Contents

Functions .................................................................................................................................3

Product Specifications (Cooling & Heating)..........................................................................6

Dimensions ..............................................................................................................................7

Refrigeration Cycle Diagram ..................................................................................................8

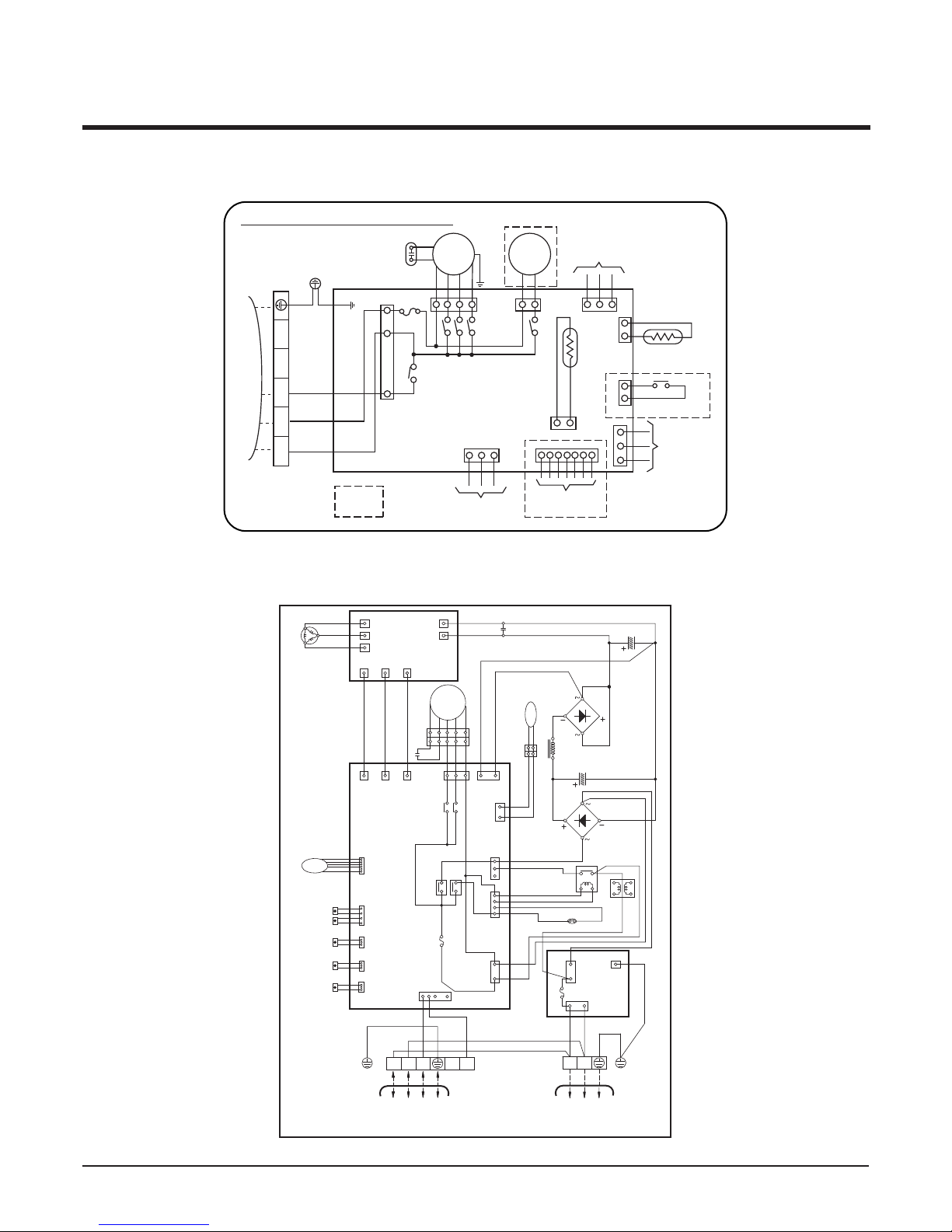

Wiring Diagram ........................................................................................................................9

Operation Details ...................................................................................................................10

Installation of Indoor, Outdoor Unit .....................................................................................14

Test Running...........................................................................................................................23

Optional Operation ................................................................................................................25

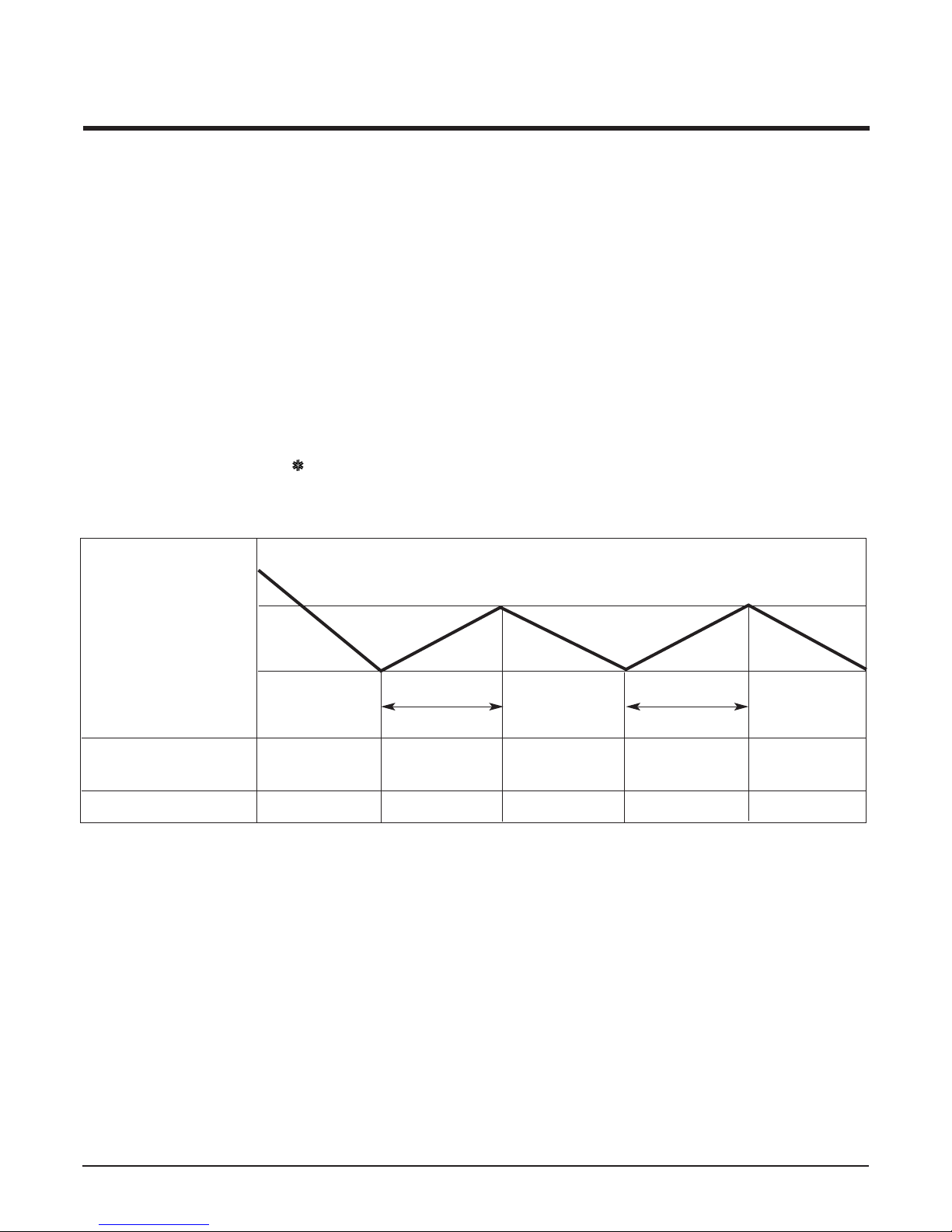

Cycle........................................................................................................................................27

Cycle Troubleshooting Guide ..............................................................................................30

Electronic Parts Troubleshooting Guide .............................................................................31

Electronic Control Device .....................................................................................................44

Exploded View ........................................................................................................................48

- 2 -

Copyright ©2007 LG Electronics. Inc. All right reserved.

Only for training and service purposes LGE Internal Use Only