6 General information

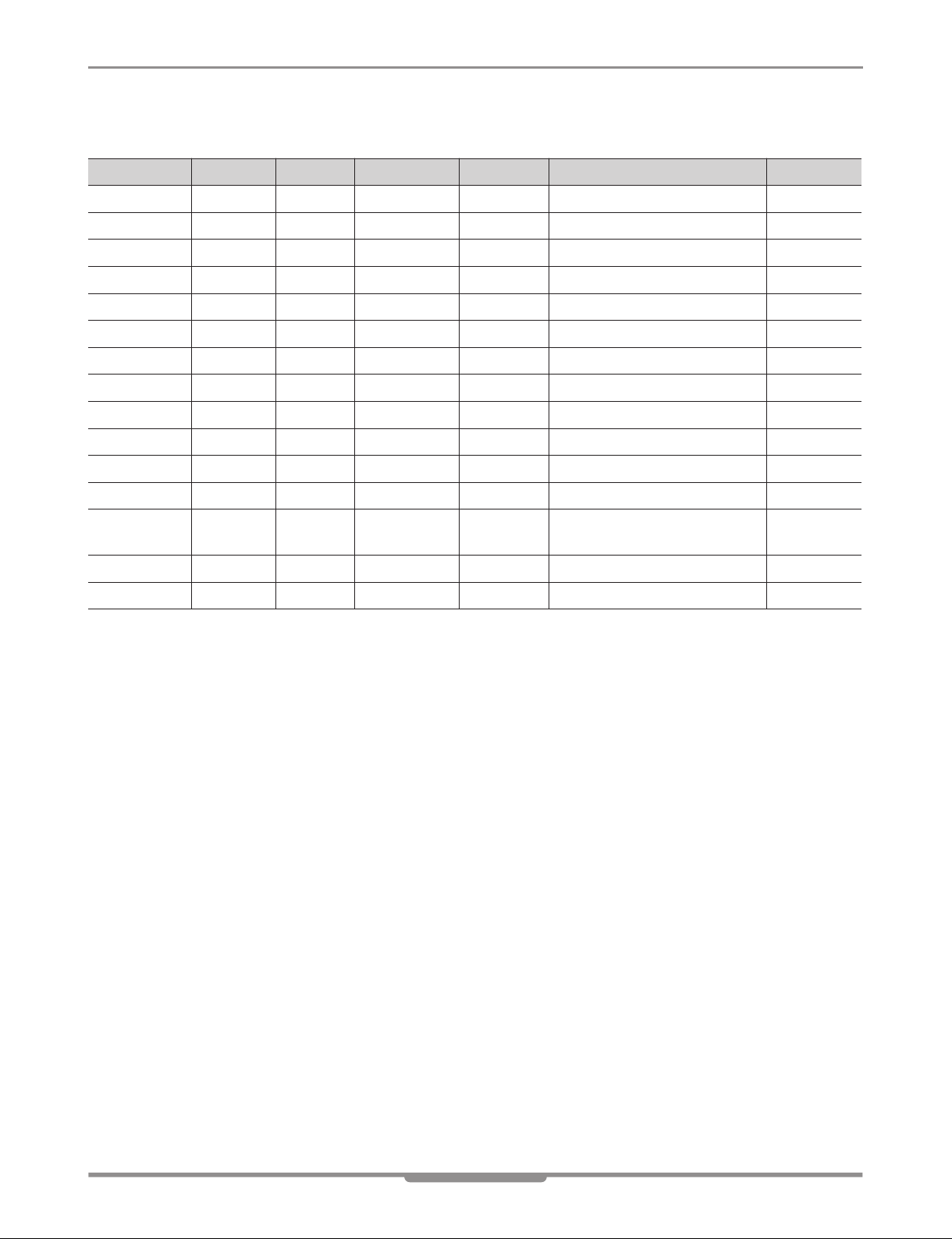

Test condition of International Standards

PTAC

6RWU0-06A

Test condition of International Standards

CLASSIFICATION KSC ISO ARI AHAM AS SSA

9306 5151 210/240 1861.1 385

Indoor DB°C(°F) 27.0 27.0 26.7(80) 26.7(80) 27.0 29.0

Cooling WB°C(°F) 19.5 19.0 19.4(67) 19.4(67) 19.0 19.0

Capacity Outdoor DB°C(°F) 35.0 35.0 35.0(95) 35.0(95) 35.0 46.0

WB°C(°F) 24.0 24.0 23.9(75) 23.9(75) 24.0 24.0

Indoor DB°C(°F) 20.0 20.0 21.1(70) 21.1(70) 21.0 21.0

Heating WB°C(°F) 15.0 15.0 15.6(60) 15.6(60) 15.0 15.5

Capacity Outdoor DB°C(°F) 7.0 7.0 8.3(47) 8.3(47) 7.0 7.0

WB°C(°F) 6.0 6.0 6.1(43) 6.1(43) 6.0 6.0

Indoor DB°C(°F) 32.0 32.0 26.7(80) 32.2(90) 32.0 29.0

Maximum WB°C(°F) 23.0 23.0 19.4(67) 22.8(73) 23.0 19.0

Cooling Outdoor DB°C(°F) 43.0 43.0 46.1(115) 43.3(110) 43.0 54.0

Operating WB°C(°F) 26.0 26.0 23.9(75) 25.6(78) 26.0 24.0

Indoor DB°C(°F) 27.0 27.0 26.7(80) 26.7(80) - -

Maximum WB°C(°F) 19.0 19.0 19.4(67) 22.8(73) - -

Heating Outdoor DB°C(°F) 21.0 24.0 23.9(75) 23.9(75) - -

Operating WB°C(°F) 15.0 18.0 18.3(65) 18.3(65) - -

Enclosure Indoor DB°C(°F) 27.0 27.0 26.7(80) 26.7(80) 27.0 27.0

Sweat / WB°C(°F) 24.0 24.0 23.9(75) 23.9(75) 24.0 24.0

Condensate Outdoor DB°C(°F) 27.0 27.0 26.7(80) 26.7(80) 27.0 27.0

Disposal WB°C(°F) 24.0 24.0 23.9(75) 23.9(75) 24.0 24.0

Freeze-up/ Indoor DB°C(°F) 21.0 21.0 19.4(67) 21.1(70) 21.0 21.0

Low WB°C(°F) 15.0 15.0 13.9(57) 15.6(60) 16.0 16.0

Temperature

Outdoor DB°C(°F) 21.0 21.0 19.4(67) 21.1(70) 21.0 21.0

WB°C(°F) 15.0 15.0 13.9(57) 15.6(60) 16.0 16.0

KS : Korea Standard AS : Australia Standard

ISO : International Standard Organization SSA : Saudi Arabian Standard

ARI : Airconditioning and Refrigeration Institute

AHAM : Association of Home Appliance Manufacturers

In the table above, temperatures are expressed in Fahrenheit(°F) within parentheses only for ARI and AHAM stan-

dards.