7

INDEX

page

1 GENERAL FEATURES................................................................... 8

1.1 Main parts – Control and adjustment points................................... 8

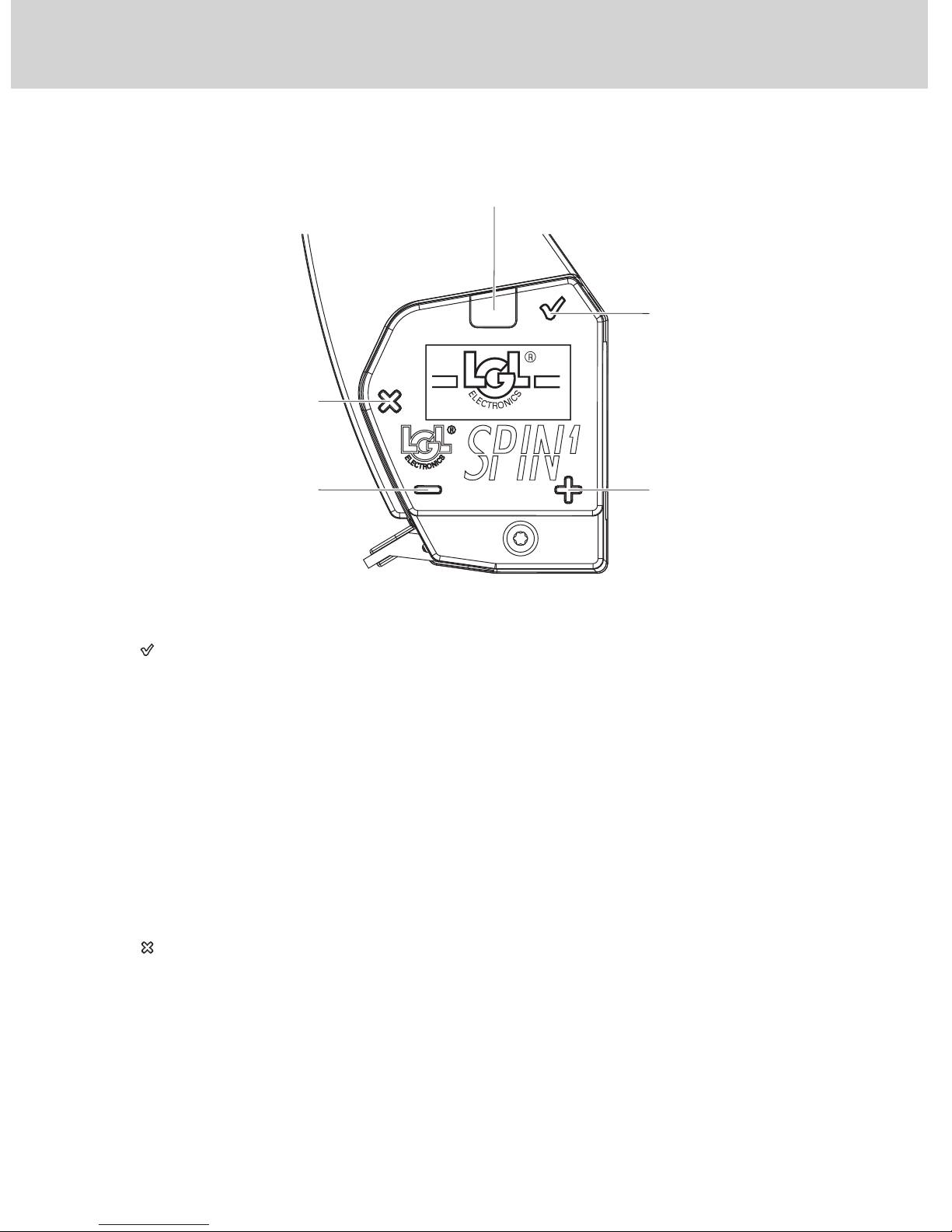

1.2 Control buttons................................................................................ 9

1.3 Display unit ..................................................................................... 11

1.4 Main menu map............................................................................... 12

1.5 Overall dimensions.......................................................................... 13

1.6 Intended use – Technical and operational features......................... 14

2 INSTALLATION............................................................................... 15

2.1 Yarn accumulator installation .......................................................... 15

2.2 Power supply box ............................................................................ 19

2.3 Module to add INC DEC signal ....................................................... 26

3 START-UP AND THREADING........................................................ 28

3.1 Offset............................................................................................... 28

3.2 Yarn winding/threading.................................................................... 29

3.3 Quick start-up.................................................................................. 31

4 PROGRAMMING THE OPERATING PARAMETERS .................... 32

4.1 Setup menu..................................................................................... 32

4.2 Parametres ...................................................................................... 33

4.3 Device Control via serial communication ........................................ 52

5 DEVICE TURN-OFF........................................................................ 54

5.1 Hardware turn-off ............................................................................ 54

5.2 Software turn-off.............................................................................. 54

6 MESSAGES AND ALARMS........................................................... 55

6.1 Messages ........................................................................................ 55

6.2 Alarms ............................................................................................. 56

7 CONVERSION TABLE.................................................................... 59

8 SCRAPPING................................................................................... 60

SPARE PARTS......................................................................................... 61