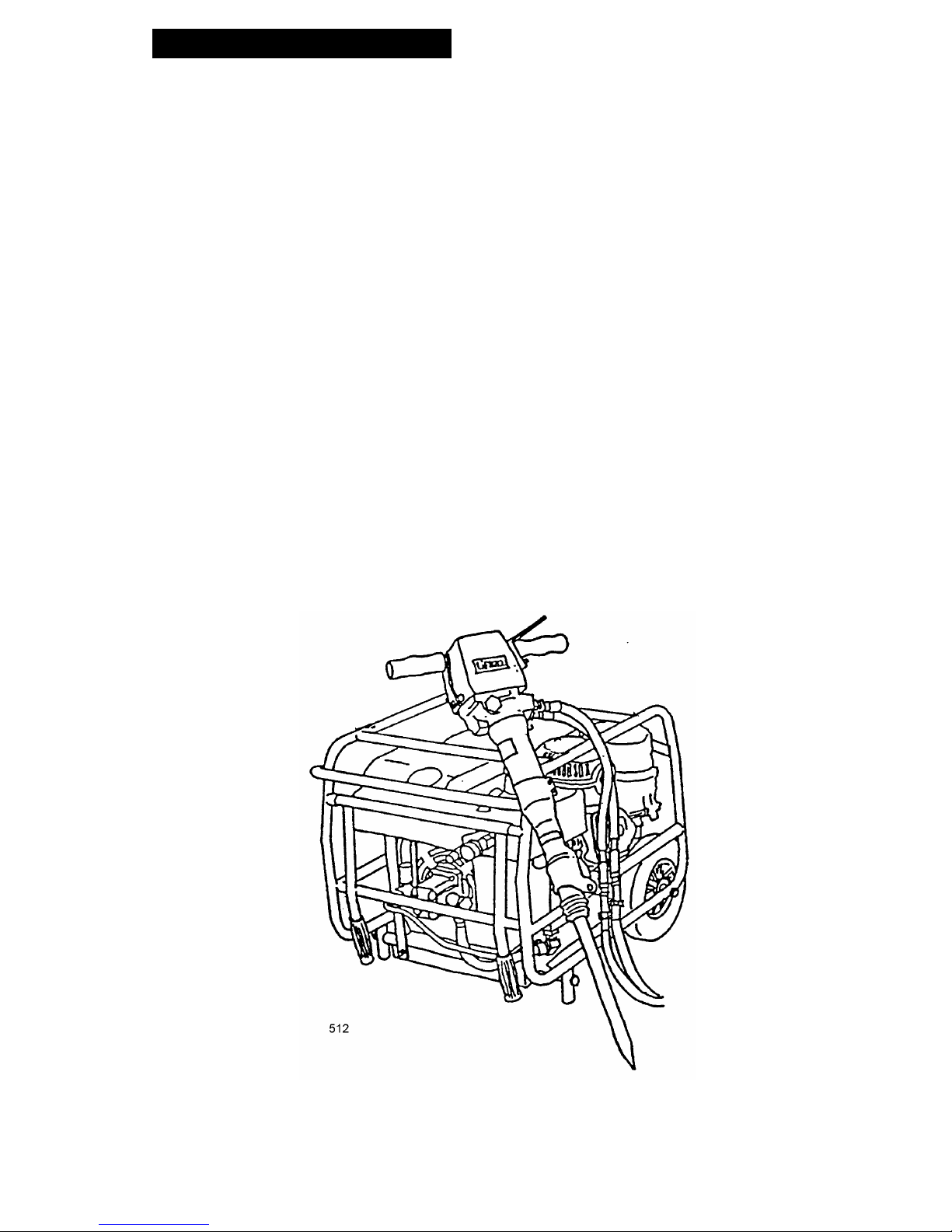

Technical Data LIFTON LP 8 E

Measures (HxWxL)....................................................................... 585x525x680 mm

Weight Incl. oil .............................................................................................70 kg

Noise Sound pressure level 1 m (ISO 11203) ................................ LPA = 81 dB

Emission Measured sound power level (2000/14/EC)...........................LWA = 91 dB

Guaranteed sound power level (2000/14/EC)......................LWA = 104 dB

Construction Chassis/tank ........................................... Combined welded steel section

with integrated fan housing, epoxy powder coated

Frame .........................Welded stainless steel tube with foldable handles

Wheels............................................................ 230 mm solid rubber tyres

Hydraulics Flow............................................................................................20 l.p.m.

Variable by means of internal by-pass valve

Pressure relief valve ........................................Set at 140 bar, adjustable

Nominal pressure ........................................................................ 120 bar

Type .....................................................................................Open centre

Pump ................. Gear pump, directly driven from the engine crank shaft

by means of flexible coupling

Oil tank capacity ............................................................................ 5 litres

Oil level gauge.................................... Automatic low-level engine cut-off

Filtration........................................................... 25 Micron return line filter

Return line filter by-pass in valve block

Filter indicator .......................................................Return line filter gauge

Cooling system ................. Thermostatically controlled air blast oil cooler

Motor ......... Three-phase asynchronous a.c. motor, bipolar, 3 x 400 V, 5.5 kW