LINE SITE LSL-210 User manual

Operating Manual

WARNING AND CAUTION

•While the instrument is operating, be careful not to expose your eyes to the

emitting laser beam. Exposure to a laser beam for a long time may be

hazardous to your eyes (laser beam: equivalent to Laser Class 2 Standard).

•Do not try to dismantle the instrument. Have it repaired by your dealer or

supplie r.

Se lf-Disma ntling may worsen the proble m.

•When attaching the instrument to a tripod, make sure the instrument is

securely fixed to the tripod and the tripod leg clamps should be securely

fastened. If not securely fastened or tightened, the main unit could fall off

or the tripod could fall ove r.

•When setting the tripod, be aware of the tripod shoes which are sharp.

These sharp points allow tripod to be securely positioned on the ground.

Operate this laser product with the height of laser avoiding that of eyes of

vehicle drivers or pedes trians. Avoid putting the laser on a hig hly reflective

material such as mirror. When disposing of this instrument, take a measure by

removing the batteries so that the laser will not be emitted.

Introduction

Congratulations on the purchase of your Linesite LSL 210 Series Laser.

Although simple to use, we recommend that you read this manual before

operating the laser.

Description

The Linesite LSL210 is ideal for general construction, site preparation,

vertical alignment and squaring. and other leveling applications. It

automatically self-levels in horizontal and vertical modes can be used for

manual grade as well.

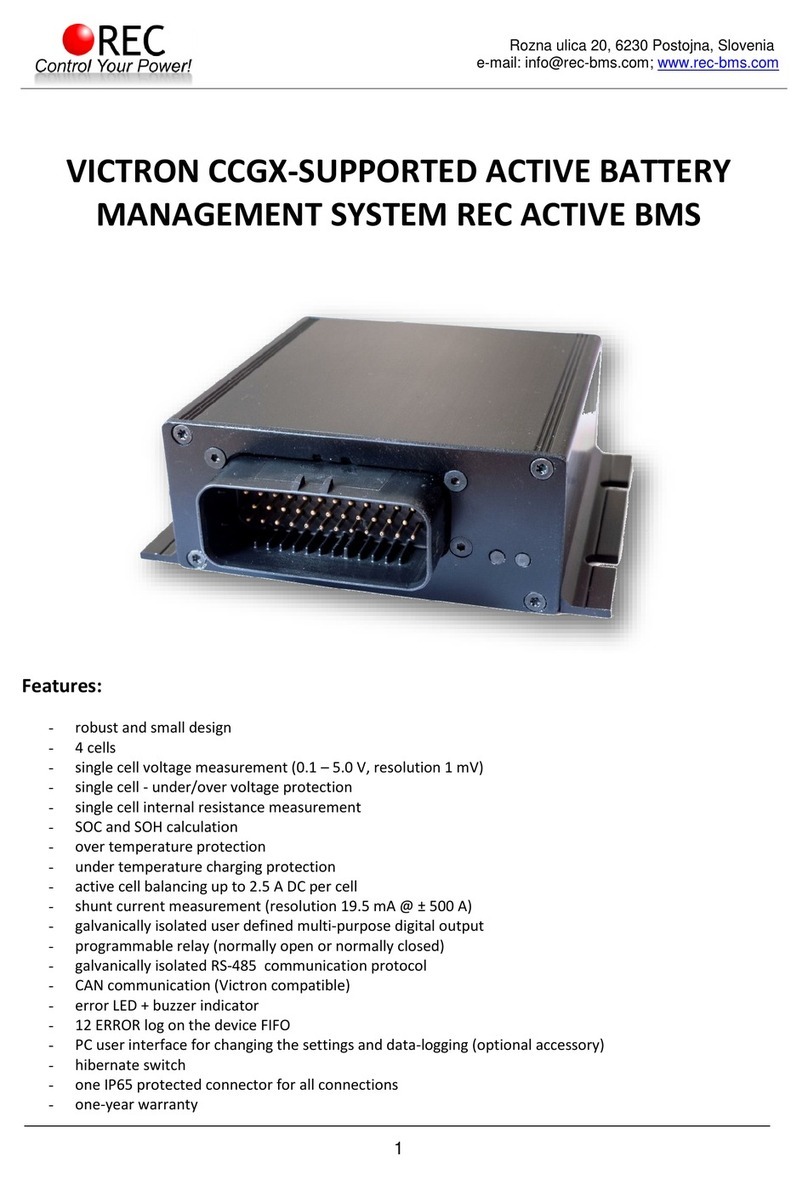

1. Functions

This instrument is equipped with the red semiconductor diode with

wavelength of 635nm. And the laser module of instrument will rotate freely

to form a laser-scanning surface. Emitting direction of rotary laser-beam

illustrated as follows:

Horizontal Position Vertical Position

When the instrument is set upright, it will emit laser-beam to form

a 360-degree horizontal scanning surface and a plumb dot

automatically. When set horizontally, it will form a 360-degree

plumb scanning surface and a plumb dot.

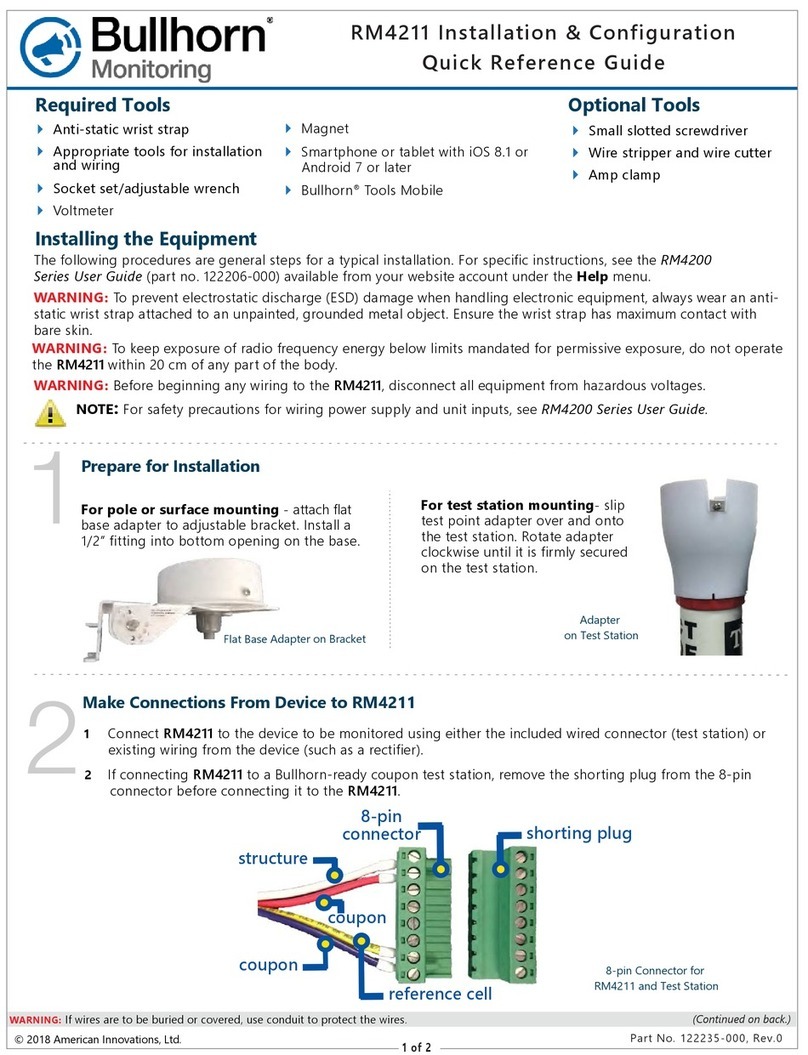

2.3 Main Panel Explanation

(1) ON/OFF: Controlling the state of power.

(2) Power indicator: When on, the instrument is starting up. Otherwise it is

shutting down.

(3) Mode indicator: When on, the instrument is leveling manually. When it

blinks, it stays in alarm. (The slope of the instrument is out of range).

(4) Key of Automatic drift system model: Warns the user for a misaligned

device

(5) Anti-shocking Alert indicator: When the indicator is blinking slowly, it is in

Automatic Drift System model. When the light is twinkling quickly, the laser

level will not level.

(6) Rotary Speed: Adjustment. Speed of scanning includes 5 Speeds:

0-60-120-300-600 RPM

2.3 Main Panel Explanation - Continued

(7) Directional scanning: Circling knob.

Angle of scanning includes 5 levels:0-10°-45° -90°-180°

(8) Manual/Automatic: Controlling the mode of leveling.

(9) Left-spinning: Making the laser module step-move counter-clockwise

when the laser module is power off or it is scanning directionally.

(10) Right-spinning: Making the laser module step-move clockwise when the

laser module is power off or it is scanning directionally.

(11) X-axis: Adjusting the slope of X-axis when the instrument stays in manual

mode.

(12) Y-axis: Adjusting the slope of Y-axis when the instrument stays in manual

mode.

3. Directions:

3.1 Battery

Please Note - Ni-MH Rechargeable battery pack is pre-installed

4x Alkaline (Size C) pack is included in the case

3.2 Instrument Placement

3.2.1 Horizontal scanning

Lay the instrument on the tripod or stable flat surface, or even hang it on

the wall. Set upright the instrument and keep the slope of instrument

within the range from -5°to +5°.

3.2.2 Vertical scanning

Lay the instrument on the flat surface and keep the slope of instrument

within the range from -5°to +5 °.

3.2 Operations

3.3.1 Power

Press the Key ON/OFF to bring automatic leveling into function when the

power indicator lights.

When Power indicator lights, it shows the voltage of the batteries is

insufficient. Then the rechargeable batteries need to be charged.

Press the Key ON/OFF again to switch off the instrument and power

indicator will go out.

3.3.2 Leveling

Press the Key ON/OFF to bring automatic leveling into function when the

laser beam begins to wink. After automatic leveling, the laser module will

rotate at the speed of 600 r.p.m.

If the instrument is placed improperly, or the slope of instrument exceeds

the range of ±5°, at that moment mode indicator and the laser beam will

wink together. Then place the instrument properly.

3.3.3 Spinning

(1) Continuous spinning

Press the Key “Rotational speed adjustment” to control the spinning speed

of the laser module. If press the key repeatedly, the spinning speed

of the laser module will continuously change as follows:0-60-120-

300-600-0 RPM

(2) Stepping spinning

Locate the Key Speeding-up at speed of 0 r.p.m, the laser module will stop

spinning. And press the Key Right-spinning, the laser module will

step-move clockwise. Then if press the Key Left-spinning, the laser

module will step-move counter-clockwise.

3.3.4 Directional scanning

(1) Locate the Key Speeding-up at speed of 0 RPM, the laser module will

stop spinning. Press the Key Directional scanning; the laser module

will scan directionally. If press the key repeatedly, the angle of

scanning of laser module will continuously change as follows: 0°-

10-°45º-90-°180°-0°.

(2) Press the Key Left-spinning or the Key Right-spinning to change the

direction of scanning.

3.3.5 Slope Adjustment

When the instrument is set upright to do horizontal scanning, the slope of X-

axis and Y-axis can be set.

Press the Key Manual/Automatic when mode indicator lights, the instrument

enters the mode of manual leveling. When the instrument is set upright to

do horizontal scanning, the slope of X-axis and Y-axis can be set. Press the

Key Manual/Automatic when mode indicator lights, the instrument enters the

mode of manual leveling.

1 Slope of X-axis

a. Aim the X1-beam to the direction of the slope required then to

adjust.

b. Press the Key or to move the laser beam up or down.

(2) Slope of Y-axis

(3) Quit slope adjustment mode

Press Manual/Automatic key again. After mode indicator goes off, the instrument

then will quit the slope adjustment mode and will self-leveling again.

4. Power

When the voltage indicator lights, the batteries need to be charged immediately.

Connecting the charger with AC, insert the plug of charger into the plughole at the

bottom of the instrument (As depicted above).

If the red indicator of charger lights, it shows the batteries are being charged.

If the green indicator of charger lights, it shows the recharging has finished.

Notices:

(1) Using the standard rechargeable batteries of the instrument, recharging will be

finished within 7 hours.

(2) Power required for the charger: Frequency: 50-60HZ; Voltage: 85-265V.

(3) Charging and using of the instrument can progress simultaneously.

(4) If keeping the instrument in storage (or Leave the instrument unused for a long

time), the batteries (dry battery or rechargeable battery) need to be taken out.

(5) Brand-new rechargeable batteries or long-time unused rechargeable batteries

need to be recharged and discharged three times to attain the capacity required.

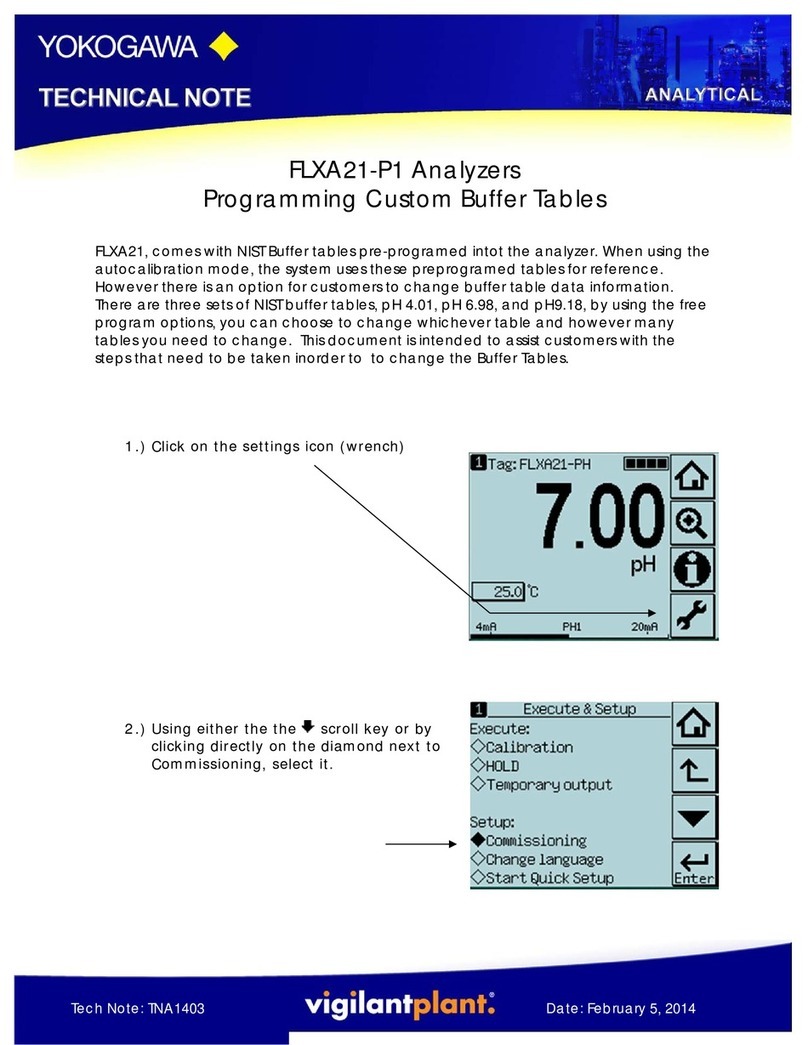

5. Remote

The remote control of the instrument adopts the infrared technique.

Aim the aperture of infrared ray to the instrument (as depicted below) to bring

remote controlling into function (Available distance: indoor: 20M; outdoor: 15M).

The keypad panel includes 9 keys; the indicator on the RC will blink to show the

operating signal has been sent out once pressing any key.

6. Accuracy Checking

6.1 Horizontal-surface Checking

(1) Place the instrument at the point of 50m in front of wall (or set a scale plate

at the point of 50m away from the instrument), and then adjust the level of

the base approximately to aim the X1 to the wall (or scale plate), as

depicted below:

(2) After switching on the power, use the laser detector measuring the h1 of

X1-beam on the wall or scale plate.

(3) Loose the screw of the tripod, turn around the instrument for 180° to

measure the h2 of X2-beam on the wall or scale- plate. The method

should be the same with h1.

D-value between h1 and h2 ought to be less than 10mm.

(4) Check the Y-beam in the same way.

6.2 Horizontal line Checking

(1) Place the instrument between two walls with the distance of 30m (or

two scale plates with the distance of 30m).

(2) Place the instrument according to horizontal setting and then adjust

the instrument.

(3) Switch on the power, and then measure the middle point of the laser

beam on the wall (or scale plate).

7. Specifications

Leveling Accuracy (H/V)

±2.4mm at 30m / ±3mm at 30m

Leveling Range

±5º

Working Range with Receiver

(Diameter) depending on working

environment

Diameter:650m

Visible Working Range depending

on working environment

40m

Spinning Speed

0、60、120、300、600 r.p.m

Directional-Scanning Angle

0º、10 º、45 º、90 º、180 º

Slope-adjusting Range

±5º(Bi-directional)

Light Source Laser Diode, Class 2 (IEC60825-

1,2014) wavelength: 635-650nm

Remote controlling Distance

Approximately 30m

Working Temperature

-5℃-- +50℃

STORAGE Temperature

-15℃-- +60℃

RL Power Supply

DC 4.8-6V (4 section of NI-MH

rechargeable batteries) / 4 Cell Alk-

battery

RL Charging Time No less than 5hrs (Do not charge

Alkaline battery)

Hours in continuous use Approximately 34 hours

(Rechargeable) / 25 hrs (Alkaline)

RL IP

IP 65

Dimension

220mm x 220mm x 210mm

Weight

3.1kg

Remote IP

IP 54

Remote Power Supply

2AA

Laser Detector Precision

Rough Band: 3mm/ Precise Band:

1mm

Laser Detector IP

IP55

Laser Detector Power Supply

9V

Table of contents

Popular Measuring Instrument manuals by other brands

Anton Paar

Anton Paar DMA 4100 M instruction manual

Loreme

Loreme IPL 144V Configuration handbook

Bosch

Bosch GRL Professional 250 HV Original instructions

Global Laser

Global Laser LDM127 manual

Agilent Technologies

Agilent Technologies E4418B Configuration guide

Pulsar

Pulsar FlowPulse Handheld instruction manual