Installing microwave oven

1. Empty the microwave oven and clean inside it with a

soft, damp cloth. Check for damage such as

misaligned door, damage around the door or dents

inside the cavity or on the exterior.

2. Put the oven on a counter, table or shelf that is

strong enough to hold the oven, food and utensils

you put in it. (The control panel side of the oven is

the heavy side. Use care when handling.)

3. Do not block the vent and the air intake openings.

Blocking vent or air intake openings can cause

damage to the oven and poor cooking results.

Make sure the microwave oven legs are in place to

ensure proper air flow.

4. The oven should not be installed in any area where

heat and steam are generated, because they may

damage the electronic or mechanical parts of the

unit.

Do not install the oven next to a conventional

surface unit or above a conventional wall oven.

5. Use the microwave oven in an ambient temperature

of less than 104°F (40°C).

6. Place the microwave oven on a sturdy and flat

surface, at least 10cm(4 inches) from the wall.

7. Place the microwave oven as far away as possible

from TV, RADIO, COMPUTER etc, to prevent

interference.

8. This oven must be plugged into a 15A outlet.

9. Do not touch the front glass during or after cooking

of the Grill, Convection and Combination mode.

This glass is very hot during heater operating.

10. Do not operate oven at microwave and combination

mode with the Convection rack or Grill rack placed

in the cavity when the oven is empty.

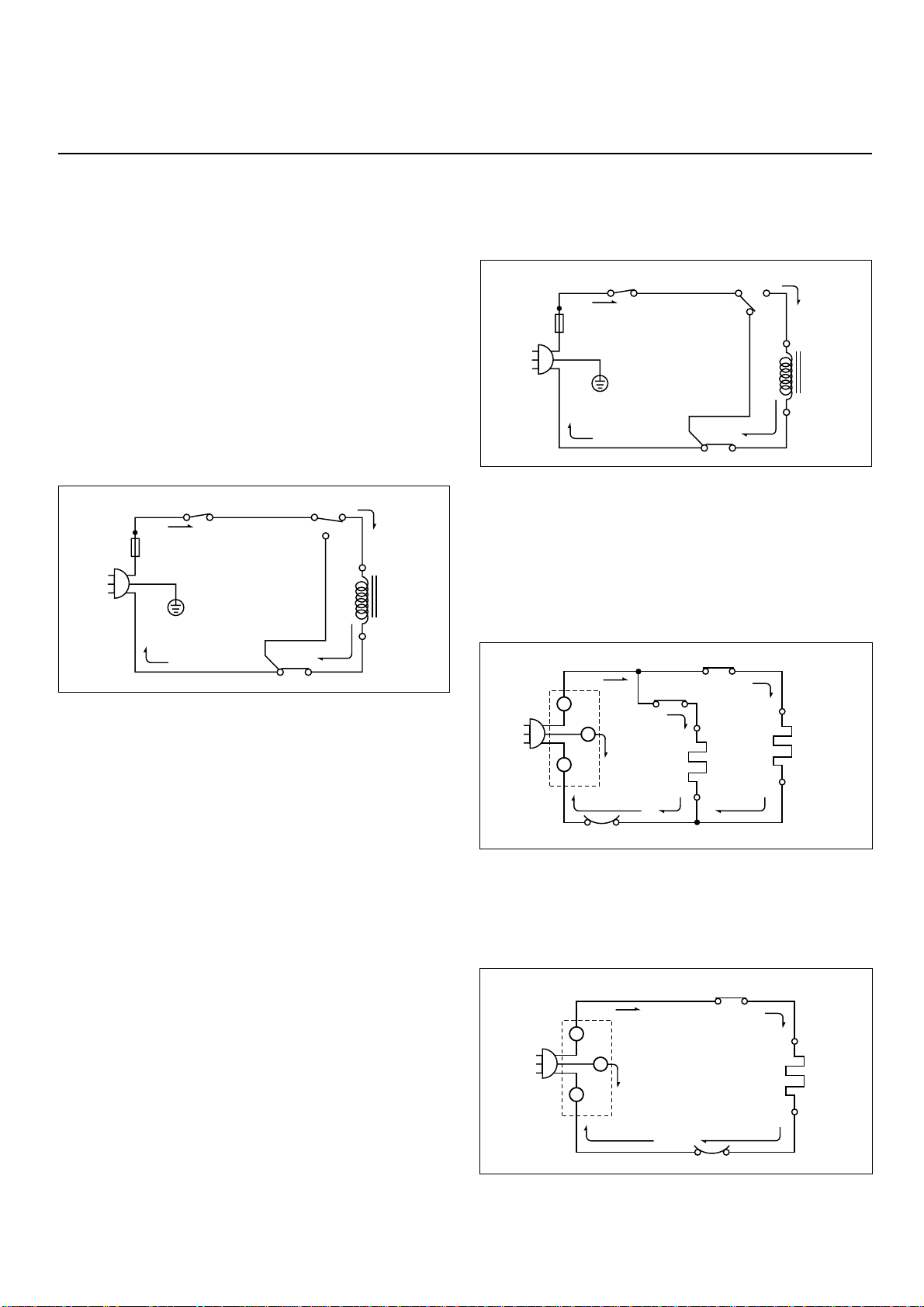

Earthing Instructions

This microwave oven is designed to be used in a fully

earthed condition.

It is imperative, therefore, to make sure it is properly

earthed before servicing.

WARNING-

THIS APPLIANCE

MUST BE EARTHED

IMPORTANT

As the colours of the wires in the mains lead of this

appliance may not correspond with the coloured

markings identifying the terminals in your plug, proceed

as follows.

The wire which is coloured green-and-yellow must be

connected to the terminal in the plug which is marked

with the letter Eor by the earth symbol (bb)or coloured

green or green-and yellow.

The wire which is coloured blue must be connected to

the terminal in the plug which is marked with the letter N

or coloured black.

The wire which is coloured brown must be connected to

the terminal in the plug which is marked with the letter L

or coloured red.

6

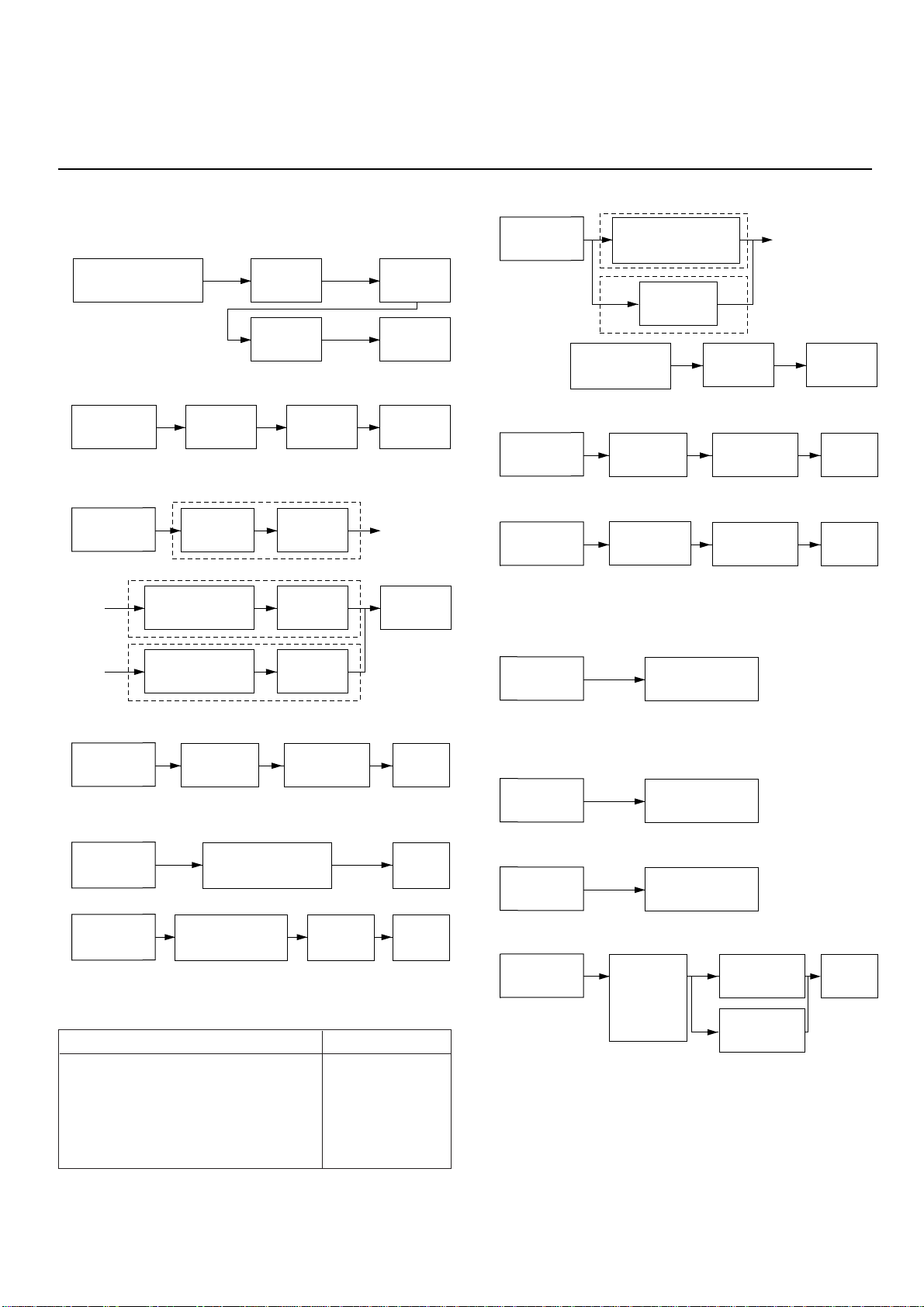

INSTALLATIONS

BEFORE YOU BEGIN, READ THE FOLLOWING INSTRUCTIONS COMPLETELY AND CAREFULLY.

The wires in this mains lead are coloured in

accordance with the following code:

Green-and-yellow: Earth

Blue: Neutral

Brown: Live