LINC 86 ver. 04082003 - pn 15107

LINC MILTON ROY • 201 IVYLAND ROAD • IVYLAND PA, 18974 • USA • TEL. 215.441.0800 Page 9

M E T E R I N G P U M P S

E L E C T R I C P U M P

To replace or repair the Suction

and/or Discharge Check Valve:

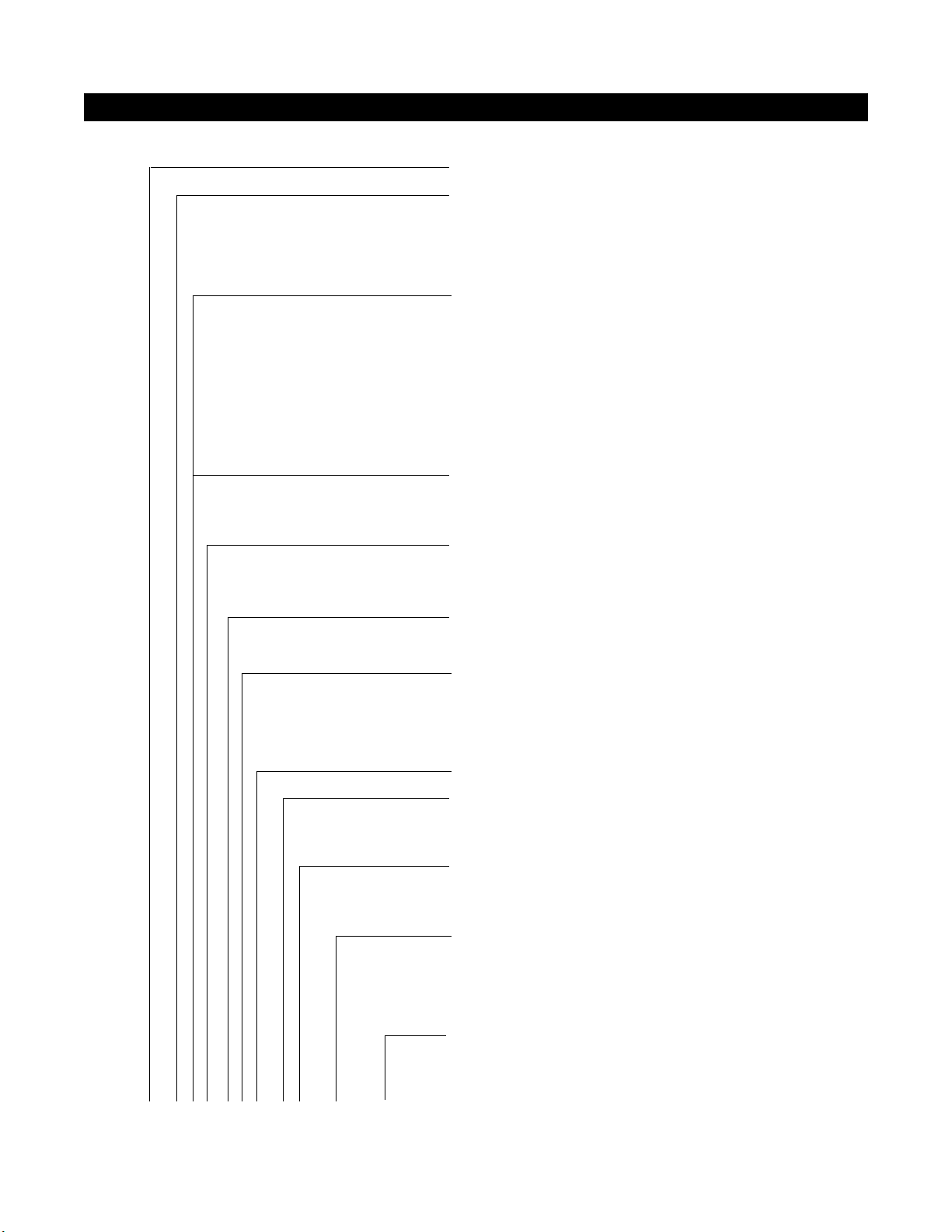

Two-Piece, fig. 1, items 10 & 13,

fig. 2, items 6 & 17, fig. 5 & 6:

Field repair of check valves

is not recommended. However, if

the checks are to be repaired, the

repairs should be done in a clean

environment that has the necessary

equipment to check the valves for

leakage after they are repaired.

The discharge check valve con-

tains a spring to hold the ball against

the seat. In the suction check valve,

the ball floats freely.

To repair the Check Valves:

1. Separate the two halves for

the check valve (fig. 5 & 6,

items 1 & 4).

2. Replace the o-rings, ball and

spring as required (fig. 5 & 6

items 2, 3, 5 & 6). In the

majority of the check valve

the seat o-ring will be Teflon

(fig. 5 & 6, item 2). This o-

ring may be removed, turned

around and reused if a new

o-ring is not available. During

this procedure, extreme care

should be exercised. The

ball should be "peened" on

the Teflon seat to ensure

proper sealing (fig. 5 & 6,

items 2, 5 & 1).

3. Connect the outlet of the

check valve to an air pres-

sure source and apply 10

psig. Place the inlet of the

check valve into water or

bubble test fluid. If bubbles

appear, reset the ball to the

seat o-ring and retest. In-

crease the air pressure to

100 psig and again check for

leaks as above.

4. Ensure that the proper flow

direction, as marked on the

valve body, is observed

when installing or replacing

the check valve.

5. Install the repaired check

valves into the pump body

and tighten securely.

Optional Bellows Pump Head

86-20 & 86-30

3/8" & 1/2" Plungers:

(figure 2)

To replace the Seals, Split

Bushings & Bellows:

1. Remove the entire bellows

pump head assembly from

the drive housing assembly

as previously described for

the standard pump head

assembly.

2. Loosen the four set screws

(fig. 1, item 4) that mount

the bellows seal body to the

head spacer (fig. 1, items

16 & 17). Pull the head

spacer assembly, with the

plunger attached (fig. 1,

item 8), out of the bellows

seal body. Loosen the six

cap screws (fig. 2, item 13)

that hold the bellows seal

body to the bellows housing

(fig. 2, item 8). Separate

the seal body and housing.

3. The split bushings, the

spacer and seals (fig. 2,

items 14, 15 & 16) can be

removed from the bellows

seal body by pushing the

round shank of a drill bit

through the plunger hole in

the bellows seal body. Use

a 25/64" diameter bit for the

3/8" plunger pump and a

33/64" diameter bit for the

1/2" plunger pump.

Note: Be careful not to scratch

the bore that houses the seals.

4. Remove the bellows (fig. 2

item 10) from the bellows

housing (fig. 2, item 8).

The bellows will be tight in

its housing and may be hard

to remove. Do not dam

age the sealing surfaces

while removing the bellows.

5. To reassemble the pump,

position the bellows hous-

ing in the vertical position,

possibly in a vise. Start by

placing the bellows spring

and bellows (fig. 2, item 9

& 10) in the bellows hous-

ing. Then, install the bel-

lows retainer and o-rings

(fig. 2, items 12, 2, 3, 4, &

5). Lubricate the o-rings be

fore installation.

6. Fill the bellows with 10W-30

or 5W-30 motor oil depend-

ing on temperature condi-

tions using the following

procedure.

7. Slowly fill the bellows cavity

until oil is flush with the top

of the bellows. Air will be

trapped in the bellows con-

volutions.