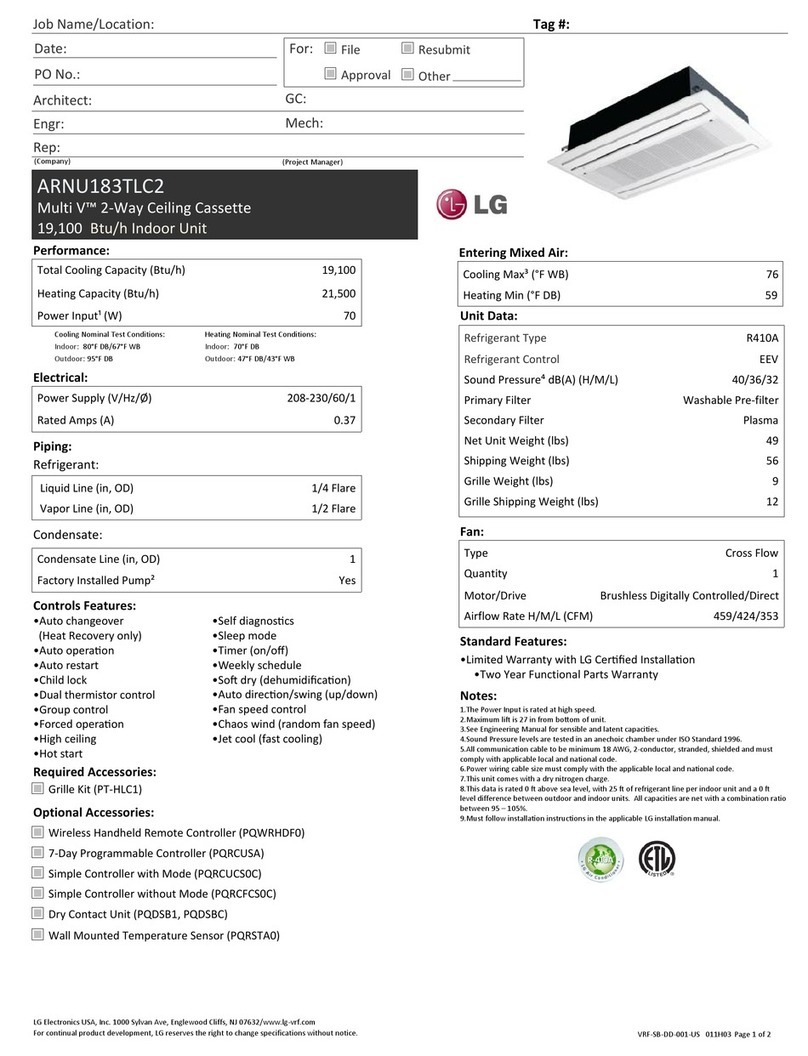

Due to our policy of continuous product innovation, some specifications may change without notification.

©LG Electronics U.S.A., Inc., Englewood Cliffs, NJ. All rights reserved. “LG” is a registered trademark of LG Corp.

SAFTY PRECAUTION

The instructions below must be followed to prevent product malfunction, property damage, injury or death to the user or

other people. Incorrect operation due to ignoring any instructions will cause harm or damage. The level of seriousness

is classified by the symbols below

INSTALLATION

TABELE OF SYMBOLS

This symbol indicates an imminently hazardous situation which, if not avoided, will result in death or serious injury.

This symbol indicates a potentially hazardous situation which, if not avoided, could result in death or serious injury.

This symbol indicates a potentially hazardous situation which, if not avoided, may result in minor or moderate injury.

This symbol indicates situations that may result in equipment or property damage accidents only.

This symbol indicates an action that should not be performed.

DANGER

Do not store or use flammable gas or combustibles

near the unit.

There is risk of fire, explosion, physical injury or death

Do not supply power to the unit until all wiring and

piping are completed or reconnected and checked.

There is risk of physical injury or death due to electric shock.

WARNING

Do not install or remove the unit by yourself (end-user).

Ask the dealer or an LG trained technician to install the

unit

Improper installation by the user may result in water leakage,

fire, explosion, electric shock, physical injury or death.

Always check for system refrigerant leaks after the unit

has been installed or serviced.

Exposure to high concentration levels of refrigerant gas may

lead to illness or death

Do not install the unit using defective hanging,

attaching, or mounting hardware.

There is risk of physical injury or death.

Wear protective gloves when handling equipment.

Sharp edges may cause personal injury.

Dispose of the packing materials safely.

•Packing materials, such as nails and other metal or

wooden parts may cause puncture wounds or other

injuries.

•Tear apart and throw away plastic packaging bags so that

children may not play with them and risk suffocation and

death.

Do not install the unit in any location exposed to open

flame or extreme heat.

hands.

There is risk of fire, electric shock, explosion, and physical

injury or death.

Install the unit considering the potential for earthquakes.

Improper installation may cause the unit to fall, resulting in

physical injury or death.

Do not change the settings of the protection devices.

If the pressure switch, thermal switch, or other protection

device is shorted and forced to operate improperly, or parts

other than those specified by LG are used, there is risk of fire,

electric shock, explosion, and physical injury or death.

If the unit is installed in a small space, take measures to

prevent the refrigerant concentration from exceeding

safety limits in the event of a refrigerant leak.

Consult the latest edition of ASHRAE (American Society of

Heating, Refrigerating, and Air Conditioning Engineers)

Standard 15. If the refrigerant leaks and safety limits are

exceeded, it could result in personal injuries or death from

oxygen depletion

Do nottouchtheunitwithwet

Installation, startup, and servicemustbe performedby a

qualifiedinstaller or aserviceagency.

Improperinstallation,adjustment,service,maintenance,or

alterationcancausepersonalinjury or lossof life.

Forreplacement of an installedunit,alwayscontact a

trainedserviceprovider.

Thereis riskof fire,electricshock,explosion,andphysical

injuryor death

Periodicallycheck thattheoutdoorunitis notdamaged.

Thereis riskof explosion,physicalinjury,or death.

Replaceallcontrolboxandpanel covers.

If coverpanelsarenotinstalledsecurely,dust, waterand

animalsmayenterthe unit,causingfire,electricshock,and

physicalinjuryor death.

Do not install the unit in potentially explosive atmospheres.

Pipes and wires should be purchased separately

for installation of the product.