M E T E R I N G P U M P S

P N E U M A T I C P L U N G E R

LINC 84T-10, 11, 12, & 14 ver. 04102003 - Pub. no. 15103

LINC MILTON ROY • 201 IVYLAND ROAD • IVYLAND PA, 18974 • USA • TEL. 215.441.0800 Page 7

Scope Of This Manual:

This manual describes and pro-

vides instructions and parts list for

the LINC84T-10, 11, 12 & 14 Se-

riesChemicalMeteringPump. This

pump is a pneumatically operated

plunger pump.

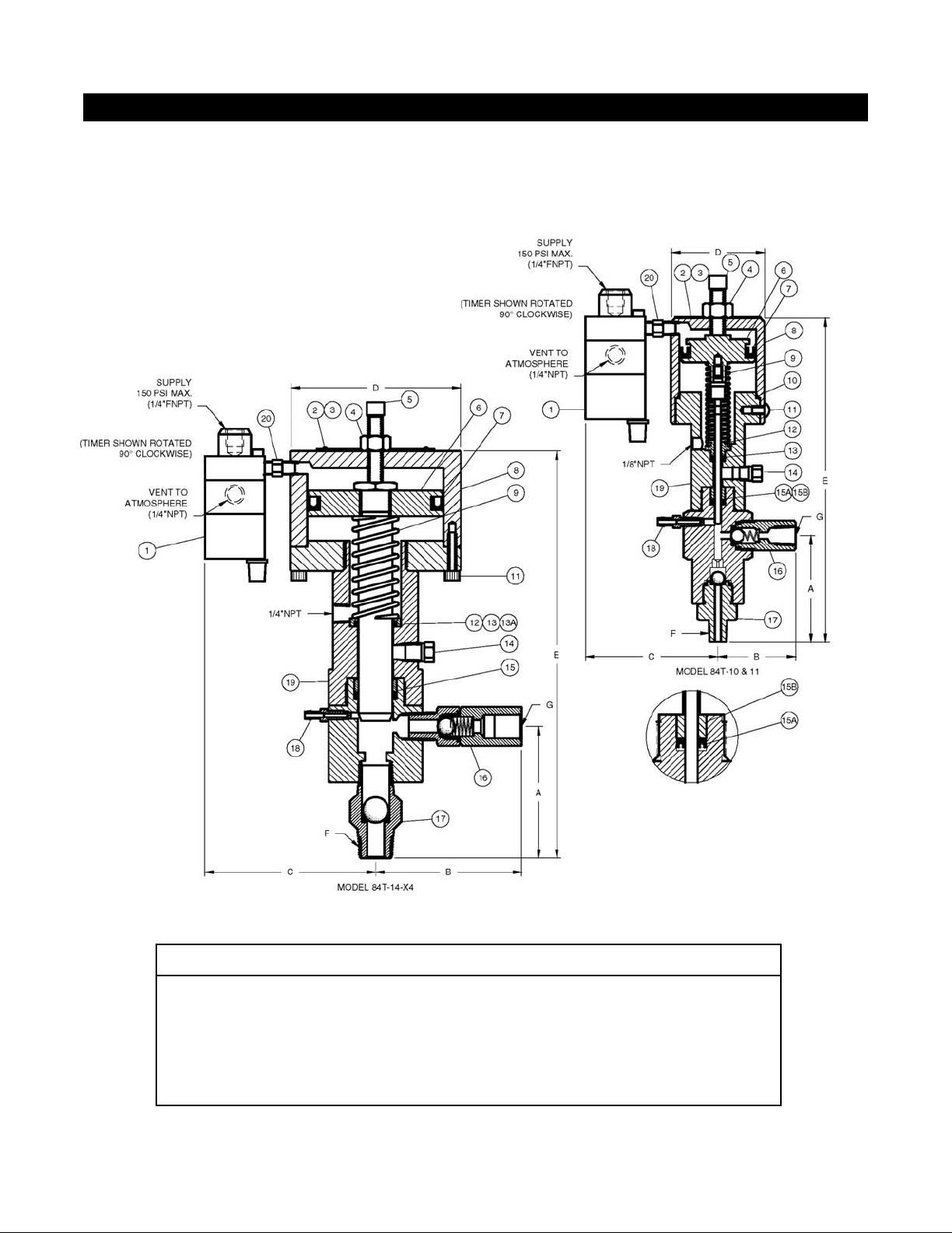

1. Figure 1 of this manual is the

sectional drawing and parts

list for the LINC84T-10, 11 &

14ChemicalMeteringPump.

2. Figure 2 of this manual is the

sectional drawing and parts

list for the LINC84T-12

Chemical Metering Pump.

Installation:

The LINC84T-10, 11, 12 & 14 re-

quire a flooded suction and must

be located lower than the chemical

supply tank. Vertical installation

of the piston housing is required.

1. Connect the suction line

through a filter or strainer to

the suction check valve (fig.

1, item 17 or fig. 2, item 16).

2. Connectthedischargelineto

the desired location.

Note:An in-linecheckvalve at the

point of injection is recommended

to prevent back flow to the pump

during shutdown or servicing.

3. Connect a supply pressure

line to the timer (fig. 1, item 1

or fig. 2, item 1). Air is the

recommended supply; how-

ever,anydryfilteredgasmay

beused. Thesupplypressure

to the timer must be regu-

lated between 15 psig and

110 psig.

4. Settheregulatortotheproper

pressure to overcome the

discharge pressure required

by the pump. Refer to the

paragraph on "Amplication

Ratio" in this manual to

determine the correct supply

pressure.

5. To prime the pump, loosen

the bleed screw (fig. 1, item

18 or fig. 2, item 18). Allow

the liquid (chemical) to flow

into the pump chamber,

ventingthetrappedairorgas.

Tighten the bleed screw.

6. Start the pump and run for a

minimum of one minute.

Open the bleed screw again

and evacuate all the remain-

ing air or gas from the pump

chamber.

7. Using a rate gauge, set the

desired pumping rate by

adjusting the timer knob and

stroke adjustment screw.

Thetimercanbesettostroke

the pump from 4 strokes/

minute to the maximum rate

for the particular pump being

used. See selection chart in

this section of the manual.

8. The stroke length is adjusted

by rotating the stroke adjust-

ment screw (fig. 1, item 5 or

fig. 2, item 4) on top of the

piston housing (fig. 1, item 8

or fig. 2, item 6). Loosen the

jam nut and adjust the stroke

adjustment screw as neces-

sary (fig. 1, item 4 or fig. 2,

item 5). Lock down the jam

nutafteranyadjustmentsare

made.

Note: Theminimumstrokeonthe

84T-10, 11 & 12 is 1/8" and 1/4" on

the 84T-14.

Maintenance:

Refertoallsectionaldrawingand

parts list in this manual. All repairs

should be performed in a clean

environment.

The following steps must be

taken before proceeding with any

maintenance operations:

Removing the Pump from Ser-

vice:

1. Rotate the control knob on

the timer to the "O" position.

2. Disconnect the supply

pressure from the timer.

3. Close the upstream and

downstream valves on the

chemical lines.

4. Open the bleed screw to

release the pressure in the

pump.

5. Disconnect the suction and

discharge lines from the

check valves.

Timer,

Figure 1, item 1 or Figure

2, item 1 & Figure 3:

1. Disconnect the supply

pressure from the timer.

2. Rotate the timer counter-

clockwise on the pipe nipple

that connects it to the piston

housing until the timer is

vertical with the supply pres-

sure port pointing down.

3. Loosen and remove the two

screws from the timer (fig. 3,

item1).

Untitled-4 2/19/2004, 4:23 PM7