www.lifebreath.com 2

Table of Contents

1 Location Notes ................................................................................................................................................................ 2

2 Ducting the System ......................................................................................................................................................... 2

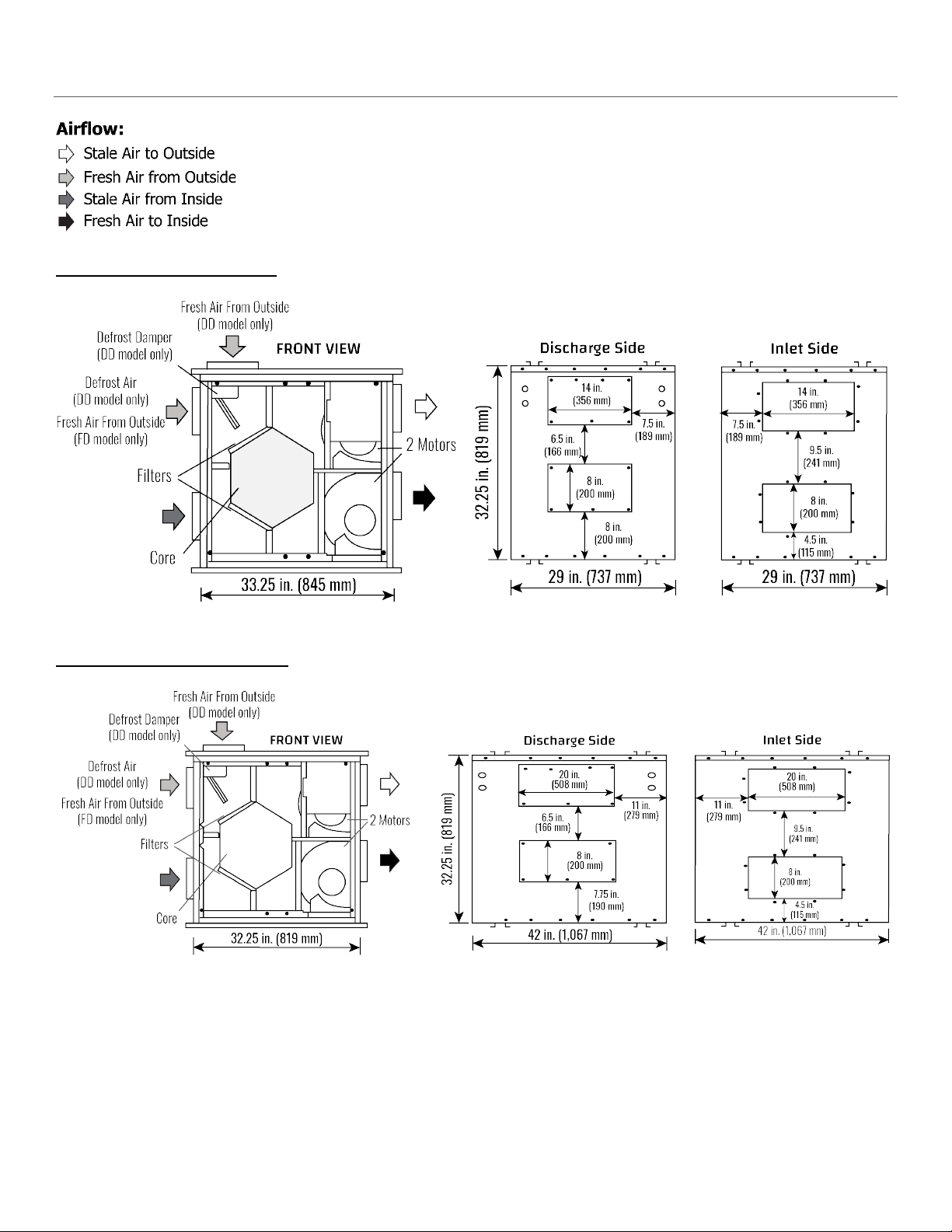

3 Dimensional Drawings .................................................................................................................................................... 3

3 Dimensional Drawings .................................................................................................................................................... 4

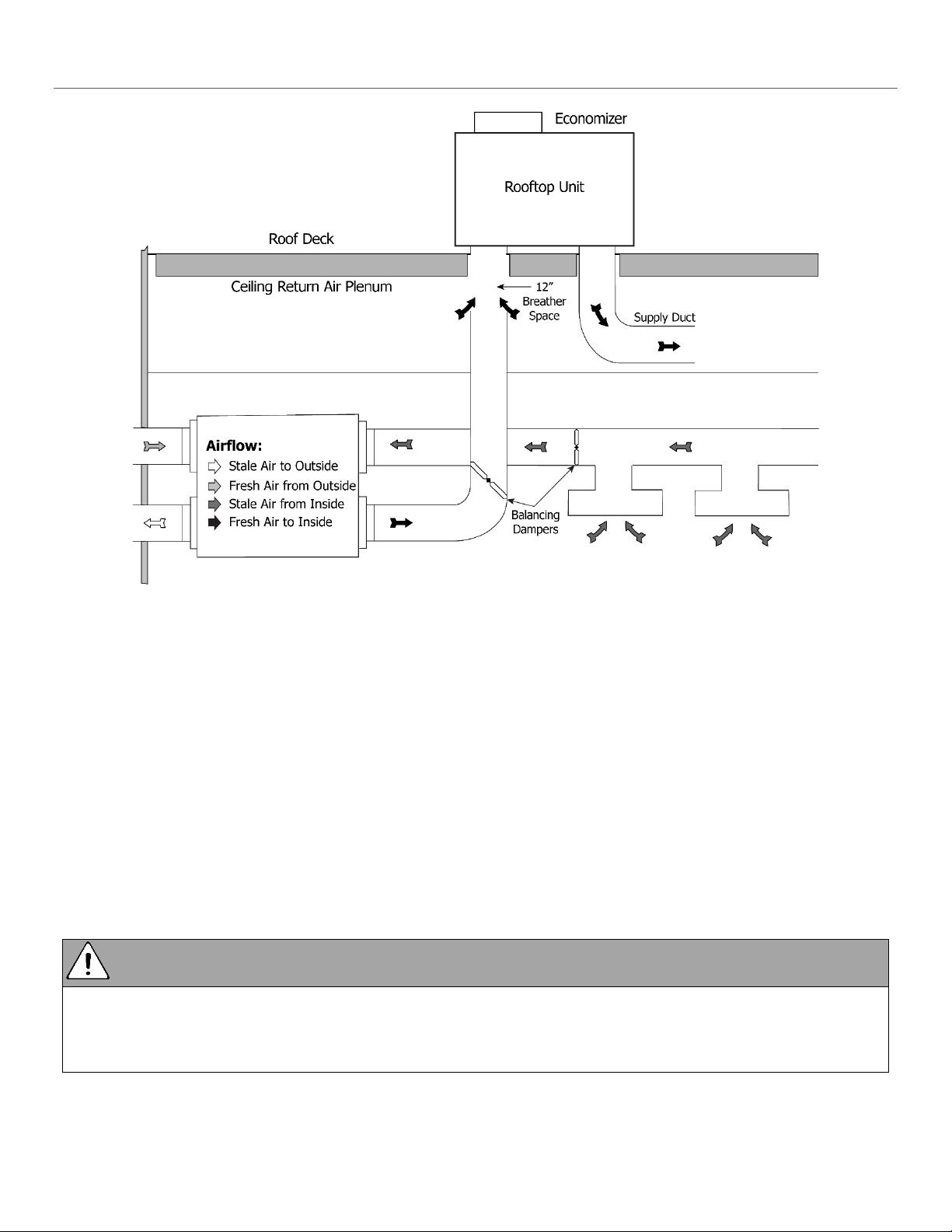

4 The Integrated HVAC System.......................................................................................................................................... 5

5 The Integrated HVAC System.......................................................................................................................................... 2

6 Stale Air Return and Fresh Air Supply System ................................................................................................................ 3

7 Weatherhoods and Grilles .............................................................................................................................................. 4

8 Drain Connections........................................................................................................................................................... 5

9 Electrical Connections..................................................................................................................................................... 6

10 Function and Controls..................................................................................................................................................... 7

11 Main Wall Control ........................................................................................................................................................... 2

12 Main Wall Controls ......................................................................................................................................................... 2

13 Main Wall Control ........................................................................................................................................................... 2

14 Main Control (99-BC02/3/4) ........................................................................................................................................... 3

15 Main Control (99-500)..................................................................................................................................................... 4

16 Timers and Repeaters ..................................................................................................................................................... 5

16 Timers and Repeaters ..................................................................................................................................................... 6

16 Timers and Repeaters ..................................................................................................................................................... 7

16 Timers and Repeaters ..................................................................................................................................................... 8

17 Air Com Relays & Interlocking to a furnace/air handler ................................................................................................. 9

18 Reversing the Supply and Defrost Air Ports (DD Models only)..................................................................................... 10

19 Fan Defrost and Damper Defrost.................................................................................................................................. 11

20 Balancing the Airflows .................................................................................................................................................. 12

21 Balancing the Airflows .................................................................................................................................................. 13

22 Service and Maintenance.............................................................................................................................................. 14

22 Service and Maintenance.............................................................................................................................................. 15

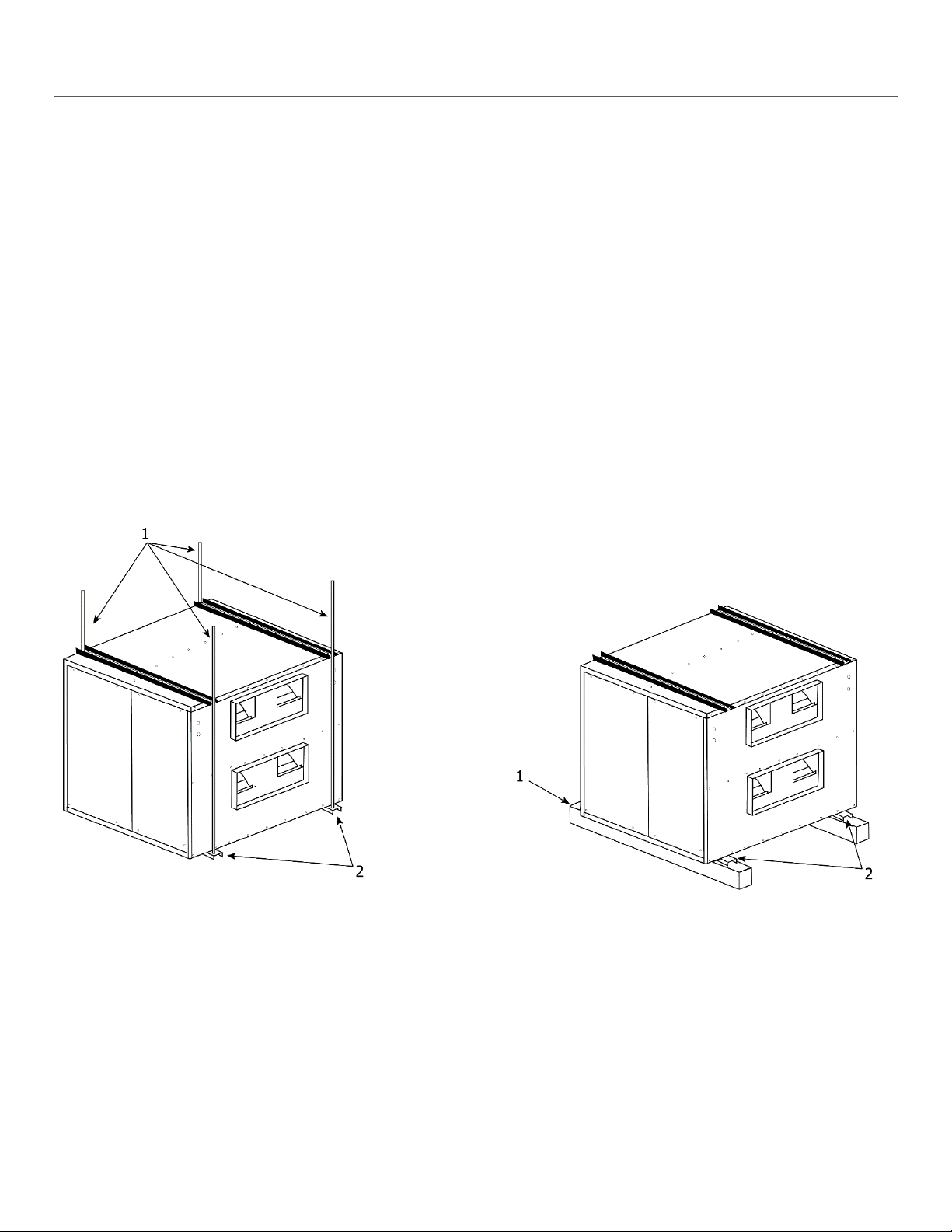

23 Reverse Installation of the HRV .................................................................................................................................... 16

23 Reverse Installation of the HRV .................................................................................................................................... 17

24 Troubleshooting ............................................................................................................................................................ 18

24 Troubleshooting ............................................................................................................................................................ 19

25 Wiring Diagrams (455FD) .............................................................................................................................................. 20

25 Wiring Diagrams (650FD, 700FD, 1200FD).................................................................................................................... 21

25 Wiring Diagrams (455DD, 650DD, 700DD, 1200DD)..................................................................................................... 22

26 Warranty ....................................................................................................................................................................... 23