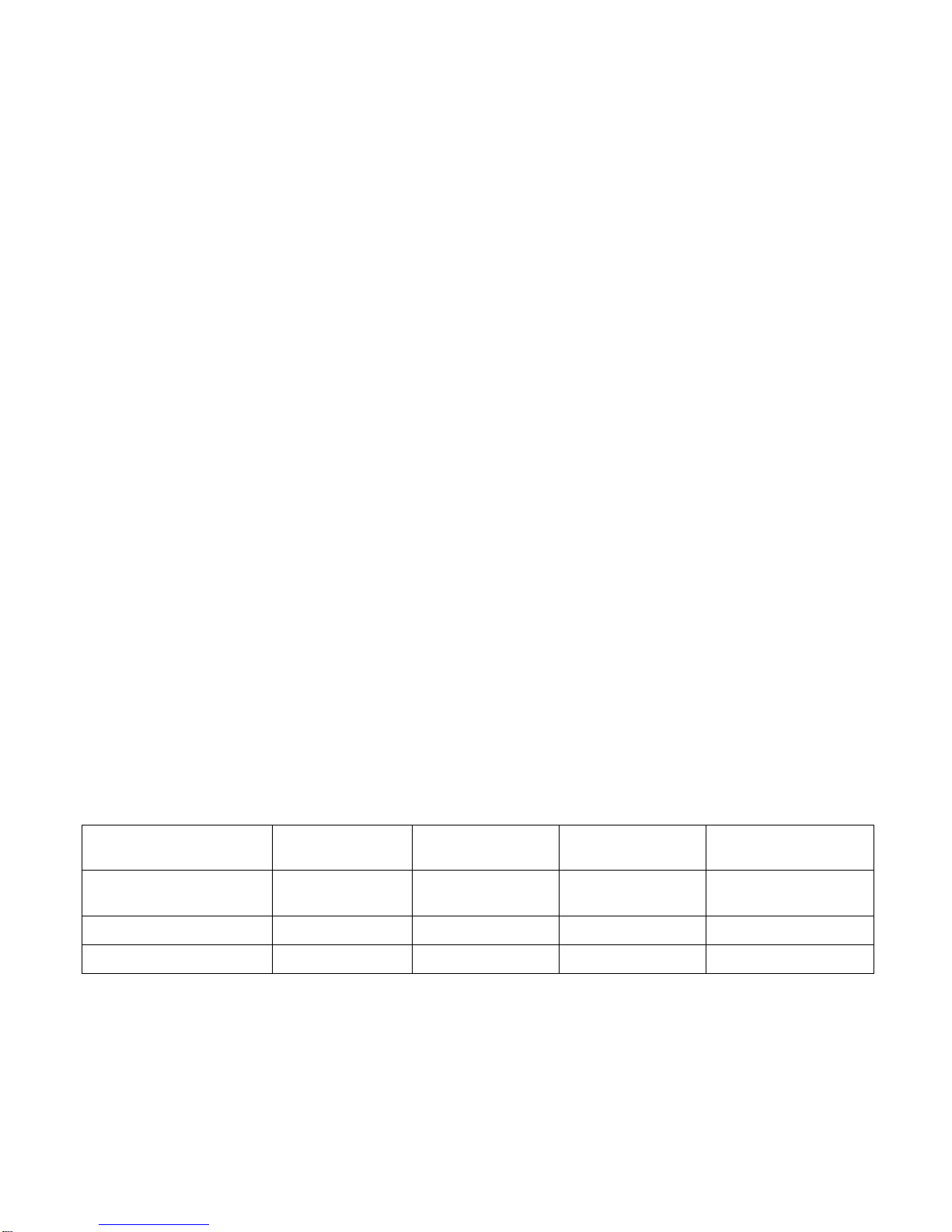

CONFIGURATION WORKSHEET........................................................................................70

CALIBRATION......................................................................................................................72

PNEUMATIC SENSOR CALIBRATION.........................................................................................72

FIELD CALIBRATION PROCEDURE ...........................................................................................72

ZERO OFFSET FOR 16 BIT SENSORS.......................................................................................75

ANALOG OUTPUT CALIBRATION..............................................................................................76

TROUBLESHOOTING..........................................................................................................78

INSTRUMENT DISPLAYS CAN’T ZERO SENSOR....................................................................78

INSTRUMENT DISPLAYS EEPROM FAILURE..........................................................................79

INSTRUMENT DISPLAYS CHECK AIR......................................................................................80