Linear AT7120 User manual

ADVANCED TV

LINE

Model AT7120

120W ATSC UHF Transmitter

OWNERS MANUAL

Linear Industries Incorporation

www.linear-tv.com

Made in USA

AT7120 Owner Manual Rev. 1.1 –March 2009 2/76

AT7120

120W UHF 8VSB-ATSC TRANSMITTER

ADVANCED TV LINE

Owner Manual

Table of Contents

User Notices and WARNINGS .................................................................................................. 3

Section 1 –AT7120 General Description................................................................................... 6

Section 2 –Control Set............................................................................................................ 15

Section 3 –8VSB Modulator and Master Clock....................................................................... 22

Section 4 –IF/UHF up-converter............................................................................................. 26

Section 5 –UHF ATSC Exciter................................................................................................ 31

Section 6 –UHF ATSC Amplifier............................................................................................. 35

Section 7 –Power Supply........................................................................................................ 40

Section 8 –DC/DC Converter.................................................................................................. 47

Section 9 –Memory Interface.................................................................................................. 48

Annex A –AT7120 Operational Software................................................................................ 49

Annex B –Checking the RF Power LDMOS Transistors......................................................... 72

Annex C –Typical Final Test Reports Results ........................................................................ 73

AT7120 Owner Manual Rev. 1.1 –March 2009 3/76

User Notices and WARNINGS

USER NOTICES

IT IS VERY IMPORTANT TO READ THE FOLLOWING MANUAL SECTIONS PRIOR TO

OPERATION OF THIS TRANSMITTER!

Notice 1

The transmitter main operating voltage setting is marked on the rear of the chassis.

Notice 2

The transmitter operating frequency is set from the factory.

Notice 3

For adjusting the RF output power setting a qualified technician should always employ the use of an RF

Wattmeter and a calibrated dummy load.

Notice 4

Should accident or injury occur to the personnel engaged in the installation, operation, or service of the

equipment should seek proper medical attention. It is advisable that such personnel have familiarity

with first-aid practices.

Notice 5

To call our technical support center or for other customer service issues at Linear Inc, refer to the

following number: 847 428-5793, or e-mail to broadcast@linear-tv.com

Notice 6

If you experience some specific difficulty and the technical information available in this manual is not

enough to help you, do not hesitate to call LINEAR technical support center.

Notice 7

The technical information presented on this manual is sole intellectual propriety of LINEAR

INDUSTRIES Inc. Reproduction of this document in full or partial is prohibiting without written

authorization. This document is legally protected by the copy rights laws.

WARNING!

THE VOLTAGES AND CURRENTS IN THIS EQUIPMENT COULD BE DANGEROUS. PERSONEL

MUST, AT ALL TIMES, OBSERVE SAFETY WARNINGS, INSTRUCTIONS, AND ANY

REGULATIONS.

AT7120 Owner Manual Rev. 1.1 –March 2009 4/76

THIS OWNER’S MANUAL IS INTENDED AS A GENERAL GUIDE FOR TRAINED AND

QUALIFIED PERSONNEL WHO ARE AWARE OF THE DANGERS THAT ARE INHERENT IN

THE HANDLING AND OPERATION OF POTENTIALLY HAZARDOUS ELECTRICAL AND

ELECTRONIC CIRCUITS. IT IS NOT THE INTENT OF THIS MANUAL TO PROVIDE A

COMPLETE SET OF SAFETY INSTRUCTIONS OR PRECAUTIONS THAT SHOULD ALREADY

BE UNDERSTOOD BY TRAINED OR EXPERIENCED PERSONNEL IN USING THIS OR OTHER

TYPES OF ELECTRONIC EQUIPMENT.

THE INSTALLATION, OPERATION, AND MAINTENANCE OF THIS EQUIPMENT INVOLVE

RISKS TO PERSONNEL AND ALSO TO THE EQUIPMENT. LINEAR, INC. SHALL NOT BE

RESPONSIBLE FOR INJURY OR DAMAGE THAT IS THE RESULT OF IMPROPER

PROCEDURES OR USE BY PERSONS IMPROPERLY TRAINED OR LACKING THE

KNOWLEDGE TO PERFORM ASSOCIATED TASKS.

ALL LOCAL CODES FOR BUILDING, SAFETY, FIRE, OR RELATED STANDARDS MUST BE

OBSERVED. CONSULT LOCAL AUTHORITIES FOR THE STANDARDS FOR THE AREA OR

REGION WHERE THE EQUIPMENT WILL BE INSTALLED AND PUT IN USE.

WARNING!

AT ALL TIMES DISCONNECT AC/MAINS POWER BEFORE OPENING COVERS, DOORS,

ENCLOSURES, PANELS, OR PROTECTIVE SHIELDS THAT EXPOSE LIVE CIRCUITS. NEVER

PERFORM MAINTENANCE, MAKE ADJUSTMENTS, OR SERVICE THE EQUIPMENT WHEN

ALONE OR FATIGUED.

WARNING!

IF ELECTROLYTIC OR OIL FILLED CAPACITORS ARE UTILIZED IN THE EQUIPMENT AND

THE COMPONENT APPEARS LEAKY, OR IS BULGING, OR IF THE CASE OR COVERING OF

THE COMPONENT APPEARS DAMAGED OR DISTRESSED ALLOW SUFFICIENT TIME FOR

THE UNIT TO COOL and FULLY DISCHARGE BEFORE SERVICING. SERVICING HOT OR

LEAKY CAPACITORS CAN CAUSE A RUPTURE OF THE CASE AND POSSIBLE INJURY.

Returns and Exchanges

Equipment (Damaged or undamaged) should not be returned without written approval and a

Merchandise Return Authorization (MRA Number) from your Linear Sales representative or Linear

Customer Service. Special shipping instruction will be provided which will assure proper handling.

The circumstances and reasons for the return must be included in the request for return. Equipment that

is special or “custom” ordered may not be returnable. In situations where return or exchange is at the

request of the customer a restocking fee may be charged. All returns must be sent freight prepaid and

AT7120 Owner Manual Rev. 1.1 –March 2009 5/76

properly insured by customer. When communicating with Linear please refer to your Order or Invoice

Number.

Unpacking

Use care when unpacking the equipment. First perform a visual inspection of the item(s) to determine if

any damage occurred during shipment. Be sure to retain all the shipping materials (crates and boxes or

cartons) until such time that it has been determined that the received equipment arrived undamaged.

Find all PACKING LISTS and keep them to assist in locating and identifying any components or

assemblies that may have been removed for safe. Make sure that all shipping straps, supports and

packing materials are completely removed from the equipment prior to initialization and use.

AT7120 Owner Manual Rev. 1.1 –March 2009 6/76

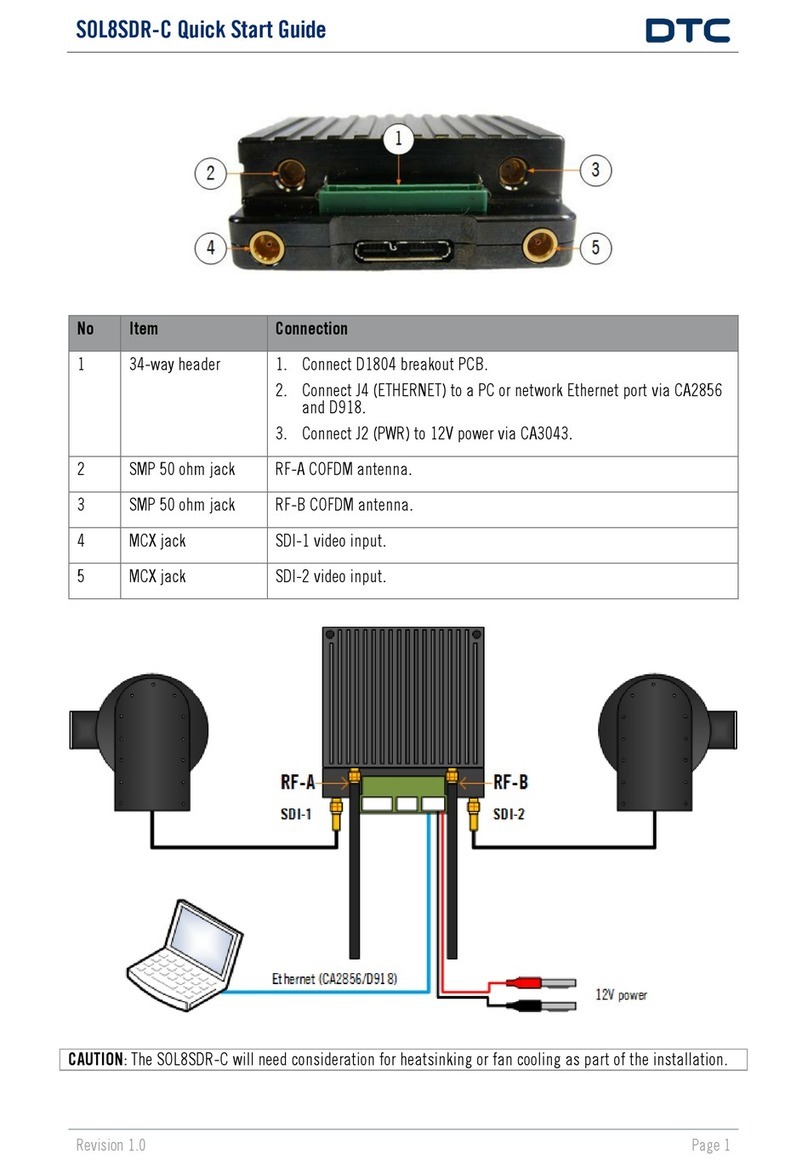

Section 1 –AT7120 General Description

The ATSC DTV transmitter model AT7120 is part of the ADVANCED TV line, having modular

construction meeting EIA 19”rack standards, and is composed for the following modules:

01 Main Control unit - CIM3297

01 Keypad - CIM3003

01 Display LCD 20 columns x 02 lines - CIM3004

01 Memory interface - CIP8421

01 1Mbits memory card –CIP8421

01 UHF ATSC Exciter- Module 4407

01 up-Digital Converter - Module 4492

01 Power Supply - Module 4401 (versions M110/M220/B220)

01 8VSB Modulator and Master Clock Generator - Module 4549

01 DC/DC Converter (+2.5V and +5V) –Module 4567

02 UHF ATSC Amplifier –Module 4442

01 OCXO –Module 4292

When AT7120 is a TRANSMITTER that can be installed with or without a 6 pole elliptical filter on its

RF output. In this application, the overall performance of the unit will meet or exceed the FCC

requirements for out of channel spurious emission. Please refer to Annex C.

AT7120 Owner Manual Rev. 1.1 –March 2009 7/76

AT7120 Block Diagram

+28V

RELIGADO

UHF ATSC EXCITER

MODULE 4407

+8V+15V

KEYBOARD

CIM3003

LINEAREQUIPAMENTOS ELET RÔNICOS

DISPLAY

CIM3004

RESTART

RFOUT

ALARME DE

TEMPERATURA LEITURA DE

POTÊNCIA DIRETA

FAN

FILTER FAN

CIM6646 +24V

IN OUT

EXC.TEMPERATURE

PA1 TEMPERATURE

PA2 TEMPERATURE

ALARMS

SHUT DOWN 1

CONTROL UNIT

CIM3297

(CIP8231)

MAIN POWER SUPPLY

MODULE 4401

ID

CURRENT

READING +28V

READING +18V

READING -18V

READING +9V

READING

+18V-18V

+9V

+28V

FIXO

+28V

RES.

1 SUBORDINATE

POWER SUPPLY

MODULE 4402

SHUT DOWN 1

+28V

FIXO

AC FAN

+32V

(VA) +32V

(VB) TEMP

PA 1 PA1

TEMP

ALARM

ID1

READ ID2

READ

+28V

FIXO

UHF ATSC

AMPLIFIER

PA1

MODULE 4442

IN OUT

+32V

(VA) +32V

(VB)

1 SUBORDINATE

POWER SUPPLY

PA1

TEMP

8VSB

MODULATOR AND

MASTER CLOCK UHF UPCONVERTER

MODULE 4492

+18V-18V

RFOUT

SW2

TEMP

ENABLE Q DAC

ENABLE I DAC

CLOCK DAC

DATA DAC

ALC

+28V

FIXO

CLOCK PLL

LOCK DETECT

MODULE 4549

+5V+2.5V +18V-18V

10MHz

OCXO

MODULE 4281

RD

ENA

CLK

DIN

DO

LD

CONTROL UNIT

+28V

MODULE 4567

DC CONVERTER

+5V+2.5V

MEMORY

MEMORY

CARD

CARD

CIP8421

CIP8421

MEMORY INTERFACE

MEMORY INTERFACE

CIP8437

CIP8437

DCLK

ASDI

CS

DATA

FROM

CONTROL

UNIT

110 / 220V

MONOPHASIC / BIPHASIC

ON/OFF

SWITCH

5A / 220V

10A / 110V

FUSE

FUSE 5A / 220V

10A / 110V

120Wrms

RF OUT

RF

PW REF

PW

+15V

REFLT

IN OUT

MODULE

4166

FPB

MODULE

4252

310M IN

ASI IN

EXT. REF. IN

EXCITER FORWARD POWER

FORWARD POWER

REFLECTED POWER

I1 MAIN POWER SUPPLY

PA1 CURRENT ID1

PA1 CURRENT ID2

PA2 CURRENT ID3

PA2 CURRENT ID4

+28V MAIN POWER SUPPLY

+18V MAIN POWER SUPPLY

-18V MAIN POWER SUPPLY

+9V MAIN POWER SUPPLY

+32V 1 SUBORDINATE POWER SUPPLY

+32V 2 SUBORDINATE POWER SUPPLY

READINGS

MASTER CLOCK LOCK DETECT

+5V

QIN

IIN

+32V

READ

ENABLE

DATA PLL

SW1

DCLK

ASDI

CS

DATA

TO MEMORY

INTERFACE

RD

ENA

CLOCK

DIN

DO

LD

MODULATOR

÷

OUT 1

OUT 2

IN

MODULE 4442

IN OUT

+32V

(VA) +32V

(VB)

2 SUBORDINATE

POWER SUPPLY

PA2

TEMP

UHF ATSC

AMPLIFIER

PA2

Σ

IN 1

IN 2

OUT

2 SUBORDINATE

POWER SUPPLY

MODULE 4402

SHUT DOWN 2

+28V

FIXO

+32V

(VA) +32V

(VB) TEMP

PA 2 PA2

TEMP

ALARM

ID3

READ ID4

READ +32V

READ

AC FAN

SHUT DOWN 2

RS232

TELESUPERVISION

CONTROL

UNIT

AT7120 Owner Manual Rev. 1.1 –March 2009 8/76

Module 4549

8VSB Modulator

The 8VSB modulator automatically recognizes the incoming transport stream as either SMPTE310M or

ASI. The transport stream input utilizes the BNC connector located on the rear panel of the unit. The

modulated output signal of this module is composed by two IF orthogonal carriers termed; signals (I)

and (Q). The central frequency of the 8VSB modulated IF signal is 18.83339MHz. The signal

processing and modulation performed on this module follows the ATSC recommendation A/53 E.

This module also performs the non-linear corrections that might be necessary to enhance the equipment

efficiency to meet FCC spurious emissions requirements. In this case, an RF output filter is required.

The recommended linear equalization is also automatically performed in this module.

Master Clock

The master clock unit generates signals utilizing a Voltage Controlled Oscillator and Phase Locked

Loop at 172.16MHz. The PLL is locked at 10MHz reference, externally or internally generated. This

signal provides the time base for the 8VSB modulator.

Module 4492

IF to UHF up-Converter

The IF carries the orthogonal (I) and (Q) signals generated in module 4549, (8VSB Modulator), which is

then routed to the up-converter module. The output signal of this module is set on the FCC/UHF

operational 6MHz channel of the transmitter AT7120.

Inside the converter the modulated IF band is mixed with the continuous wave local oscillator LO. As a

result of this mixing, the IF translation to the UHF band is performed. The LO is a free oscillator, that

has its frequency locked via PLL. The LO/PLL is generated by a 10MHz OCXO (oven controlled

crystal oscillator), or provided by an external reference signal.

Module 4281

10MHz reference automatic switching

Both circuits; the 8VSB modulator and the up-converter, share the same reference signal source. The use

of the same reference signal creates perfect synchronization and stability during the DTV transmission

process. The internal 10MHz signal is obtained from an OCXO oscillator with a stability of 0.3ppm. An

external 10MHz signal can be used as the reference signal; a GPS signal for instance. The external

reference input is a BNC connector located on the rear panel of the unit. In the absence of this external

source, the unit automatically utilizes the internal 10MHz source generated by the OCXO.

AT7120 Owner Manual Rev. 1.1 –March 2009 9/76

Module 4407

60W UHF band multistage amplifier

The IF modulated signal (previously converted into UHF) is amplified by a 60W UHF amplifier. This

amplifier uses transistors built with LDMOS technology operating in a class AB configuration, which

provides excellent efficiency and linearity. The RF OUT connector of the unit provides the high power

RF output.

RF Output monitoring

Module 4407 detects the direct and reverse RF power present on the RF OUT connector of the unit. The

detected information is then converted to correspondent DC levels before being routed to the master

control unit, where it is processed and displayed at the front panel LCD screen in watts.

Module 4442

AT7120 transmitter has two Modules 4442 connected in parallel, which work as digital TV end

amplifiers in all UHF band. The amplifier is made of the following components:

Input Coupler

The input RF coupler equally divides the UHF signal present in the input connector for the two

amplification cells, maintaining 50Ω impedance.

Cell A –35W Amplifier

The amplification cell A is obtained by a Push-Pull 35W amplifier, class AB. Transistor T1 is in this

cell. The polarization circuit of cell A is made of a VGS timer circuit with temperature compensation,

differential amplifier and gate impedance reducer.

Cell B –35W Amplifier

Just as cell A, cell B’s amplification is obtained by a Push-Pull 35W amplifier, class AB. Transistor T2 is in this

cell. The polarization circuit in cell B also is made of a VGS timer circuit with temperature compensation,

differential amplifier and gate impedance reducer.

Output Coupler

It is a hybrid coupler built with a special semi-rigid coaxial cable, better known as “wireline”. This type

of cable has 2 internal conductors interlinked; this set has the characteristics of a hybrid coupler. As the

input coupler, this coupler also has four gates (input/output; isolated, -3dB 0˚, -3 dB 90˚).

Temperature Alarm

Module 4442 has a protection circuit that disarms the module in case the temperature rises above 65˚ C.

This circuit is basically made of thermal sensor S1, DC amplifier and voltage comparator CI-1.

AT7120 Owner Manual Rev. 1.1 –March 2009 10/76

CIM3297

Control unit card

The digital management of the DTV AT7120 transmitter is done by the control unit card, CIM3297.

This control unit uses an A128 microcontroller programmed in assembler language. The unit process

data regarding the following operational parameters:

Warns of signal lock failure of the PLL in the up-converter.

Warns of excessive temperature of the 60W amplifier.

Monitors and displays the RF direct and reflected powers of the 60W amplifier, muting the transmission

in case of extreme levels.

Displays DC current levels of the main power supply module.

Process and displays power supply voltage(s).

Sets in the operational channel of the Up-converter unit and transmits power levels via ALC. Sets and

monitors the operational channel frequency in the up-converter unit as well as the transmit power levels

which is controlled by the automatic level control circuits.

The control unit is directly connected to a keypad and LCD screen, both located on the front panel of the

transmitter AT7120. Numerous parameters can be set via the keypad and monitored by the LCD screen.

The same functions can be performed via RS232 HyperTerminal connection.

Module 4401

Power Supply

The power supply module is a switching power supply type, utilizing a half-bridge topology. A control unit

monitors the power supply output and adjusts to varying load to maintain a nominal +32 VDC. The voltage and

current data is provided to the control unit card for display on the LCD screen.

AT7120 Owner Manual Rev. 1.1 –March 2009 11/76

AT7120 External Interfaces

Fig.1.2: AT7120 Front View

AT7120 Owner Manual Rev. 1.1 –March 2009 12/76

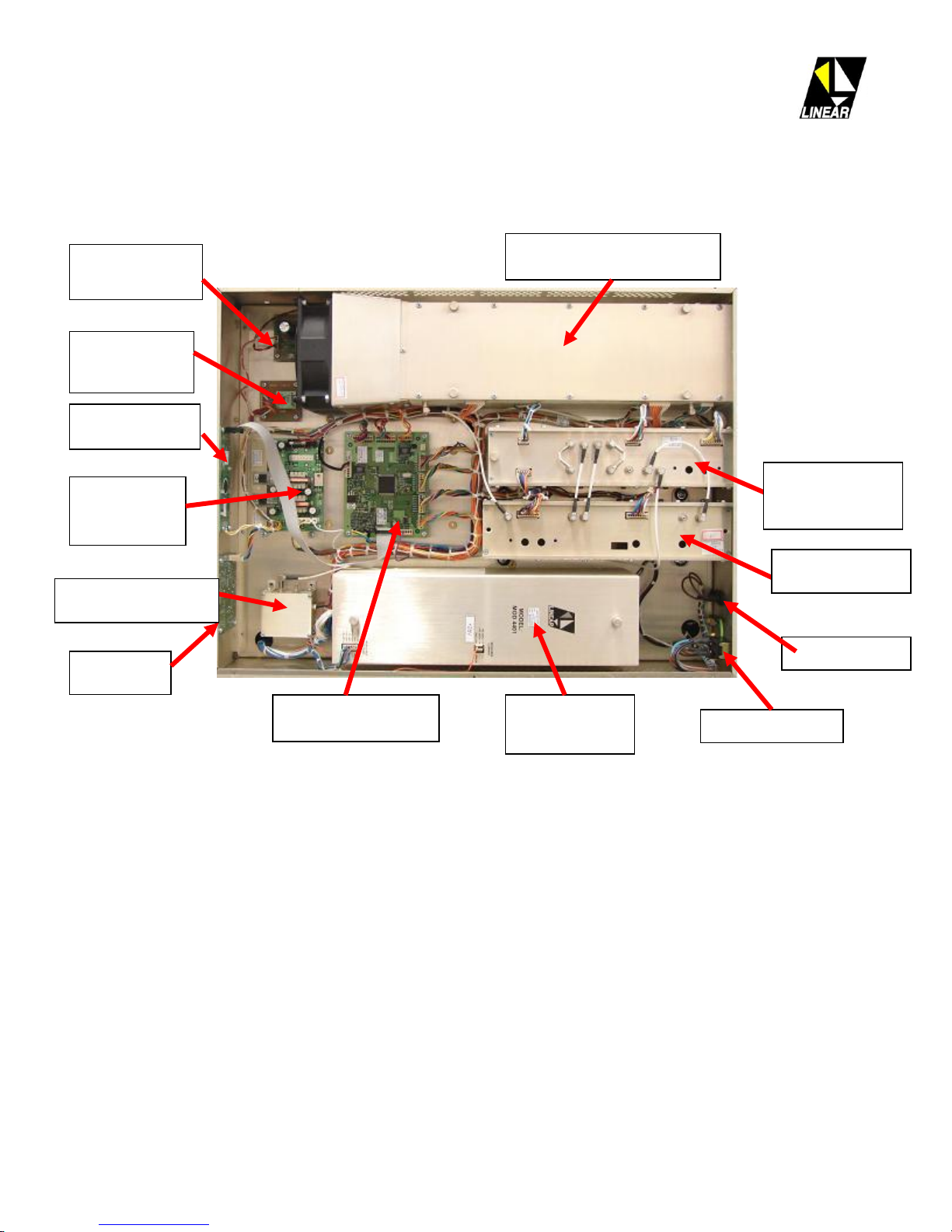

Fig.1.3: AT7120 Rear Panel View

Power Switch

ID Tag

External 10MHz

Reference Input

Main Fuse

ASI/SMPTE310M Transport

Stream Input

AC Power Cord

(DB-9) RS232

Hyper-terminal Interface

Hot Air Outlets

GND

RF Output

Connector

Internal DB-9

Not Used

AT7120 Owner Manual Rev. 1.1 –March 2009 13/76

AT7120 - Modules and Parts Displacement

Fig.1.4: AT7120 Modules and Parts displacement

Key Pad

CIM3003

RF Power Amplifier

Module 4407

LCD Screen

CIM3004

Memory Card &

Interface

CIP 8437

DC/DC

Converter

Module 4567

DC Fan Filter

CIM6646

Digital Control Card

CIM3297/CIP8231A

+32V Power

Supply Module

4401

Ref. 10MHz OCXO

Module 4281

Power Switch

Fuse & GND

Up Converter

Module 4492

8VSB Modulator &

Master Clock

Module 4549

AT7120 Owner Manual Rev. 1.1 –March 2009 14/76

AT7120 - 120W ATSC UHF Transmitter - Technical

Specifications

Table XX: AT7120 Technical specifications

Electrical

Main

220 VAC, bi phase, 50-60 Hz. standard

Consumption

400W @ 120W RMS/RF

Power Factor Correction, FPC.

Included

Signal Input

Transport Stream Input

ATSC/MPEG2, compliant to

SMPTE310M

Input Data Rate

19.39 Mbps

External Reference Signal

10MHz. (0 to +10 dBm).

Input Connector

75Ω (BNC),

Reference Input Connector

50Ω (BNC),

RF

Modulation Mode

8VSB.

IF

18.833916 MHz.

Channel Bandwidth

6MHz.

Test Signal

PRBS

Frequency Range

UHF. C14 to Ch53, (3 bands).

Frequency Step

1 Hz. ± 220kHz

Symbol Rate

10.76 MSymbol/sec.

Digital/Analog Converter

16 bit

Linearization Pre-Correction

Included

Pilot frequency stability overall

± 4.6 ppm.

Initial tolerance

± 1.0 ppm.

Vs. temperature in operating temperature range (steady

state)

± 10 ppb.

Holdover 24 hours, full temp. range

± 12 ppb.

24 hours drift (after 30 days)

± 1.0 ppb.

Long term stability over 15 years

± 3.5 ppm.

Peak to peak frequency response

0.15 dB.

Peak to peak group delay response

10 ns.

Phase noise

≤ -104 dBc/Hz @ 20kHz offset.

Conducted spurious and harmonics

< -60 dBc, FCC 47 Part 74.

Radiated spourious and harmonics

< -80 dBc, FCC 47 Part 74.

MER (Modulation Error Rate)

≥ 29 dB (transmitter output) typical.

RF output connector

N

Communication

Hyper-terminal

RS232 (DB-9)

External Command –ON/OFF

(DB-9)

Mechanical

Air speed over drawers

50 ft/minute.

Dimensions

5UR (H), 19”(W), 26”(D)

Weight

Gross: 110 lb.

AT7120 Owner Manual Rev. 1.1 –March 2009 15/76

Section 2 –Control Set

Functional Description

The digital control is responsible for all management of AT7120 transmitter.

This unit Monitors and assures the system is operating within acceptable parameters and provides user control

access via key pad located on the front panel, or via RS232 hyper-terminal.

Its main attributions are:

Warns of signal lock failure of the PLL in the up-converter.

Warns of excessive temperature of the 60W amplifier.

Monitors and displays the RF direct and reflected powers of the 60W amplifier, muting the

transmission in case of extreme levels.

Displays DC current levels of the main power supply module (I1).

Process and displays power supply voltage(s).

Sets in the operational channel of the Up-converter unit and transmits power levels via ALC.

Sets and monitors the operational channel frequency in the up-converter unit as well as the

transmit power levels which is controlled by the automatic level control circuits.

The control unit is directly connected to a keypad and LCD screen, both located on the front panel of the

transmitter AT7120. Numerous parameters can be set via the keypad and monitored by the LCD screen.

The same functions can be performed via RS232 HyperTerminal connection.

Control unit block diagram

CONTROL

UNIT

CIP8231

(CIM3297)

MICROCONTROLLER

DISPLAY

CIM3004

KEYBOARD

CIP8002

(CIM3003)

EXCITER FORWARD POWER READING

EXCITER REFLECTED POWER READING

EXC.20W ID CURRENT READING

VOLTAGES SUPPLY READINGS

RS232 REMOTE CONTROL

EXTERNAL FUNCTIONS

Fig.2.1: Control unit general block diagram

AT7120 Owner Manual Rev. 1.1 –March 2009 16/76

The printed circuit board CIP8231 is referred to as the control unit, and provides the major functionality

of the AT7120 digital control unit.

For a better understanding of the functioning of this board please refer to Fig.2.1 “Control unity general

block diagram”, above, which depicts the main components and connections. Figure 2.2, below, shows

a detailed schematic of CIP8231 including connector pin layout.

01 control unit board - CIP8231 (CIM3297)

01 keypad board - CIP8002 (CIM3003)

AT7120 Owner Manual Rev. 1.1 –March 2009 17/76

01 20 x 2 LCD display board - CIM3004

CIP8231 Connections

(BK) SW2 PIN 3 –CON 6 –CIP8388 –MOD. 4492 –UHF UPCONVERTER

(GR) TEMPERATURE ALARM PIN 4 –CON-5 –CIP8209 –MOD.4408 –UHF AMPLIFIER

(GY) RESTART PIN 6 –CON-8 –CIP8111 –MOD. 4401 –POWER SUPPLY

CON-1

BL

7

CON-2

1 9

9

1

36CON-7 CON-8 CON-9

1

GND

VCC

DA1

DA2

+15V

IRQ

CON-3

1

6

CON-4

8

CON-5

8

1

CON-6

8

1

PA21

PA31

PA41

PA51

PA61

PA71

1

PA02

PA12

PA22

PA32

PA42

PA52

PA62

PA72

PB01

PB11

PB21

PB31

PB41

PB51

PB61

PB71

PB72

PB62

PB52

PB42

PB32

PB22

PB12

PB02

GND

TX

RX

PC6

PC5

GND

A16

A15

A14

A13

A12

A11

A10

A09

GND

A08

A07

A06

A05

A04

A03

A02

A01

CI -7

LM7805

CI-1

1 2 3

TPO-1

AJUSTE

LUM. DISPLAY

XTAL1

1

14

SCL

SDA

PM4

PM3

PJ1

PJ0

16MHz DTR

CTS

RX

TX

GND

RTS

DCD

CON-11

1

6

CON-10

1

7

J1 VM

BDM IN

MC34064

LM358

CI -4

MCS12A128BMCS12A128B

MC9S12A128B

Q1

BCX53

CON-12

1

1

.

DS229

..

RS232

RS485

J4

J5

.

DS229

CI -6

CI-2

.

CI-3

.

(GY) DATA PLL PIN 6 –CON-3 –CIP8388 –MOD. 4492 –UHF UPCONVERTER

A

B

GND

(WH) RX RS232 PIN 2 –CON DB9 RS232 –REAR PANEL

(RD) TX RS232 PIN 3 –CON DB9 RS232 –REAR PANEL

(SH) GND RS232 PIN 5 –CON DB9 RS232 –REAR PANEL

(WH) GND PIN 1 –CON-6 –CIP8388 –MOD. 4492 –UHF UPCONVERTER

(BL) +15V PIN 1 –CON-13 –CIP8111 –MOD. 4401 –POWER SUPPLY

(GR) +8V PIN 1 –CON-11 –CIP8111 –MOD. 4401 –POWER SUPPLY

(YL) ENABLE QDAC PIN 8 –CON 6 –CIP8388 –MOD.4492 –UHF UPCONVERTER

(GY) SW1 PIN 4 –CON 6 –CIP8388 –MOD.4492 –UHF UPCONVERTER

(OR) CLOCK DAC PIN 7 –CON-6 –CIP8388 –MOD.4492 –UHF UPCONVERTER

(OR) LD CLOCK GENERATOR PIN 1 –CON-7 –CIP8358 –MOD. 4549 –8VSB MODULATOR

(BK) DATA OUT PIN 3 –CON-2 –CIP8357 –MOD. 4549 –8VSB MODULATOR

(BR) ENABLE PLL PIN 5 –CON-3 –CIP8388 –MOD. 4492 –UHF UPCONVERTER

(YL) CLOCK PLL PIN 7 –CON-3 –CIP8388 –MOD. 4492 –UHF UPCONVERTER

(VL) LOCK DETECT PIN 8 –CON-3 –CIP8388 –MOD. 4492 –UHF UPCONVERTER

(OR) DATA IN PIN 2 –CON-2 –CIP8357 –MOD.4549 –8VSB MODULATOR

(RD) MODULATOR CLOCK PIN 4 –CON-2 –CIP8357 –MOD.4549 –8VSB MODULATOR

(GR) MODULATOR ENABLE PIN 5 –CON-2 –CIP8357 –MOD.4549 –8VSB MODULATOR

(VL) MODULATOR READ PIN 6 –CON-2 –CIP8357 –MOD.4549 –8VSB MODULATOR

(VL) DATA DAC PIN 6 –CON-6 –CIP8388 –MOD.4492 –UHF UPCONVERTER

(YL) TX ON PIN 3 –CON DB9 –REAR PANEL

(RD) ENABLE IDAC PIN 9 –CON 6 –CIP8388 –MOD. 4492 –UHF UPCONVERTER

(YL) BACK LIGHT DISPLAY POINT A –LCD DISPLAY–CIM3004

(YL) CS MEMORY PIN 4 –CON-2 –CIP8437 –MEMORY INTERFACE

(YL) ROW1_KEYBOARD PIN 1 –CON-3 –CIP8002 –KEYBOARD

(BL) LINE1_KEYBOARD PIN 6 –CON-3 –CIP8002 –KEYBOARD

(GY) ROW3_KEYBOARD PIN 3 –CON-3 –CIP8002 –KEYBOARD

(OR) DCLK_MEM PIN 6 –CON-2 –CIP8437 –MEMORY INTERFACE

(OR) LINE3_KEYBOARD PIN 4 –CON-3 –CIP8002 –KEYBOARD

(WH / RD) ALC PIN 2 –CON-6 –CIP8388 –MOD. 4492 –UHF UPCONVERTER

(RD) ASDI_MEM PIN 5 –CON-2 –CIP8437 –MEMORY INTERFACE

(VL) DATA_MEM PIN 3 –CON -2–CIP8437 –MEMORY INTERFACE

(RD) +32V OUTPUT VOLTAGE READING PIN 5 –CON-8 –CIP8111 –MOD. 4401 –POWER SUPPLY

(OR) +32V OUTPUT CURRENT READING PIN 1 –CON-7 –CIP8111 –MOD. 4401 –POWER SUPPLY

(BL) +15V READING PIN 2 –CON-8 –CIP8111 –MOD. 4401 –POWER SUPPLY

(BR) TEMPERATURE READING PIN 5 –CON-6 –CIP8388 –MOD. 4492 –UHF UPCONVERTER

(BL) FORWARD POWER READING PIN 1 –CON-5 –MOD. 4408 –UHF AMPLIFIER

(WH) GND INPUT EXTERNAL PIN 5 –CON-DB09 –PANEL

(GY) REFLECTED POWER READING PIN 2 –CON-5 –MOD. 4408 –UHF AMPLIFIER

(GR) +8V READING PIN 1 –CON-8 –CIP8111 –MOD. 4401 –POWER SUPPLY

(BK) -15V READING PIN 3 –CON-8 –CIP8111 –MOD. 4401 –POWER SUPPLY

(BK) LINE2_KEYBOARD PIN 5 –CON-3 –CIP8002 –KEYBOARD

(BR) ROW2_KEYBOARD PIN 2 –CON-3 –CIP8002 –KEYBOARD

Fig.2.2: CIP8231- the control unit board - components and connections.

The major components and functions of CIP8231 are described below:

Integrated circuit CI-4 (A128) is a 16 bit microcontroller programmed in assembly that performs all

system management functions. This component is programmed in the factory and includes a numeral

AT7120 Owner Manual Rev. 1.1 –March 2009 18/76

designation identifying the unity and software version. The unit contains firmware control software that

allows the operating system software to be updated as needed.

All the available analog parameter information from the system is sent to connector CON-9 on the

CIP8231 board. The parameters monitored and displayed are as follows:

Direct power –120W Amplifier

Reverse power - 120W Amplifier

(+9V) - Power supply

(+18V) - Power supply

(-18V) - Power supply.

(+32V) - Power supply.

(I1) –the main power supply electrical current.

The analog signals are sent to microcontroller CI-4, where they are digitalized and processed. The

software of this microcontroller compares the readings with the stored nominal values. Readings

outside of nominal values generate associated alarms. Values and alarm states are displayed on the LCD

panel located on the front of the unit. Important note: The equipment is designed so that a nominal

analog reading presents +4 volts DC to the Con-9 connector. The voltage level presented to Con-9 can

be adjusted during setup or maintenance when external equipment is used to assure proper calibration /

reading.

Each module that generates analog control / monitoring information has an associated test point on the

unit. If during the calibration process external measurements indicate the correct nominal value for that

function, a trimpot is adjusted to set the voltage on the test point to +4Volts.

Note: Set the voltage on the test point associated with reflected power, if the voltage becomes higher

than +4Volts, the control unit will process this event as an alarm. This event is associated with a reverse

power in excess of 10% of the transmit power.

Alarm detection

For the alarms listed below, the CIP8231 control unit board shuts down the transmission by Setting the

Automatic Level Control (ALC) to zero volts (provided to the up-converter module 4492). For more

details see the power control description on the next page.

The following alarms reach the connectors CON-4, CON-5 and CON-6 at the CIP8231 board as digital

information.

In case of substitution of the CI-4 or the entire PCB CIP8231, it is mandatory to

provide the factory, prior to replacement, the programming identification number

that is clearly indicated on CI-4.

AT7120 Owner Manual Rev. 1.1 –March 2009 19/76

Lack of lock voltage of the PLL at the Up-converter - Module 4492.

Excessive temperature of the 60W UHF amplifier - Module 4407 –(above 65ºC).

Excessive reverse power (above +4V at CON-9).

Overflow of the FIFO register in the 8VSB modulator (communication between microcontroller

and modulator).

Failure of synchronization of the transport data (MPEG) stream

Presence of non-programmed hardware (a false alarm may present during the warm-up phase of

the equipment).

Imperfections associated with the generation of master clock signal in the modulator 8VSB -

Module 4549.

Nominal operation of the equipment presents +5Vdc on the alarm pins on CON-4 and CON-6; CON-5

indicates that there is no alarm condition. An alarm state is indicated by a voltage of less than 5 VDC.

In most cases the alarm state will present zero volts dc to the associated connector. The microcontroller

(CI-4) will inhibit transmission during an alarm state.

The alarms generated in the system are shown in the LCD display of the MCU. The corresponding

indication for these alarms are “*” for active alarms - - and “#” for previous alarms (an alarm state that

has been resolved or that has ended.) - PAST. The occurrence of an alarm “*” will automatically end the

transmission. When the reason for this alarm “*” is resolved, a symbol “#” will appear and the

transmission will be restored automatically. To erase old alarms, just press the “CLR.ALL” key on the

front panel of the equipment or when using a hyper-terminal press “1” on the keyboard.

Communication with 8VSB modulator

The CIP8231 board communicates with the 8VSB modulator - Module 4549 - through a set of serial

port interfaces (SPI). These SPI’s are located on pins 2 to 5 of connector CON-3 and on pins 5 and 6 of

connector CON-5.

The communication between CIP8231 board and the 8VSB modulator - Module 4549 - monitors and

sets the configuration parameters of this module. For example, the adjustment of the pilot programming

stream (the 8VSB signal), and adjustment of the superior lateral band rejection are managed over this

communication interface.

Setting the FCC/UHF operational channel

The operational channel of the equipment is set via the CIP8231 board. The board generates a code that

represents the selected channel (UHF) which is then sent over the SPI to the up-converter - Module 4492

- This stream of information is composed by data, clock and enabling code, and is presented on pins 1, 2

and 3 of connector CON-4 of the CIP8231 board.

AT7120 Owner Manual Rev. 1.1 –March 2009 20/76

The control board also sends the operational channel information to program the PLL circuit at

CIP8388, which will then synthesize the local oscillator frequency required to create the desired

channel. During normal operation the CIP8231 continuously manages the PLL of module 4492.

It is important to remember that the initial programming of the CIP8231 board for the transmitter

AT7120 is made at the factory. These programming procedures are not accessible to the end user.

In turn, Module 4492 sends the lock detected information to the CIP8231 board indicating that the PLL

circuitry is in lock and ready for operation. This information is presented as voltage level of

approximately +3.6V and is routed to pin 5 of connector CON-4. The absence of this voltage will trigger

the lock alarm that will terminate transmission (RF output power is set to zero dbm) and present an

alarm “*” on the LCD display located on the front panel of the transmitter.

RF power control

RF transmitter power is set by the end user, via the front panel. The CIP8231 board converts this digital

input programming information into analog voltage levels. This voltage is then sent to the up-converter

of the exciter. This specific voltage level is called ALC REFERENCE VOLTAGE or trellis voltage, and

is shown on the LCD digital display as V.P. Adj.

The trellis voltage is directly proportional to the RF power level at the output of the exciter, in other

words, the higher the trellis voltage the higher the exciter RF power level. The typical value of trellis

voltage at normal rated power output is between 3V and 4V.

In case of failures or malfunctions, the power control is responsible for acting immediately to set the RF

power level to zero, thus correspondingly, the trellis voltage is set to zero. This may occur in during any

alarm state where transmission must be terminated to protect equipment or to maintain regulatory

compliance.

A warm up period of approximately five (5) seconds is required for the exciter to reach nominal RF

power. This period of time, is also known as SLOPE UP time, it is the time necessary for the trellis

voltage to increase from its initial zero volts up to its the value, set corresponding to the programmed RF

power level as measured at the output of the transmitter.

Programming the off-set operational frequency

The AT7120 transmitter is factory set to a FCC/UHF operational channel, under ATSC standards. The

channel off-set frequency can be changed at the end user discretion. The offset can shift the RF channel

band up to 30 kHz, in 1Hz increments. The shift of frequency can increase or decrease the start

frequency of the band of the UHF channel. The offset is programmed at the CIP8231 board, which

provides control signals to the up-converter - Module 4492 - on pins 1, 2, 3 of connector CON-4.

While the equipment is turned on, the CIP8231 board automatically re-confirms the last set of

programmed data at the up-converter –module 4492. The programming instructions generated by the

CIP8231 board of the transmitter are set at the factory and, therefore, are not accessible to the user.

+32V power supply ON/OFF control.

The CIP8231 board sends a +5 volt dc signal to the power supply - Module 4401- to switch it ON. The

signal is located at pin 6 of connector CON-3.

Table of contents