WM2277 WASHER PAGE 6 of 84 TRAINING MANUAL

INTRODUCTION

The WM2277** washer is most notable in that there are two distinct versions with

this same model number. The only way to tell them apart is by date code, which

is included in the serial number. (See page 7 concerning serial numbers.) Models

with a date code of 608 or later are the newer model (without the recirculation

pump); models beginning with 607 or earlier are the older models (with the

recirculation pump).

The later series includes three added options: TubClean, SpinSense, and

Water+Plus. The recirculating pump has been eliminated and the pump housing

changed accordingly. As a result, there have been changes in the display board

and assembly, the main control board, the flat cable, the owner’s manual, and

the tub size.

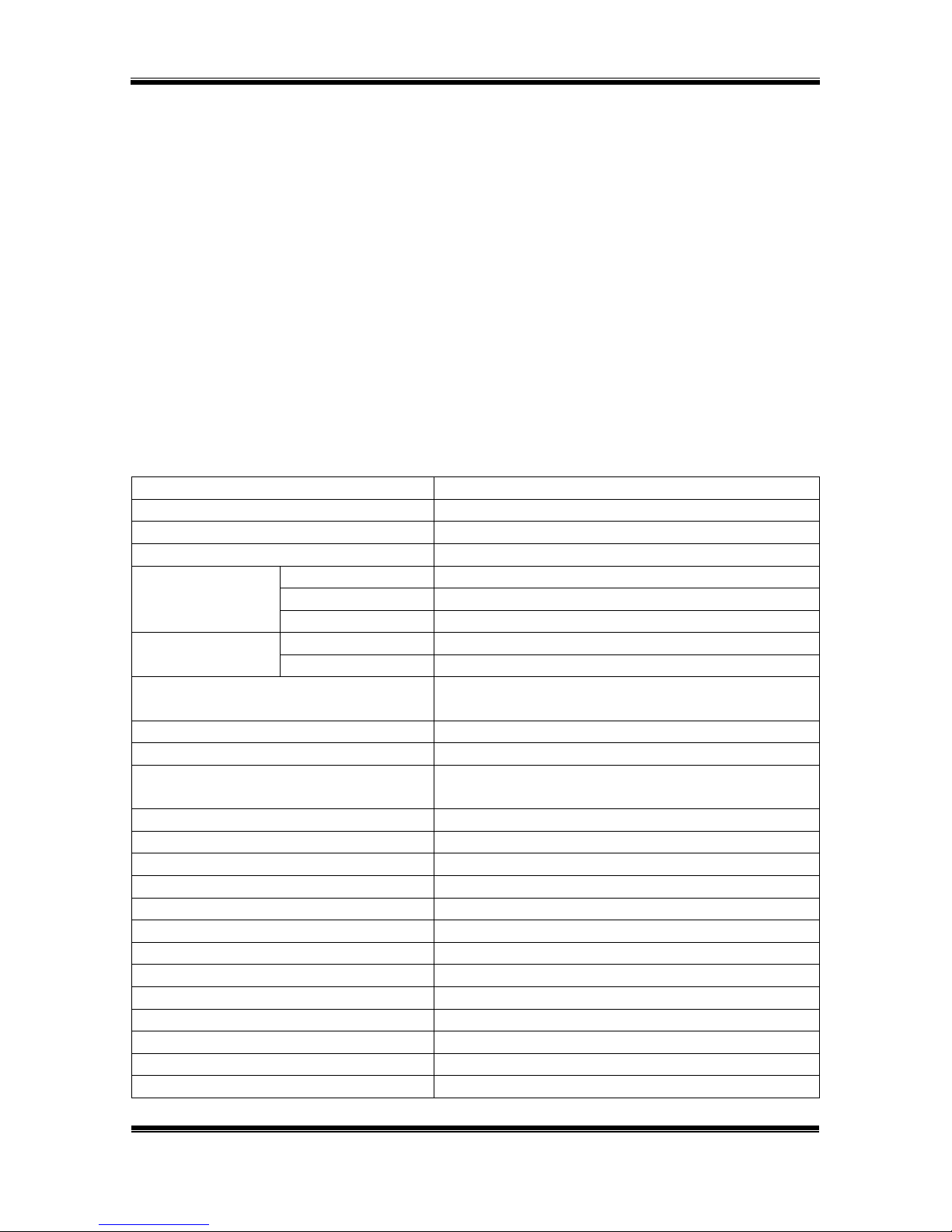

SPECIFICATIONS

Item WM2277H*

Color W– White, B– Black, S– Titanium

Power Input 120 VAC, 60 HZ

Weight 190 lbs (86 kg)

Washing 280 W

Drain Motor 80 W

Electric

Power

Consumption Water Heater 1000 W

Wash 42 rpmDrum Speed

Spin 0 ~ 1150 rpm

Options Prewash, Stain cycle, Extra Rinse,

Rinse+Spin, Delay wash, Water Plus

Cycles 7

Wash/Rinse temperatures 5

Options Prewash, Stain cycle, extra rinse,

Rinse+Spin, Delay Wash, Water+Plus

Custom Program Available

Water Circulation Pump Varies by production date

Control Type Electronic

Water Pressure Requirement 4.5 ~ 145 PSI (30 ~ 1,000 kPa)

Wash Capacity (cu. ft.) 3.32 (3.83 IEC)

Dimensions W x D x H 27” x 29¾” x 3811/16” (5013/16 door open)

Delay Wash up to 12 hours

Water Levels 10 steps, controlled by sensor

Load Sensing Included

Error Diagnosis Included

Auto Power-Off Included

Child Lock Included

Remote Laundry Monitor Available