Disassembly and Reassembly

A. Removing the PC Boards

1. Power the LI-6400 off, and disconnect all cables and batteries

2. Assemble the tools shown below; be sure to use the disposable grounding wrist strap (not pictured) before

opening the LI-6400 console case or beginning the installation procedure.

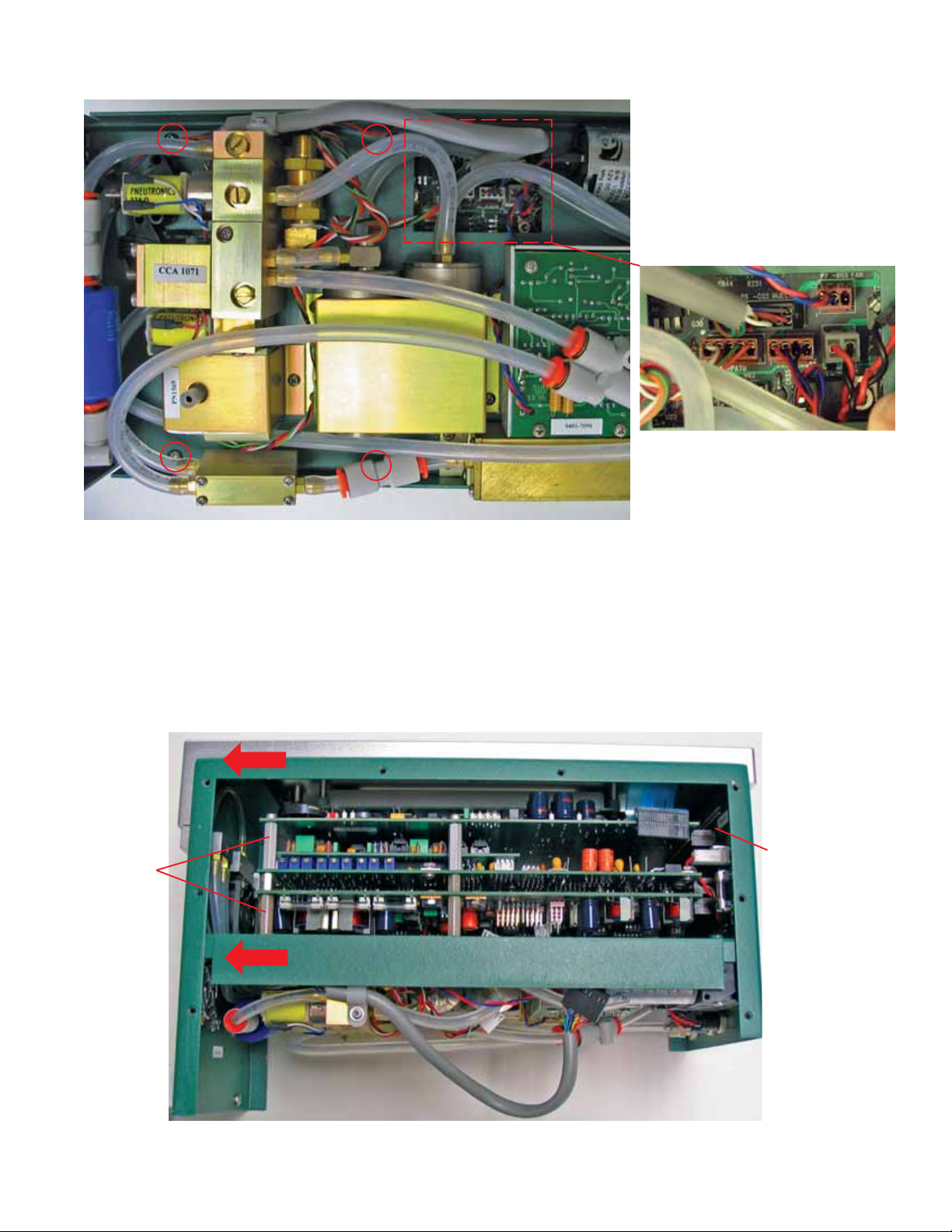

3. Remove the console bottom shell

There are 8 screws on the front and rear panels that must be removed. Remove the batteries from the shell; the

old shell will not be re-used, and can be discarded. Make sure to loosen the 4 spring-loaded screws on the

bottom of the shell; remove the plate that has the rubber feet attached and install the plate on the new shell.

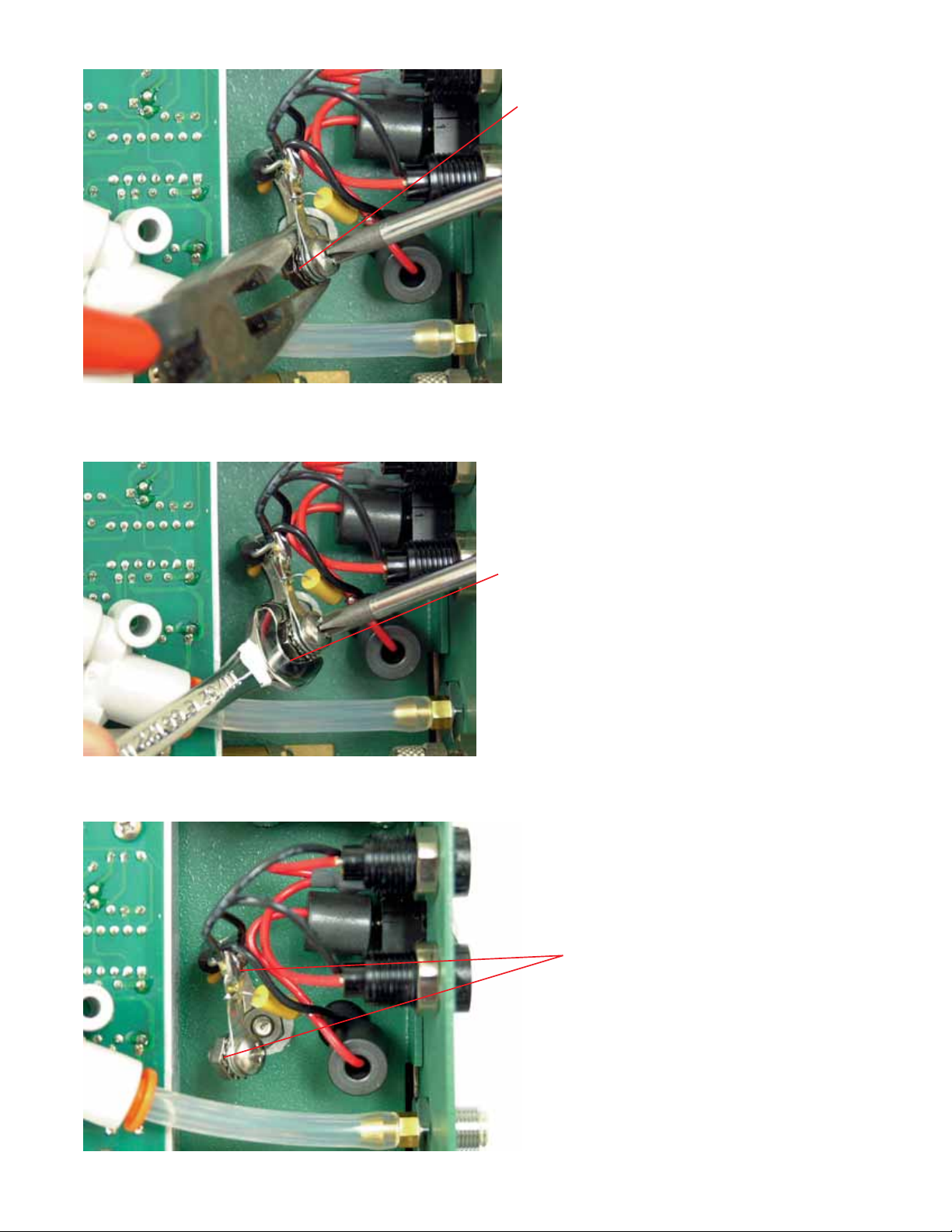

4. Unplug the display and keyboard connectors

Unplug the keyboard connector by carefully lifting it up from the pins on which it sits (Figure 6).Then, unplug

the display connector on the other side of the console (B). Finally, if there is one, unplug the back light connec-

tor (C).

Phillips head screw-

driver (#1 or #2)

11/32" nut driver

11/32" open end wrench

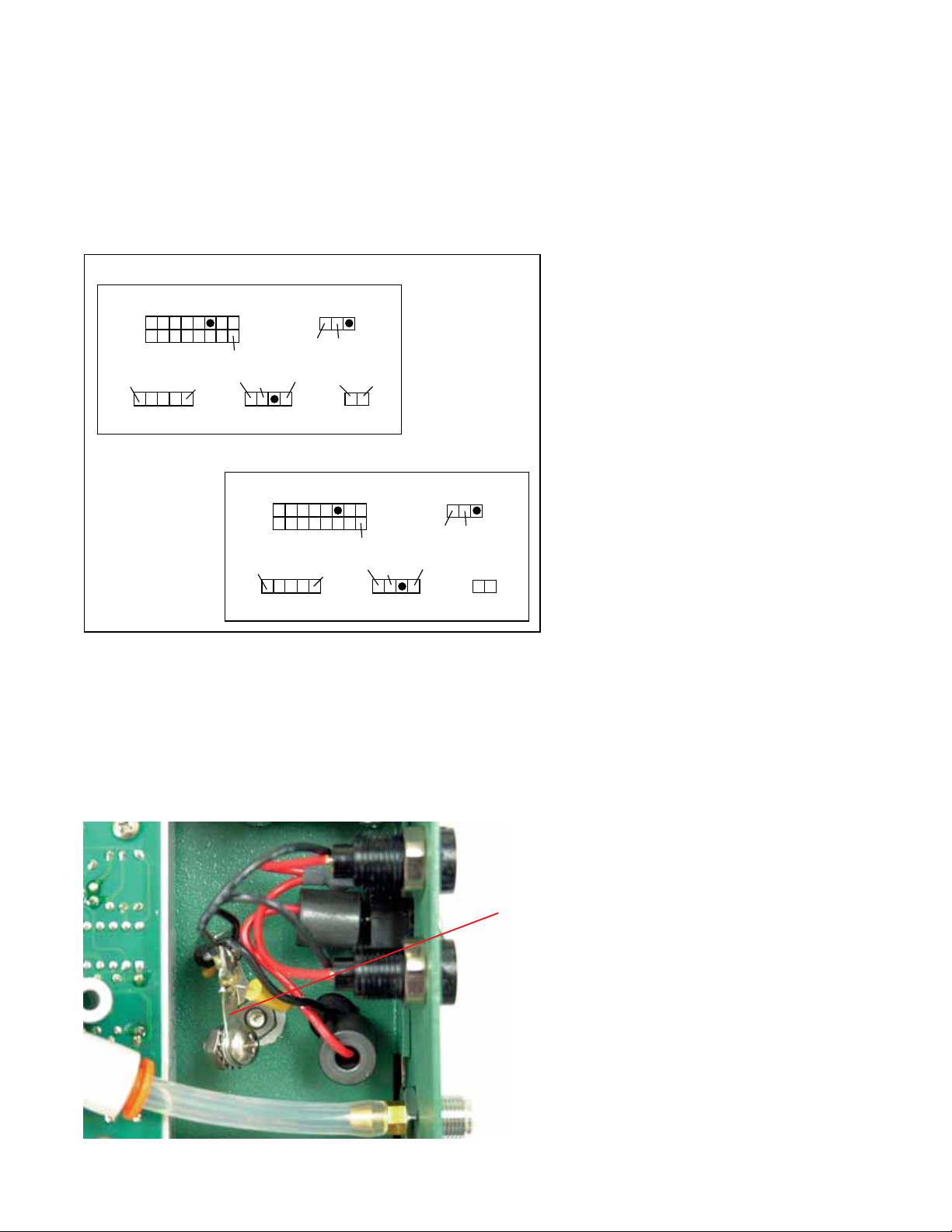

Diode circuit

Needle nose pliers

Kep nuts, star

washer, and

screw

NOTE: The 11/32” nut driver and open

end wrench are required only when

installing the diode circuit. Your

instrument may have the diode circuit

installed already; if so,you can skip the

instructions on page 7 (Installing the

Diode Assembly). See page 7 for

location of diode assembly.

4

Figure 4. Unplug the keyboard connector

by lifting straight up; be careful not to bend

the ribbon cable attached to the connector.

Keyboard connector

Backlight connector

Figure 5. Turn the console around and unplug

the display and backlight connectors (if

present).

Display connector