3

1. IMPORTANT SAFETY INSTRUCTIONS

READ ALL INSTRUCTIONS BEFORE USE

IMPORTANT SAFETY INSTRUCTIONS

¥ Read all instructions before using the washer.

¥ Do not wash articles that have been previously

cleaned in, washed in, soaked in, or spotted with

gasoline, dry cleaning solvents, or other

flammable or explosive substances, as they give

off vapors that could ignite or explode.

¥ Do not add gasoline, dry cleaning solvents, or

other flammable or explosive substances to the

wash water. These substances give off vapors that

could ignite or explode.

¥ Under certain conditions, hydrogen gas may be

produced in a hot water system that has not been

used for 2 weeks or more. HYDROGEN GAS IS

EXPLOSIVE. If the hot water system has not been

used for such a period, before using the washing

machine, turn on all hot water faucets and let the

water flow from each for several minutes. This will

release any accumulated hydrogen gas. As the

gas is flammable, do not smoke or use an open

flame during this time.

¥ Do not allow children to play on or in the washer.

Close supervision of children is necessary when

the washer is used near children.

¥ Before the washer is removed from service or

discarded, remove the door to prevent children

from hiding inside.

¥ Do not install or store the washer where it will be

exposed to the weather.

¥ Do not tamper with controls.

¥ Do not repair or replace any part of the washer or

attempt any servicing unless specifically

recommended in the user-maintenance

instructions or published user-repair instructions

that you understand and have the skills to carry

out.

¥ See Installation Instructions for grounding

requirements.

¥ ALWAYS follow the fabric care instructions

supplied by the garment manufacturer.

¥ Do not place items exposed to cooking oil in your

washer. Items contaminated with cooking oils may

contribute to a chemical reaction that could cause

a load to catch fire.

¥ Do not use fabric softeners or products to

eliminate static unless recommended by the

manufacturer of the fabric softener or product.

WARNING: To reduce the risk of fire, electric shock, or injury to persons when using the washer, follow basic

precautions, including the following:

SAVE THESE INSTRUCTIONS

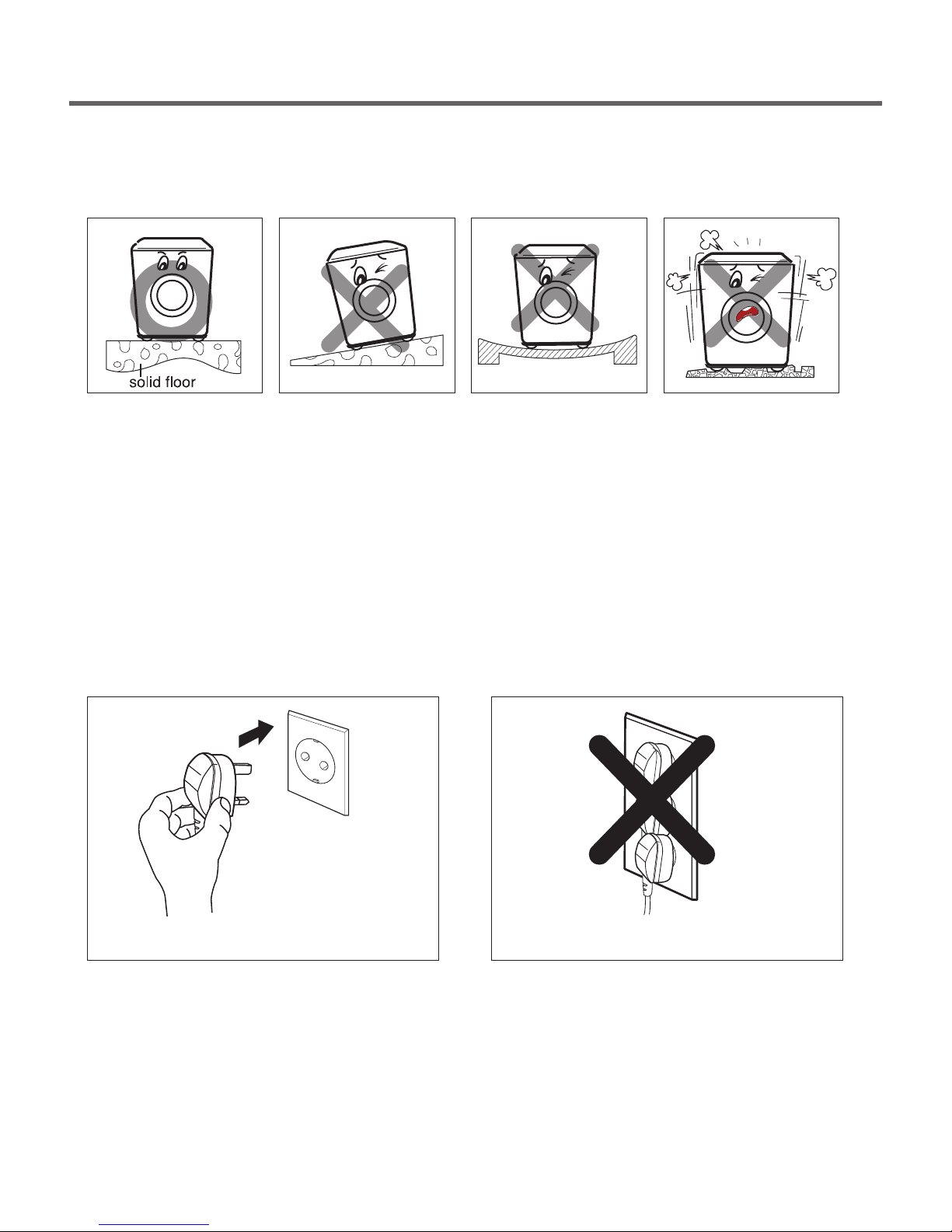

This appliance must be grounded. In the event of malfunction or breakdown, grounding will reduce the risk

of electric shock by providing a path of least resistance for electric current. This appliance is equipped with

a cord having an equipment-grounding conductor and grounding plug. The plug must be plugged into an

appropriate outlet that is properly installed and grounded in accordance with all local codes and ordinances.

¥ Do not use an adapter or extension cord.

¥ Do not remove ground prong.

¥ If you don’t have the proper outlet, consult an electrician.

GROUNDING INSTRUCTIONS

WARNING: Improper connection of the equipment-grounding conductor can result in risk of electric shock.

Check with a qualified electrician or serviceman if you are in doubt as to whether the appliance is

properly grounded. Do not modify the plug provided with the appliance - if it does not fit the outlet,

have a proper outlet installed by a qualified electrician.

WARNING

For your safety, the information in this manual must be followed to minimize the risk of fire

or explosion, electric shock, or to prevent property damage, injury to persons, or death.